Additive manufacturing method and product of high-entropy alloy using noble metal material

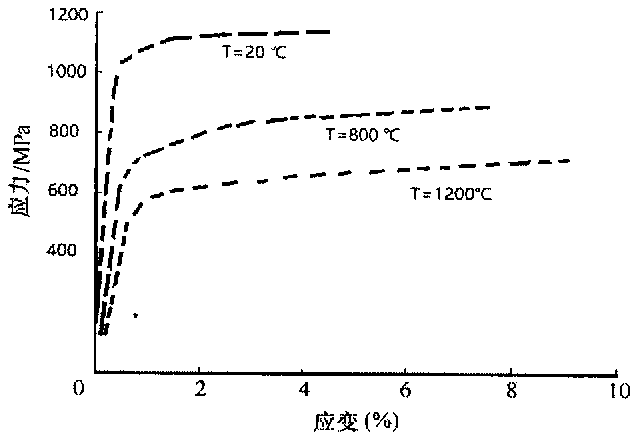

A high-entropy alloy and additive manufacturing technology, applied in the field of additive manufacturing of parts with special service conditions in the aerospace field, can solve the problem that the performance of precious metals has not been fully exploited, hinder the development of aerospace technology, and increase aerospace budget costs, etc. problems, to achieve high thermal stability and anti-oxidation ability, improve material utilization, low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

