Electrostatic spraying process device for fine blanking machine

A technology of electrostatic spraying and process equipment, applied in spraying devices, liquid spraying equipment, etc., can solve the problems of fast consumption of stamping oil, uneven coating, fast wear and consumption of wool rollers, etc., to increase the contact area and reduce the spraying pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

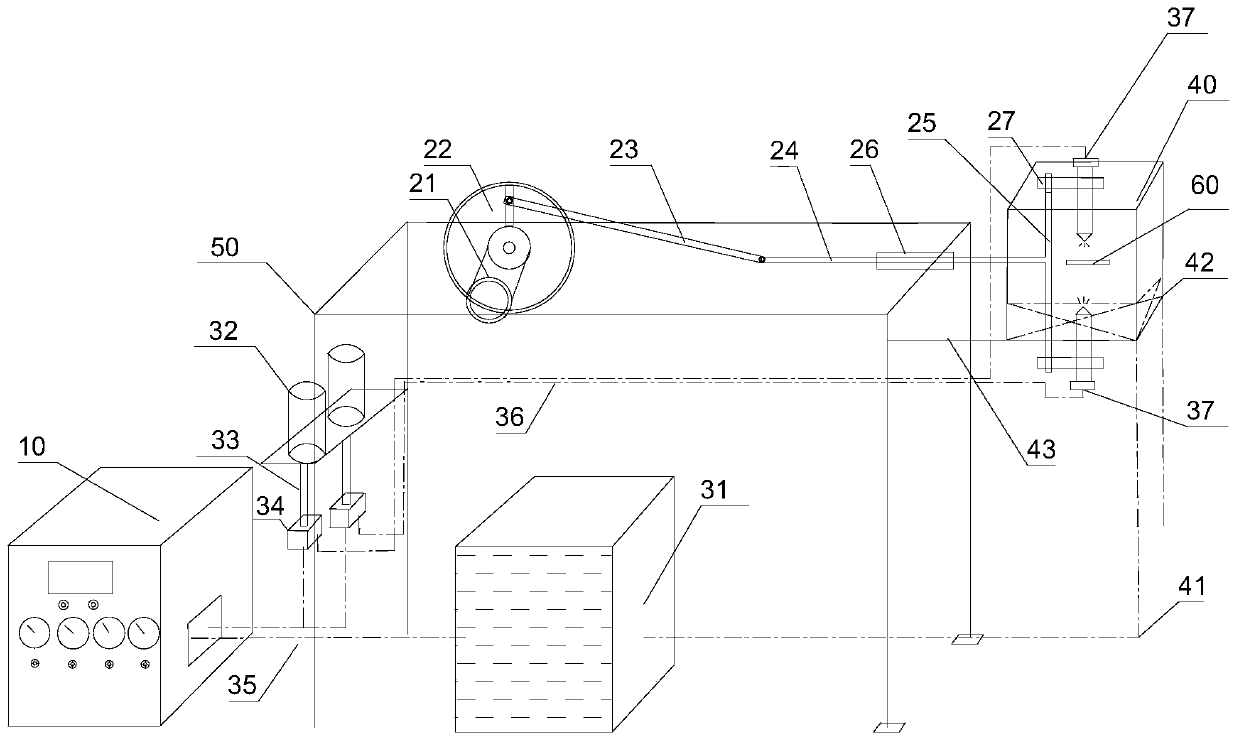

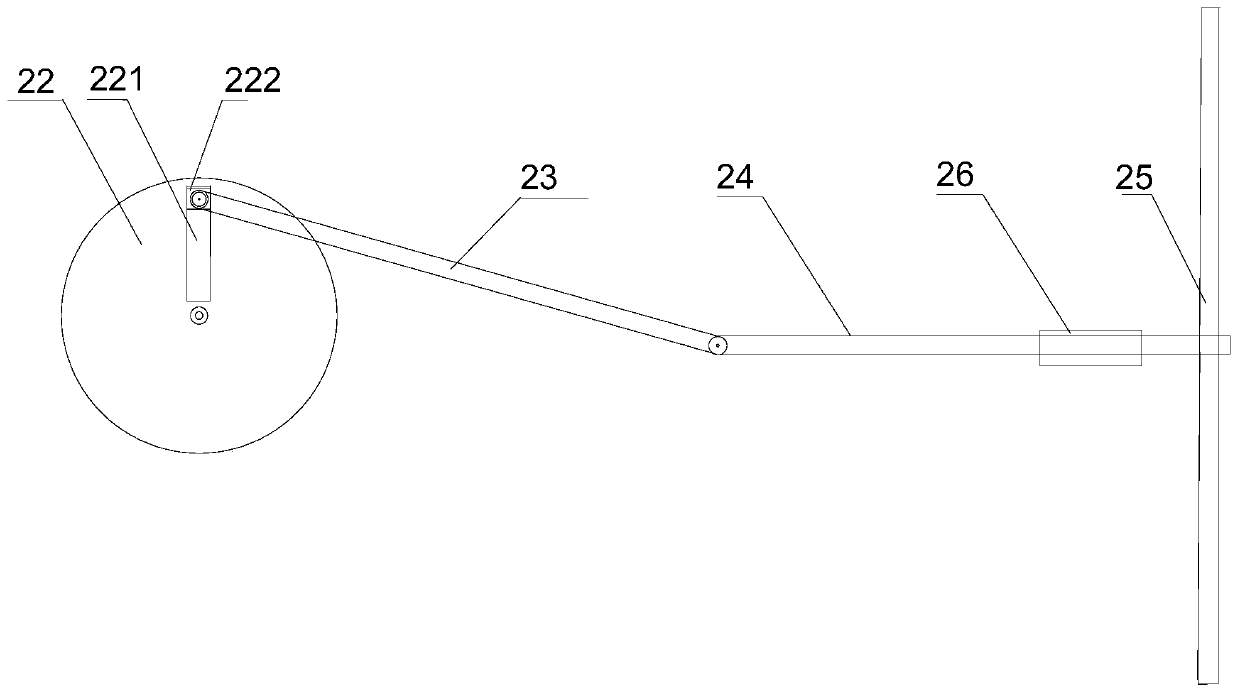

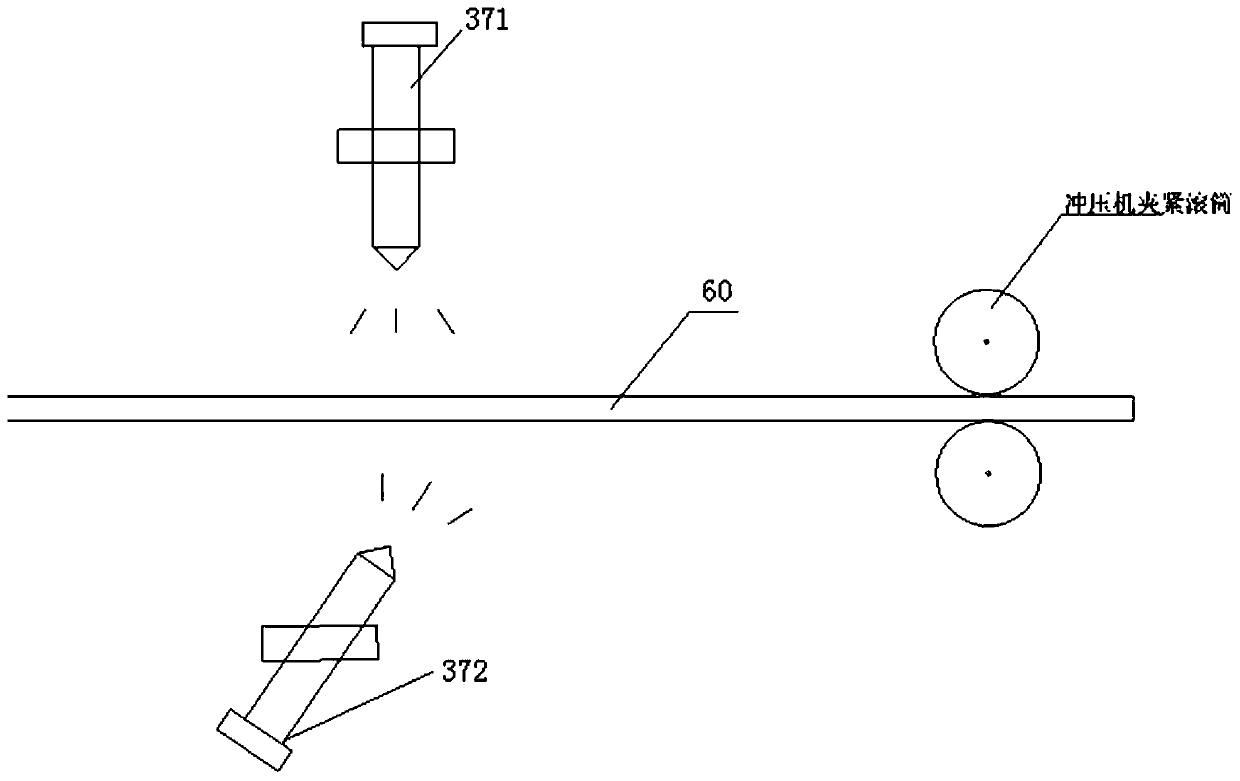

[0032] Such as Figure 1-3 Shown is an electrostatic spraying process device for a fine blanking machine according to a preferred embodiment of the present invention, including a bracket 50, an electrostatic spraying system and a swinging reciprocating mechanism. The electrostatic spraying system includes an oil storage tank 31, a spraying system motor 32, a pressure pump shaft 33, a pressure valve 34 and an electrostatic spray gun 37. The oil storage tank 31 and the pressure valve 34 are connected through an oil inlet pipeline 35, and the connection between the pressure valve 34 and the electrostatic spray gun 37 is The spraying system motor 32 is installed on the bracket 50, the output shaft of the spraying system mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com