Control method and device for drain valve of gas-liquid separator, fuel cell and vehicle

A gas-liquid separator, fuel cell technology, applied in fuel cells, fuel cell additives, power system fuel cells, etc., can solve problems affecting system efficiency and safety, leakage, etc., to prevent safety problems and prevent improper leakage , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

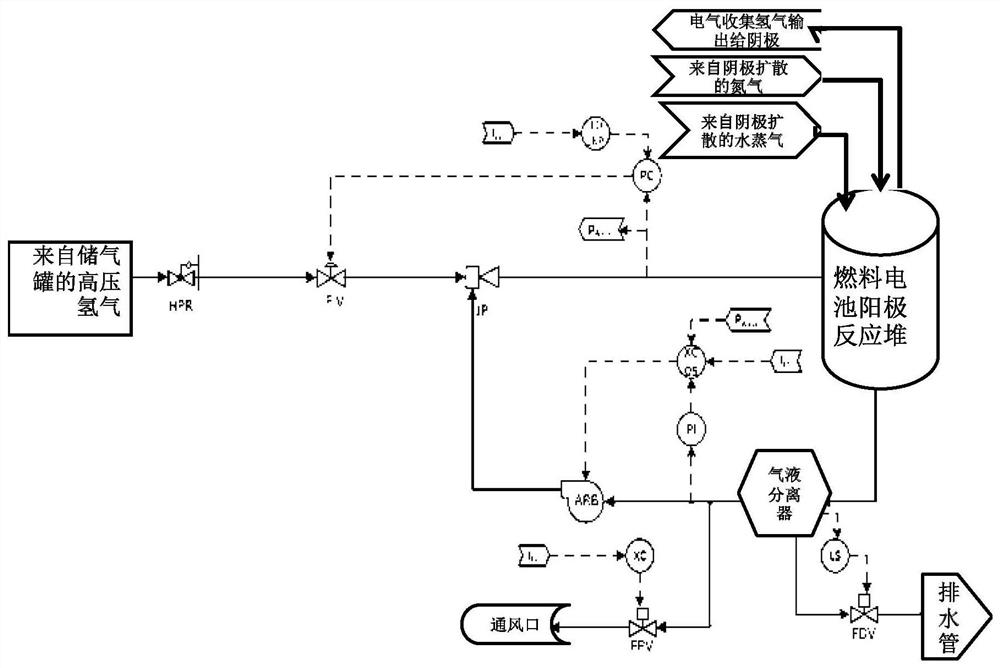

[0042] This embodiment relates to a method for controlling a drain valve of a fuel cell gas-liquid separator. In this embodiment, the fuel cell is a hydrogen-oxygen fuel cell.

