Serial friction transmission mechanisms and rotary transmission mechanisms and their manufacture

A technology of friction transmission and friction roller, which is applied in the direction of friction transmission, transmission, differential transmission, etc., can solve the problems of assembly of brakes into friction transmission, unfavorable cost, etc., and achieve the effect of reducing manufacturing cost and preventing manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

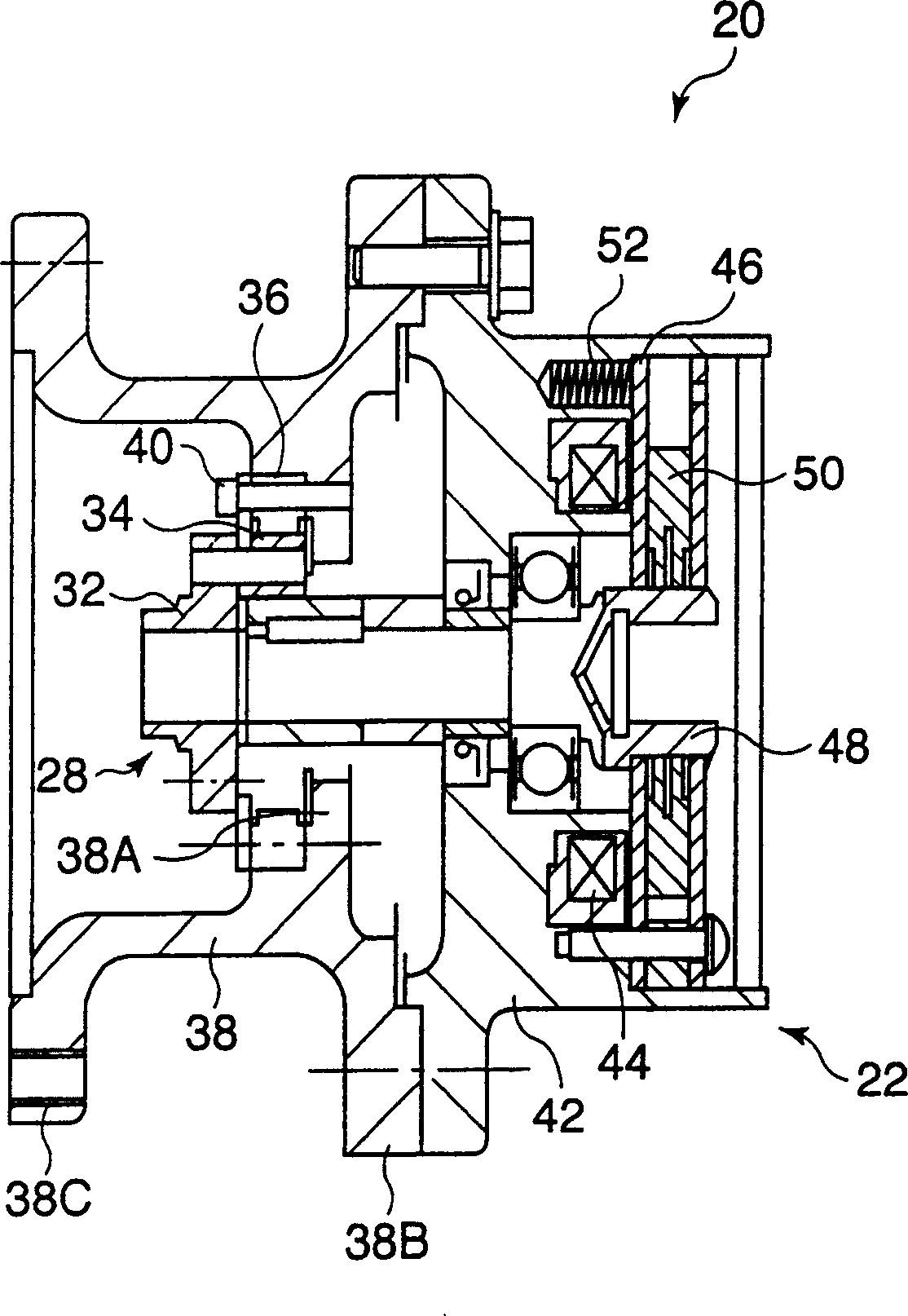

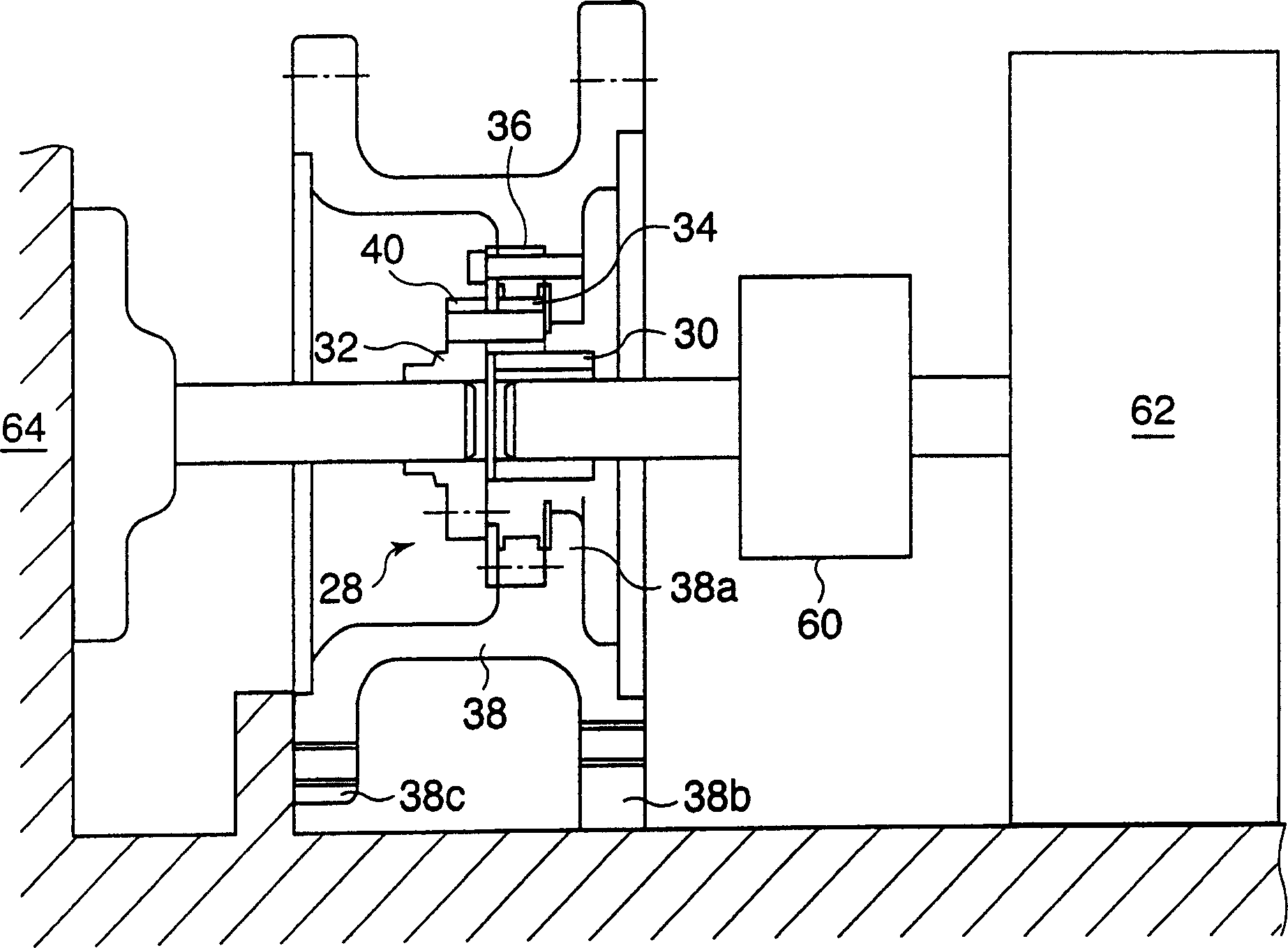

[0080] figure 1 It is a partial cross-sectional view showing a friction transmission device 20 according to an embodiment of the present invention. The friction transmission is equipped with a simple planetary roller mechanism 28 comprising friction rollers comprising a sun roller 30, a planetary roller 34 and a ring roller 36, which are held on a planetary carrier and rotate with the outer circumference of the sun roller contact, the planetary rollers are in rotational contact with the inner circumference of the ring roller while restricting the ring roller's own rotation; and

[0081] The brake 22 is connected with the sun roller 30 and brakes the rotation of the sun roller 30 .

