Automatic maintenance device for concrete member

A technology for concrete and components, applied in spraying devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of adjustment, vertical wall spraying maintenance spraying range, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

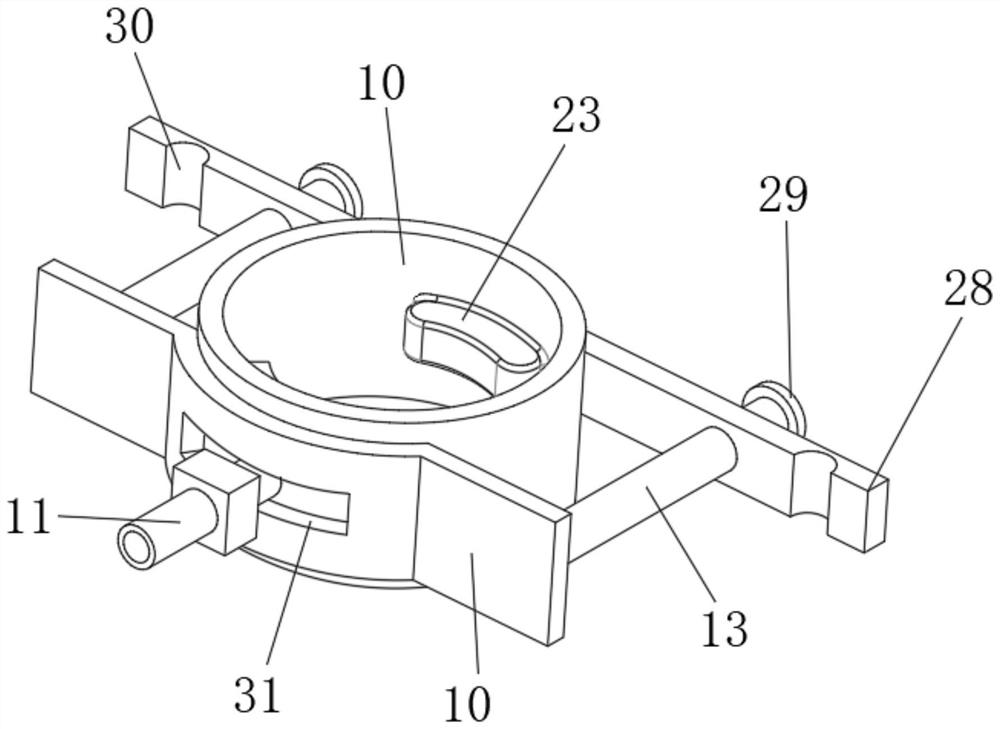

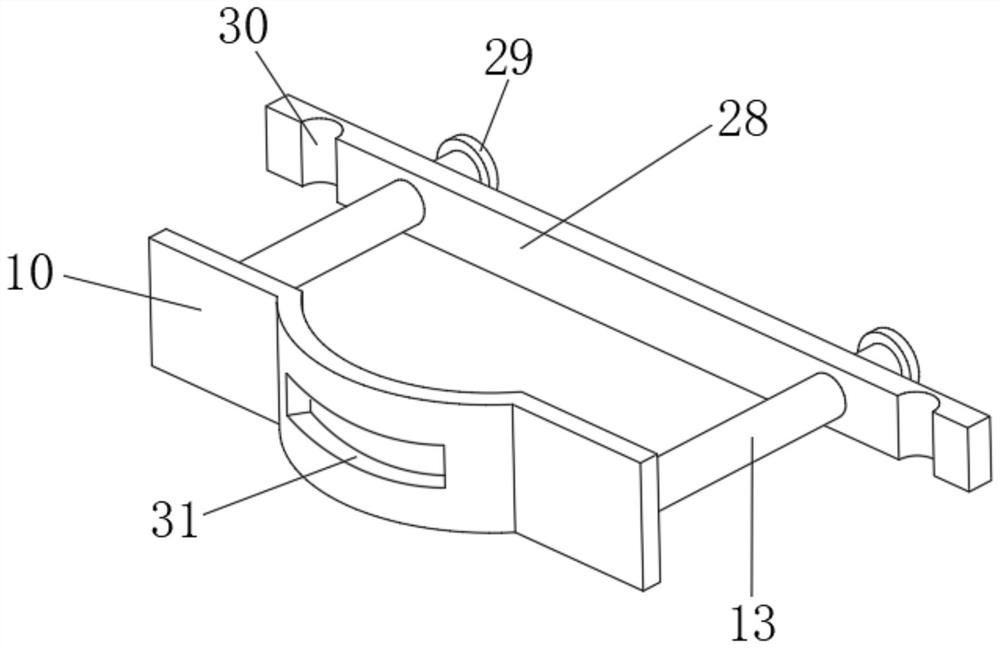

[0031] An automatic curing device for concrete components, the curing device includes a water inlet pipe 1, an adjustment component, a clamping component and a lifting component.

