Workpiece surface defect detection method and system based on deep learning

A defect detection and workpiece surface technology, applied in the field of workpiece surface defect detection based on deep learning, can solve problems such as inability to perform data statistics, low accuracy and speed, and difficult quantitative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

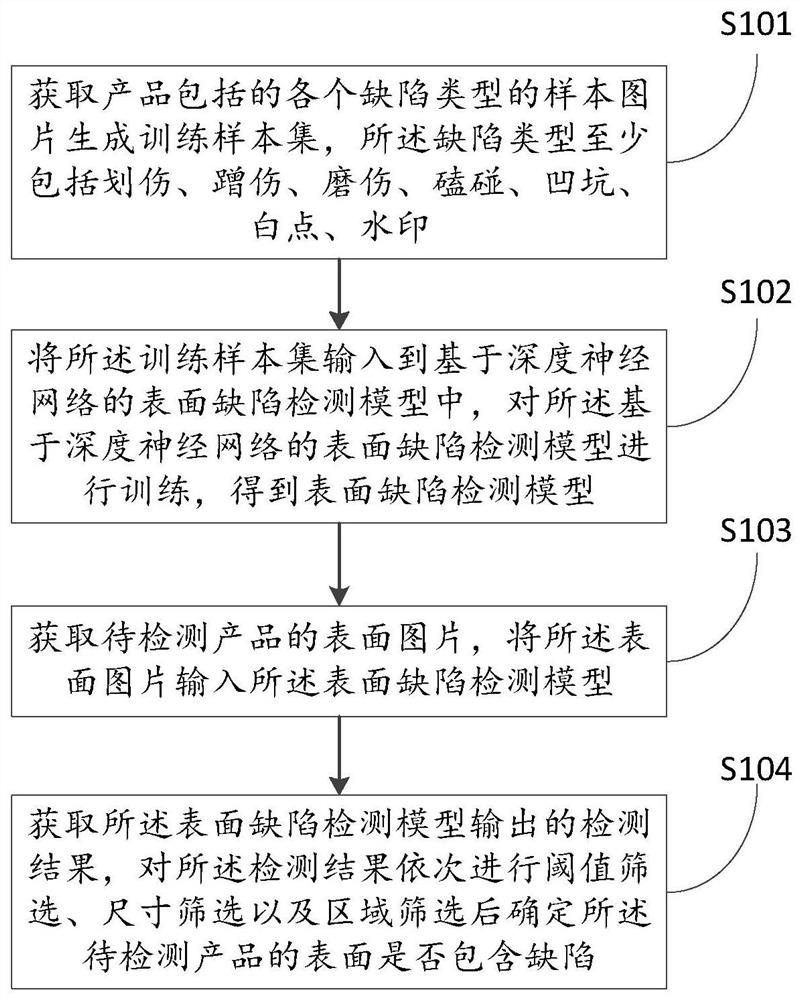

[0041] see figure 1 , which is a deep learning-based workpiece surface defect detection method provided by an embodiment of the present invention, such as figure 1 As shown, the method can include:

[0042] S101: Obtain sample pictures of each defect type included in the product to generate a training sample set, where the defect types at least include scratches, rubs, abrasions, bumps, pits, white spots, and watermarks;

