Gate electrode and froming method thereof

A gate electrode and gate oxide film technology, which is applied in the field of gate electrodes, can solve the problems of fluorine atom penetration, increase in the thickness of the gate oxide film 12, and deterioration of the electrical properties of the gate oxide film 12.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

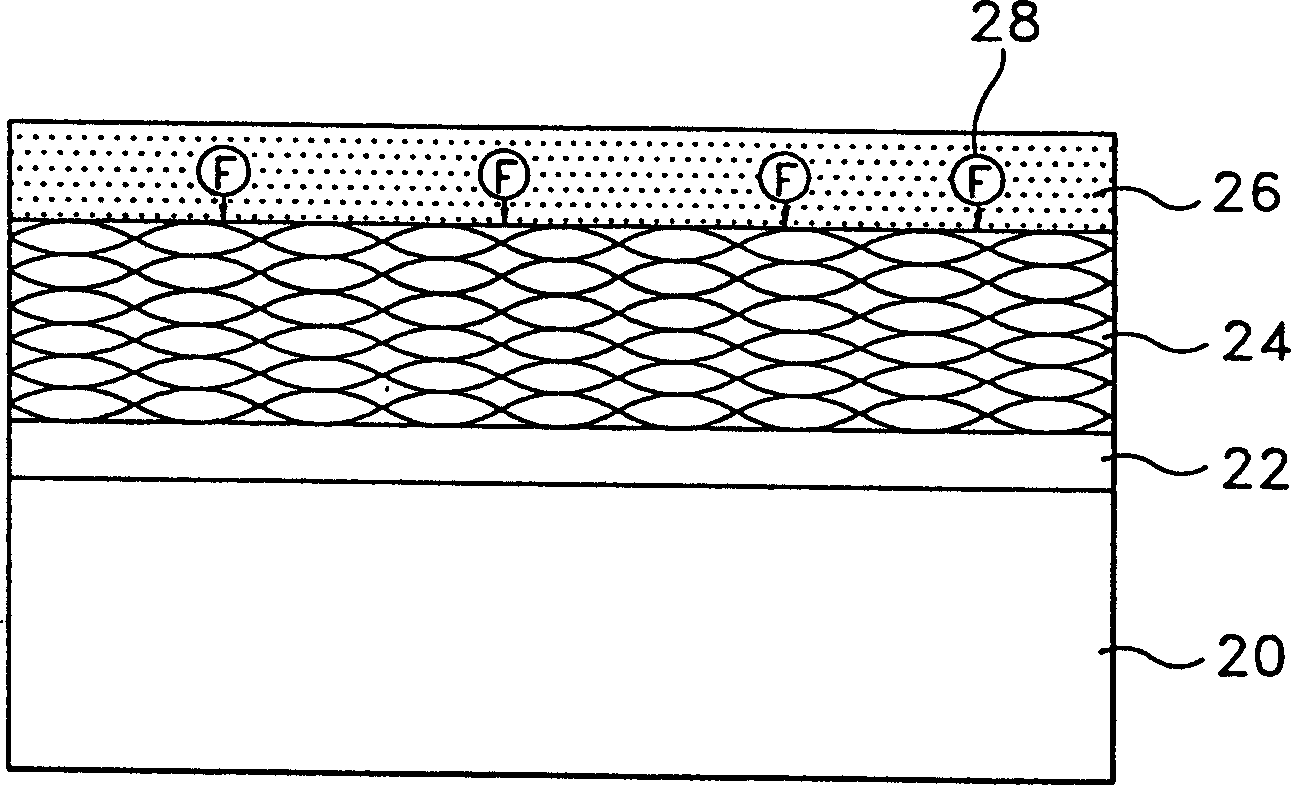

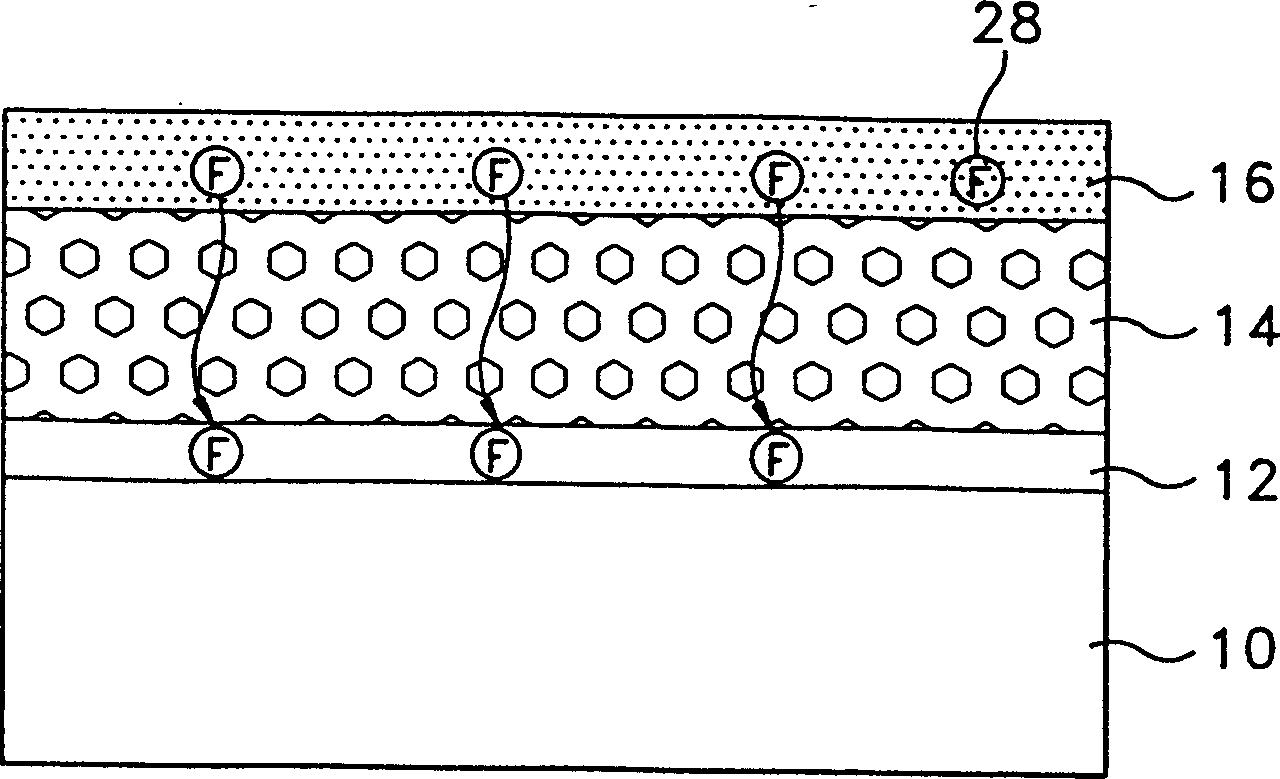

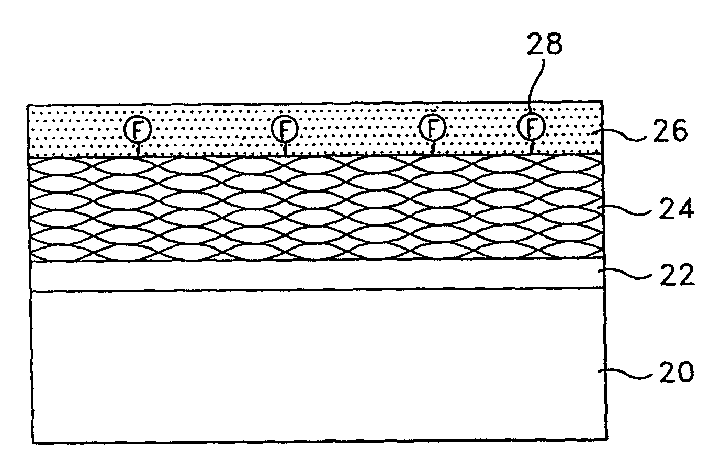

[0021] refer to figure 1 A gate insulating film 22 is formed on the upper portion of the semiconductor substrate 20, and an amorphous silicon layer 24 containing large structural grains and a tungsten silicide layer 26 containing a small amount of fluorine atoms are stacked on the upper portion of the gate insulating film 22.

[0022] With disilane (Si 2 h 6 ) as the source gas, the amorphous silicon layer 24 is formed by chemical vapor deposition, and its structure grain size is about 2-3 μm, compared with the existing structure of crystalline silicon stacking, its grain size is 10 times larger degree. Therefore, in the amorphous silicon layer 24, the impurity penetration path to the gate insulating film 22 side can be reduced to at least 1 / 10 compared with the conventional polysilicon layer used for the gate electrode. As a result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com