Quick-coordination hinge

A hinged and fast technology, used in pivot connections, door/window fittings, hinges without pins, etc., can solve problems such as disadvantages and reduce the cost of hinged bodies, and achieve the effects of simple structure, reduced weight, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

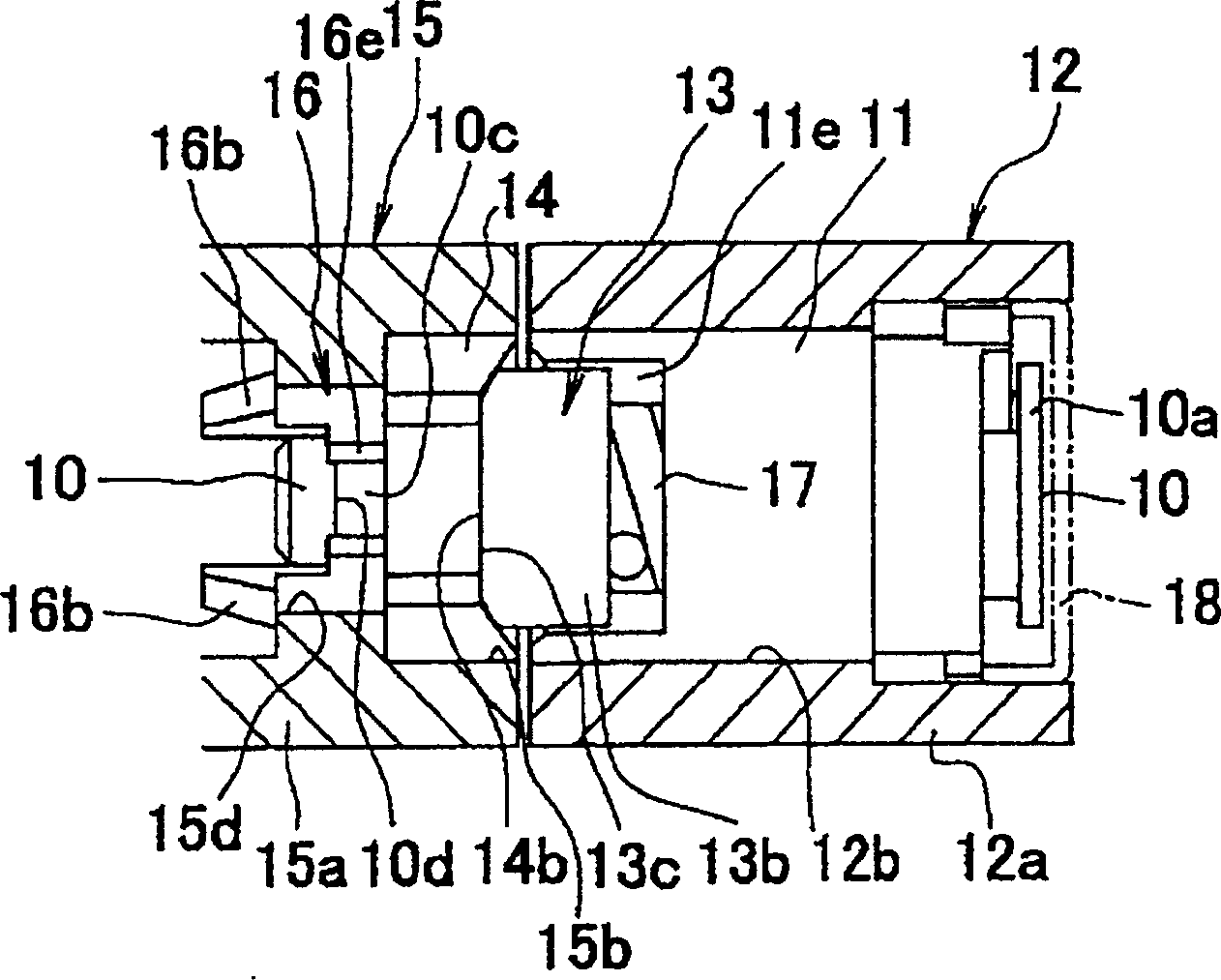

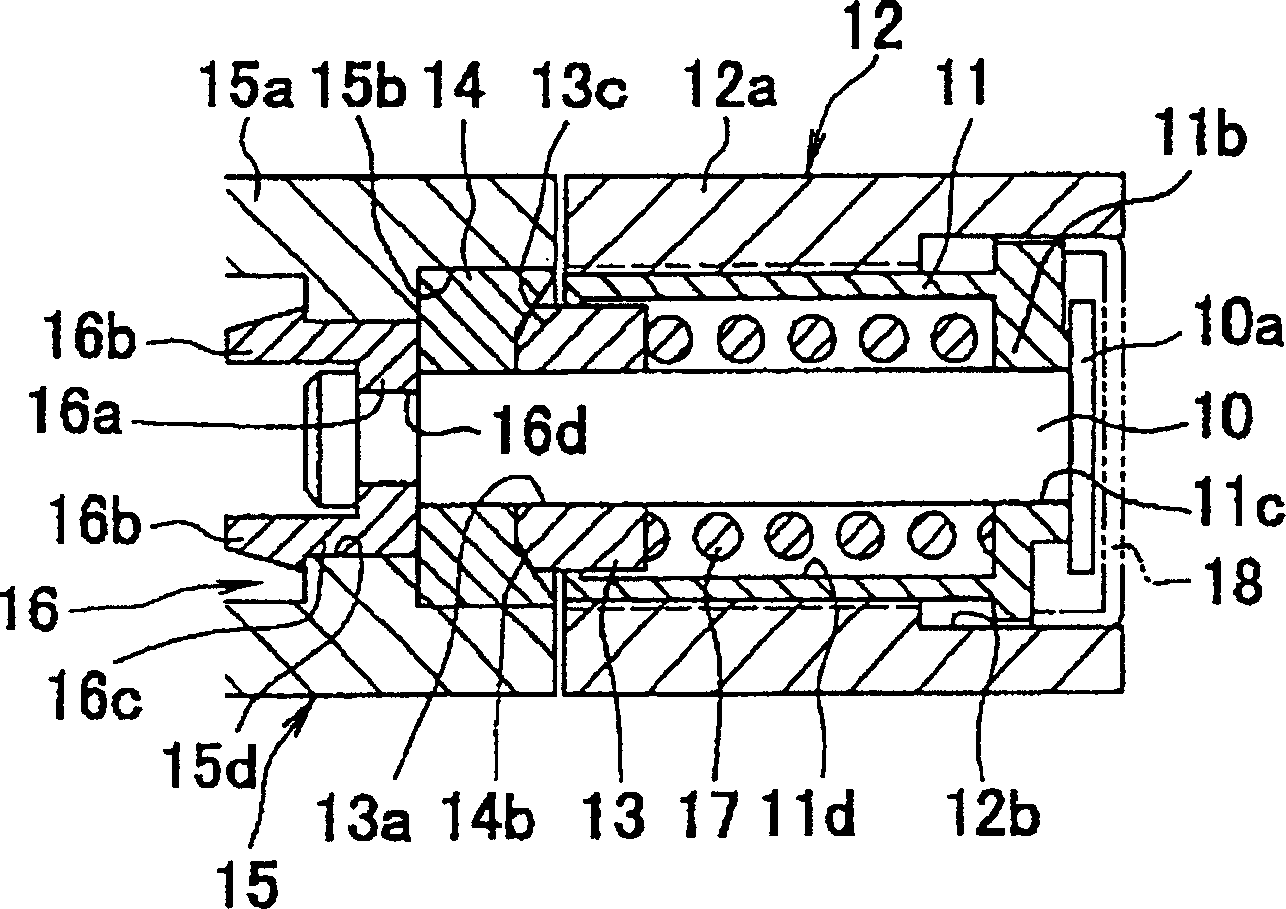

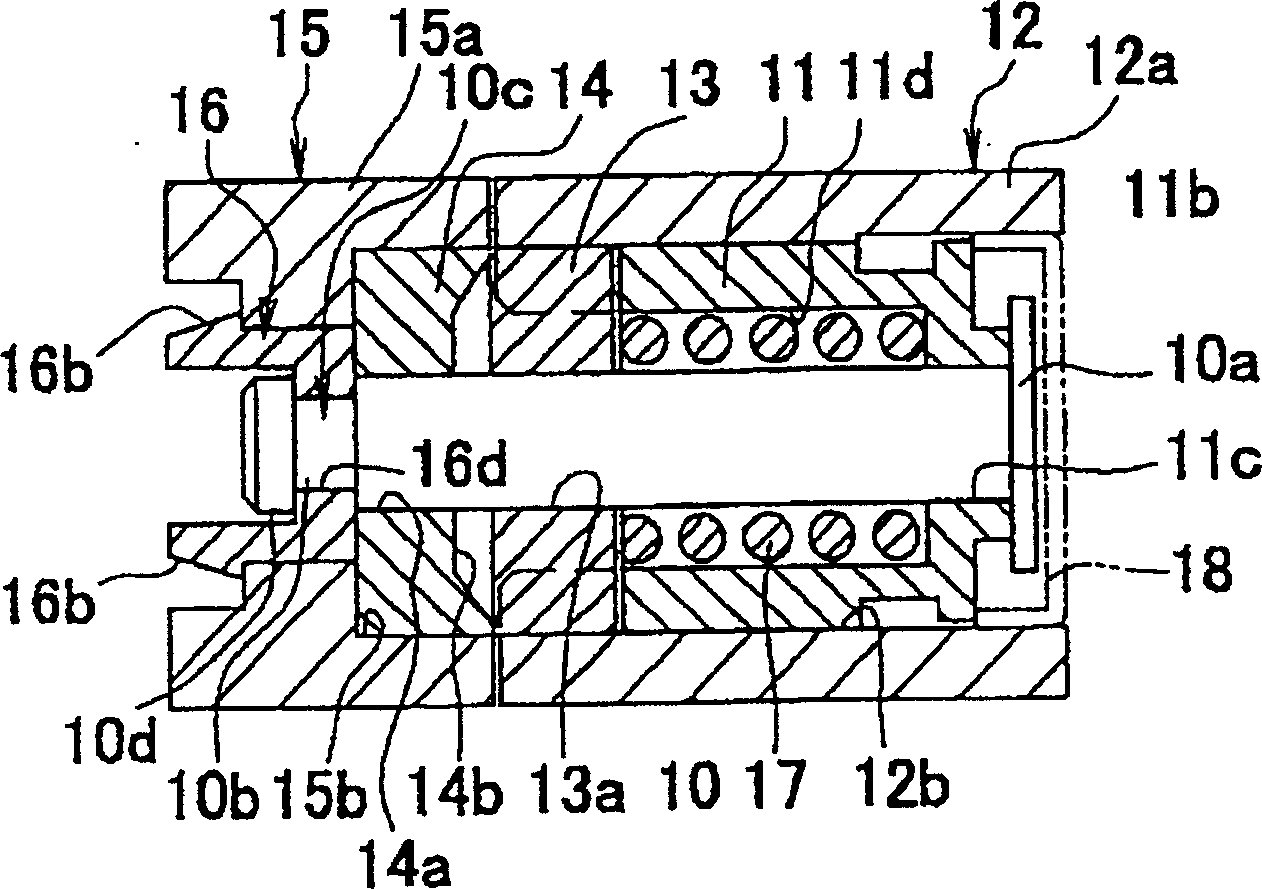

[0044] Below, the situation of implementing a kind of implementation form of the present invention on the mobile phone is described, and the quick-fit hinged body of the present invention can also be used as the hinged body for opening and closing bodies with large openings such as other small-sized OA machines. Open and close the keyboard main body as the first part and the display body as the second part in a small personal computer such as an electronic notebook, a small word processor, or the like.

[0045] According to the picture, in Figure 1 to Figure 13 Among them, reference numeral 10 is a rotating shaft. As shown in FIG. 4, a flange portion 10a is provided at one end thereof, and a matching portion 10c formed by a stepped portion 10d formed by an annular groove 10b is provided at the other end. The material of the shaft 10 may be, for example, a processed metal rod such as SUM24L or a synthetic resin material such as POM.

[0046] Number 11 is a cylindrical shell, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com