Patents

Literature

33results about How to "Flexible shape design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hybrid solid state supercapacitor

InactiveCN102509637AReduce contact resistanceSolve reunionSolid electrolytic capacitorsCapacitor electrolytes/absorbentsSolid state electrolyteHybrid type

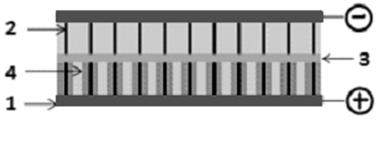

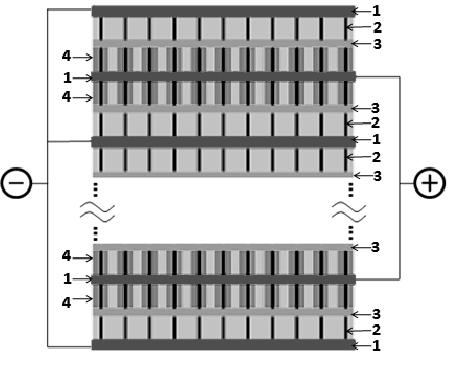

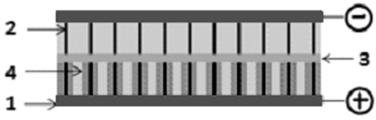

The invention discloses a hybrid solid-state supercapacitor based on an oriented carbon nano tube material, which comprises a positive pole, a negative pole and solid-state electrolyte dissepiments between the positive pole and the negative pole. The positive pole is composed of oriented carbon nano tube arrays and polyaniline films directly arranged on a conductive substrate in a compounding manner; the negative pole is composed of the oriented carbon nano tube arrays also directly arranged on the conductive substrate; and the solid-state electrolyte dissepiments are polymer gel or solid-state electrolytes containing H2SO4. Based on the oriented carbon nano tube material, the positive pole and the negative pole are assembled with the solid-state electrolyte dissepiments in an overlapping manner. The hybrid solid-state supercapacitor provided by the invention has the advantages of high energy concentration, high power concentration, high safety, lower cost and no pollution.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

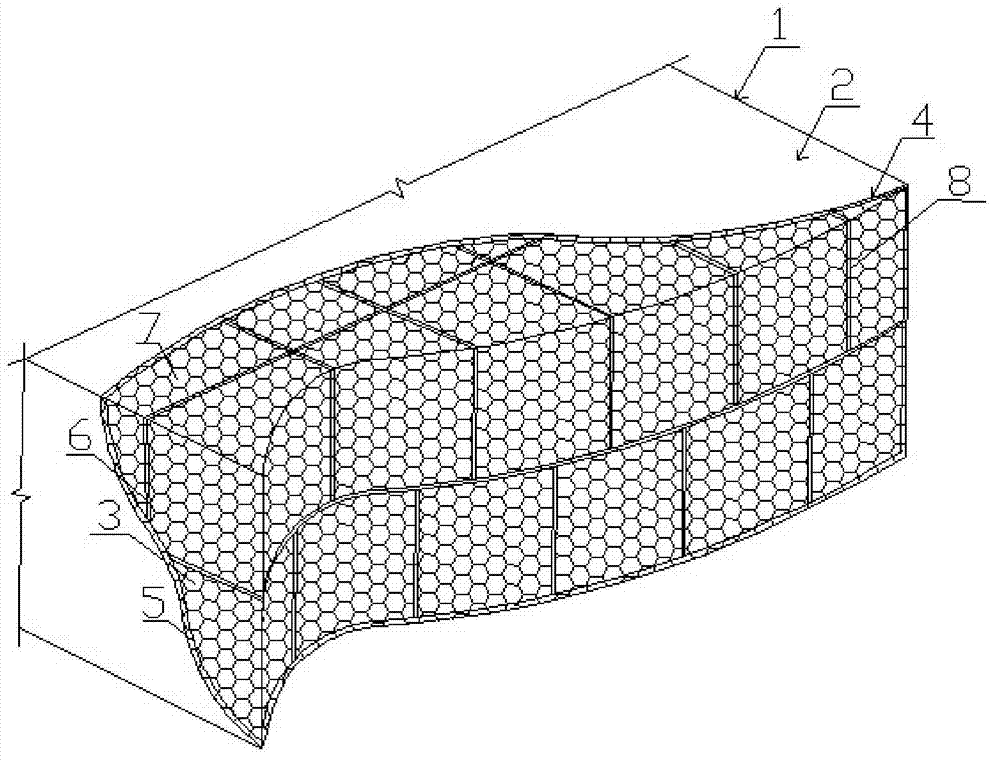

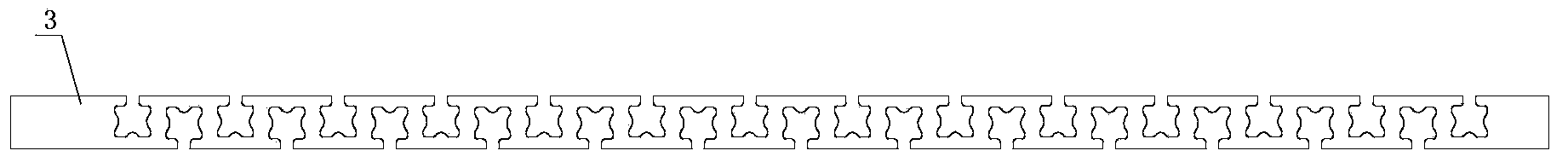

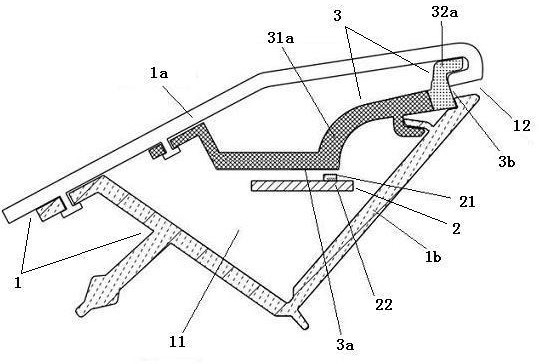

Buffering energy-absorbing type anti-collision island head for safety island

InactiveCN102926343APermanent paint effectImprove corrosion resistanceRoadway safety arrangementsFiberSurface layer

The invention discloses a buffering energy-absorbing type anti-collision island head for a safety island, comprising an anti-collision unit, connecting elements and a fastening element, wherein the anti-collision island head for the safety island is formed by combining one or more anti-collision units via the connecting elements and fixed on a road surface or the end head position of the safety island via the fastening element, and the anti-collision unit is composed of a housing and a filling material body arranged in the housing; and the housing comprises a composite material surface layer, the filling material body comprises a spatial lattice body and an energy-consuming material, the spatial lattice body is formed by arranging fibre webs, and the energy-consuming material is located in the interior gap of the spatial lattice body and / or between the spatial lattice body and the inner wall of the housing. The invention discloses the buffering energy-absorbing type anti-collision island head for a safety island, which is convenient to popularize, simple and convenient to construct, capable of adequately absorbing collision energy, low in cost, green and environment-friendly.