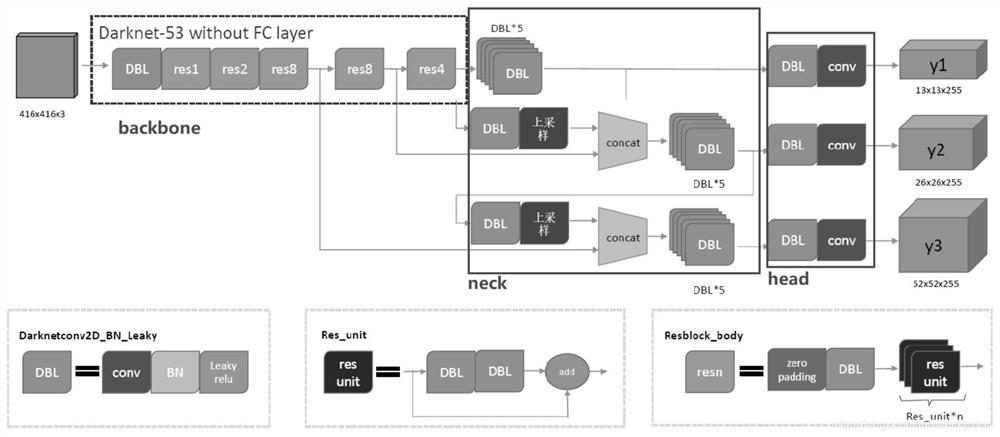

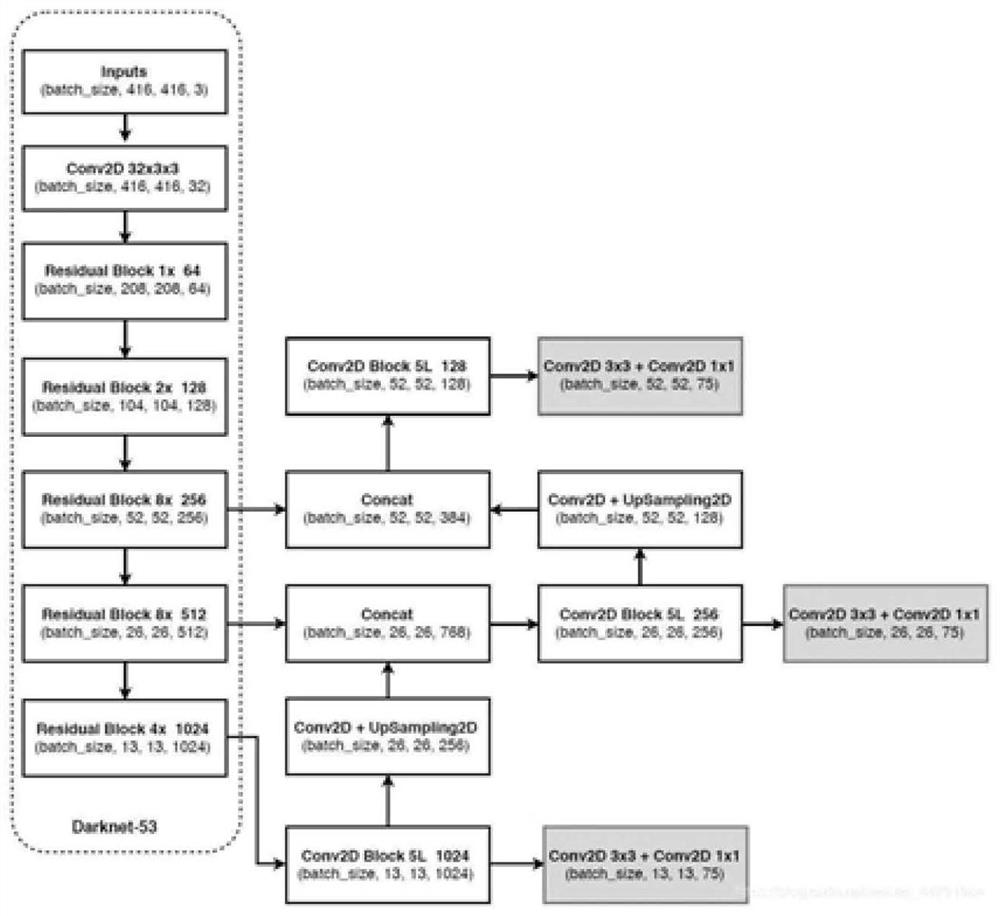

[0043] S102: Input the training sample set into a deep neural network-based surface defect detection model, and train the deep neural network-based surface defect detection model to obtain a surface defect detection model;

[0044]S103: Obtain a surface picture of the product to be detected, and input the surface picture into the surface defect detection model;

[0045] S104: Acquire the detection results output by the surface defect detection model, and perform threshold screening, size screening, and area screening on the detection results in sequence to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com