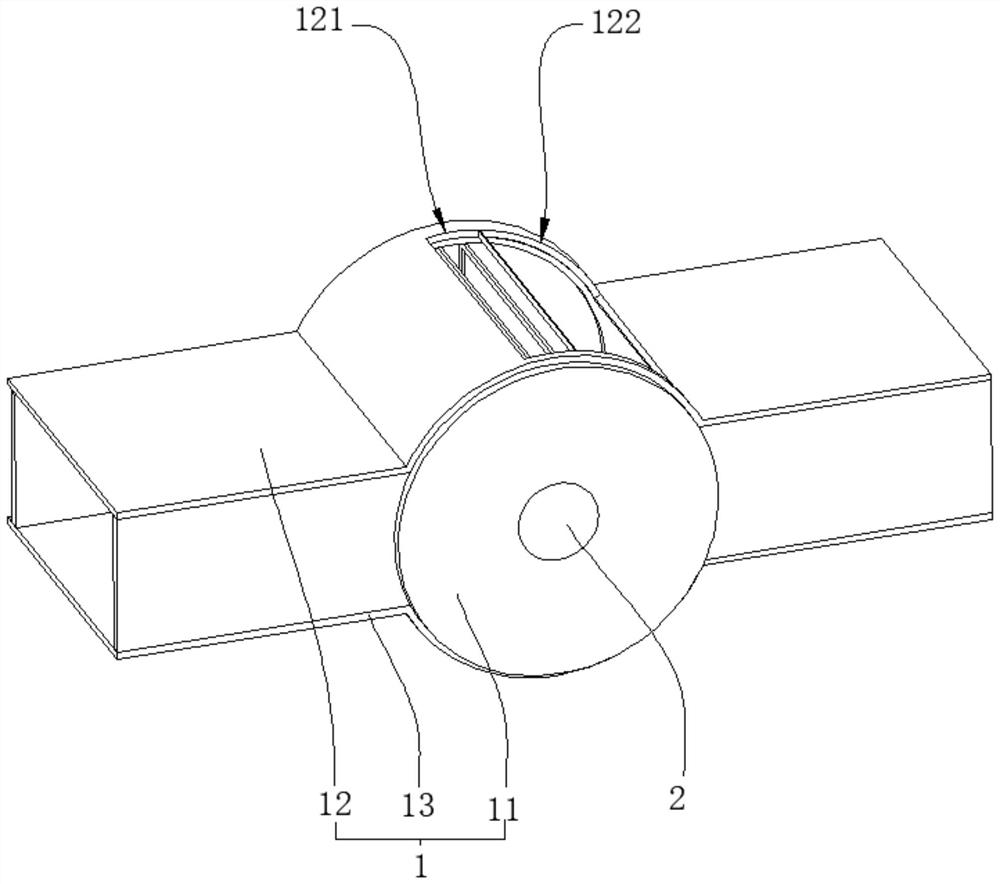

Dust collecting equipment

A technology of dust collection and equipment, which is applied in the field of dust collection, can solve the problems of increased harmful substances and inability to achieve purification, and achieves the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

