Partition device for fixing acoustic reinforcement and assembly method and application thereof

A technology of separation device and assembly method, applied in frequency/direction characteristic devices, electrical components, sensors, etc., can solve the problems of particle vibration, particle collision with speaker shell, etc., to reduce vibration and collision, improve acoustic performance, and improve acoustics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

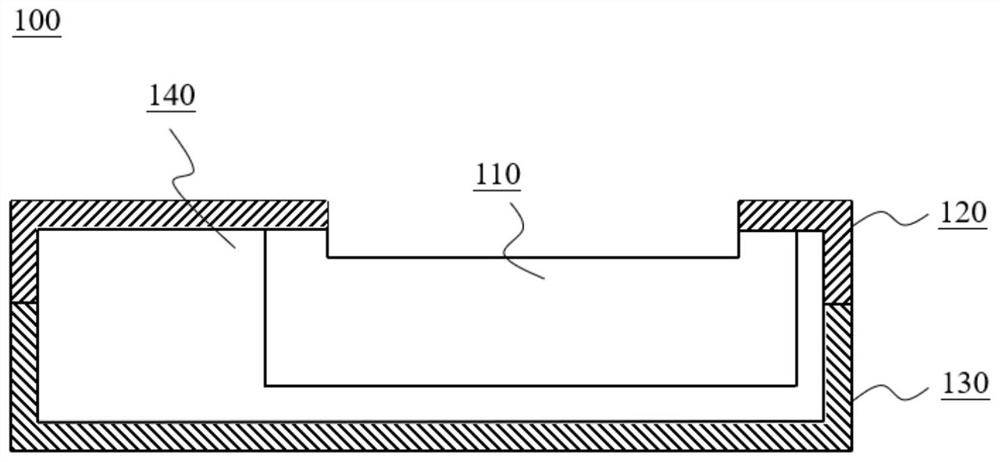

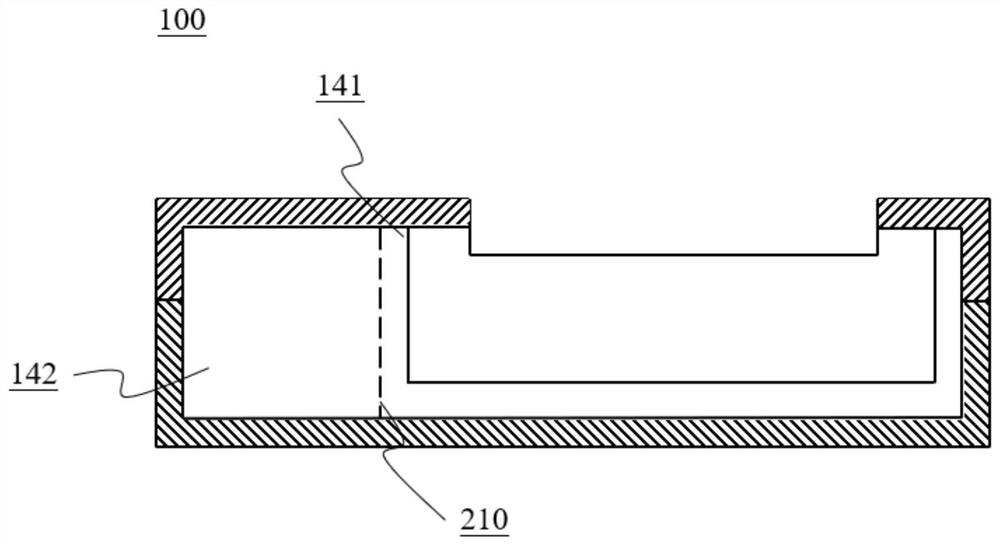

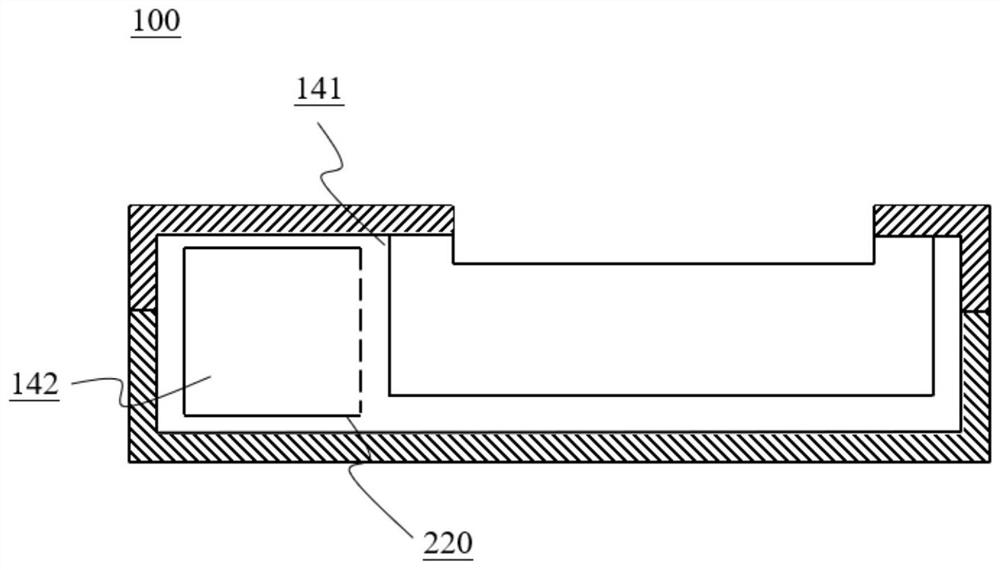

[0058] The present embodiment provides a separation device for fixing an acoustic enhancer, wherein the manufacturing process of the separation device and its assembly with the acoustic enhancer are as follows:

[0059] The stainless steel grid and aluminum plate with a thickness of 0.1mm are selected as the base material, and are made into a cubic container with an internal volume of 9.9mm×9.9mm×9.9mm by means of stamping, welding and other processes, at least one surface of which is a stainless steel grid surface. The side length of a single mesh hole in the stainless steel mesh is 180 μm. Fill as many zeolite particles (particle size 200-400 μm) as possible into the container, and the final filling amount is 0.86cc, and then package to reach the initial state of assembly.

[0060] Mechanical force is applied in any one or more of the three axial directions of the container, so that one or more surfaces of the container are recessed inwards, so as to realize the compact wrap...

Embodiment 2

[0062] The present embodiment provides a separation device for fixing an acoustic enhancer, wherein the manufacturing process of the separation device and its assembly with the acoustic enhancer are as follows:

[0063] The heat-shrinkable PET mesh cloth with a thickness of 0.1 mm is made into a bag-shaped container, the length and width of which are 12 cm×12 cm, and the aperture is 1.5 cm; the container is laid on the inner surface of a cylindrical mold. Fill as many activated carbon particles as possible (particle size 2cm) into the container, the final filling amount is 260cc, and then encapsulate, the apparent volume of the container after encapsulation is 370cm 3 , to reach the initial state of assembly.

[0064] The packaged bag-shaped container and mold were heat-treated at 110°C for 20 minutes, so that each side wall of the container was recessed inward to realize the tight wrapping of the internal activated carbon particles, and then demolded to reach the assembled st...

Embodiment 3

[0066] The present embodiment provides a separation device for fixing an acoustic enhancer, wherein the manufacturing process of the separation device and its assembly with the acoustic enhancer are as follows:

[0067] Take a polypropylene rubber mesh cloth with a thickness of 0.1 mm, its length and width is 10 mm × 10 mm, and the aperture is 350 μm; the mesh cloth is bonded to the rear cavity wall of the speaker to form a limited space together with the rear cavity wall. Fill as many porous metal oxide sheets as possible (the shortest side length of the sheet is 400-600μm) in the limited space, the final filling amount is 0.95cc, and then encapsulate, the apparent volume of the limited space after the thickness of the sheet is packaged about 1cm 3 , to reach the initial state of assembly.

[0068] The rear cavity of the speaker is treated with ultraviolet light for 20 minutes, so that the mesh cloth is recessed into the limited space, so as to realize the tight wrapping of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com