Sealing collar

A technology for sealing leather cups and clamping parts, which is applied to the sealing of engines, other washing machines, washing devices, etc., and can solve the problems of inability to freely design the geometry of the connecting part and high installation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

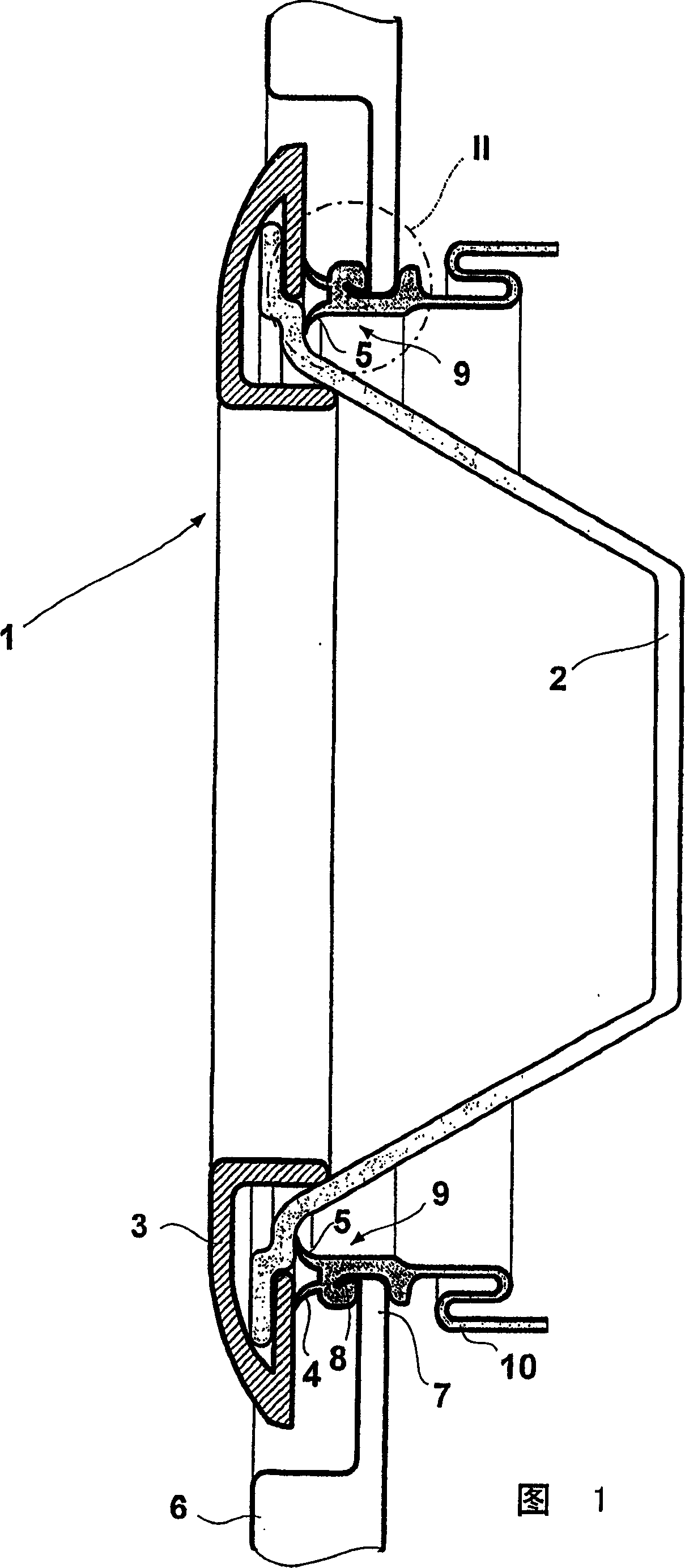

[0017] The cross-sectional view of the door area of the front loading washing machine in FIG. 1 shows a sealed round window door 1 . The window door consists of a basin-shaped glass window 2 fixed on a door frame 3. On the inner side of the edge area of the window door 1, sealing lips 4, 5 are attached to the closing part of the door. overflow from the washing machine cavity on the side.