Owner:NANJING UNIV OF TECH

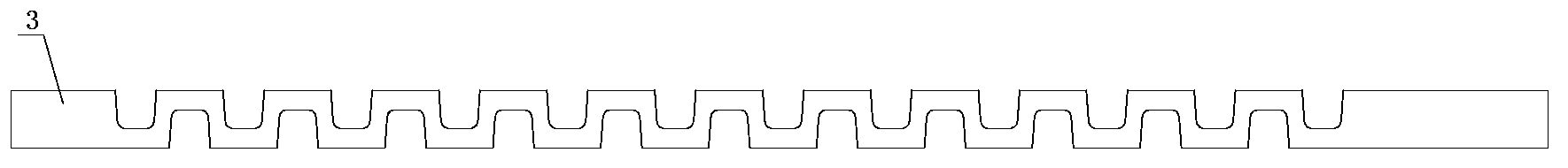

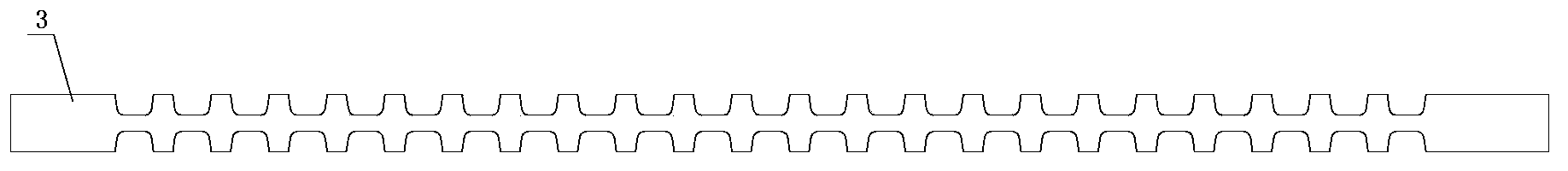

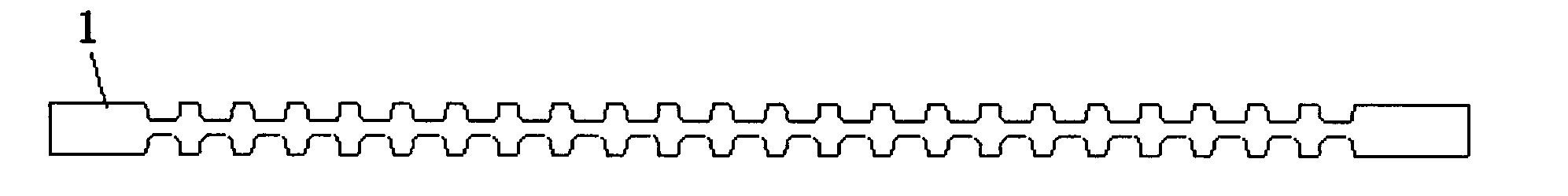

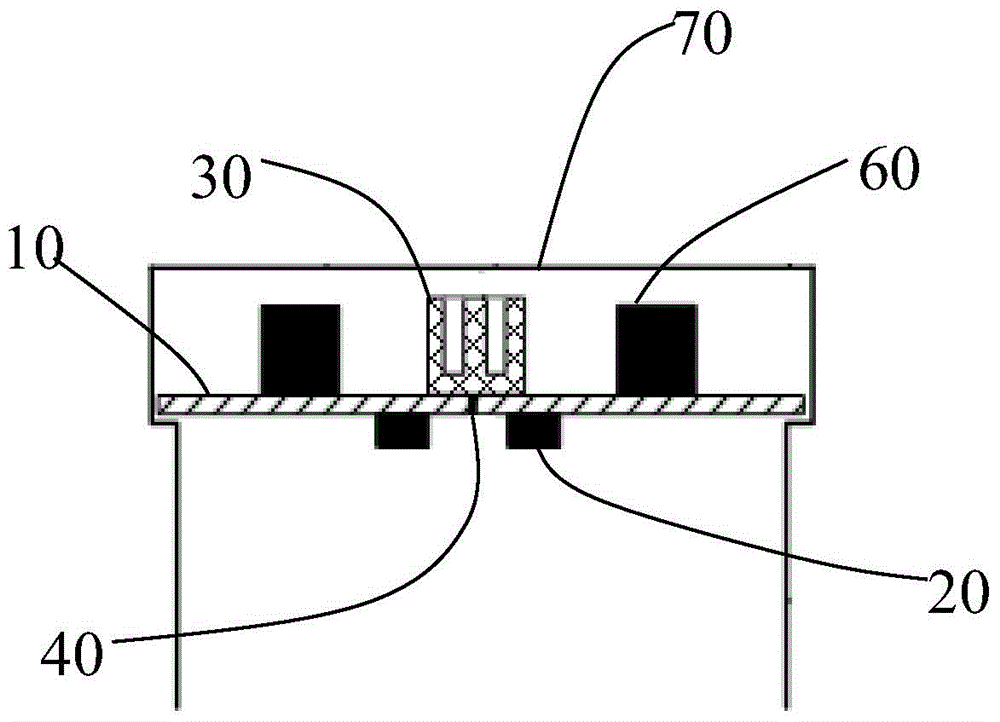

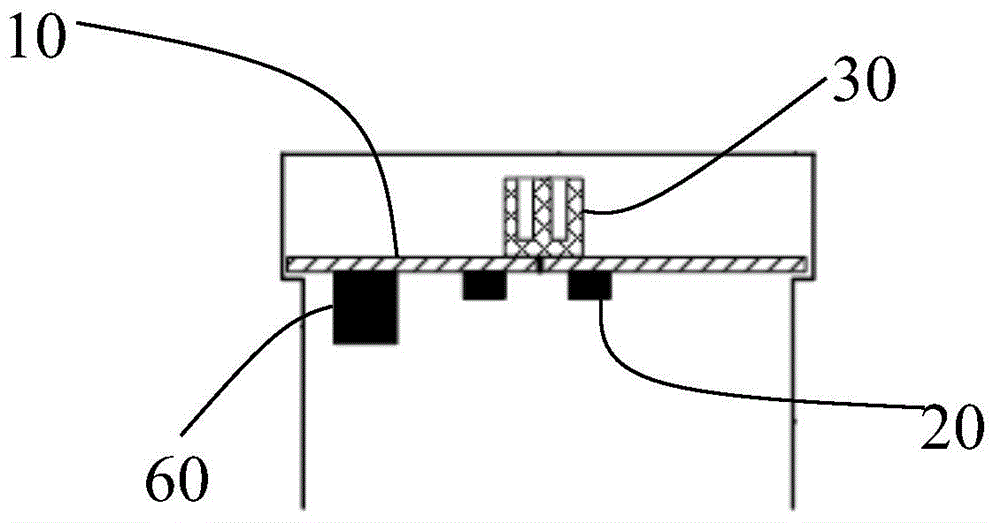

Air-cooled integrated bipolar plate for fuel cells

ActiveCN103915631ATemperature controlImprove performanceFuel cell heat exchangeCell electrodesFuel cellsEngineering

The invention relates to an air-cooled integrated bipolar plate for fuel cells. The air-cooled integrated bipolar plate includes a cathode plate and an anode plate, at least one layer of radiating fin is arranged between the cathode plate and the anode plate, and the radiating fin is provided with a fluid channel. Compared with the prior art, the air-cooled integrated bipolar plate for fuel cells provided by the invention has the advantages of good radiating effect, high reliability, convenient installation, and arbitrary combination of radiating fin, etc.

Owner:QINGDAO HANHE HYDROGEN ENERGY EQUIP TECH CO LTD

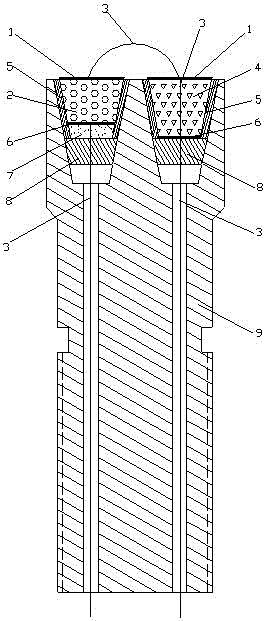

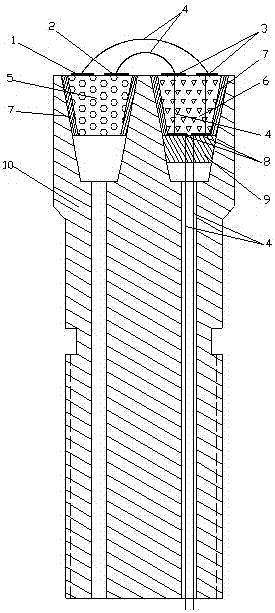

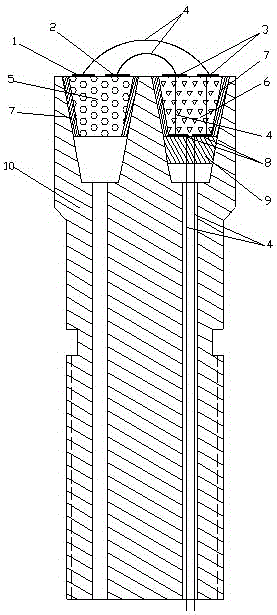

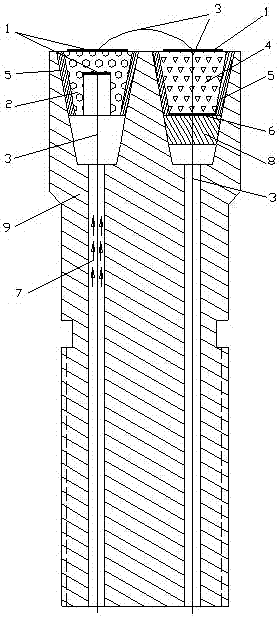

Oxygen chemical sensor for high-temperature and high-pressure hydrothermal system and preparation method of oxygen chemical sensor

ActiveCN105004777AImprove corrosion resistanceGood mechanical strength at high temperatureMaterial analysis by electric/magnetic meansOxygen sensorMetal sheet

The invention discloses an oxygen chemical sensor for a high-temperature and high-pressure hydrothermal system and a preparation method of the oxygen chemical sensor. The oxygen chemical sensor comprises a base, circular platform-shaped high-temperature-resistant insulating conical pads, a solid oxygen buffer agent, high-temperature-resistant insulating conical sleeves, circular platform-shaped solid electrolyte ceramic, circular platform-shaped high-temperature-resistant insulating ceramic, spongy inert metal layers, inert metal sheets and electrode leads. The oxygen chemical sensor, namely an oxygen sensor based on an electrochemical cell, is formed by combining all the components into a conical self-tightening mechanism, and can be utilized for in-situ direct measurement of the oxygen fugacity or the oxygen activity in the high-temperature (250 to 700 DEG C) and high-pressure (normal pressure to 100 MPa) hydrothermal system, so as to solve the problems that various conventional oxygen chemical sensors for a high-pressure hydrothermal system are low in operating temperature and operating pressure (the operating temperature and the operating pressure can hardly exceed 400 DEG C and 40 MPa simultaneously), low in response speed, and low in reliability when being applied to a complex concentrated water fluid sample.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

