Steam compressor

一种压缩机、气缸的技术,应用在压力泵、机械设备、机器/发动机等方向,能够解决不再能保证操作流体安全操作、操作流体准确液位测量不再可能等问题,达到可靠操作、低结构支出、长使用寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

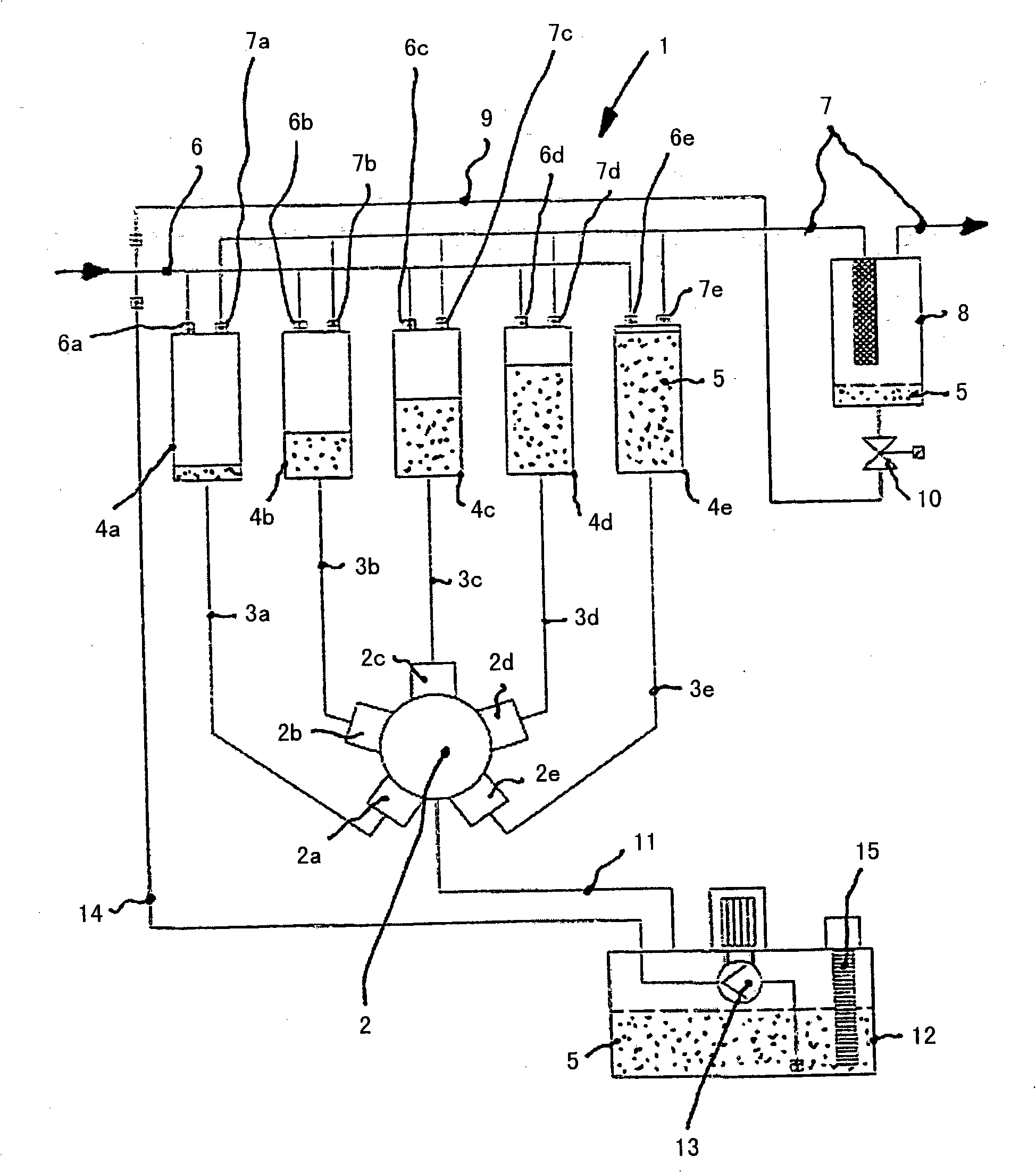

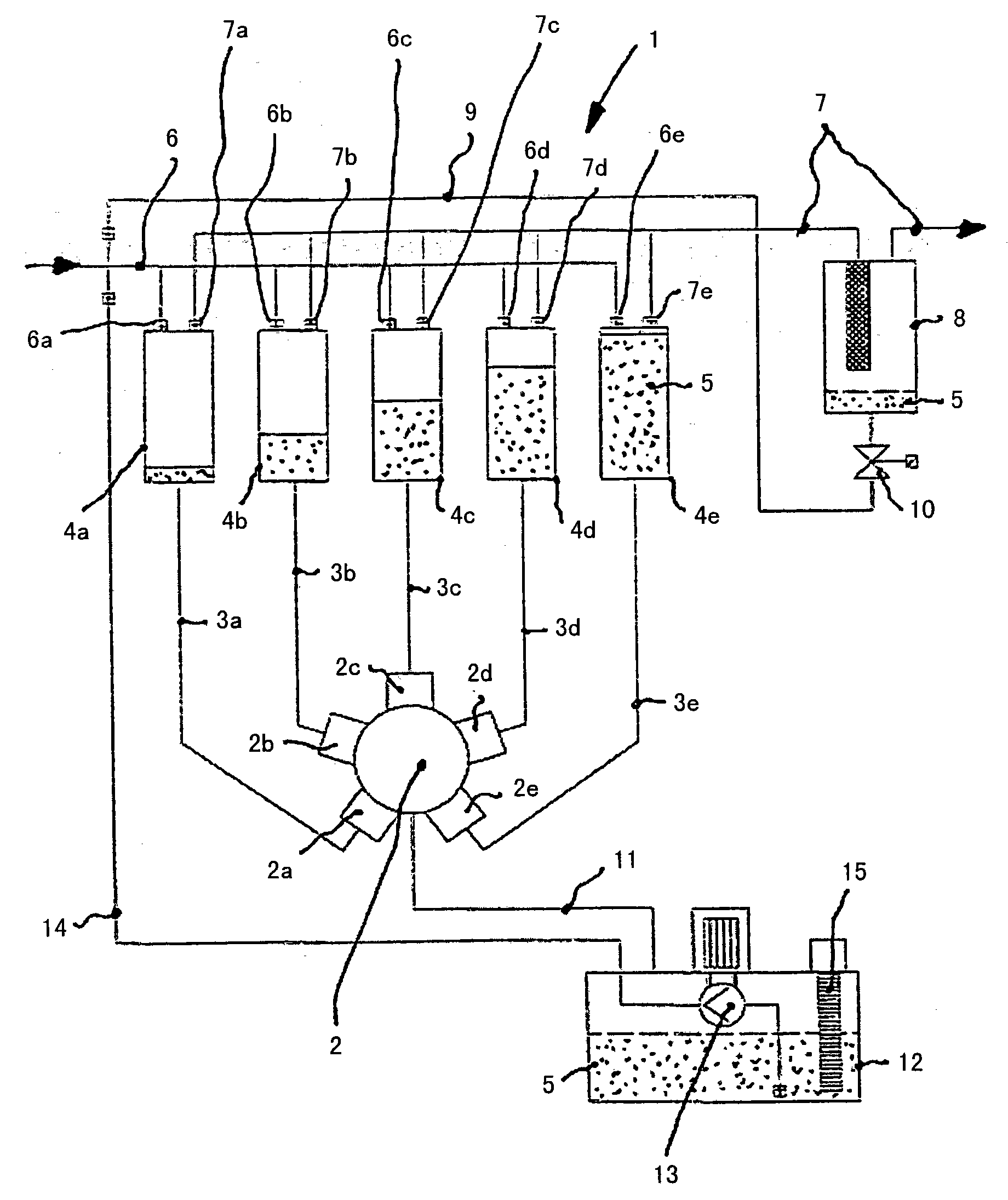

[0017] In the figure, a circuit diagram shows a compressor 1 according to the invention. The compressor 1 has a mobile machine configured as a piston machine 2, for example a radial piston machine, provided with several cylinder chambers 2a, 2b, 2c, 2d, 2e. Each cylinder chamber 2a, 2b, 2c, 2d, 2e (in which a piston not shown is respectively movably mounted) is connected to a compressor cylinder 4a, 4b, 4c by means of a connecting duct 3a, 3b, 3c, 3d, 3e , 4d, 4e are connected. In the compressor cylinders 4 a , 4 b , 4 c , 4 d , 4 e is located an operating fluid 5 in the form of an ionic fluid which is movable by means of the piston machine 2 .

[0018] The compressor cylinders 4a, 4b, 4c, 4d, 4e are connected on the input side via inlet valves 6a, 6b, 6c, 6d, 6e respectively to inlet lines 6 for the medium to be compressed, eg natural gas or hydrogen. In order to increase the input pressure and thus the output performance, a pre-compressor can be associated with the inlet d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com