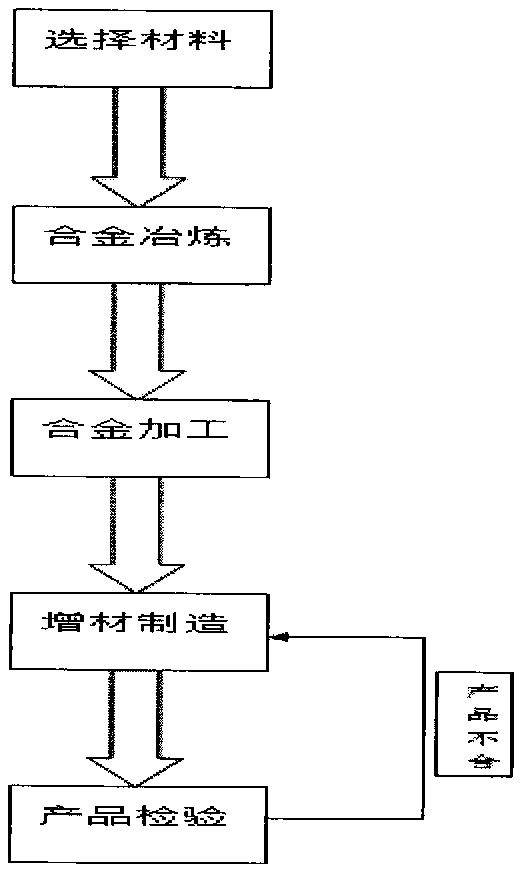

Method used

Image

Examples

Embodiment 1

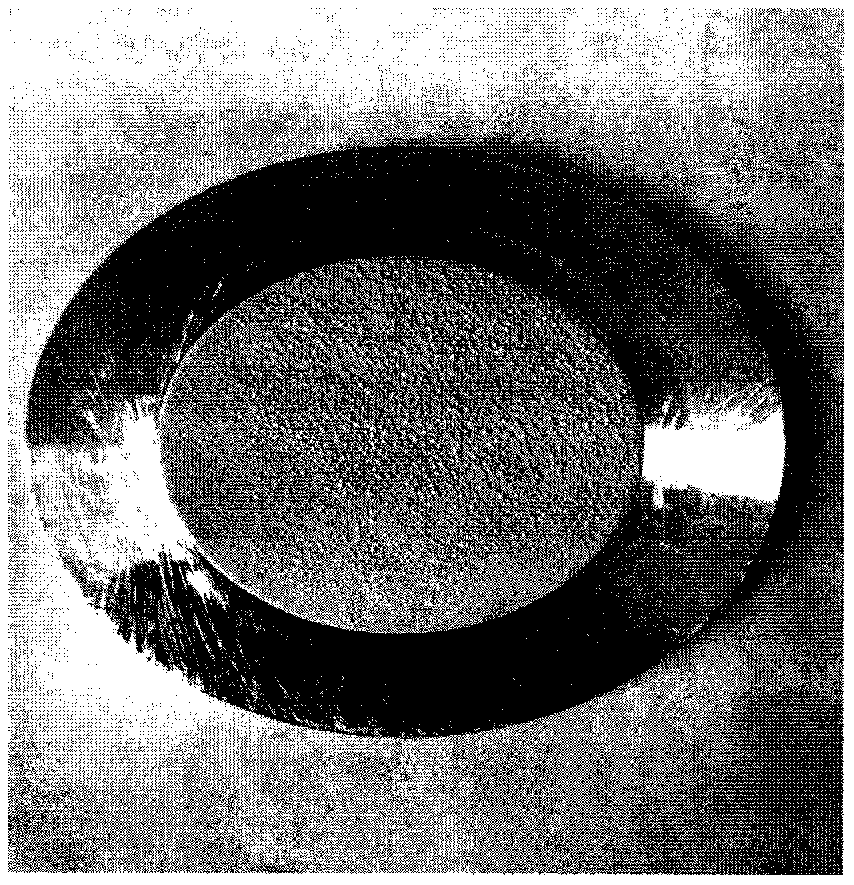

[0021] Example 1 Prepare a high temperature resistant component for aerospace, the size is 10X10X5mm

[0022] The first step is to select the material. The basic principal component precious metal materials selected in this embodiment are gold and silver in turn, and the added sub-principal components are copper, titanium and aluminum;

[0023] In the second step, alloy smelting, the gold, silver, copper, titanium, and aluminum of the metal are mixed in a certain proportion (Au 20 Ag 25 Cu 10 Ti 35 al 10 ) into a special crucible or mold of a vacuum furnace, heating and melting, not only extracting a vacuum, so that its vacuum degree is (0.2Pa), the crucible or mold is preferably a detachable or assembled airtight container, filled with helium for protection, Keep it warm until it is completely melted, and then cool it with liquid nitrogen to obtain a massive noble metal high-entropy alloy. The heating temperature is 1800-2000°C, preferably 1900°C, and the holding time is ...

Embodiment 2

[0029] Embodiment 2 uses additive manufacturing technology to collect high-entropy precious metals, and the product is a functional part of a decommissioned spacecraft instrument panel.

[0030] The first step is blank preparation, collecting functional parts of a decommissioned spacecraft instrument panel, made of high-entropy alloys of precious metals, cleaning the surface with ultrasonic waves, and then polishing the surface to remove impurities;

[0031] In the second step, powder making, the processed noble metal high-entropy alloy is melted at high temperature, cooled, and then purged with an inert gas to form a powder with a particle size of 20-50 microns;

[0032] The third step, additive remanufacturing, this process is basically the same as the steps of the embodiment;

[0033] The fourth step, product inspection, this process is basically the same as the steps in the embodiment.

Embodiment 3

[0034] Example 3 uses additive manufacturing technology for thermal spraying to obtain a high temperature resistant surface coating.

[0035] The first step is to use the method of this invention to prepare a new noble metal high-entropy alloy. The basic principal noble metal materials are iridium and platinum in turn, and the added sub-principal components are copper, titanium and aluminum. The mass percentage of each component is: Iridium is 20.50-40.33%, platinum is 20.11-30.23%, copper is 7.75-9.88%, titanium is 5.55-665%, and the rest is aluminum and unavoidable impurities;

[0036] In the second step, the high-entropy alloy prepared in the first step is made into powder, and then the surface of the product is thermally sprayed using additive equipment. The heating temperature is above 4000°C, and the temperature of the flame center is above 10,000°C. According to the specified trajectory, high-temperature melting and deposition of iridium-platinum-copper-titanium-aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com