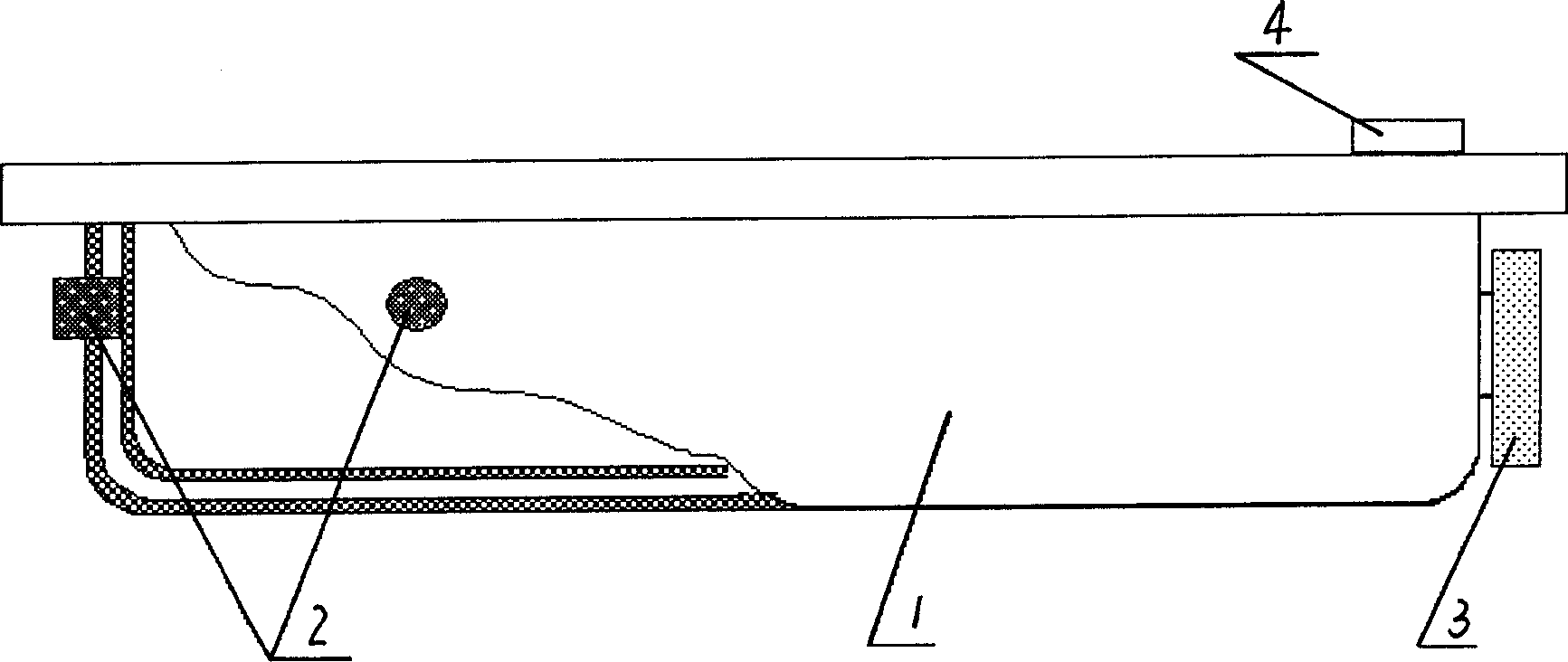

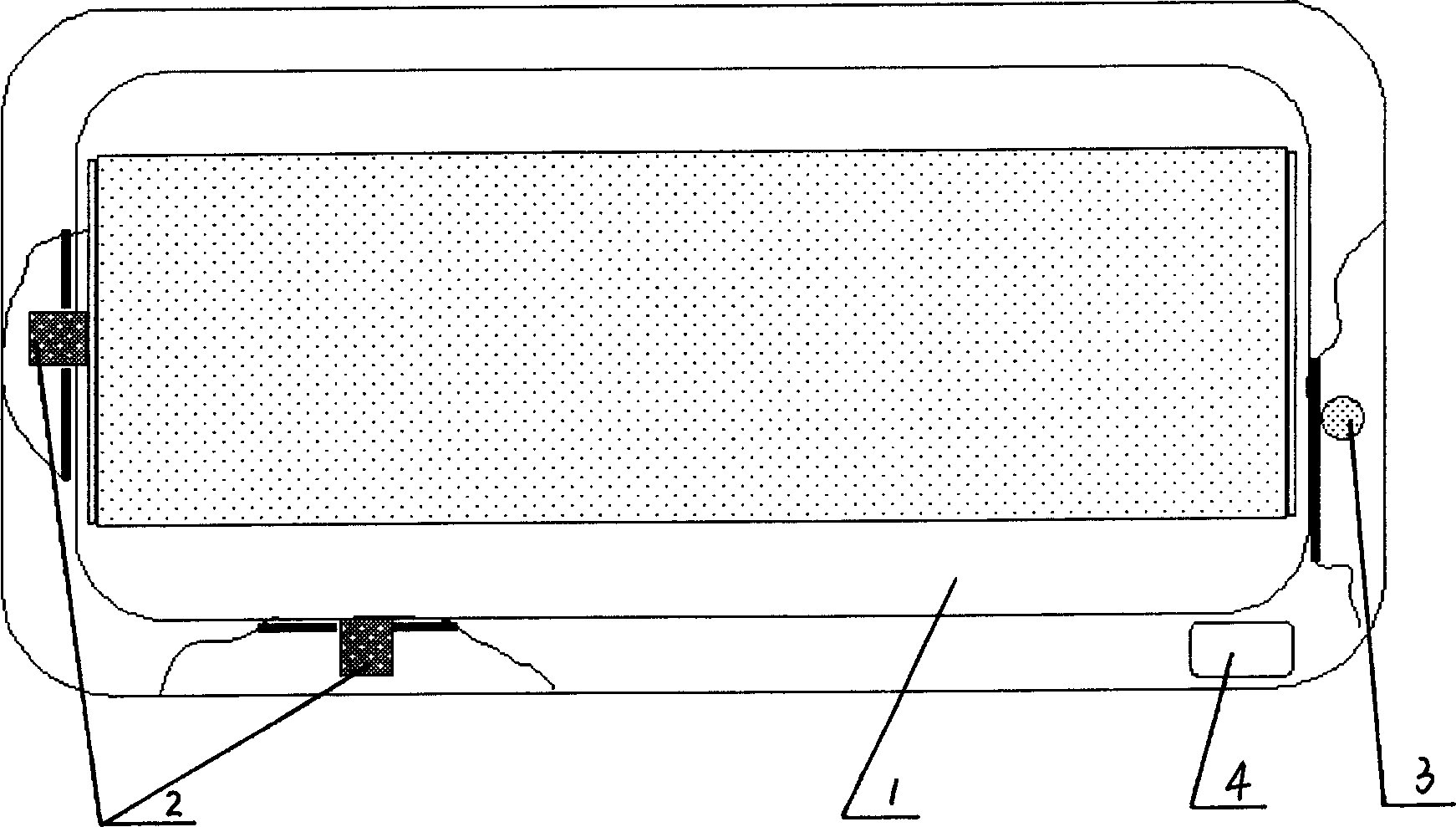

Tetra dimensional body sensing music bathtub

InactiveCN1830415AWide selection of materialsImprove transient characteristicsBathing devicesSomatosensory systemWater quality