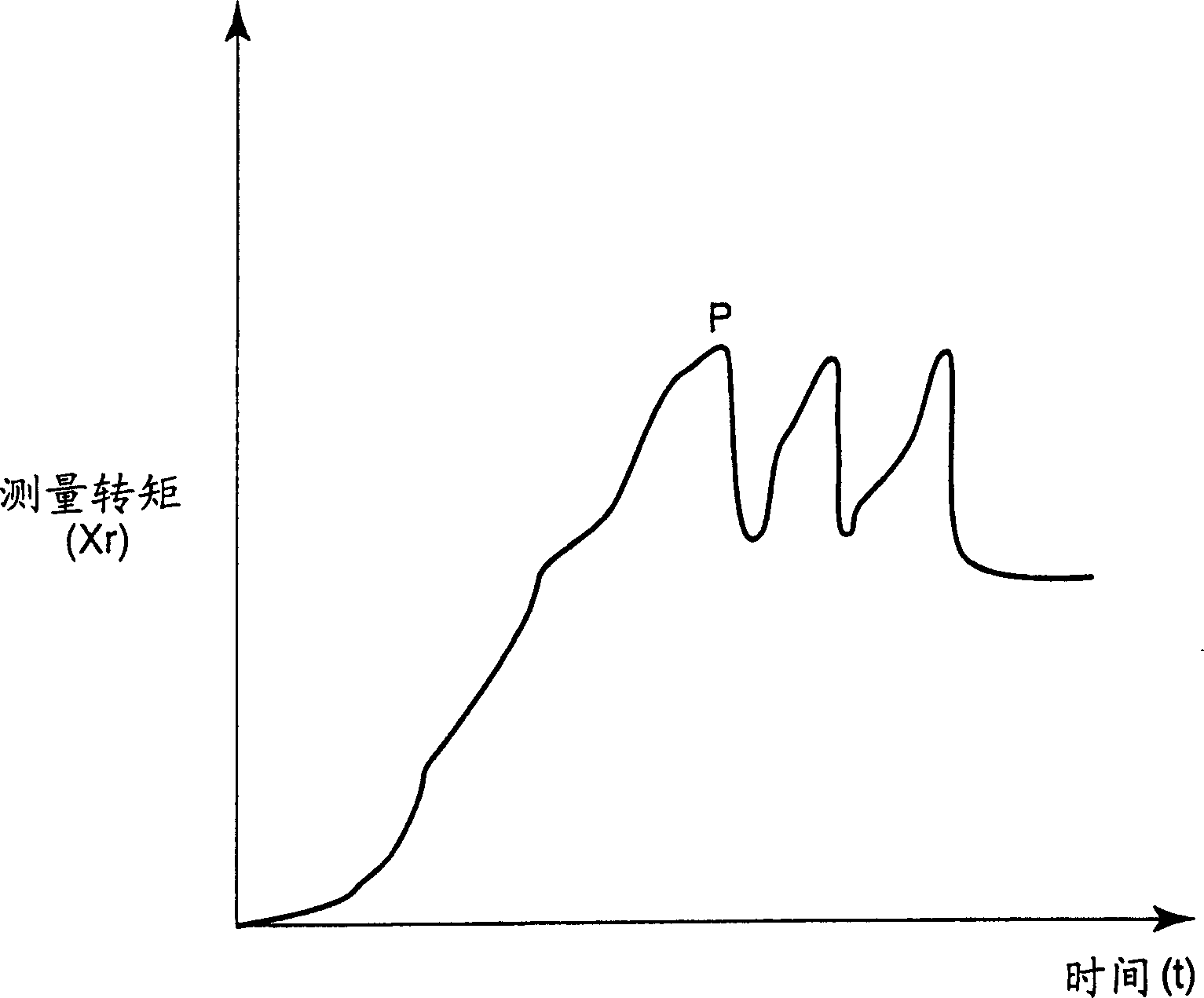

[0082] The static friction torque Y obtained from the brake is set to 0.1Xd<Y<0.7Xd, preferably 0.2Xd<Y<0.5Xd, where Xd is the critical test torque of the simple planetary rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com