A discharge adjustment mechanism for textile machinery and equipment

A technology of textile machinery and regulating mechanism, which is applied in the direction of textiles and papermaking, thin material processing, and conveying filamentous materials, etc., to achieve the effects of shortened time, reduced breakage, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

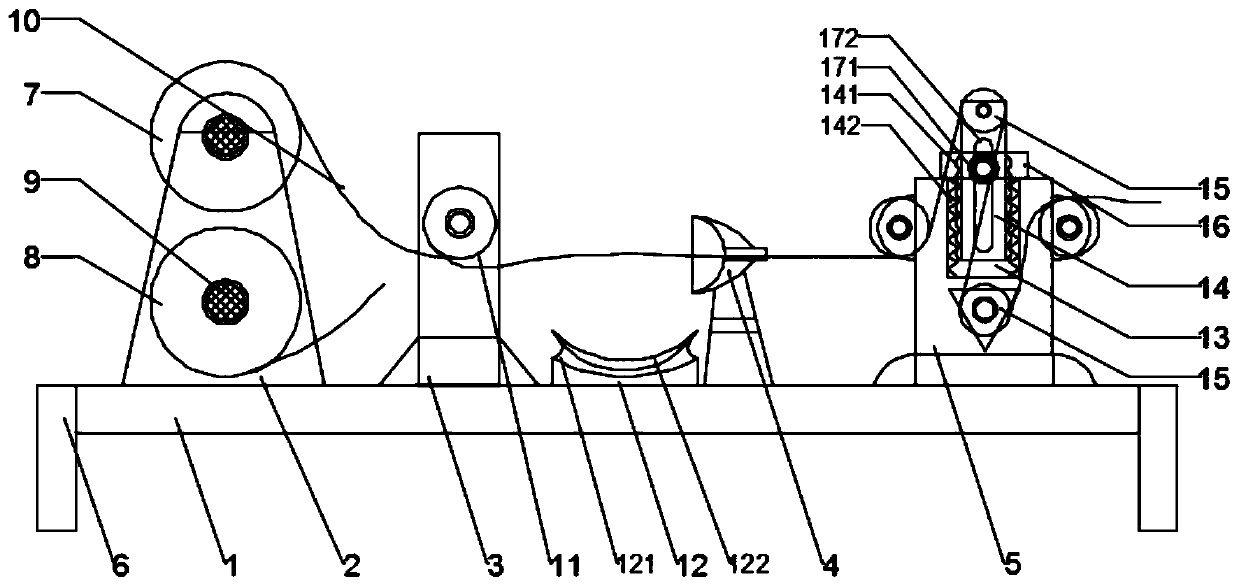

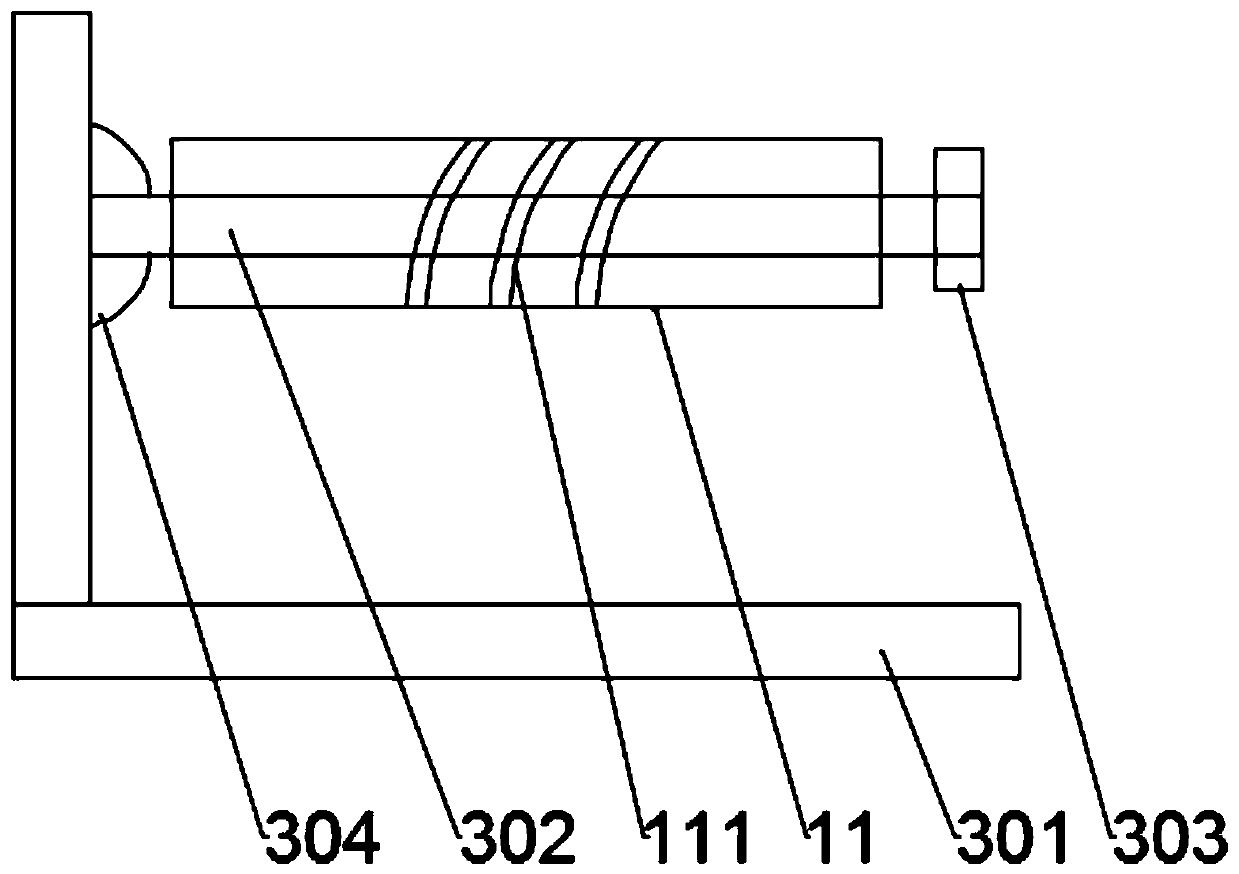

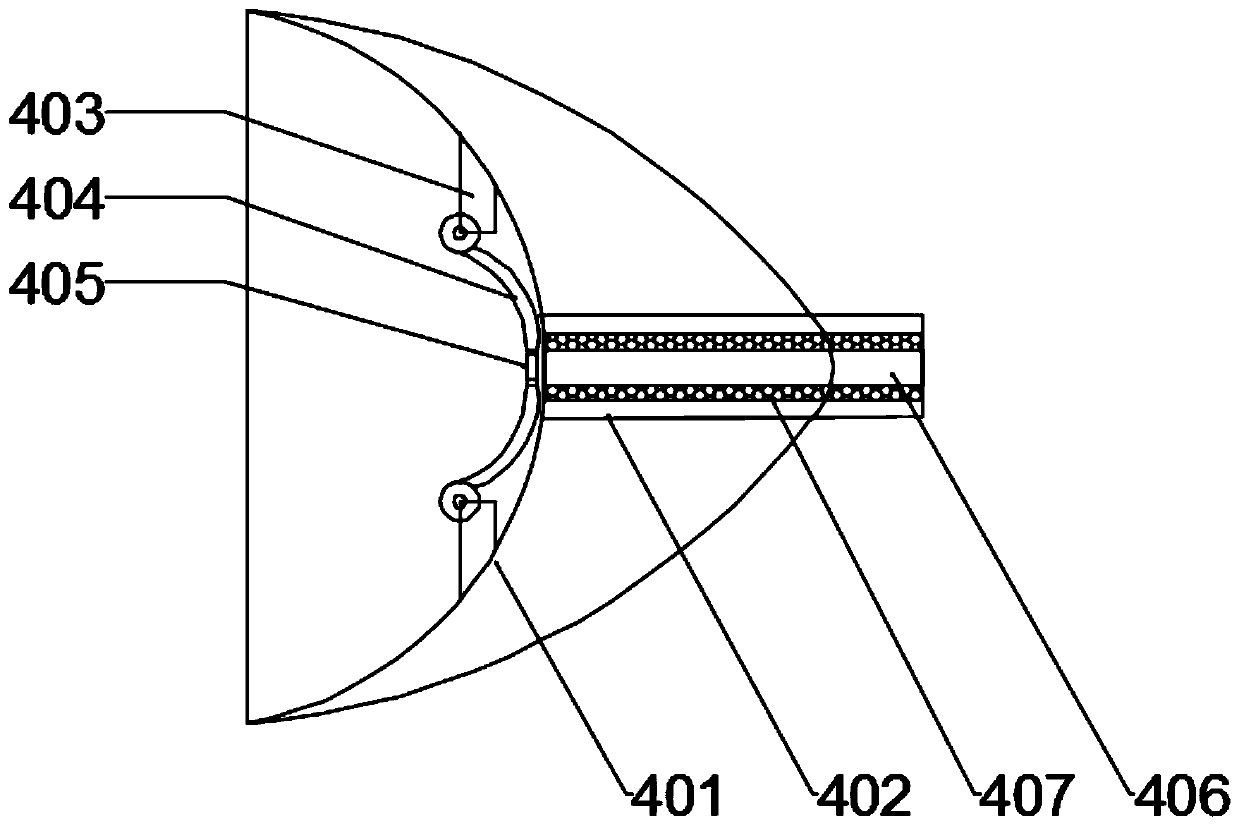

[0025] like figure 1 and figure 2 As shown, the present invention provides a discharge adjustment mechanism for textile machinery equipment, including a discharge substrate 1, the upper surface of the discharge substrate 1 is sequentially provided with a discharge roller frame 2, a flat height The drum frame 3, the dust removal filter sleeve 4 and the tensioning main frame 5, and two fixed frames 6 are symmetrically installed at both ends of the discharging substrate 1, and the discharging substrate 1 is fixedly installed on the On the textile machinery equipment, the upper discharge drum 7 and the lower discharge drum 8 are symmetrically installed on the discharge drum frame 2, which can reduce the time for replacing the discharge drum and improve the working efficiency of the discharge adjustment mechanism. The middle of the discharge drum 7 and the lower discharge drum 8 is connected to the discharge drum frame 2 through the rotating shaft 9, and the textile thread 10 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com