Owner:王文有

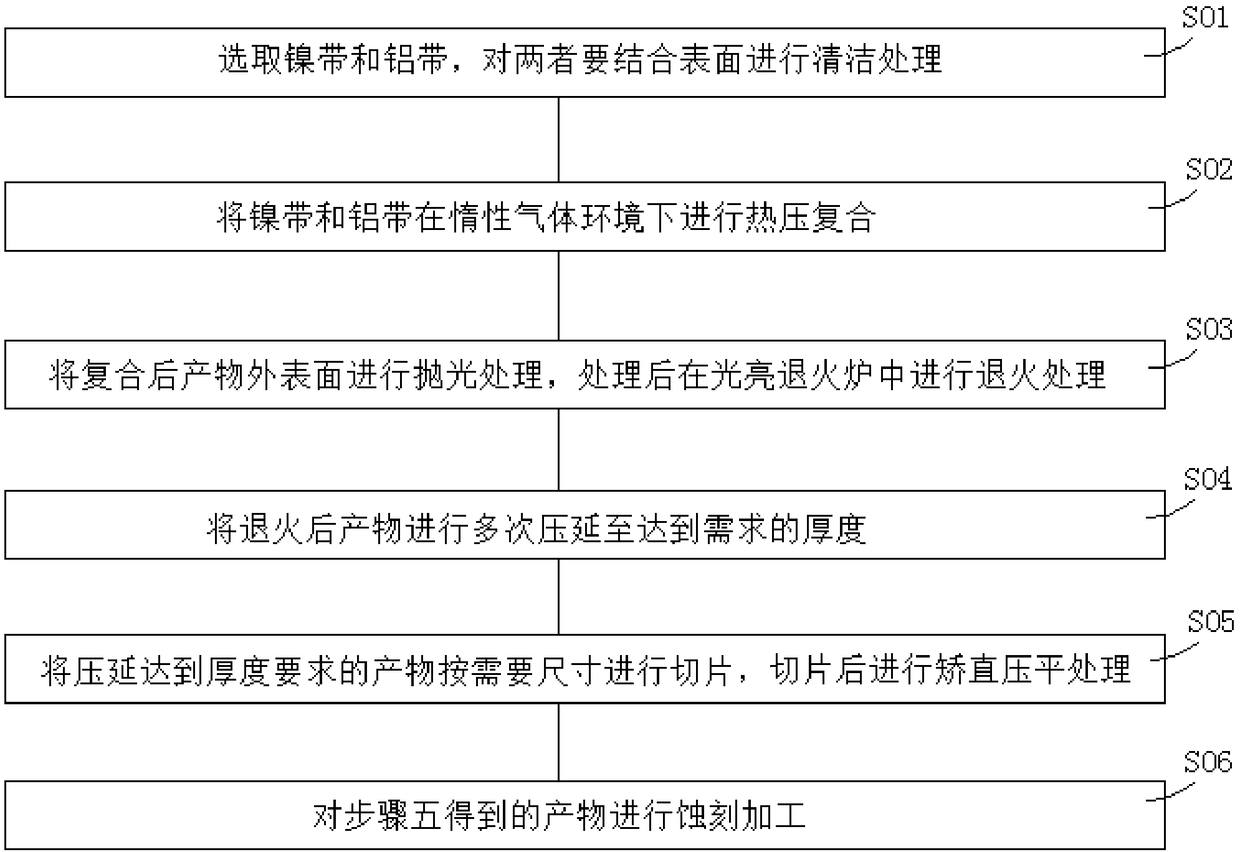

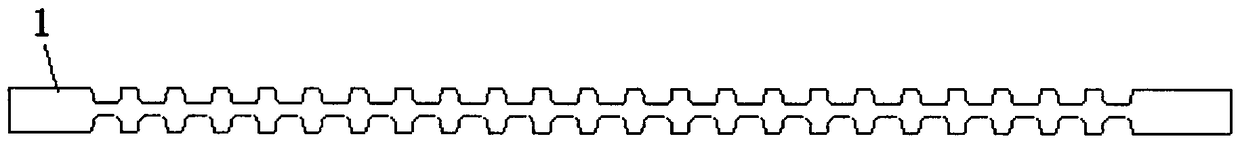

Lightweight aluminum-nickel composite busbar processing method

InactiveCN109346657AReduce lossExtended service lifeCell component detailsElectrical resistance and conductanceAfter treatment

The invention relates to a lightweight aluminum-nickel composite busbar processing method which is implemented as follows: selecting a nickel tape and an aluminum tape, performing cleaning treatment on the to-be-combined surfaces of the nickel tape and the aluminum tape; hot-pressing and compounding the nickel tape and the aluminum tape in an inert gas environment; performing polishing treatment on the outer surface of a compounded product and performing annealing treatment in a bright annealing furnace after treatment; and calendaring an annealed product multiple times till the required thickness is reached. The lightweight aluminum-nickel composite busbar processing method provided by the invention has the benefits that two materials, namely aluminum and nickel are compounded into a whole through a calendaring compound machine by fully utilizing the plastic deformation of metals and a principle of atomic diffusion between the metals, so that no re-connection is required in a local spot welding manner; after the two materials are compounded into a whole through calendaring, the contact resistance between the materials is far less than that of a local welding product after stamping, so that the loss of a battery after welding is reduced, and the service life of the battery is prolonged; the compounded material is flexible in product appearance design, and the product can be quickly delivered by utilizing an etching technology; therefore, the lightweight aluminum-nickel composite busbar processing method is very conducive to the development of new products.

Owner:深圳市中金岭南鑫越新材料有限公司

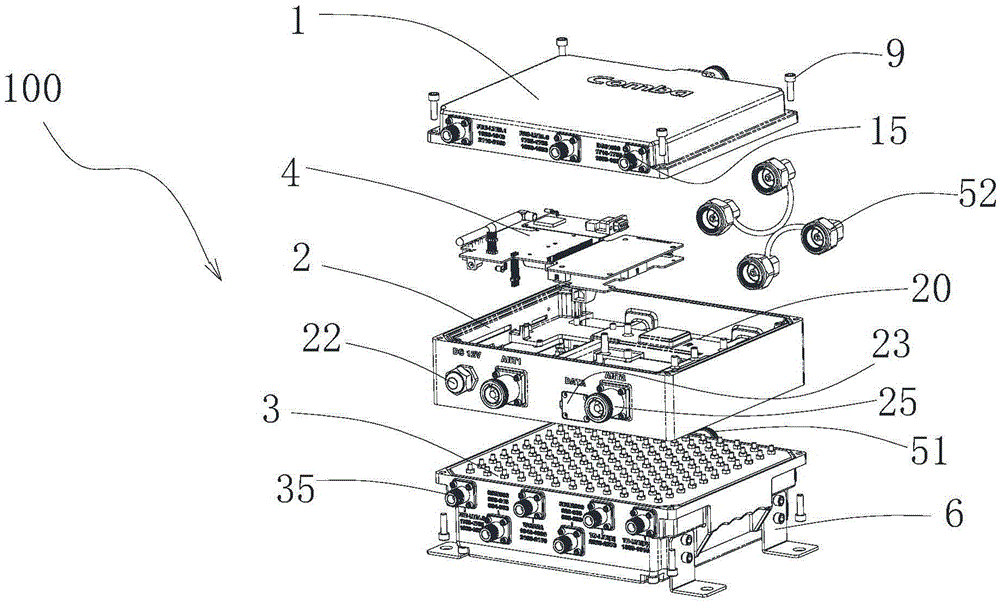

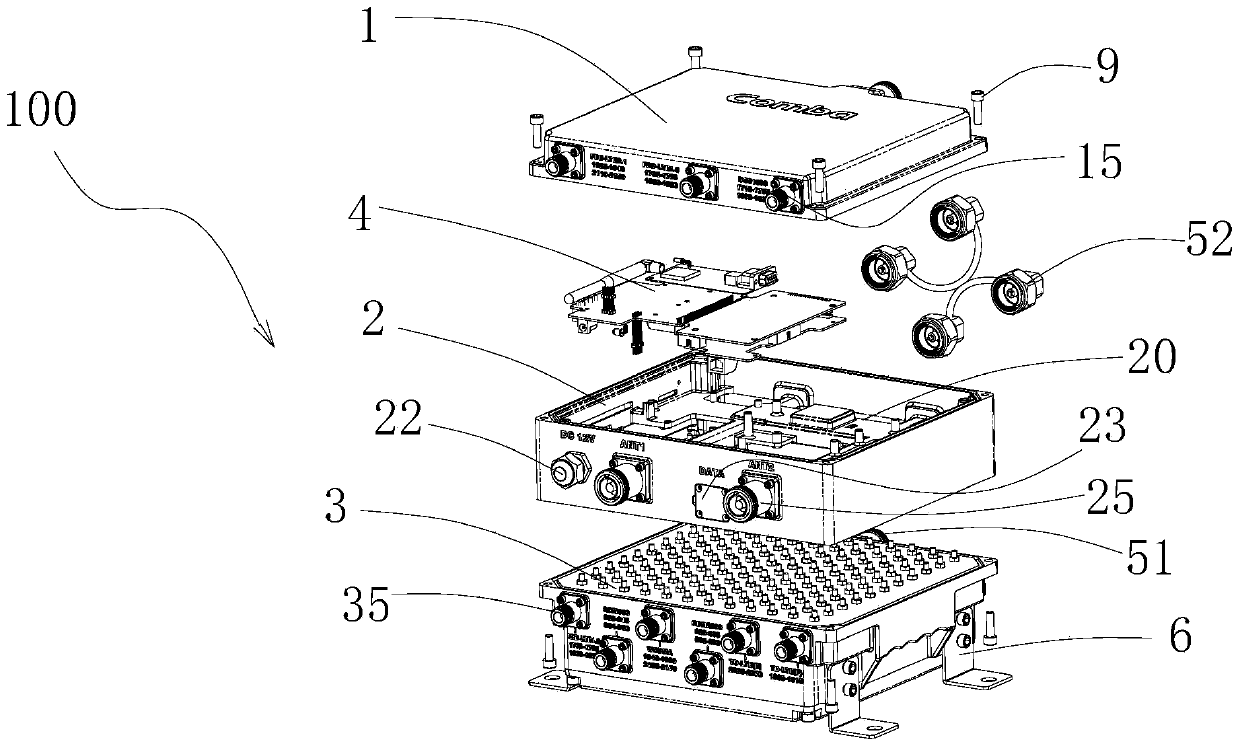

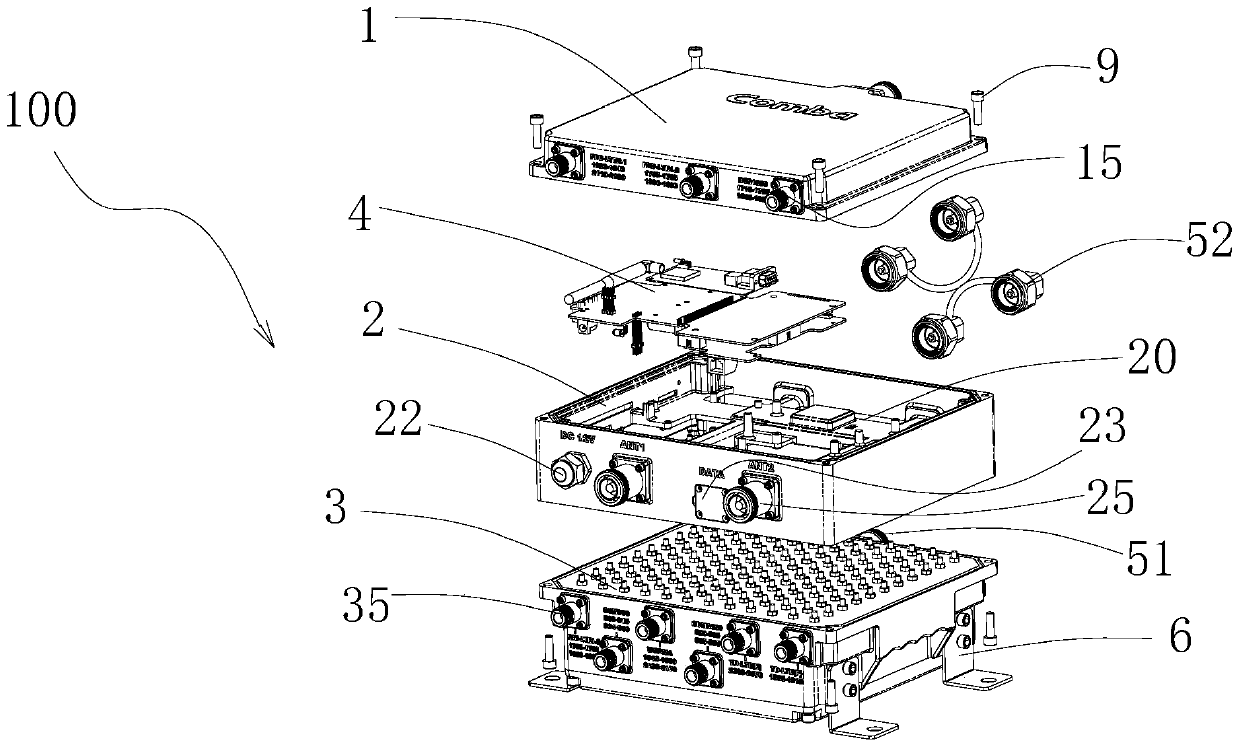

Integrated point of interface (POI)

