Rolling ball screw having cooling channel

A ball screw and cooling channel technology, which is applied in the manufacture of tools, feeding devices, friction transmission devices, etc., can solve the problems of ineffective cooling, inconvenient and limited application, and unfavorable machining accuracy of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

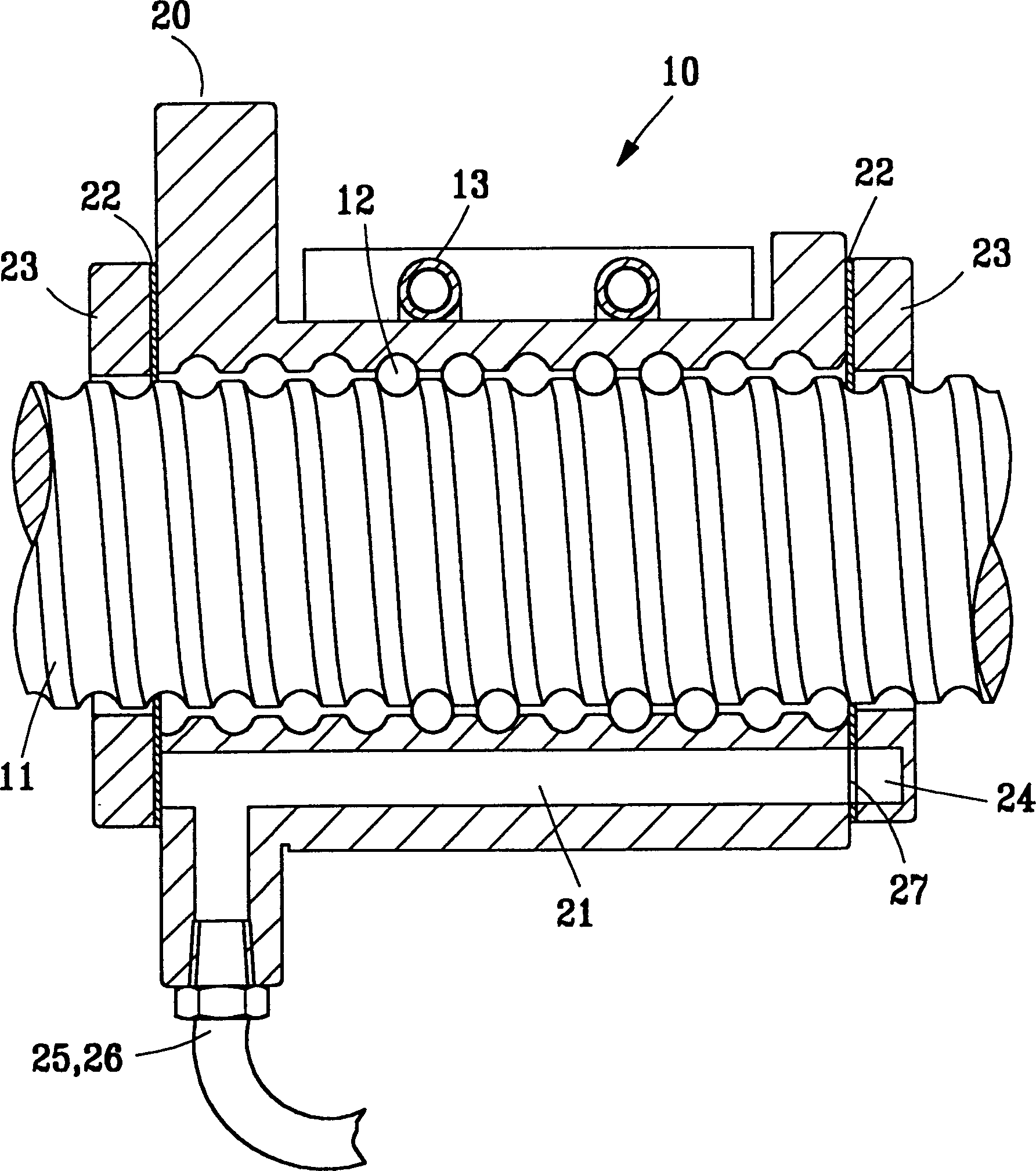

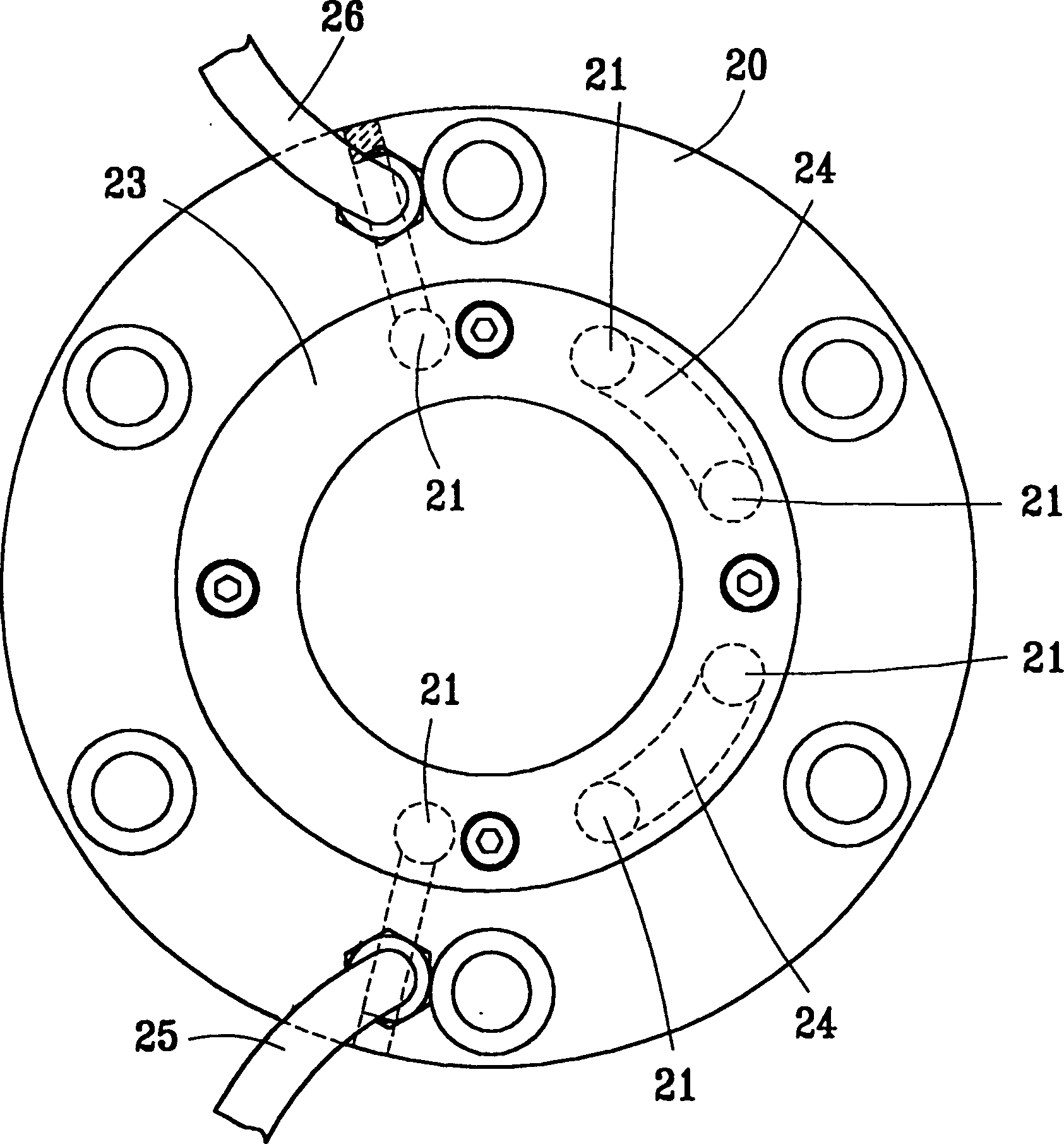

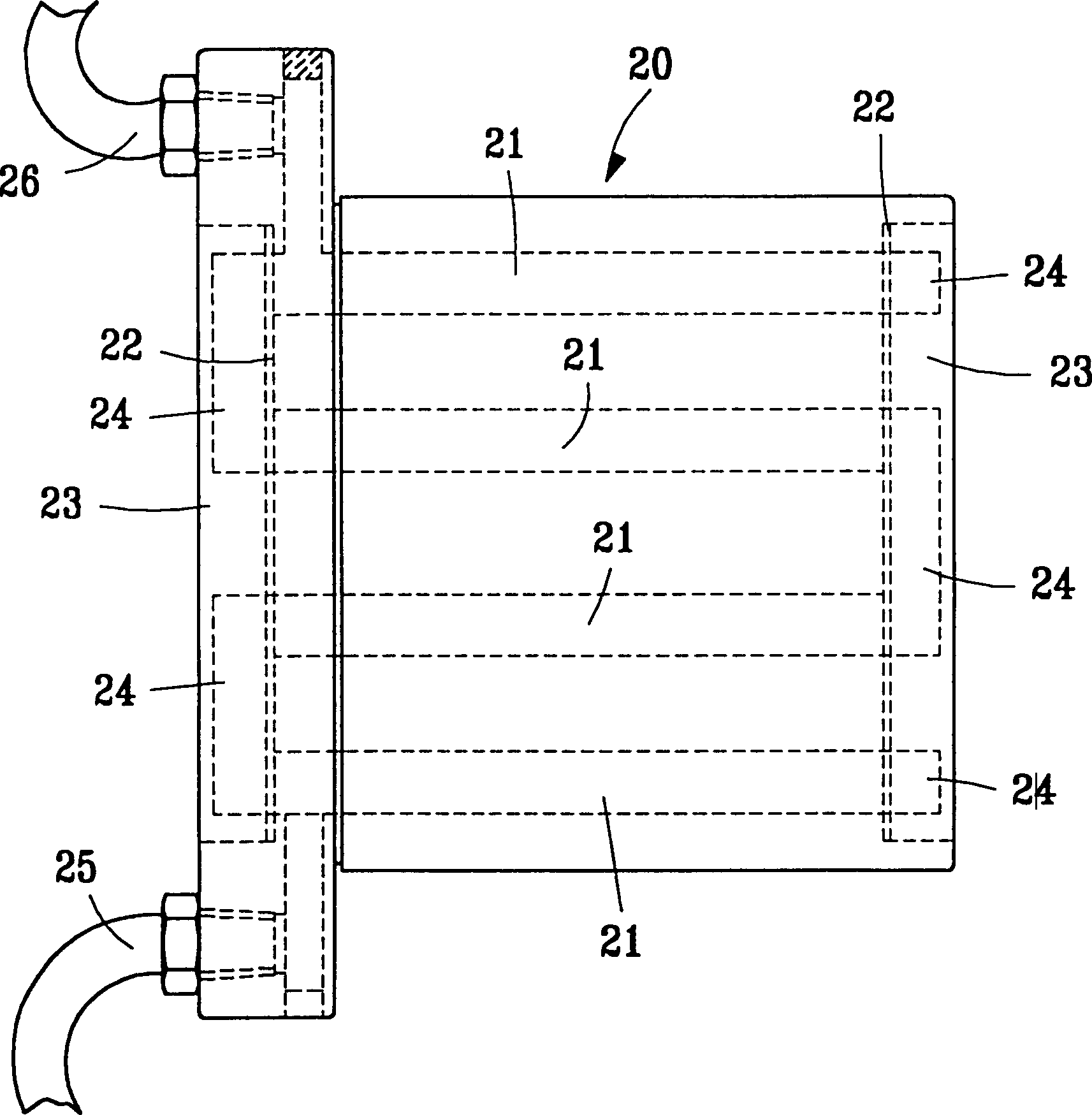

[0021] see figure 1 , the ball screw 10 provided by the present invention includes a screw 11 of a known form, a plurality of steel balls 12, a steel ball circulation system 13 and a nut 20 with several cooling through holes 21 of the main technical feature part of the present invention The steel ball 12 is placed between the screw 11 and the nut 20, and the steel ball circulation system 13 is used to make it circulate; when the screw 11 rotates, the nut 20 can be driven to make a linear movement through the steel ball 12, so that The ball screw 10 can be used, for example, as a feed device of a machine tool or the like.

[0022] In the present invention, several cooling through holes 21 through the nut 20 are provided in the nut 20 along the axial direction, so that the cooling medium with a set working temperature value can enter the nut 20 and communicate with the nut. 20 for heat exchange to take away the heat generated between the nut 20 and the steel ball 12 due to cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com