Temperature expansion valve

A technology for expansion valves and passages, which is applied in the field of temperature expansion valves, and can solve problems such as unstable valve movements and incomplete control of oscillation phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

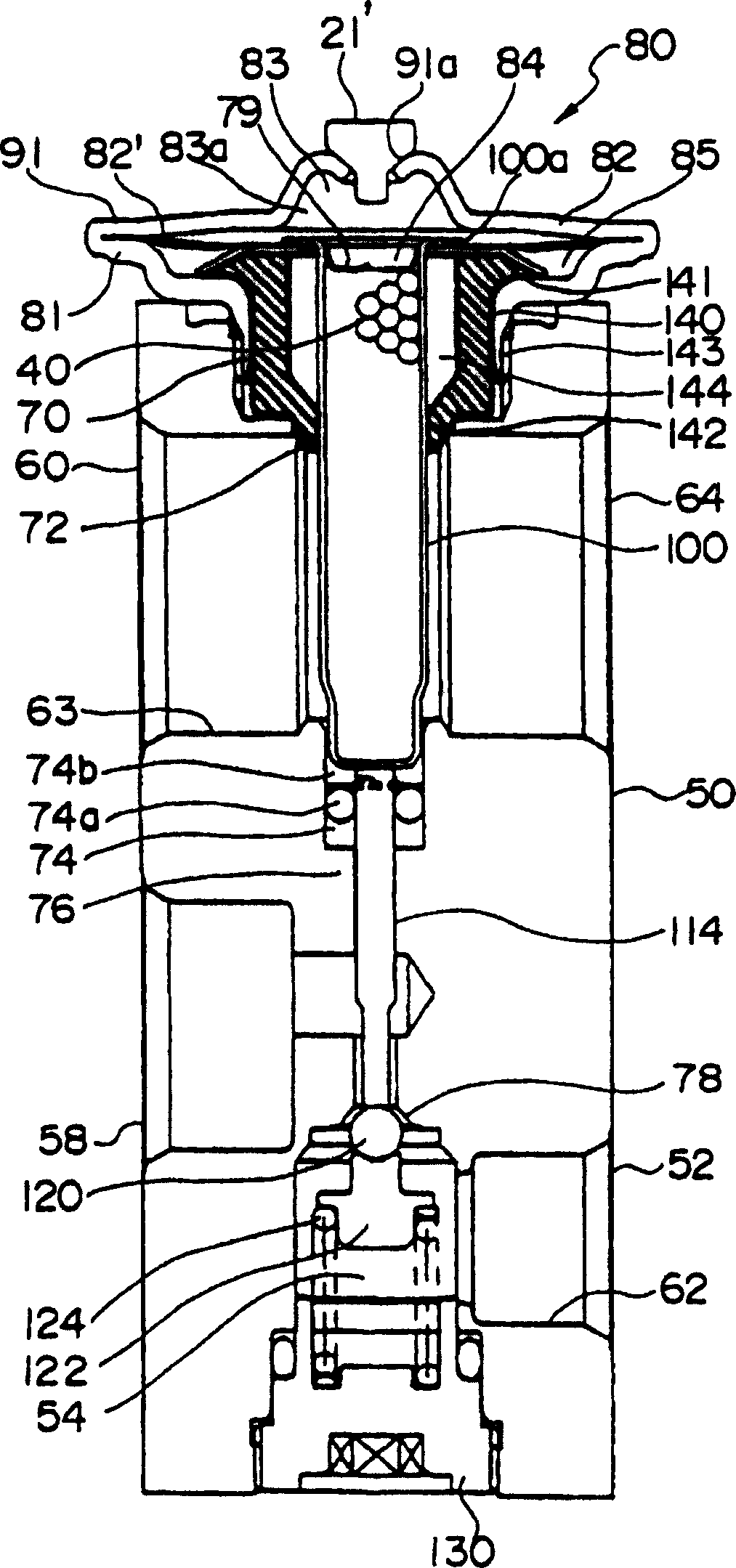

[0027] Hereinafter, embodiments of the temperature type expansion valve of the present invention will be described with reference to the drawings.

