Processing and conveying device for solar circuit board

A technology for conveying devices and circuit boards, which is applied in the direction of conveyor objects, transportation and packaging, sustainable manufacturing/processing, etc., which can solve the problems of solar circuit boards falling, weak grasping, etc., and achieve the effect of avoiding bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

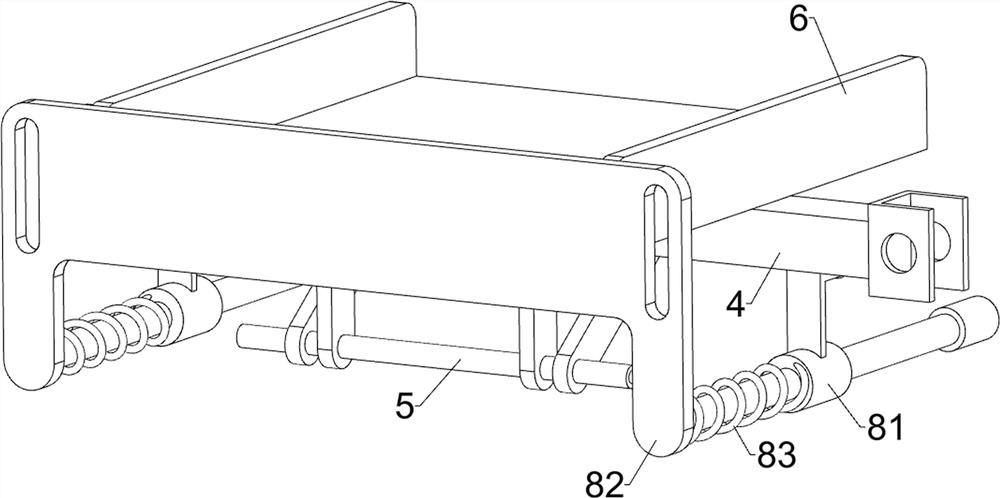

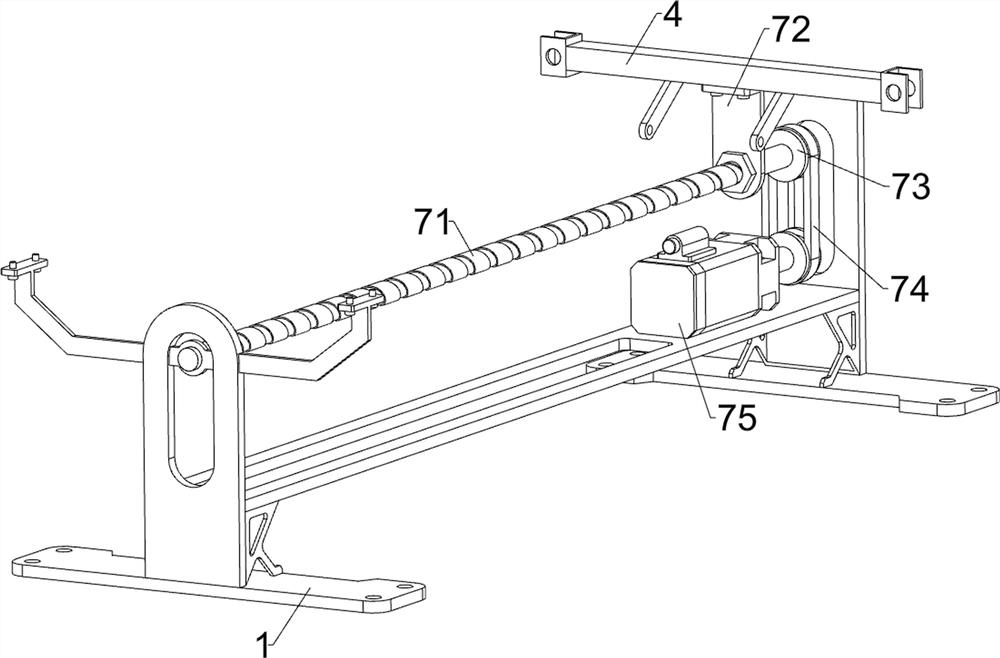

[0032] A processing and conveying device for solar circuit boards, such as Figure 1-5 As shown, it includes a bracket 1, a slide rail 2, a baffle plate 3, a sliding block 4, a rotating rod 5, a placing plate 6, a moving component 7 and a blocking component 8. The upper part of the bracket 1 is fixed with a sliding rail 2 by bolts. 2. Baffles 3 are welded on the front and rear sides between the lower part of the right side and the upper part of the left side of the bracket 1. The upper part of the slide rail 2 is slidably provided with a sliding block 4. There is a placing plate 6 on it, the sliding block 4 supports the right side of the placing plate 6, a moving assembly 7 is arranged between the bracket 1 and the sliding block 4, the moving assembly 7 can drive the sliding block 4 to slide left and right, and the sliding block 4 is provided with The blocking member 8 on the left side of the placing plate 6 can be blocked.

[0033] When using the device, the solar circuit bo...

Embodiment 2

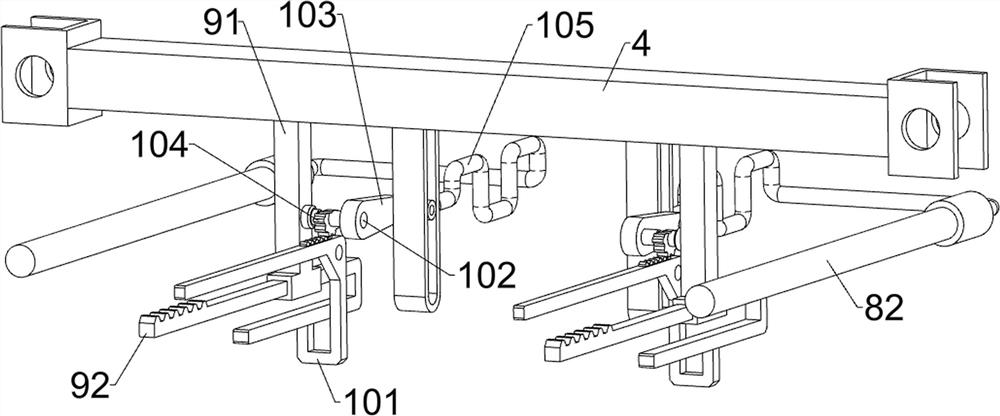

[0039] On the basis of Example 1, as figure 1 , image 3 , Image 6 and Figure 7 As shown, it also includes a rotating assembly 9, which can automatically rotate the placing plate 6, and the rotating assembly 9 includes a guide block 91, a first rack 92, a second elastic member 93, a common gear 94 and a positioning plate 95, Guide blocks 91 are welded on the front and rear sides of the bottom of the sliding block 4. The guide blocks 91 are located inside the sliding sleeve 81. The lower parts of the guide blocks 91 are slidably provided with a first rack 92. The first rack 92 is connected to the guide block 91 on the same side. A second elastic member 93 is connected between them. The second elastic member 93 is a tension spring. The front and rear sides of the rotating rod 5 are connected with a common gear 94. The common gear 94 is matched with the first rack 92 on the same side. The bottom left side of the slide rail 2 is welded with a positioning plate 95 symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com