ActiveCN105489992AReduce investmentImprove product qualityWaveguide type devicesClassical mechanicsMechanical engineering

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

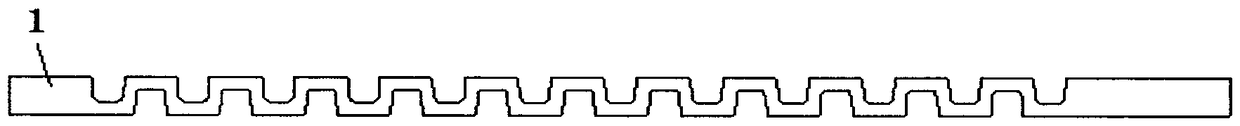

Heat radiation bipolar plate of fuel battery

The invention relates to a heat radiation bipolar plate of a fuel battery. The heat radiation bipolar plate comprises a cathode plate and an anode plate. The bipolar plate is characterized in that a heat radiation section is arranged between the cathode plate and the anode plate; the heat radiation section consists of a plurality layers of heat radiation plates which are overlapped in sequence; a plurality of parallel straight grooves are formed in the heat radiation plates; after the plurality layers of heat radiation plates are sequentially overlapped, fluid channels are formed by the parallel straight grooves between every two adjacent plates; an end hole I and an end hole II are formed in one ends of the parallel straight grooves which form the first layer of fluid channels and the last layer of fluid channels in the heat radiation section; the end hole I and the end hole II are exposed in air; the end hole I and the end hole II are respectively formed in two ends of the heat radiation section; two ends of the other parallel straight grooves in the heat radiation section are sealed. Compared with the prior art, the bipolar plate has the advantages that the heat radiation effect is good, the reliability is high, the mounting is convenient, heat radiation fins can be randomly combined, and the like.

Owner:QINGDAO HANHE HYDROGEN ENERGY EQUIP TECH CO LTD

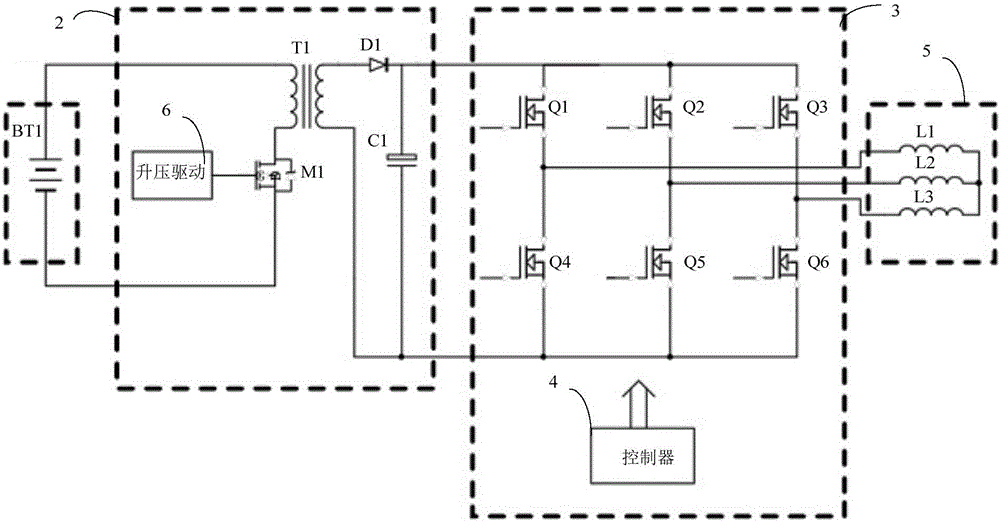

Starting device and method for digital power generator electrically started in reverse dragging manner

InactiveCN106677949ASave weightSave volumeElectric motor startersMachines/enginesConductor CoilPwm signals

The invention discloses a starting device and method for a digital power generator electrically started in a reverse dragging manner. The device comprises a controller, a three-phase motor, a battery pack, a voltage boosting module and a three-phase H bridge, wherein the battery pack, the voltage boosting module and the three-phase H bridge are in sequential cascading. The voltage boosting module achieves voltage boosting on the input voltage of the three-phase H bridge. The controller outputs a PWM signal to control alternate conduction of six MOS transistors Q1-Q6 in H bridge type connection of the three-phase H bridge, the three-phase H bridge is made to output three-phase current to three windings L1, L2 and L3 of the three-phase motor, the three windings L1, L2 and L3 are powered on alternately, the current flowing through generates the magnetic field, a rotor of the three-phase motor is driven to rotate, and therefore the digital power generator connected to the rotor is started. The device can replace the functions of a starting motor, the weight and the size of products are saved, the using shape design becomes more flexible, and the product design is made more compact.

Owner:SUZHOU ERMA MECHNICAL & ELECTRICAL

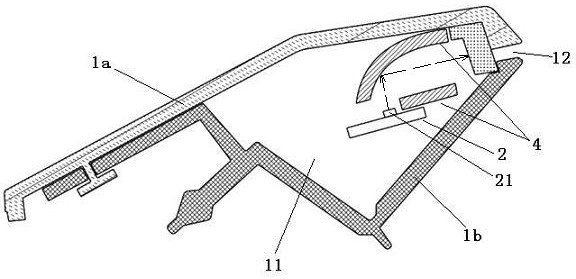

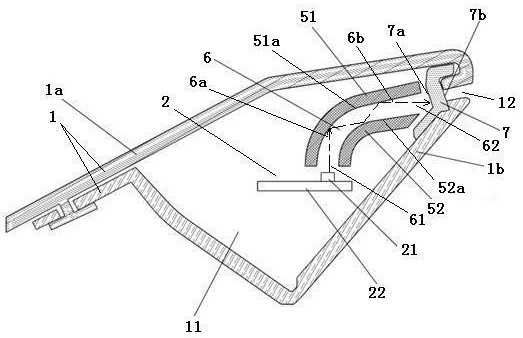

Light guide type lighting decoration device

PendingCN112325187AReduced precision requirementsReduce lossesMechanical apparatusLight guidesLight guideEngineering

The invention discloses a light guide type lighting decoration device which comprises a shell, a light source and a light guide channel. The shell is provided with an inner cavity and a light outlet,and the light source and the light guide channel are arranged in the inner cavity. The light guide channel is composed of a gap between the light guide cover plate and the light guide bottom plate, and a light guide medium of the light guide channel is air; the light guide channel is provided with a light inlet and a light outlet, and the light inlet and the light outlet are respectively close tothe light source and the light outlet; light emitted by the light source enters the light guide channel through the light incident port, is reflected by the inner side surface of the light guide coverplate and the inner side surface of the light guide bottom plate and then is transmitted to the light outlet. The device has the advantages of low manufacturing cost and high light utilization efficiency, and can fully mix the polychromatic light emitted by the light source.