[0032] The water inlet pipe 1 is arranged in parallel with the vertical wall, and the outer wall of the water inlet pipe 1 is provided with a clamping sleeve 2, the water inlet pipe 1 and the clamping sleeve 2 are fastened and clamped, and the outer wall of the clamping sleeve 2 is fixed on the connecting rod 3. On the wall, through the cooperation of the clamping sleeve 2 and the connecting rod 3, the line of sight water inlet pipe 1 and the wall are fixed in parallel and vertically.

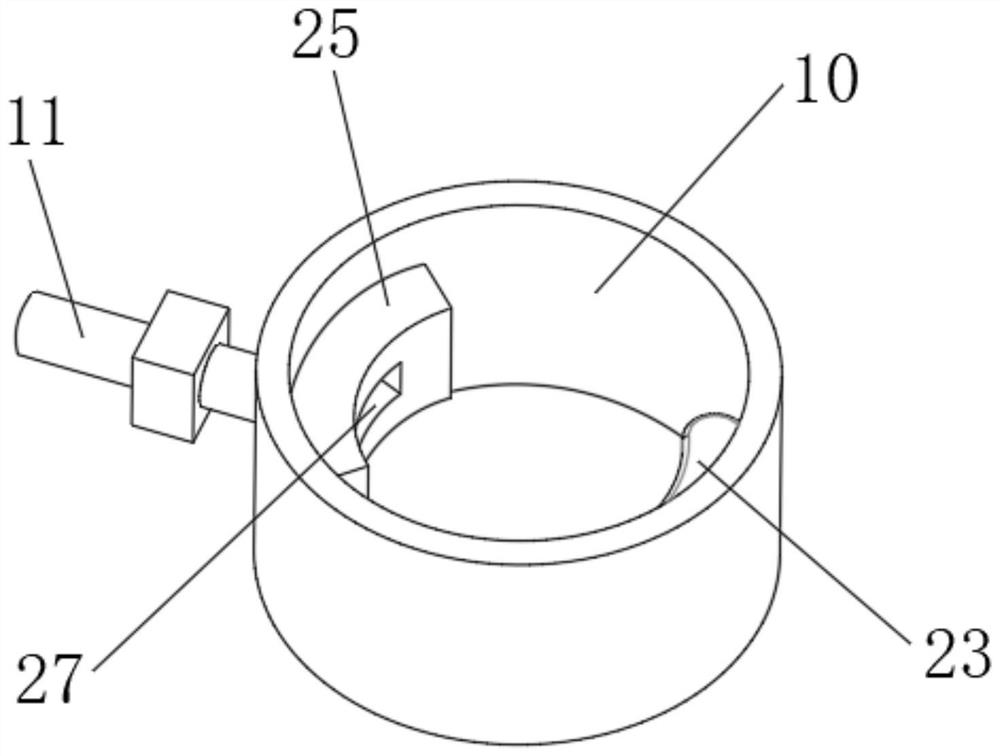

[0033] The adjustment assembly includes a fixed plate 9 and a rotating sleeve 10. The fixed plate 9 is fixed on the outer wall of the water inlet pipe 1. The rotating sleeve 10 is coaxially sleeved on the outer wall of the water inlet pipe 1. The outer side of the rotating sleeve 10 is provided with a spray head 11. ...

Embodiment 2

[0040]On the basis of Embodiment 1, in order to limit the rotation angle of the spray head 11 , the present application further includes a rotating arc groove 31 on the clamping arc plate 12 , and the clamping arc plate 12 is inserted into the spray head 11 through the rotating arc groove 31 . The spray head 11 rotates and adjusts along the rotating arc groove 31 .

[0041] The rotation angle of the spray head 11 is limited by setting the rotating arc groove 31 , so as to avoid the excessive rotation of the rotating sleeve 11 and the separation of the rubber pressing block 25 from the water outlet hole 26 .

Embodiment 3

[0043] On the basis of Example 2, in order to further limit the rotation angle and avoid the extrusion of the spray head 11 and the rotating arc groove 31 during the rotation process, so that the spray head 11 is broken, the present application also has a space between the rotating sleeve 10 and the water inlet pipe 1 . There is a circular inner cavity, the rubber pressing plate 25 and the air bag 23 are located in the inner cavity of the circular ring, a pair of limit posts 24 are arranged on the fixed plate 9, and the limit posts 24 are located on the front and rear sides of the air bag 23, and The column 24 is vertically installed in the inner cavity of the ring, and the arc angle between the symmetrically distributed pair of limiting columns 24 is smaller than the arc angle of the rotating arc groove 31 .

[0044] The rotation angle of the airbag 23 is limited by the limit post 24, and then during the rotation of the rotating sleeve 10, the airbag 23 squeezes the limit post...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com