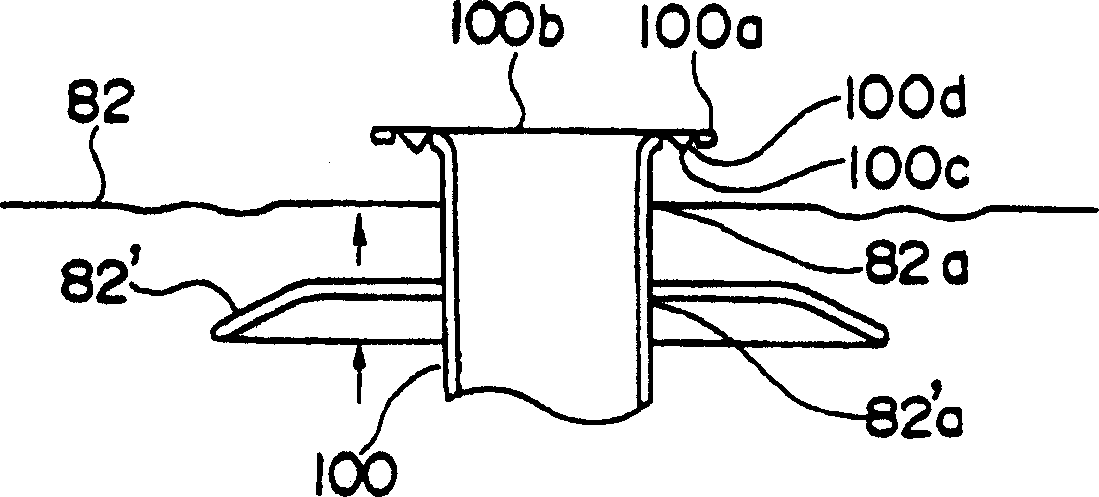

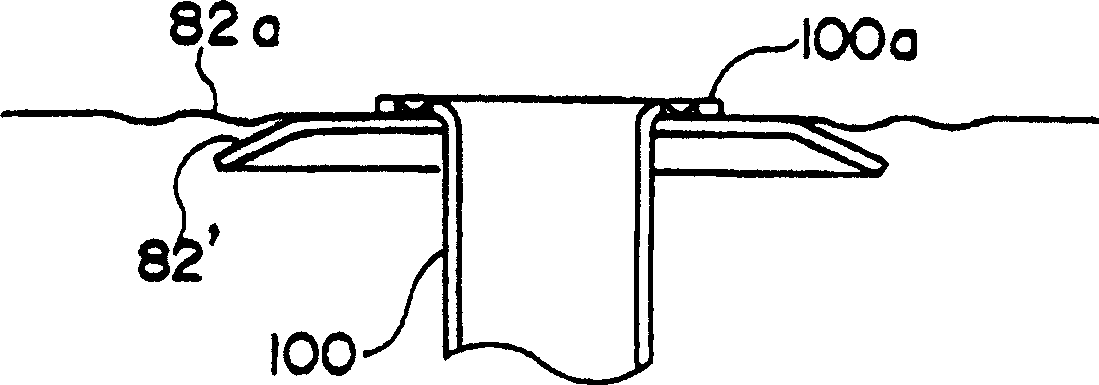

[0028] figure 1 2( a ) and FIG. 2( b ) are sectional views showing the structure of the main parts thereof. figure 1 The shown embodiment has the same basic structure as the existing temperature-type expansion valve, so only the parts with different structures will be described, and the parts that are the same as or equivalent to the existing temperature-type expansion valve use the same symbols, and their descriptions will be omitted. .

[0029] figure 1 Among them, symbol 140 is a heat conduction hysteresis member, for example, made of resin such as nylon or polyacetal, and made into a roughly cup shape, with a wide and thick wall with a flange portion 141 on the outside of the upper end and a tapered necking portion 142 at the lower end. The cylindrical part 143 is formed, and the upper end is in contact with the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com