Adjustable assembly pipeline

An adjustable, pipeline technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor pipe straightness, increase the cost of transformation, increase production costs, etc., to meet the installation requirements, large vertical height , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

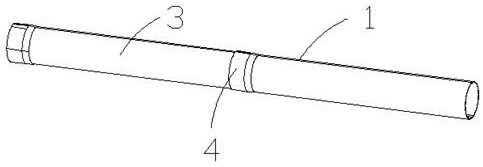

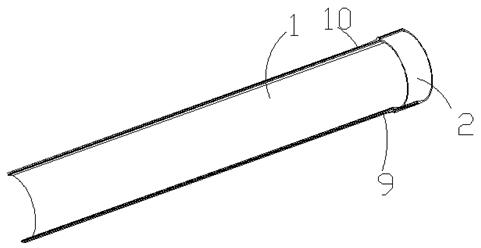

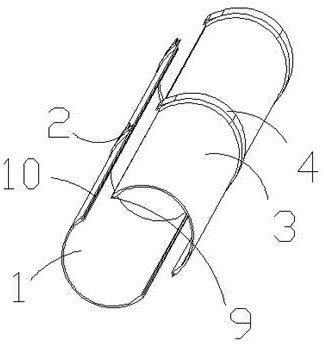

[0024] like Figure 1-Figure 5 As shown, an adjustable assembly pipe includes a number of pipe units that are inserted in sequence, each of which includes a first half pipe 1 , a second half pipe 3 , a first connecting plate 5 and a second connecting plate 6 , one side of the first half-pipe 1 is spliced with one side of the first connecting plate 5 or one side of the second half-pipe 3, and one side of the second half-pipe 3 is The other side of the first connecting plate 5 or one side of the first half pipe 1 is spliced and matched, and the other side of the first half pipe 1 is spliced with one side of the second connecting plate 6 or the first half pipe 1 . The other sides of the two half-pipes 3 are spliced and matched, and the other side of the second half-pipe 3 is spliced and matched with the other side of the second connecting plate 6 or the other side of the first half-pipe 1 . ;

[0025] There are two types of pipeline combinations in this embodiment:

...

Embodiment 2

[0032] Embodiment 2: No illustration, in order to improve the scope of application of the pipeline, the difference between this embodiment and Embodiment 1 is that the first connecting plate 5 and the second connecting plate 6 both include at least two splicing connecting plates, The sides of the adjacent splicing connection plates are spliced and matched, and the first connection plate 5 and the second connection plate 6 are arranged into a structure in which a plurality of spliced connection plates are spliced together, which can be assembled according to the needs of changing the size of the pipeline, and the realization of Diversification, and only need to be equipped with molds for splicing connecting plates during production, there is no need to design multiple sets of molds, which greatly saves production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com