Device and method for preventing oscillation and offset of vertical conveyor loader

A vertical conveyor, conveyor technology, applied in transportation and packaging, elevators, elevators in buildings, etc., can solve the problems of passengers being tripped, alarmed, and passengers are uncomfortable, and achieve the effect of eliminating the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

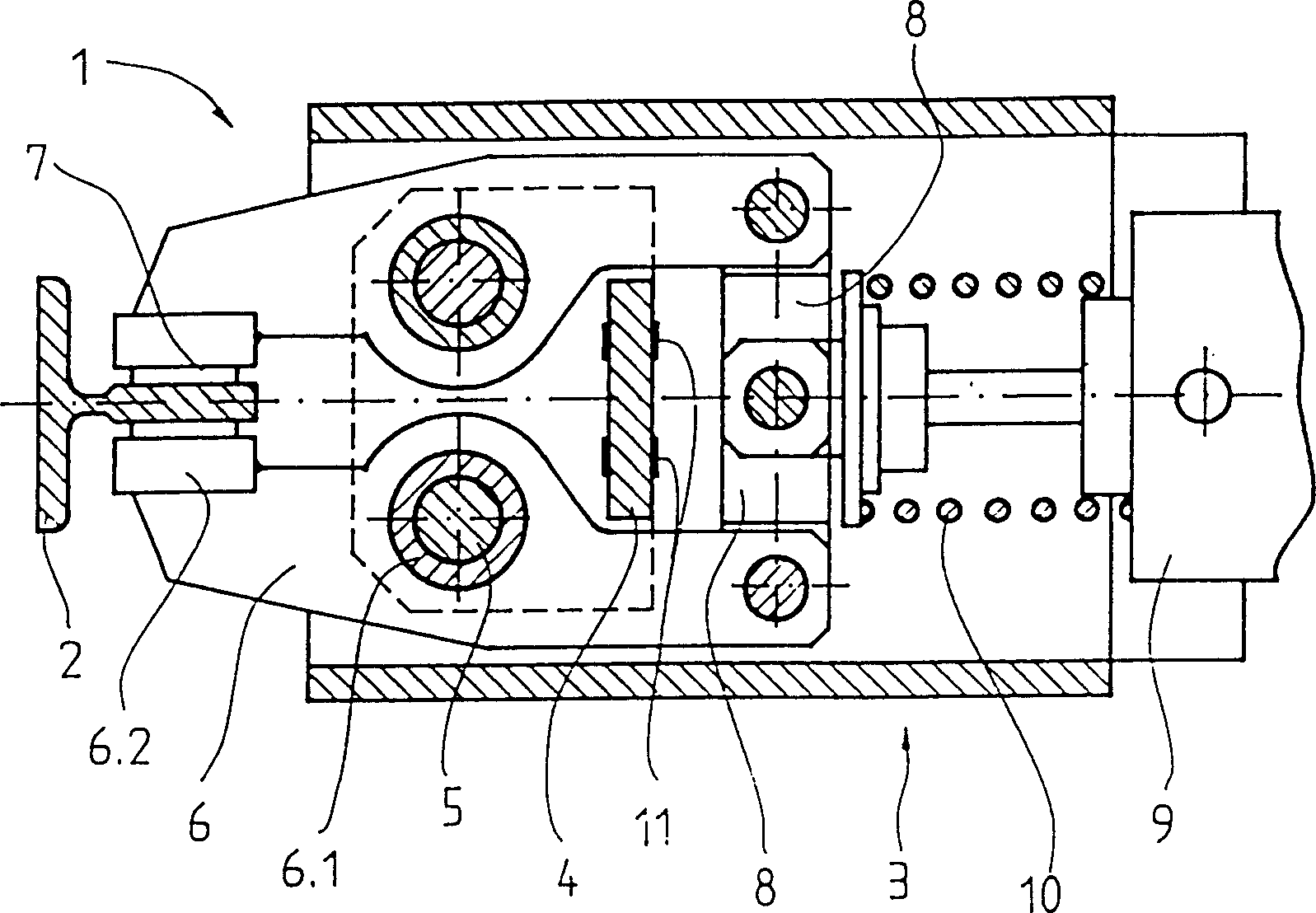

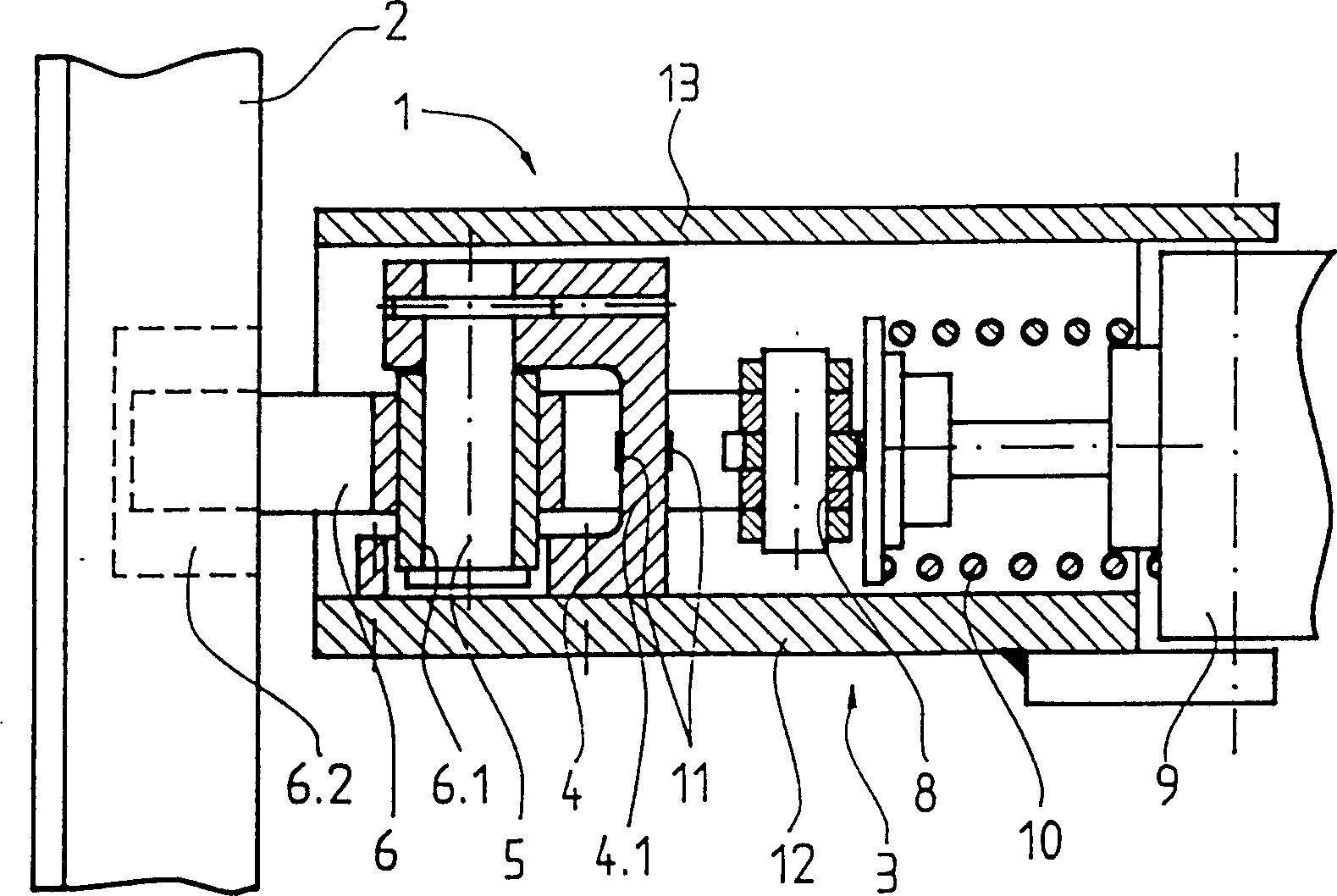

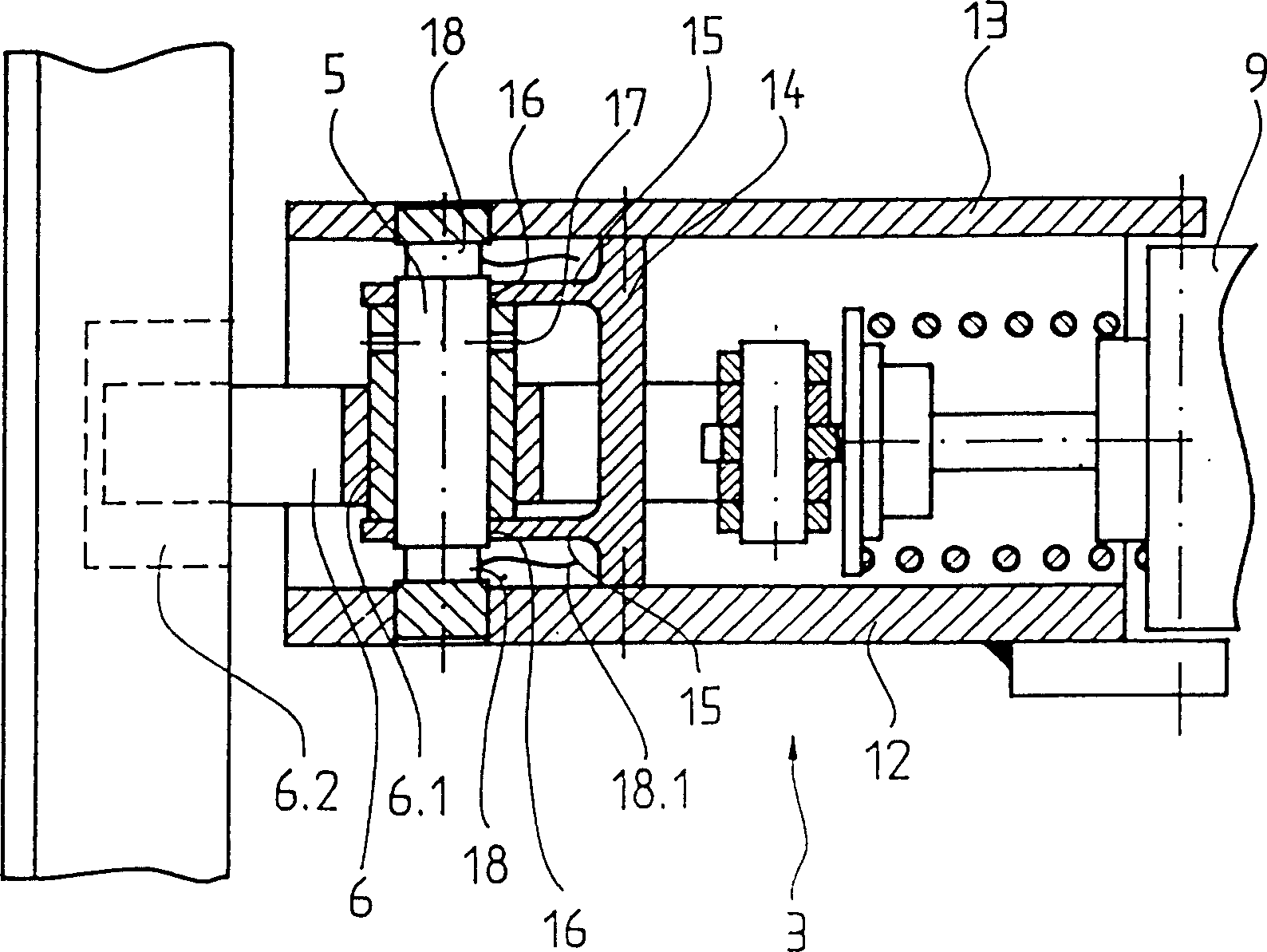

[0030] The car braking device 1 mainly includes a rectangular block housing 3, in which is installed: a brake arm bracket 4, which has two brake arm steering bolts 5, a brake arm hub 6.1 and a brake shoe 6.2; A moving lining 7; a toggle mechanism 8; a stroke transmission mechanism 9 in the form of a solenoid, a hydraulic cylinder or a spindle motor; and a compression spring 10. It also has a wire strain gauge 11, with which the clamping force of the brake lever can be recorded.

[0031] Through the action of the compression spring 10, the brake arm, which can pivot on the brake arm steering bolt 5, is pushed away via the toggle mechanism 8, thereby depressing the brake end of the brake arm and the brake lining 7 together. , against the running surface of the guide rail, so that the clamping effect of the car brake device can be obtained. In this process, the toggle mechanism amplifies the spring force a lot. The position of the car braking device shown in the figure correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com