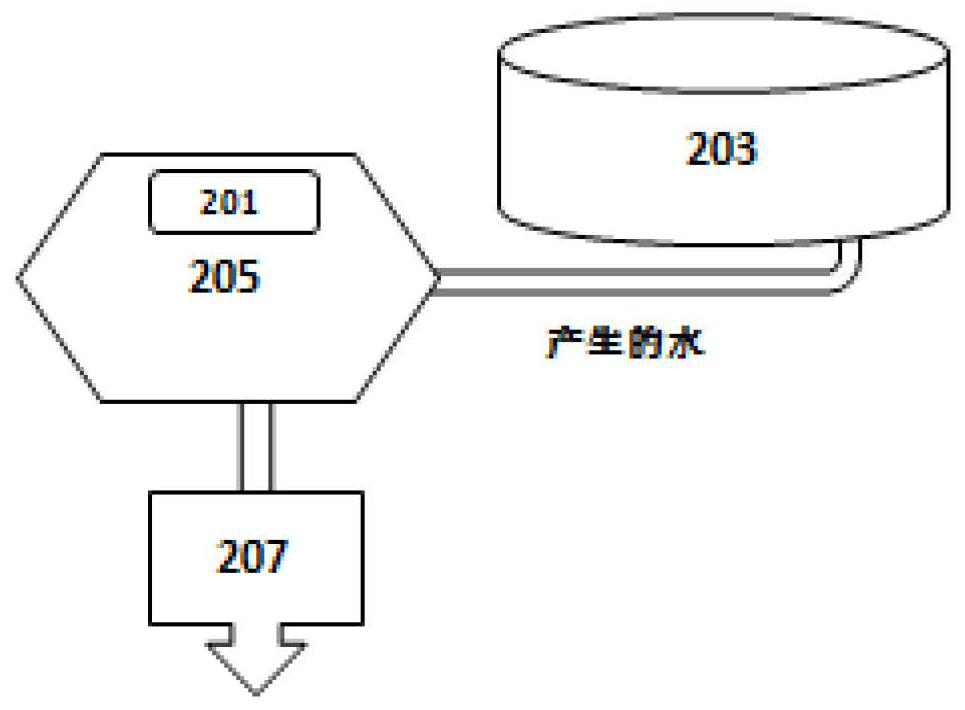

[0043] see figure 1 , which is a schematic diagram of the fuel cell structure; in addition, see figure 2 , which enlargedly shows the control mode and structure of the drain valve 207 of the gas-liquid separator 205 . It can be seen that during the working process of the fuel cell, the anode reactor will produce water, so a water outlet is provided on the side of the anode reactor, and the water generated by the reaction is transported to the gas-liquid separator 205 through the water pipeline. The function of the gas-liquid separator 205 is gas-liquid separation, that is, to separate water and hydrogen. The water is discharged through the drain valve 207 below, and the hydrogen is recycled for reuse.

[0044] As described in the background art, in the structure of the above-mentioned prior art, i...

no. 2 example

[0055] This embodiment relates to a method for controlling a drain valve of a hydrogen-oxygen fuel cell gas-liquid separator for automobiles and a control device for the drain valve of the fuel cell gas-liquid separator.

[0056] As described in the background and see figure 2 As shown, the fuel cell gas-liquid separator drain valve control method and control device in the prior art, wherein 201 is a water level sensor.

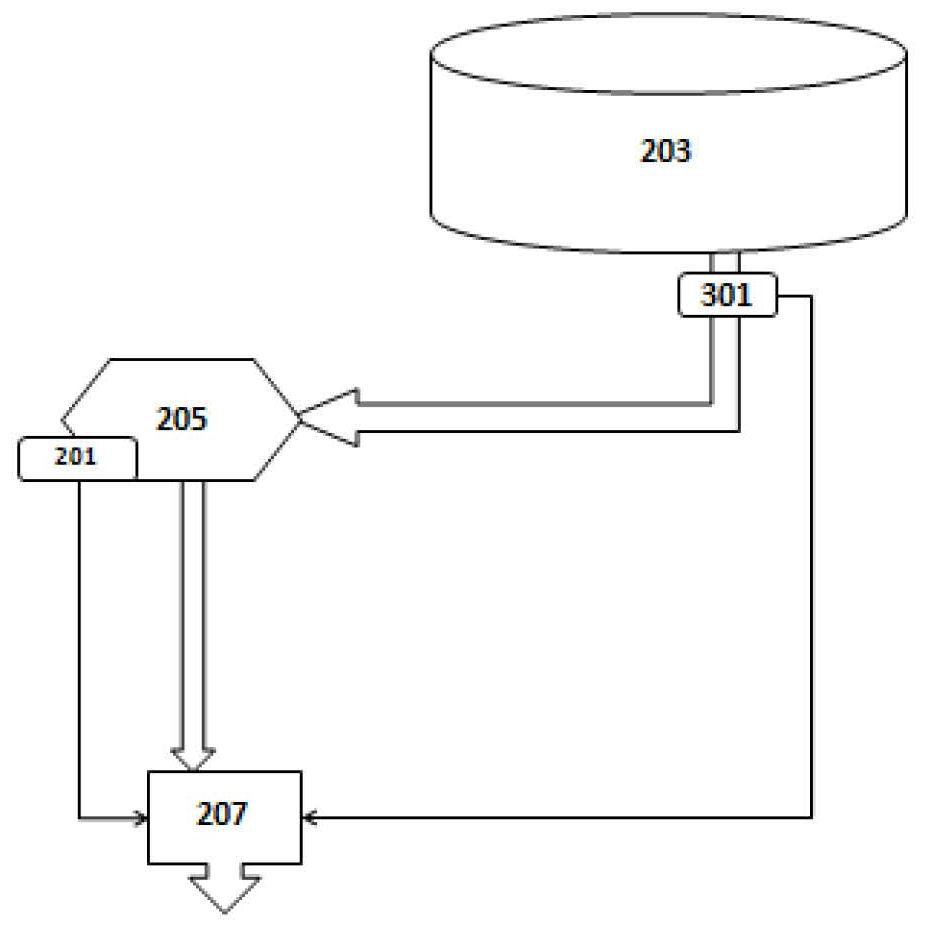

[0057] Figure 3B A control method and a control device of a gas-liquid separator drain valve (FDV) according to another embodiment of the present disclosure are shown.

[0058] Such as Figure 3B As shown, according to the exemplary embodiment of the present disclosure, the air pressure sensor 301 may also be disposed in the downstream part of the gas passage of the gas-liquid separator to detect the gas pressure drop rate.

[0059] see figure 1 and Figure 3B , in the method of this embodiment, it also includes detecting the state of the fuel cell exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com