Making process of integrated corpse bag

A manufacturing method and integrated technology, applied in the field of bag manufacturing, to achieve the effects of less leakage, material and labor cost savings, and competition in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

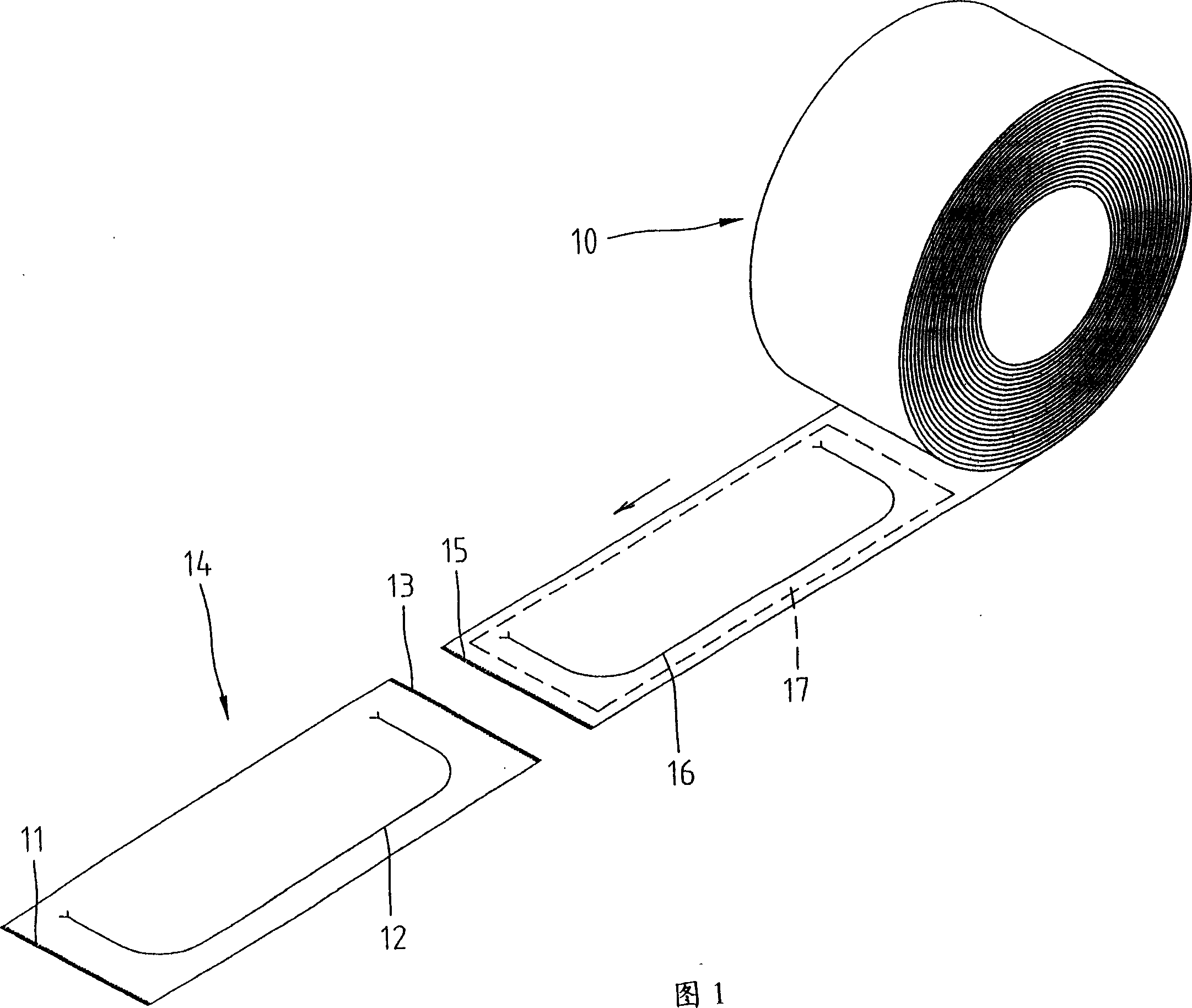

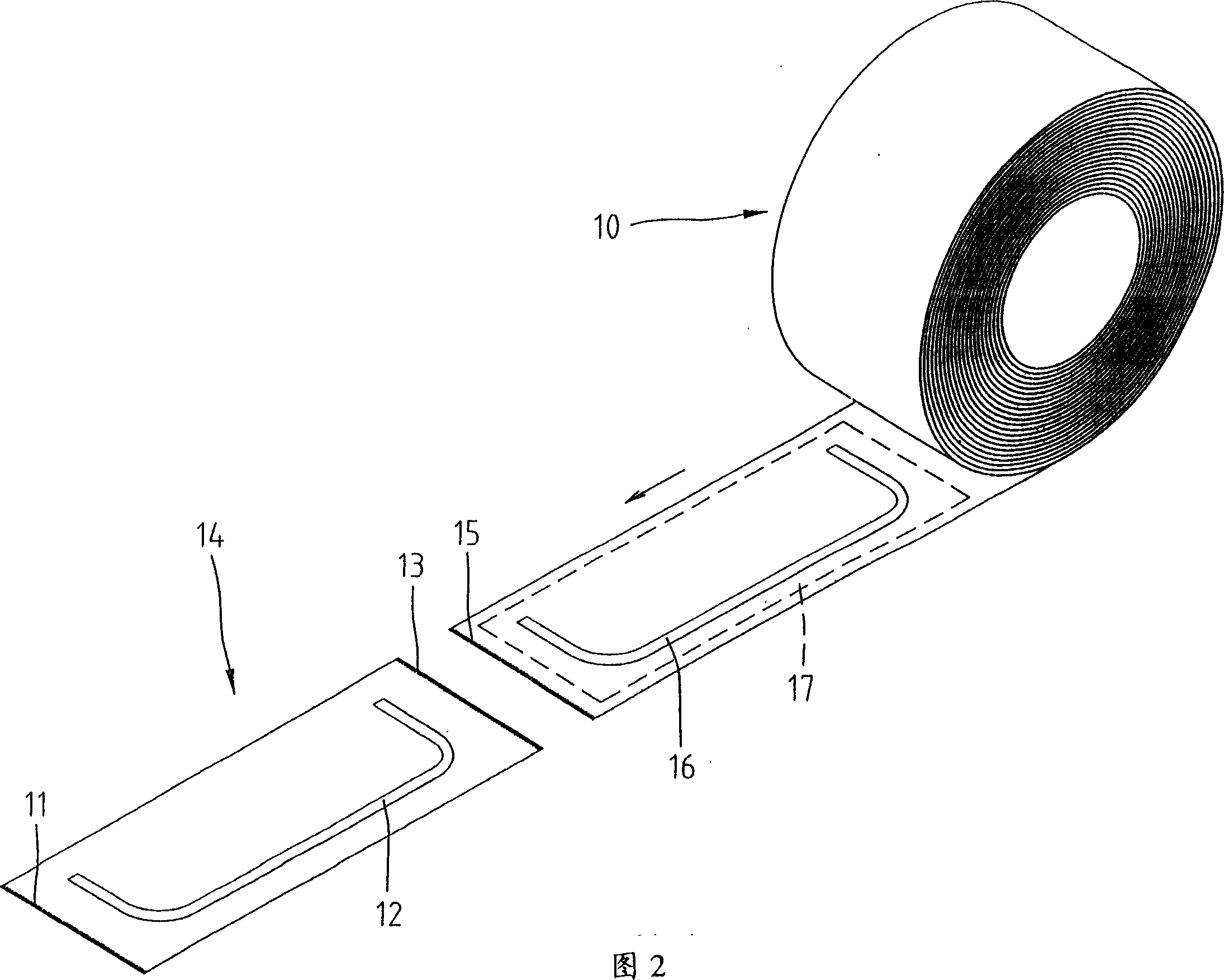

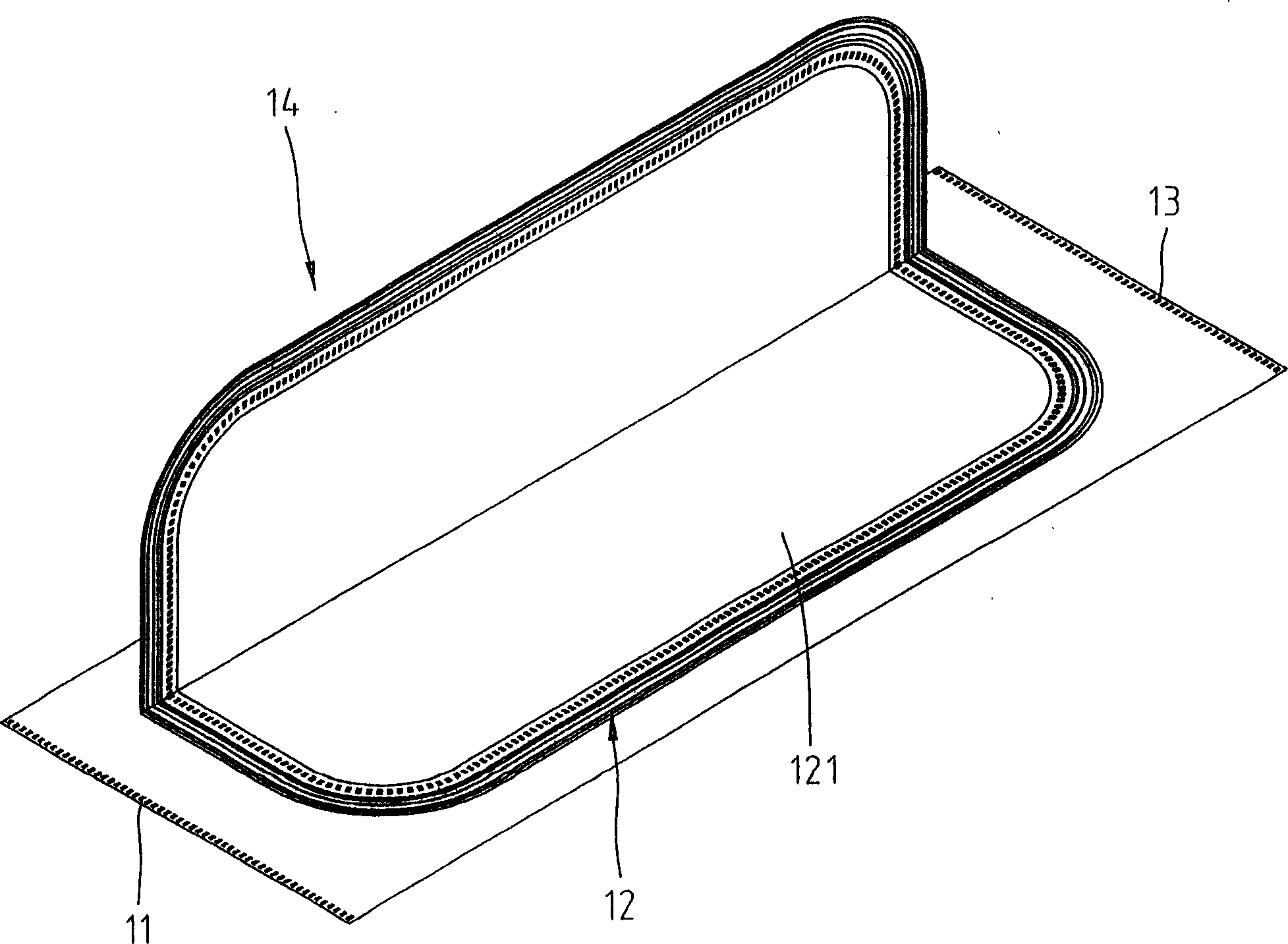

[0025] The present invention provides an integrally formed body bag manufacturing method, please refer to Figure 1 and Figure 2;

[0026] The manufacturing process of the present invention is as follows:

[0027] A. Blow environmental protection materials or thermoplastic chemical materials such as PE [Polyethylene (polyethylene)] into double-layer laminated cylinders by blowing processing;

[0028] B. Curl and store the formed elongated body bag body (10), as shown in Figure 1, then pull out the opening end (11) of the body bag body (10), and place it between the upper and lower pieces Put a backing plate (17) for the die cutter to press-cut the zipper opening;

[0029] C. Bond the opening end (11) with high frequency or hot pressing to form a first sealing end, and at the same time press out an arc-shaped zipper opening (12) on the appropriate part of the body bag body (10) with a die-knife;

[0030] D. Pull the end opposite to the open end (11) to the position of the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com