Conveying and anti-stacking assembly of multi-roadway loading and unloading device

A technology of loading and unloading devices and stacking components, which is applied in the direction of conveyor objects, conveyors, loading/unloading, etc., can solve the problems of small quantity of goods, unsatisfactory, waste of resources, etc., and achieve the effect of strong universality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention are further described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

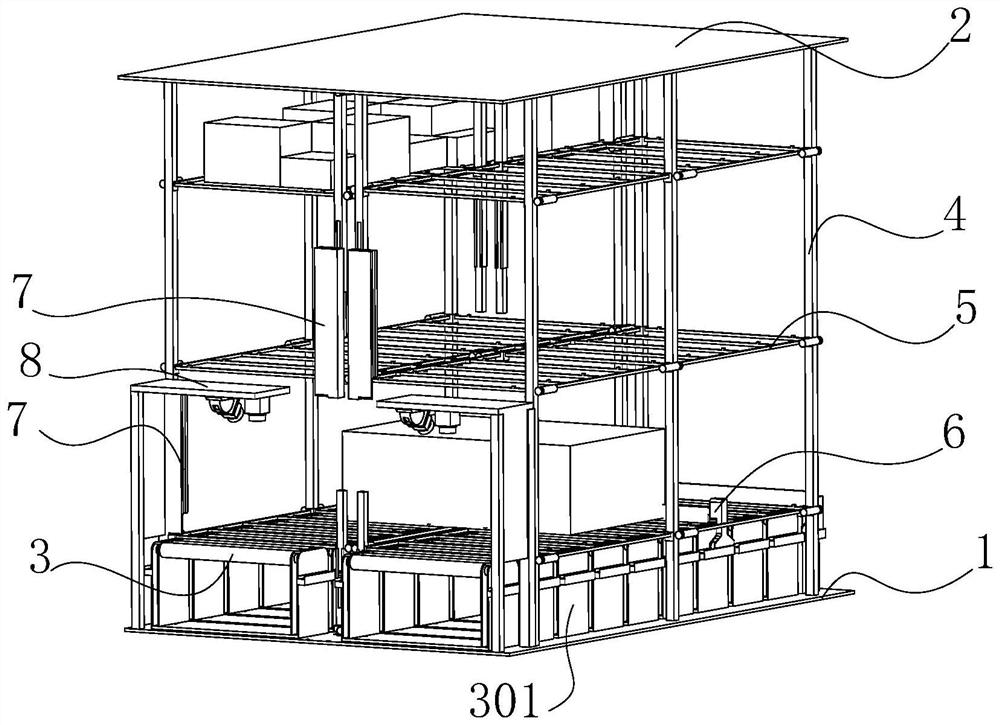

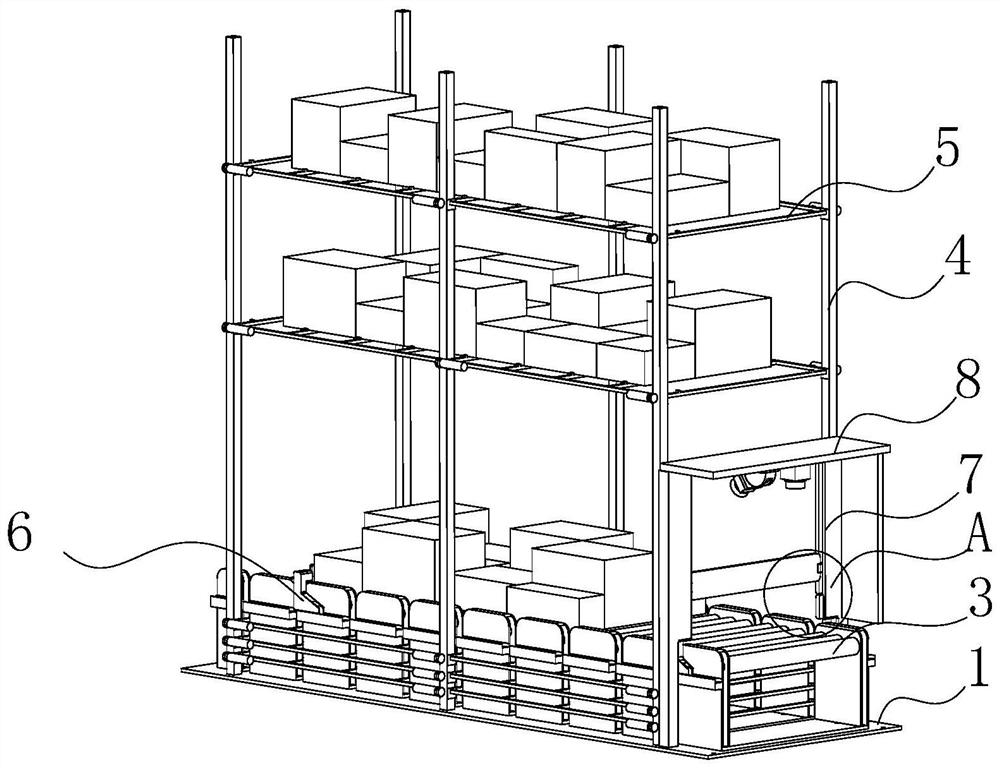

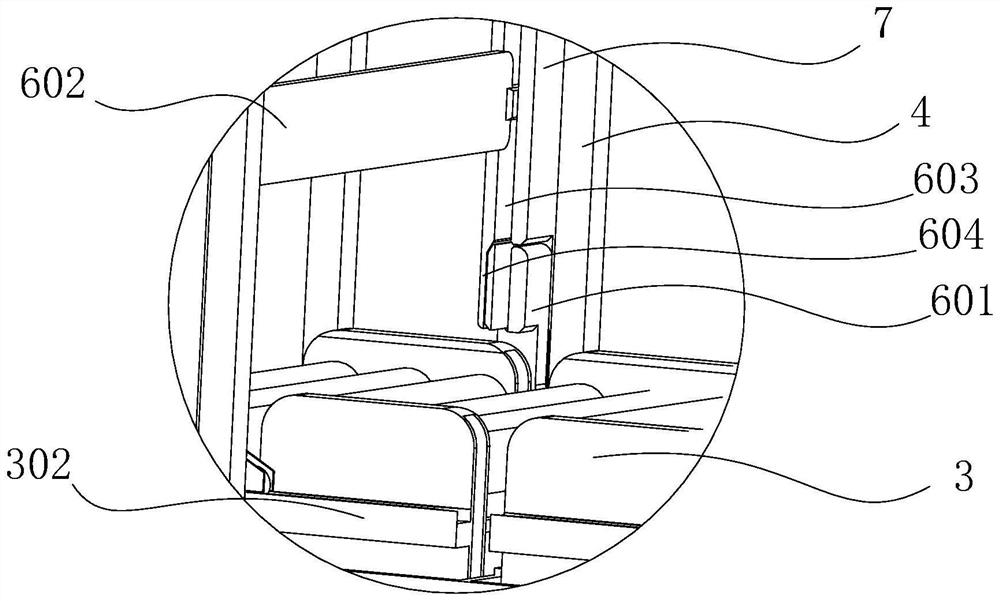

[0036] See 1- Figure 8 As shown, a conveying and anti-stacking assembly of a multi-lane loading and unloading device includes a first base plate 1 , a second base plate 2 and a plurality of conveying lanes 3 for loading and unloading goods, and the second base plate 2 is arranged above the first base plate 1 , a plurality of said transmission lanes 3 are arranged in parallel on the first substrate 1, and the transmission lanes 3 are located between the first substrate 1 and the second substrate 2, and both sides of each transmission lane 3 are provided with telescopic columns 4, and also include The push plate structure 6 and the baffle rail 7 are slidably connected with the transmission tunnel 3 , and the baffle rail 7 is arranged on the telescopic column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com