Owner:KEBODA TECH CO LTD

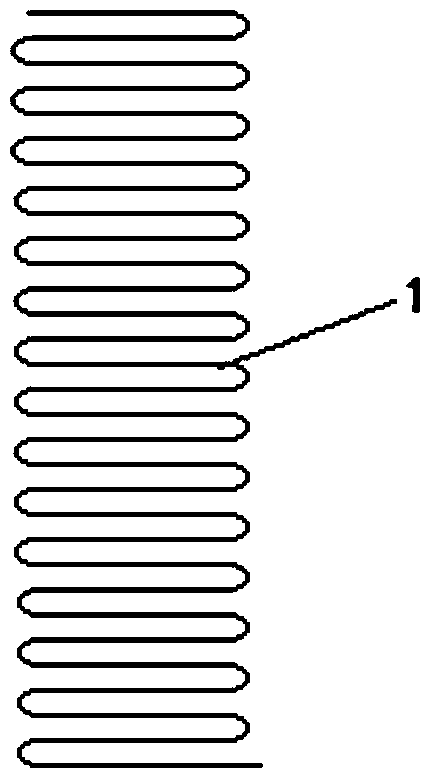

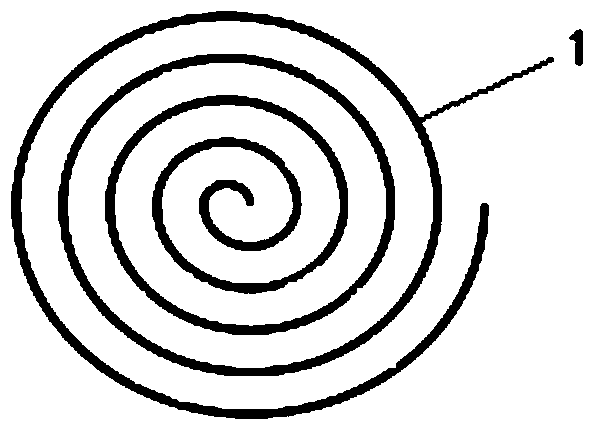

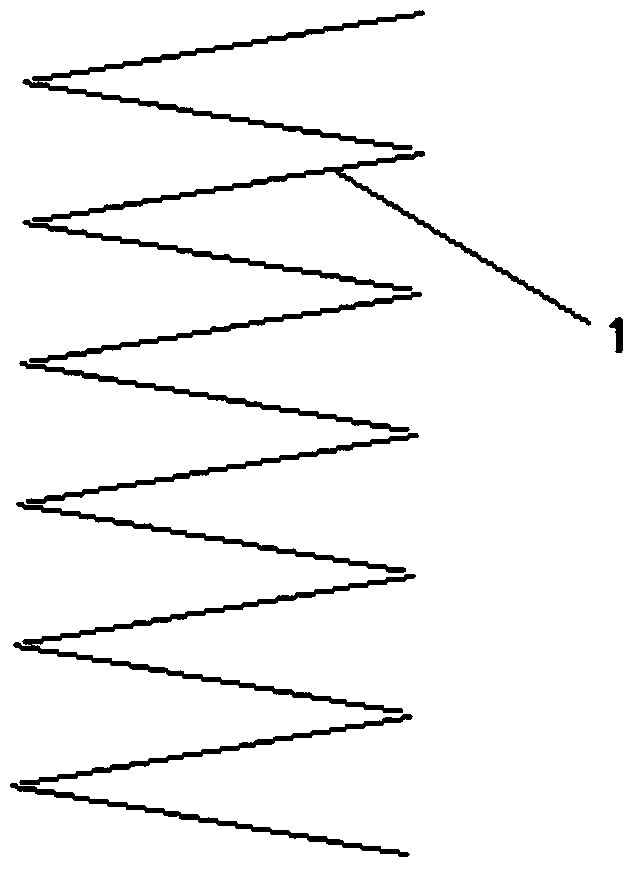

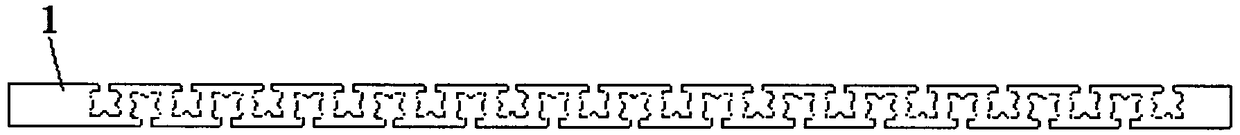

Wearable electric field treatment device

ActiveCN103638603AAchieve strengthNo discomfortElectrotherapyMagnetotherapy using coils/electromagnetsEngineeringVoltage source

A wearable electric field treatment device comprises an electrode couple, wherein the electrode couple comprises a first electrode and a second electrode. The first electrode and the second electrode are correspondingly arranged to form an electric field passing through a tested person, the first electrode is connected to the first end of a voltage source, and the second electrode is connected to the second end of the voltage source. The first electrode and the second electrode are respectively formed by coiled lead wires. The electrode couple is arranged on a wearable fabric or woven in the wearable fabric. Due to the fact that the electric field treatment device uses the coiled lead wires as the electrodes, the electrodes can be woven or sewn in the fabric or on the fabric, the treatment device can be worn on the body, treatment is facilitated greatly, a patient can wear the device for a long period of time and does not feel uncomfortable, and possibility is provided for long-time micro-dose treatment. Due to the fact that the electrodes are formed by the coiled lead wires, the shapes of the electrodes are very flexible to design. The intensity required by the electric field at the positions of human tissues or organs can be accurately achieved, and precise treatment can be achieved.

Owner:GENERAL HOSPITAL OF PLA

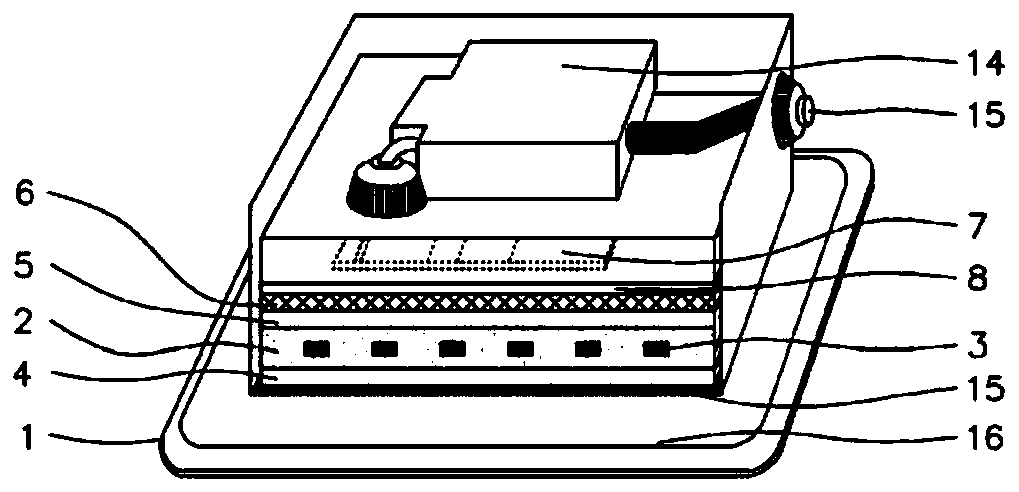

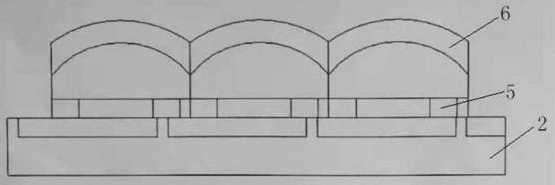

LED lamp and LED light source module

InactiveCN104832818AReduce volumeFlexible shape designPoint-like light sourceLighting heating/cooling arrangementsOptoelectronicsLED lamp

The invention discloses an LED lamp and an LED light source module. The LED lamp comprises a light source plate, multiple LED particles installed on the light source plate and multiple radiators. Every two LED particles correspond to one or more radiators, and heat transfer is formed between each LED particle and the corresponding radiator.

