Organic cementing material concrete

A technology of concrete and organic glue, applied in the processing of building materials, building components, walls, etc., can solve the problems of reduced strength, affecting building safety, weak connection of concrete exterior walls, etc., to enhance the connection and improve the overall strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

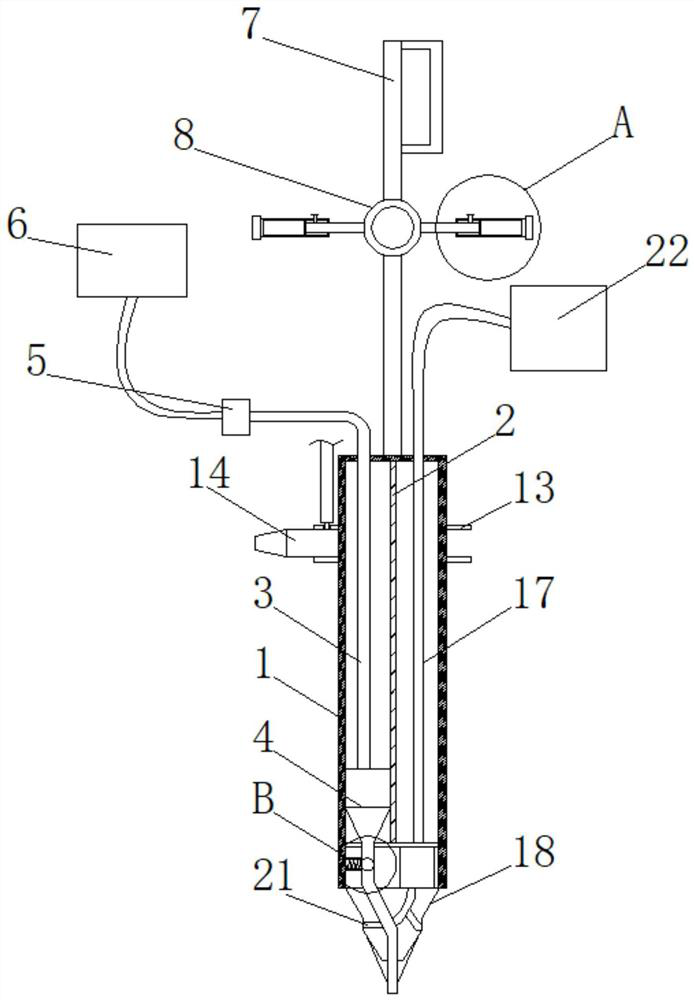

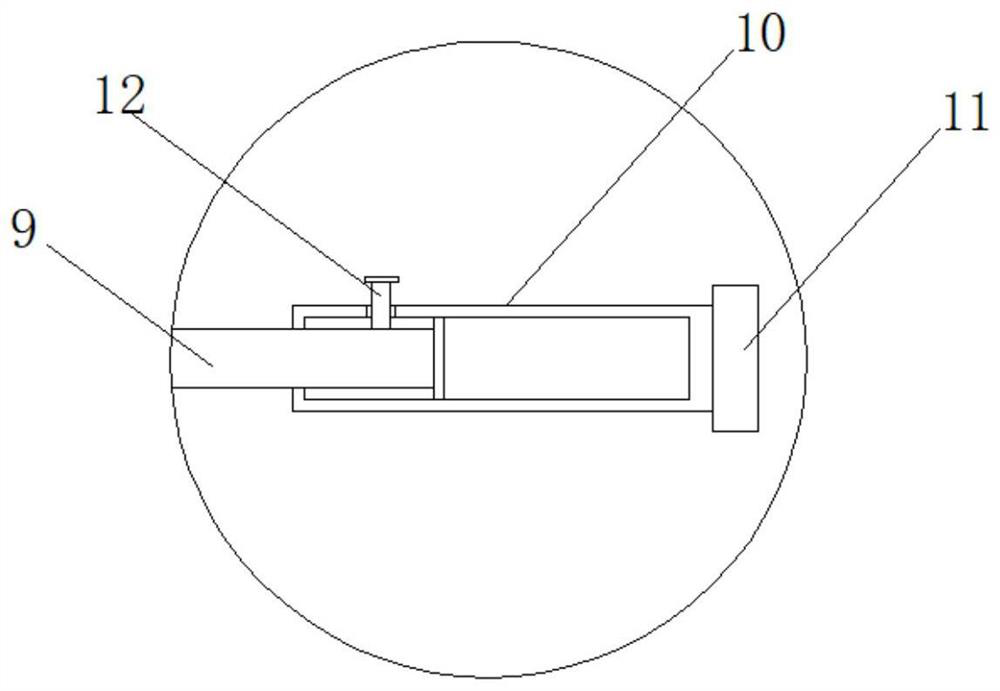

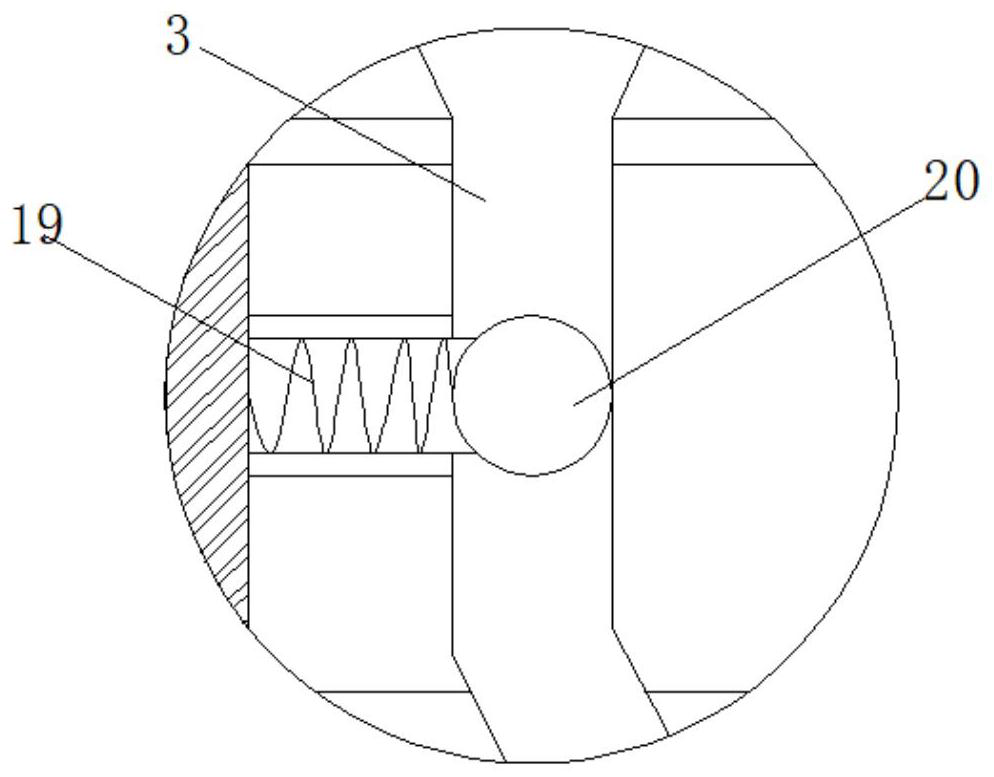

[0041] see Figure 1-4 , a kind of organic cementitious material concrete, its composition comprises concrete base material and cementitious medium loading material, and concrete base material composition comprises mineral powder, fly ash, aggregate, admixture, crushed stone, admixture and Water, the composition of the gelling medium carrier material includes phenolic resin, polyurethane resin, polyamide resin, parylene, aromatic polyamide, and the gelling medium carrier material also includes a plasticizer and a stabilizer.

[0042] Concrete base materials and gelling medium loading materials are added into the concrete building slab wall using a sealed exhaust injection gun 1, which can be used to fill the gaps between the concrete pore partition wall panels by cooperating with the sealed exhaust injection gun. Reduce the hollow area formed by the irregular hollow area inside, enhance the overall connection of the concrete exterior wall, and then improve the overall strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com