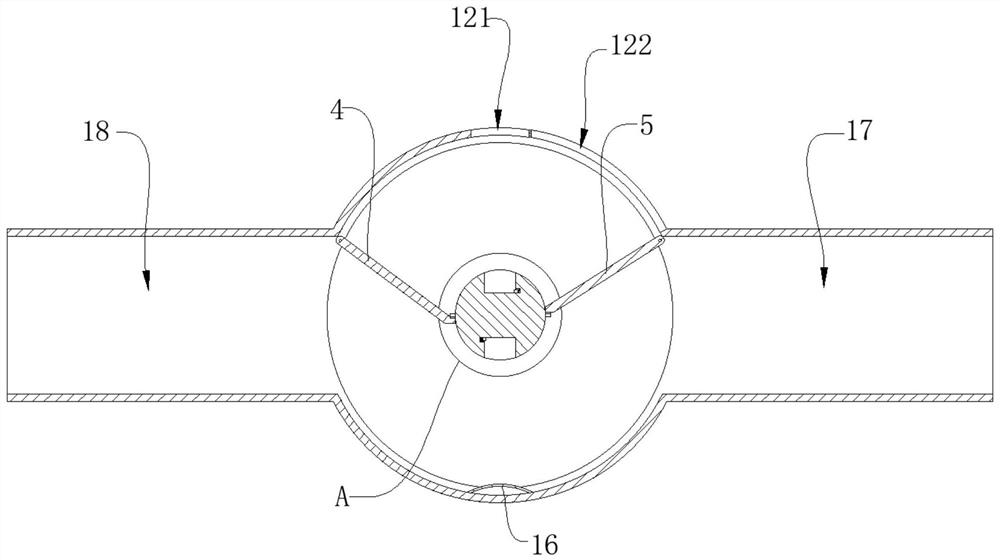

Method used

Image

Examples

Embodiment 2

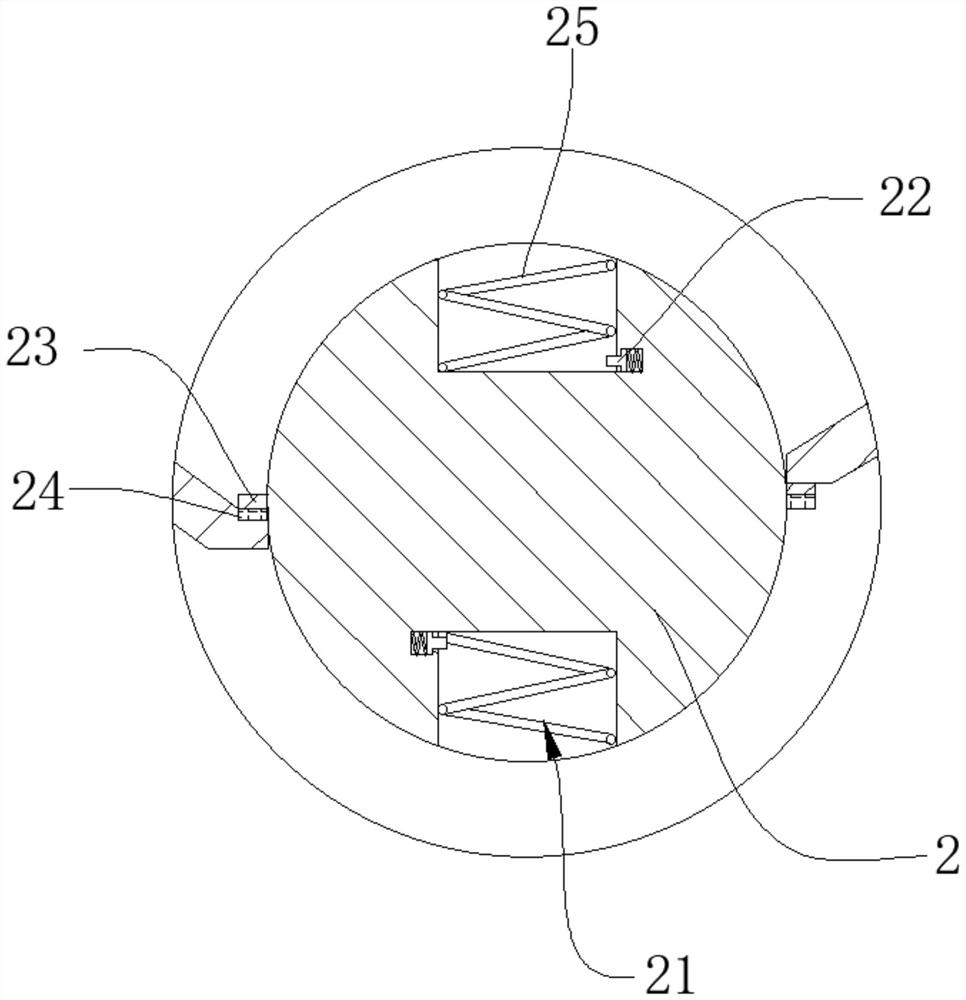

[0044] The difference from the Example One is:

[0045] Combine Figure 2-Figure 4 It shows that there is a parallel parallel plug -in film 33 on one side of the fixed box 31. There is a certain interval between the plug -in chip 33. Tank 321, at the same time, extend the card connection sheet 34 at the end of the two plugs 33 near the activity box 32, the two card connecting pads 34 are V -shaped and the opening faces the fixed box 31, of which 33 and the card of the card and the card The connection 34 is composed of elastic metal sheets. At the same time, on the activity box 32 is located on one side of the installation slot 21 and departs from the fixed frame 31, there is a lock slot 322. 22, the upper side of the lock block is also provided with a guidance slope, and a support spring 25 is also fixed in the installation slot 21, and the support spring 25 has a trend of promoting dust plate 3 to move out of the installation slot 21;

[0046] During the dust collection process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com