Redunant inputting driver and use thereof

A redundant input and drive technology, applied in the field of mechanics, can solve the problem of redundant input drive unbalanced force, achieve the effect of solving the problem of unbalanced force, reducing manufacturing and use costs, and evenly sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

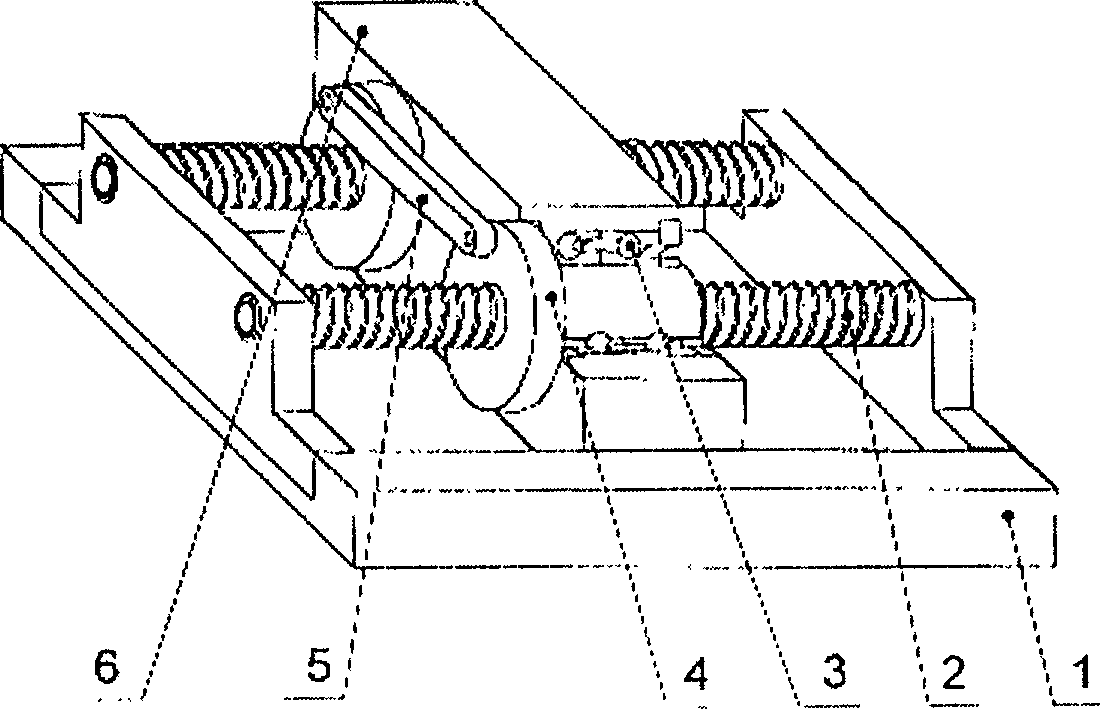

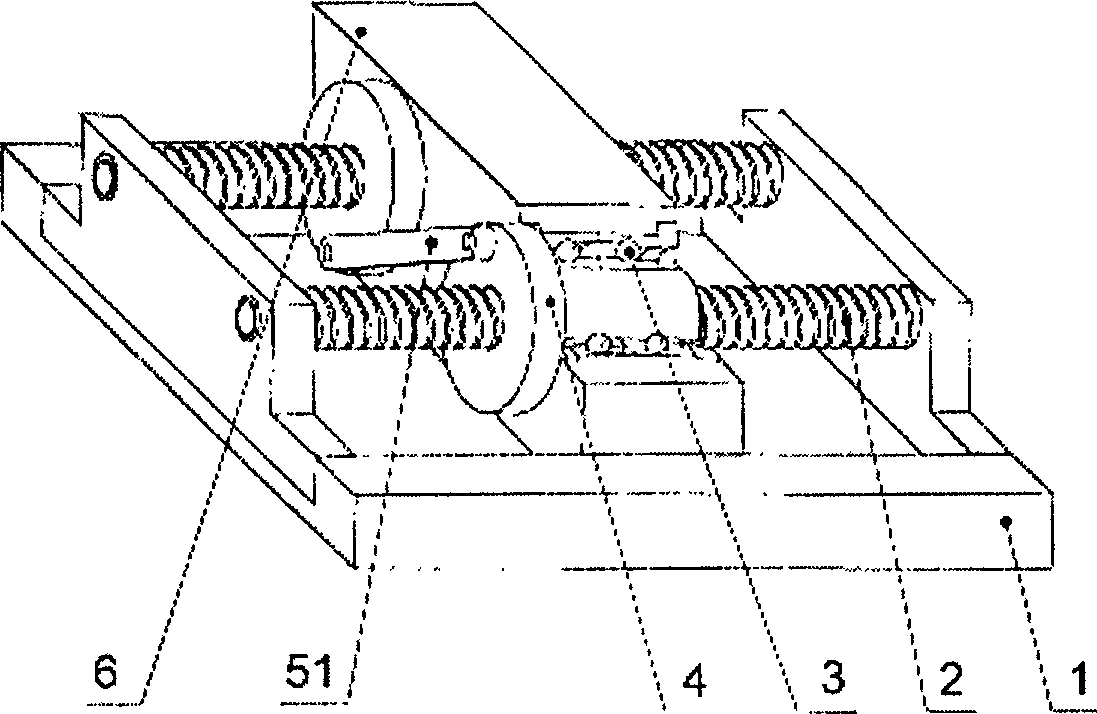

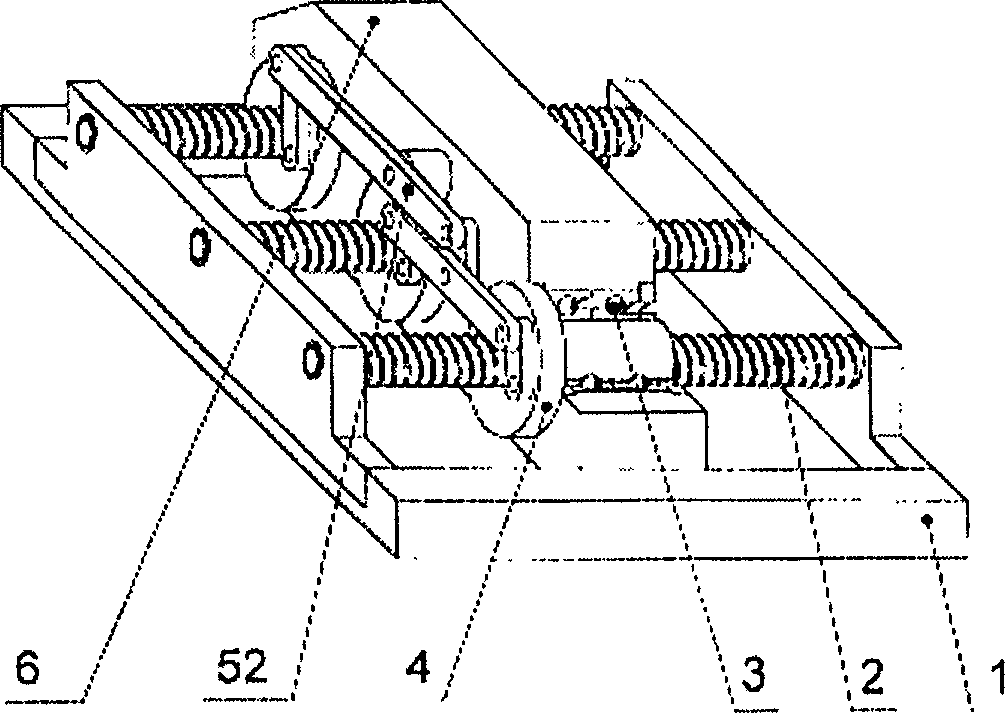

[0017] Redundant input drivers of the present invention (see figure 1 , hereinafter referred to as the driver) is characterized in that it includes a base 1, two or more than two lead screws 2 installed in parallel on the base 1, each lead screw 2 is equipped with a nut 4, each The nuts 4 are respectively connected with a moving platform 6 sleeved on all the lead screws 2 through the bearings 3 , and the nuts 4 are connected by the transmission device 5 .

[0018] The working principle of the redundant input driver of the present invention is: the screw 2 connected to the base 1 is connected to the moving platform 6 through the nut 4 and the bearing 3; the screw 2 is the input power source, and it can only Pure rotation relative to the base 1; the transmission device 5 is connected to each nut 4. When a certain nut rotates, it can drive the rest of the nuts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com