[0018] The window door 1 is fastened via a hinge (not shown) to the window of a housing 6 of the washing machine, which has a beading 8 rolled forward in the edge region 7 of the window. The projection 9 of the outside of a sealing cup 10 is buckled on this flange. A clamping element embedded in the projection, such as an annular helical spring, clamps the projection 9 in the groove of the crimping projection 8 .

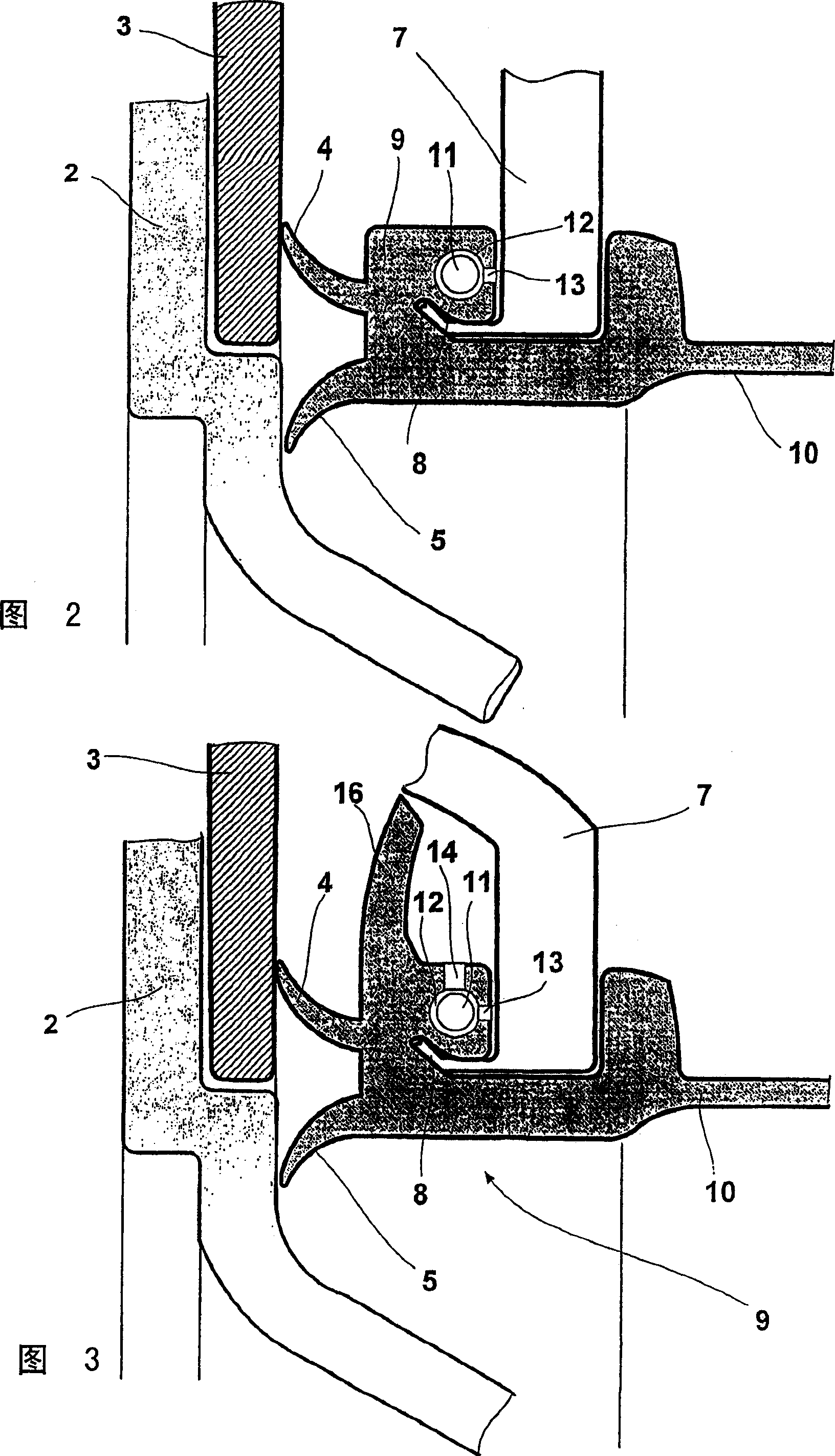

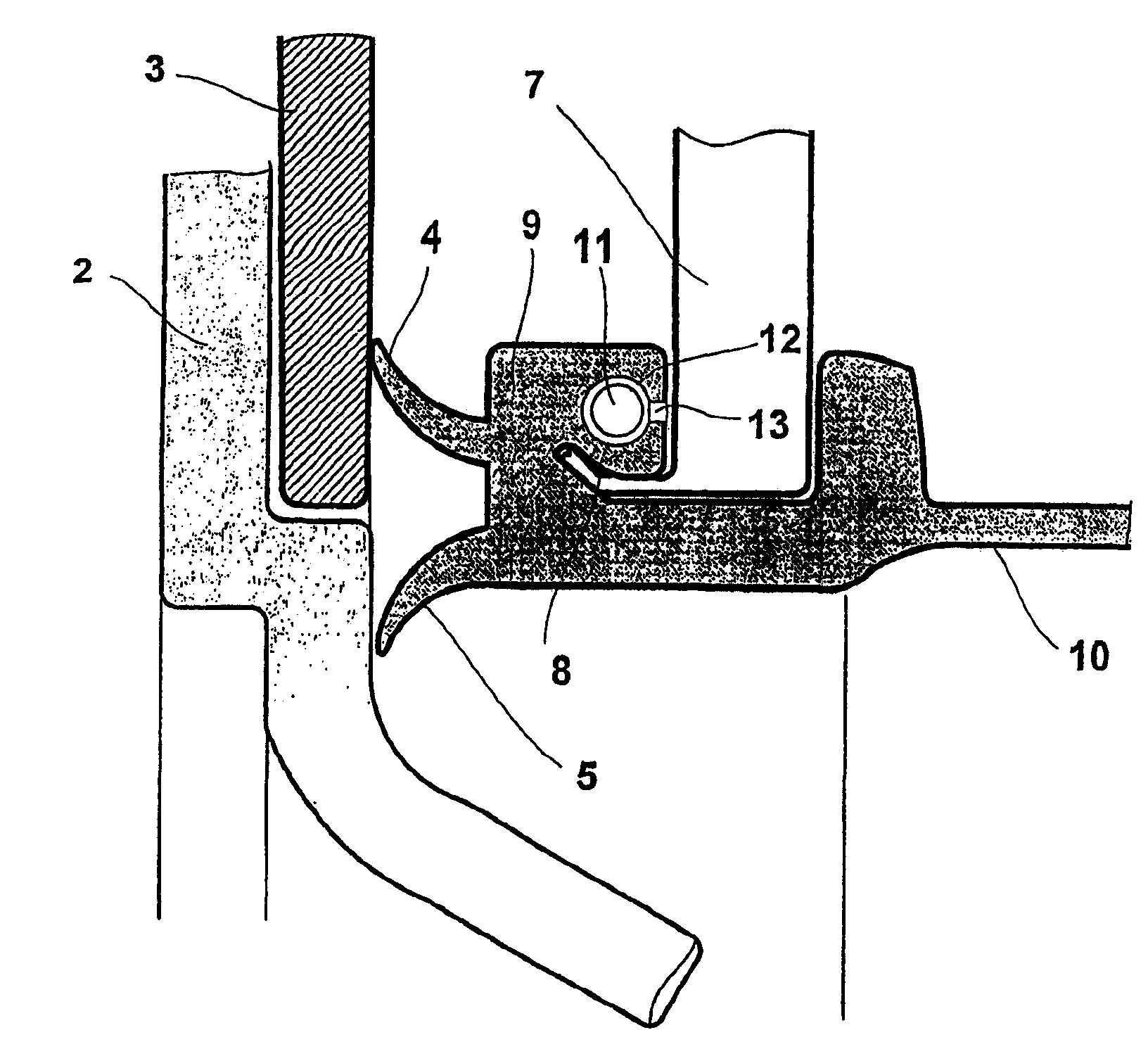

[0019] FIGS. 2 and 3 show in enlarged sectional views the projection 9 of the sealing cup 10 which has an annular channel 12 inside it. In FIG. 2 the channel 12 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com