Owner:OPPLE LIGHTING

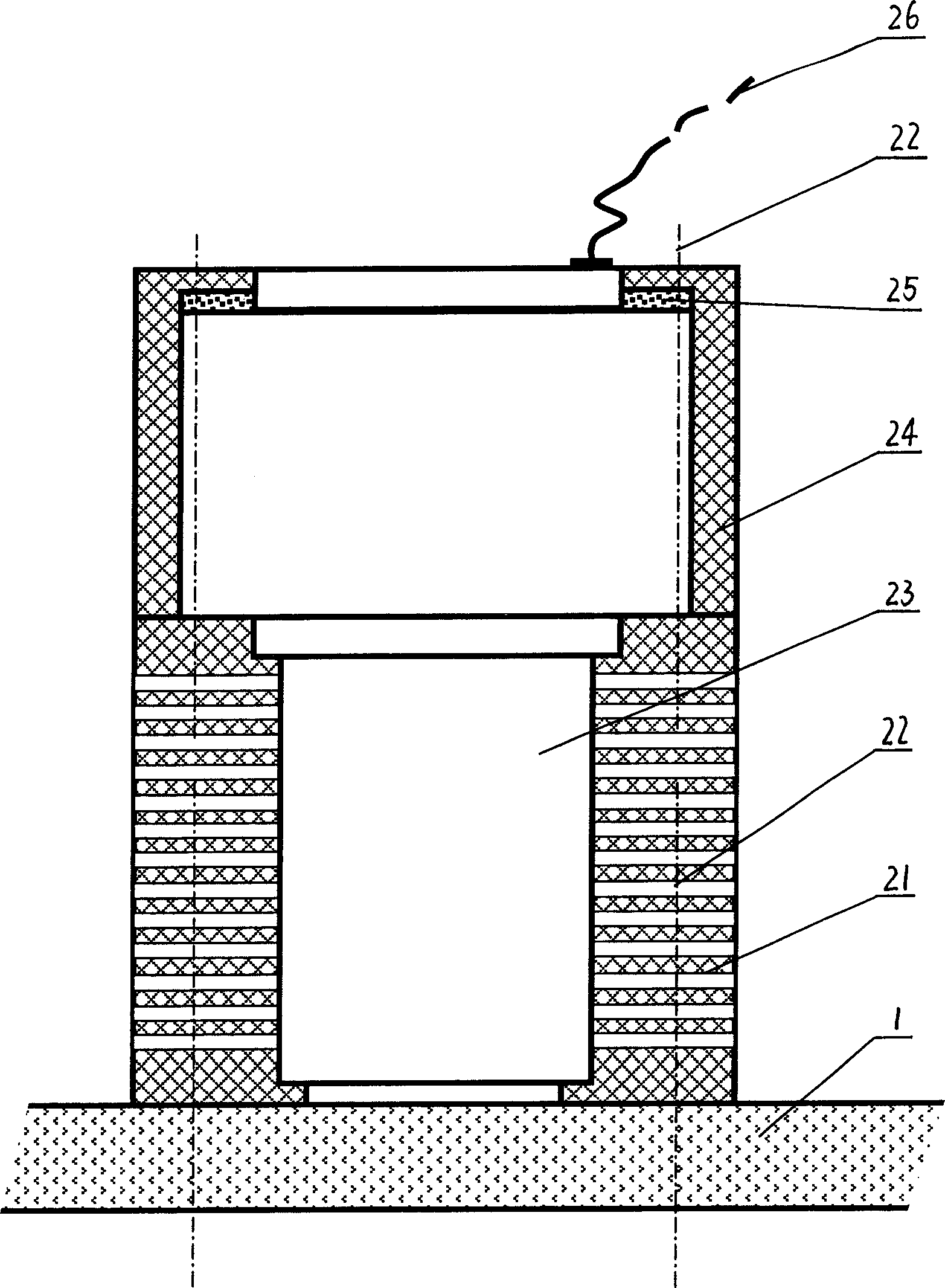

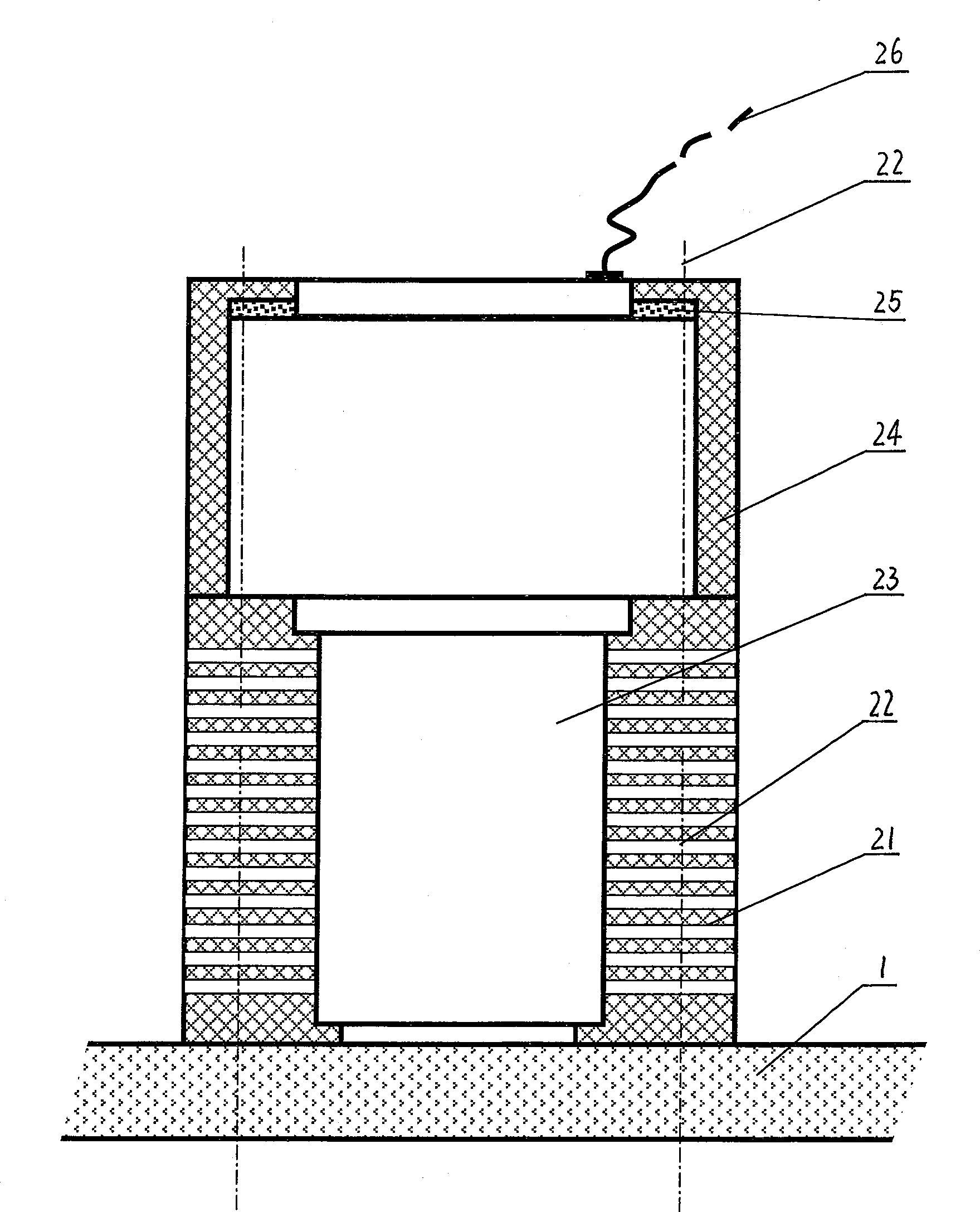

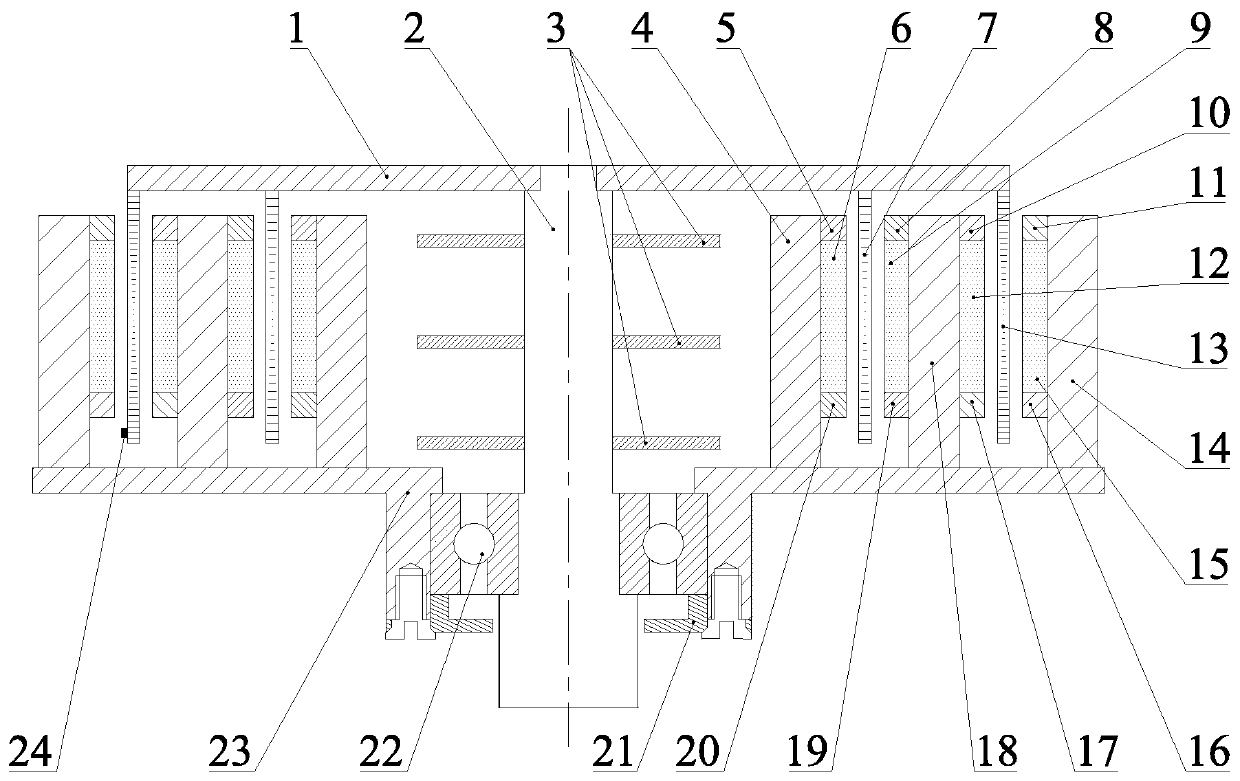

A new type of bathroom heating device

InactiveCN110017524BReduce energy consumptionEven heat dissipationLighting and heating apparatusElectric heating systemFiberTemperature control

The invention relates to a novel bathroom heating device. The bathroom heating device comprises a shell, heating elements, a main control panel and an intelligent temperature control device, wherein the heating elements are flexible heating elements prepared from a flexible carbon material, and each flexible heating element comprises a high-temperature-resistant fiber layer and a microcrystallinegraphite layer wrapping the high-temperature-resistant fiber layer; the heating elements are uniformly laid in the lower layer of the shell and are connected with the main control panel, and the intelligent temperature control device is connected with the main control panel; and the intelligent temperature control device controls the to-be-heated heating elements through the main control panel. The novel bathroom heating device has the advantages of no need of preheating, uniform heat dissipation, high safety, small volume, low noise, flexible installation and self-service temperature adjustment.

