Separator for a water-steum separating device

A technology for separators and separation chambers, applied in the field of separators, which can solve problems such as long start-up time, slow load change speed, temperature change speed limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation

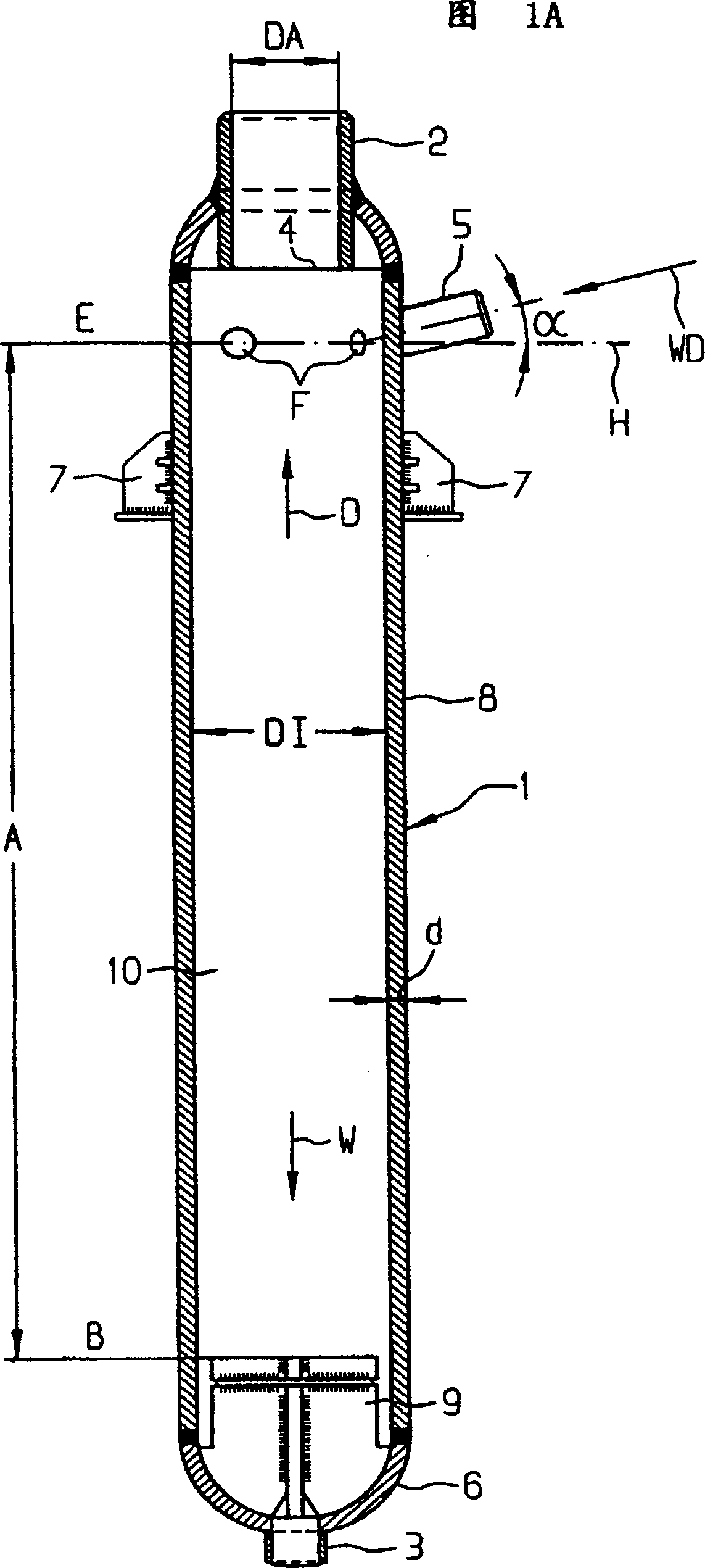

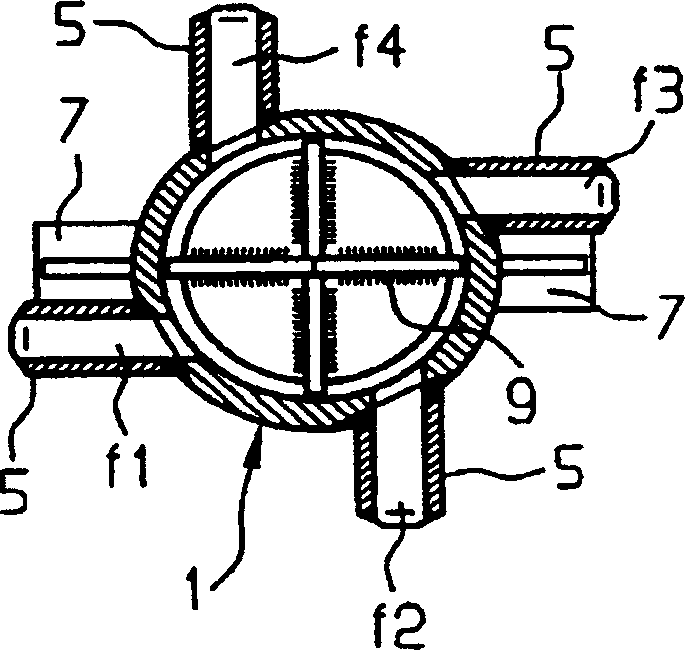

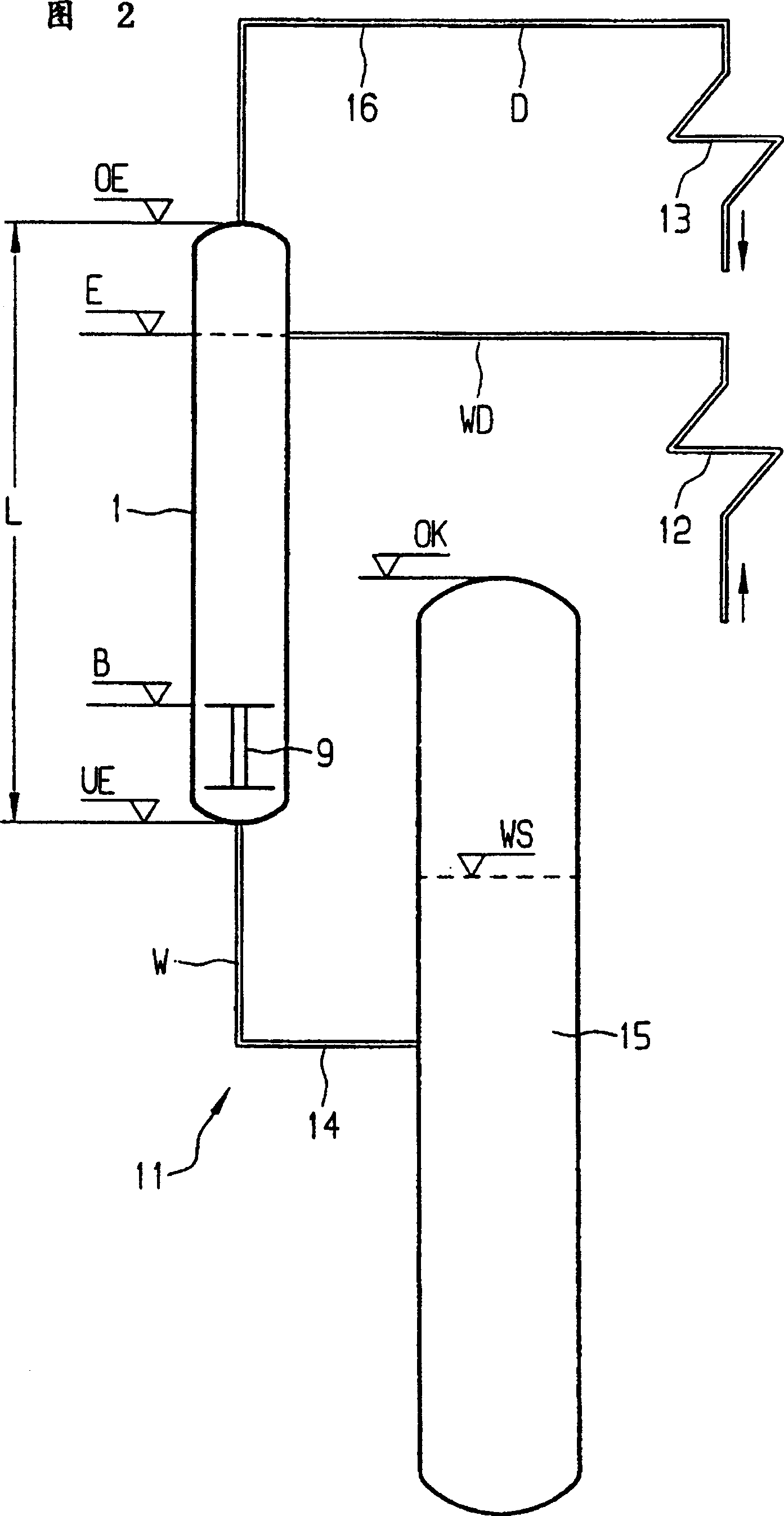

[0020] Figure 1a shows a separator or cyclone 1 in longitudinal section, while Figure 1b shows the separator in cross section. The separator 1 has an upper steam outlet 2 and a lower water outlet 3 . Below the steam discharge pipe 2, in the inflow or input plane E near its inflow port 4, some inlet pipes 5 are distributed along the periphery of the separator 1 for input of water to be divided into water W and steam D- Vapor mixture WD. Here, the inlet pipes 5 are on the one hand inclined at an angle α with respect to the horizontal plane H and on the other hand are connected tangentially to the separator. Below the inlet plane E of the inlet pipe 5 , on the wall 8 of the separator 1 there is a support clip 7 which holds the separator in an upright position.

[0021] Through the setting of the inlet pipe 5, the water-steam mixture WD flowing into the separator 1 flows downward to the bottom 6 of the separator 1 on the one hand, and forms a sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com