Sealing method and device for ink box

A technology for sealing devices and ink cartridges, applied in printing and other fields, can solve the problems of additional, insignificant improvement, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

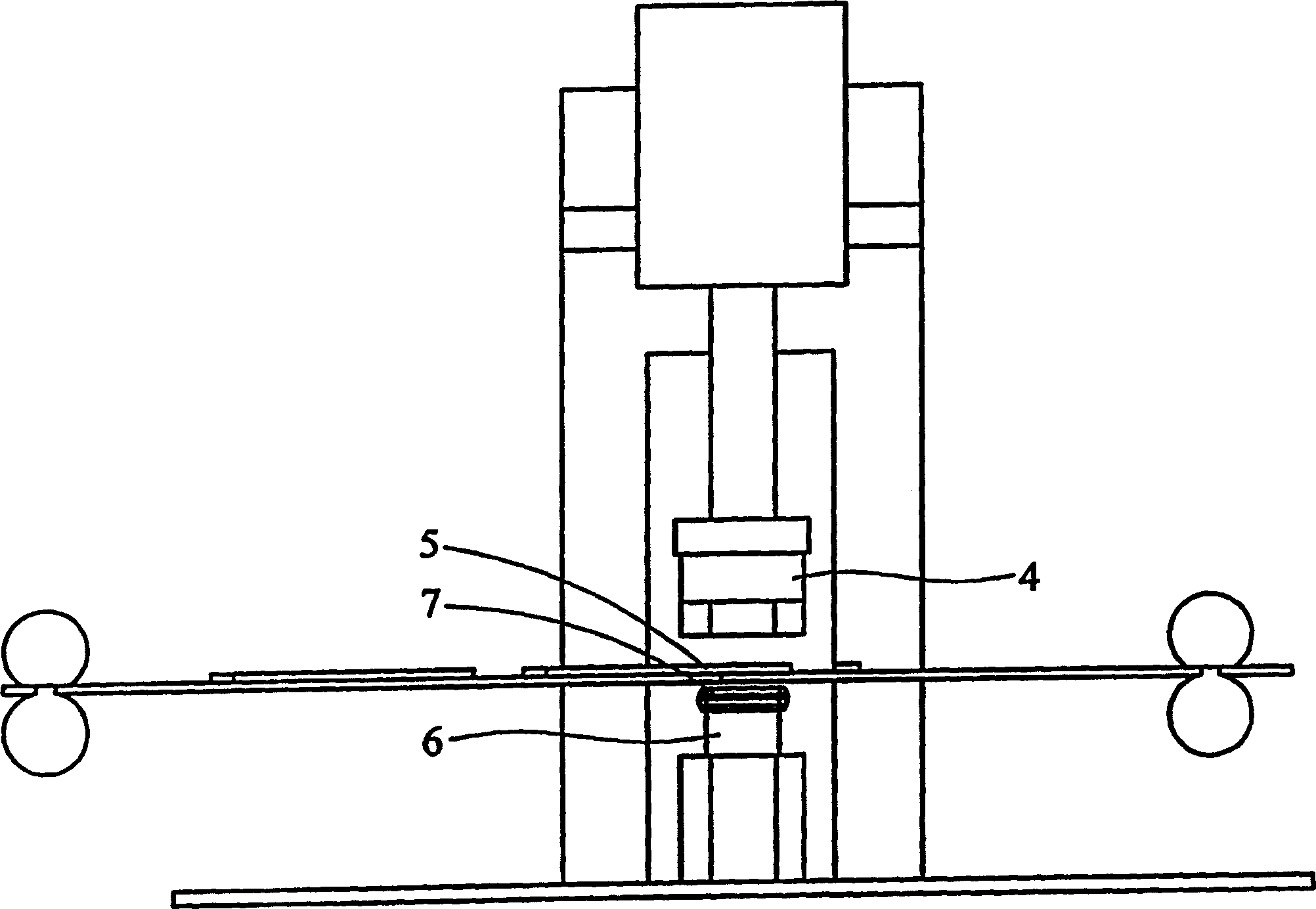

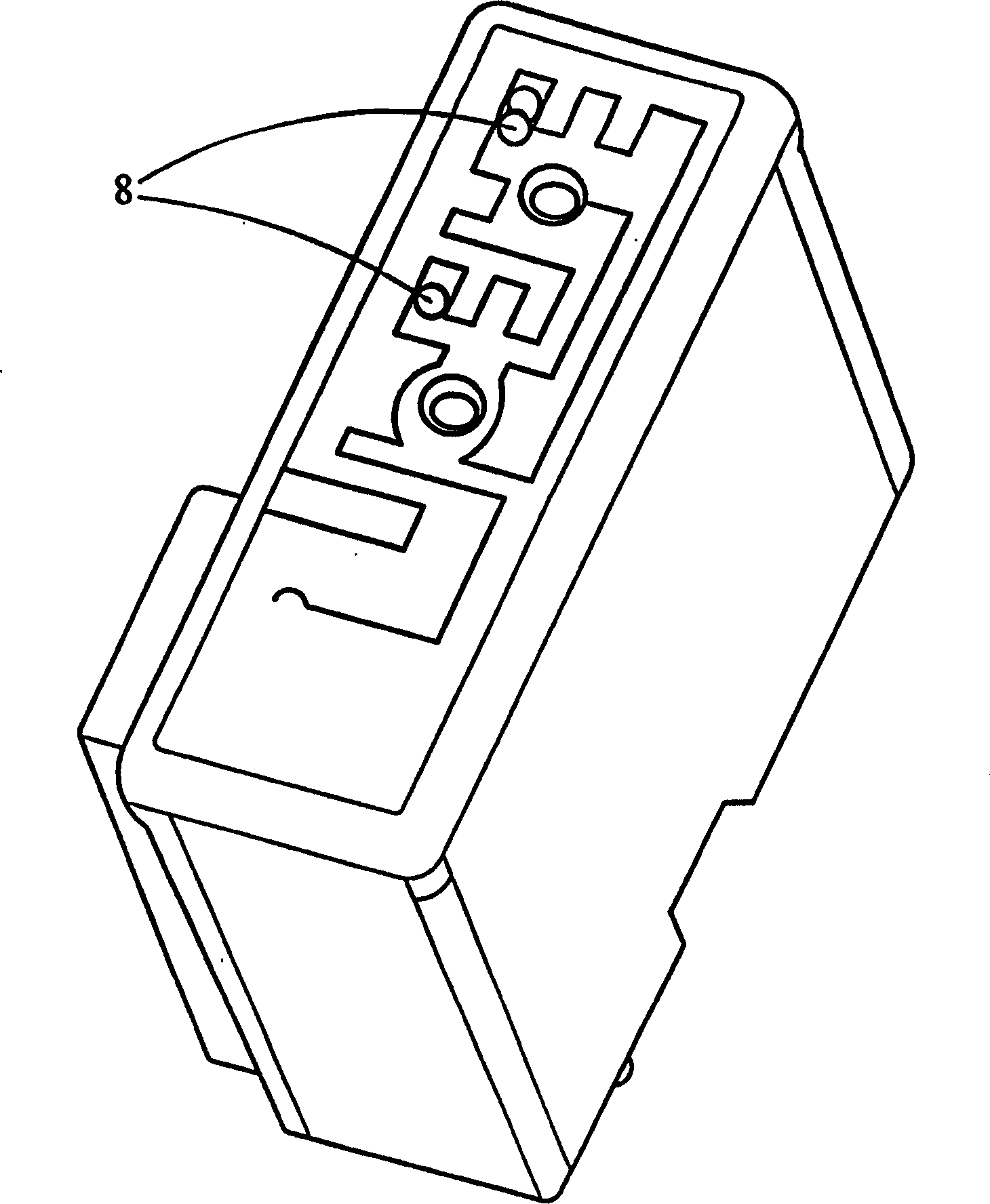

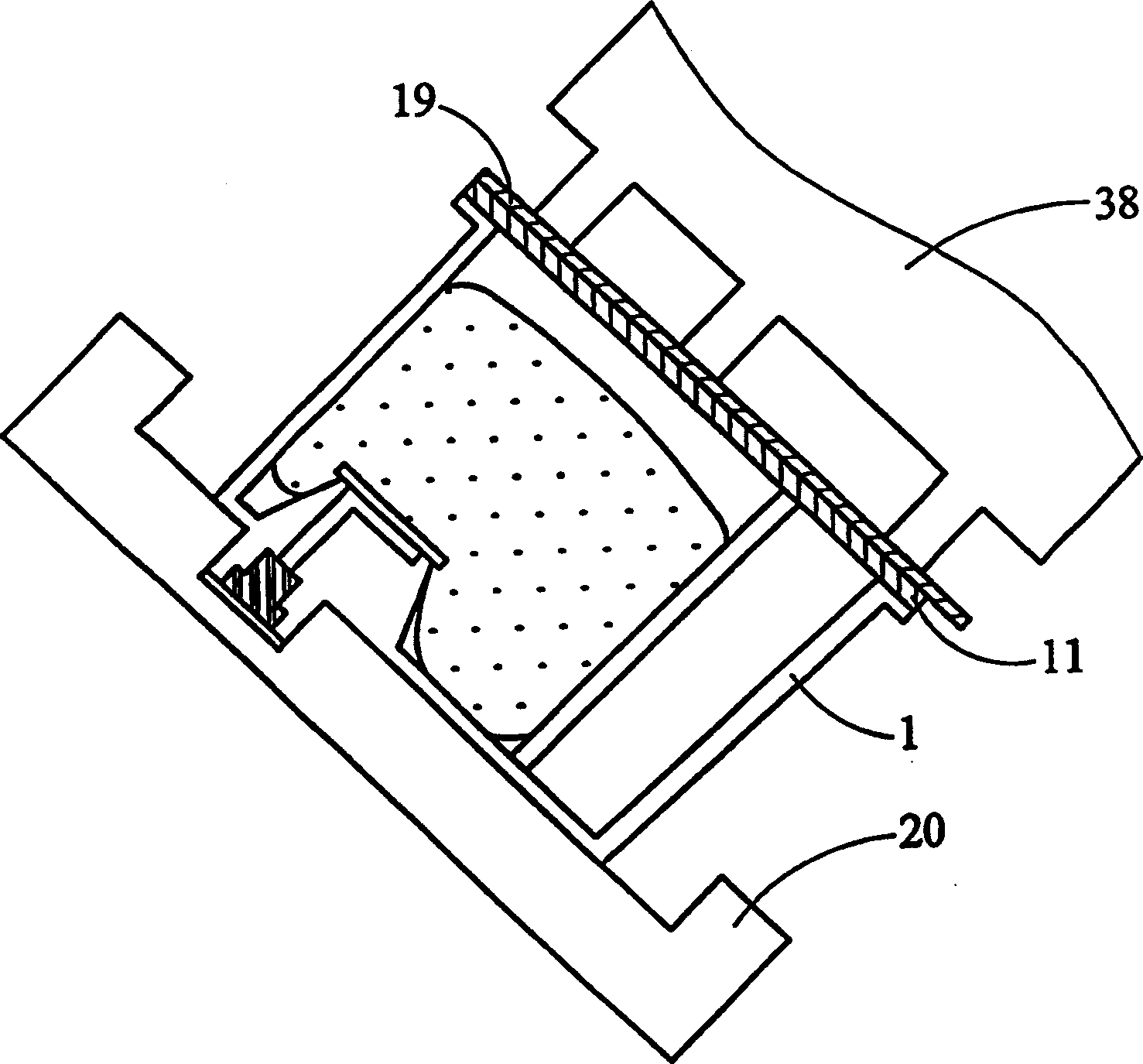

[0031] Please refer to Figure 4 , The ink cartridge sealing device 50 provided by the present invention is mainly composed of an airtight isolation device 100 , a decompression device 200 and a heat-press sealing device 300 . The airtight isolation device 100 includes an upper sealing cover 110 , a lower sealing cover 120 , an ink cartridge positioning seat 130 and a sealing elastic body 140 (such as an O-ring). The decompression device 200 includes an air extraction pump 210, an air valve 220 and an air extraction pipeline 230, wherein the air extraction pipeline 230 is connected to the air extraction pump 210 and the air valve 220, and is connected to the air valve 220 and the airtight isolation device 100. Seal mask 110 . The hot-press sealing device 300 includes a hot-press head 310 and a pressurized cylinder 320 .

[0032] Please refer to Figure 5a and Figure 5b , place an ink box 900 to be sealed in the ink box positioning seat 130 , and make the upper cover 910 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com