Owner:TANWENG BEIJING TECH CO LTD

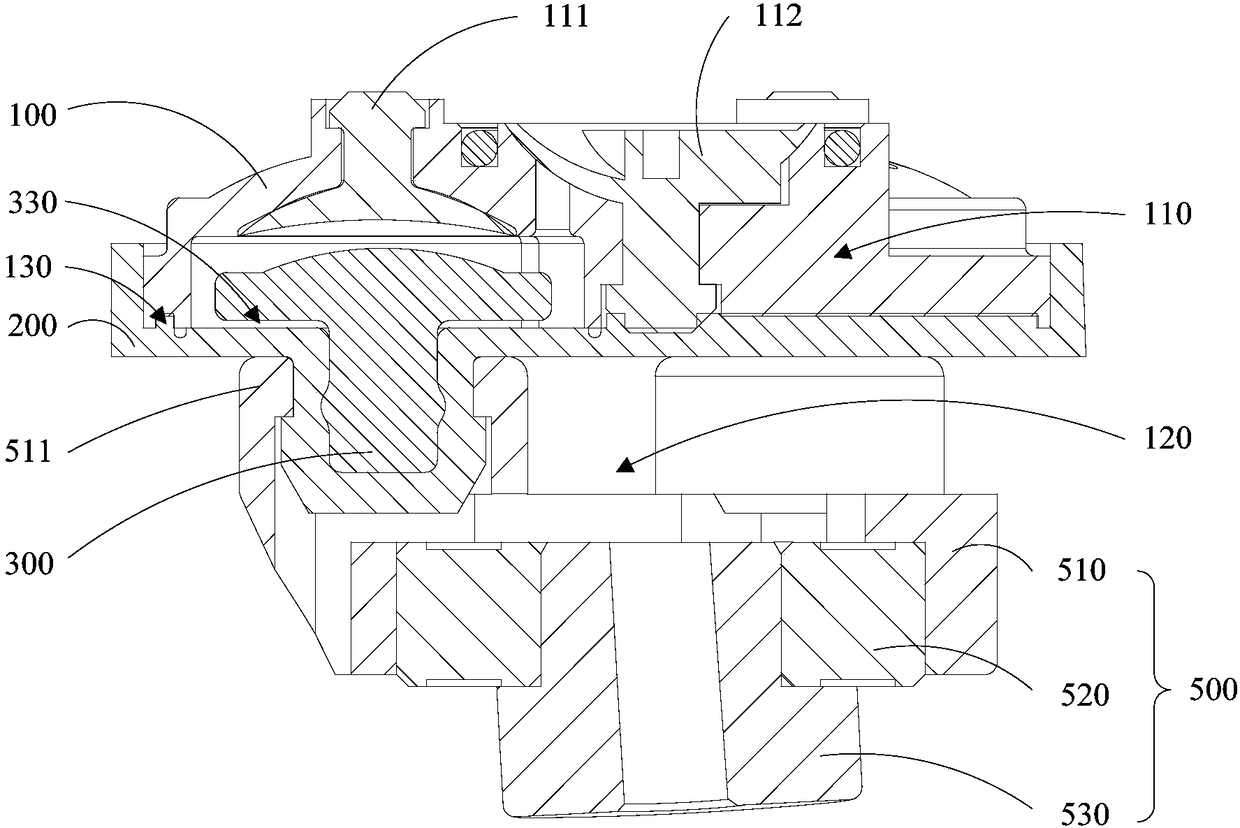

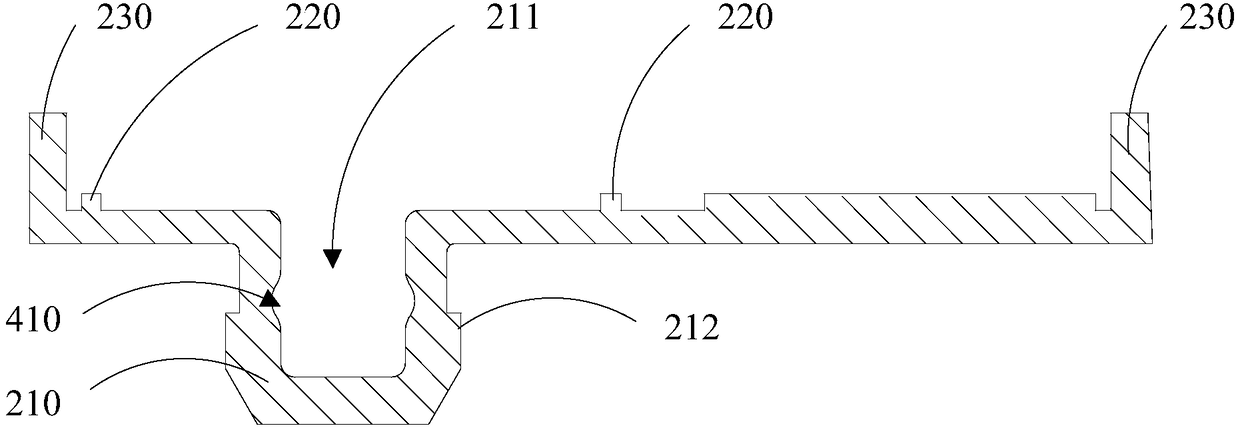

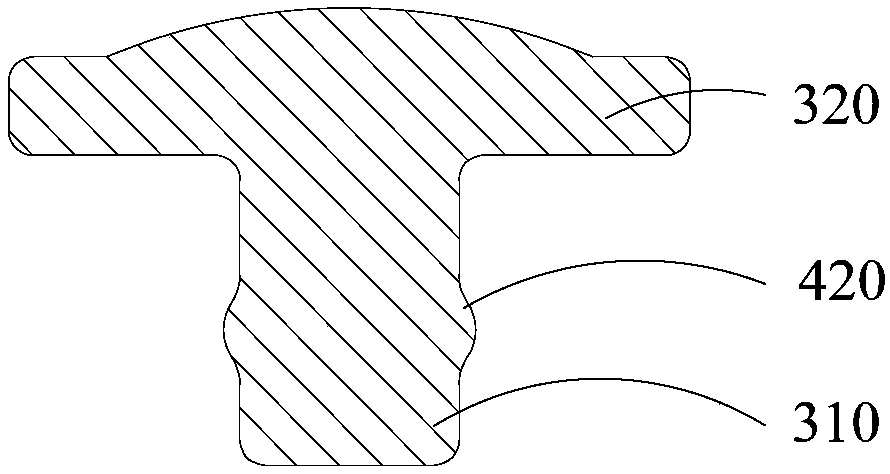

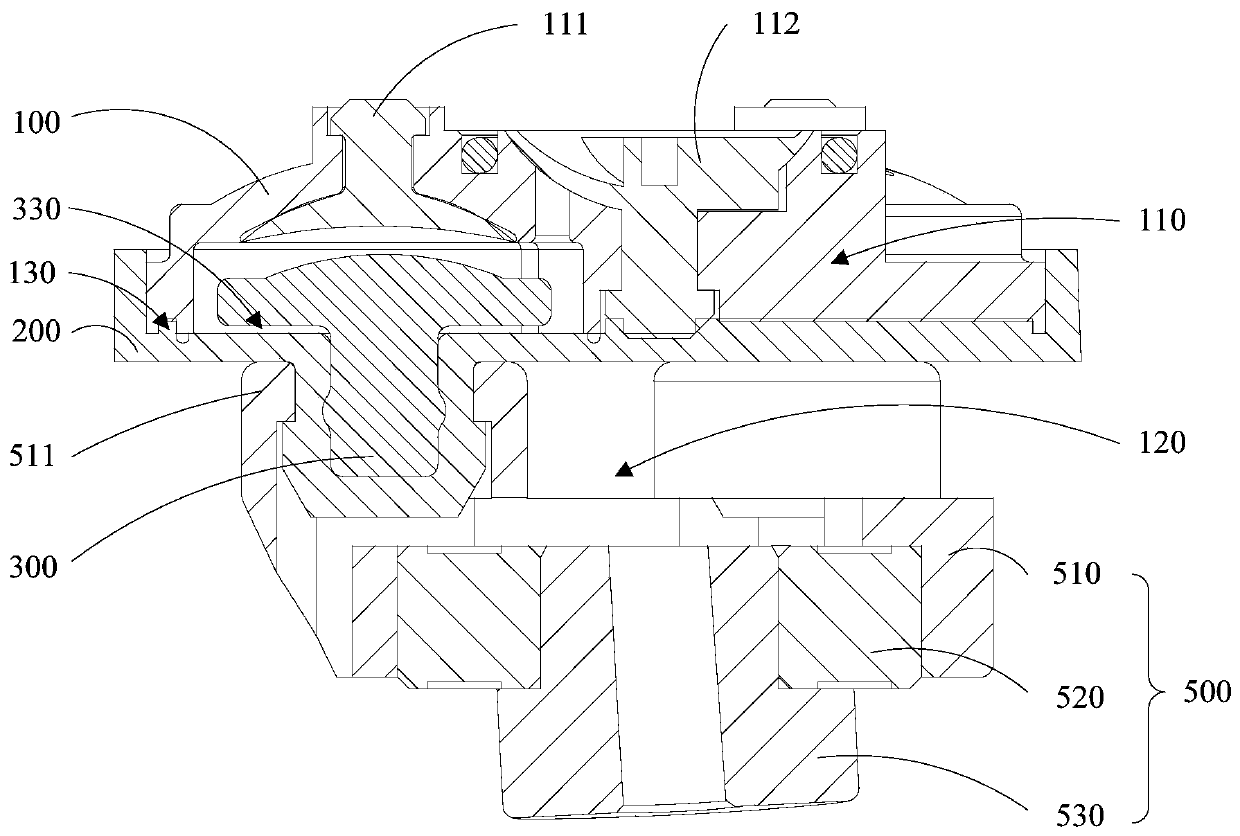

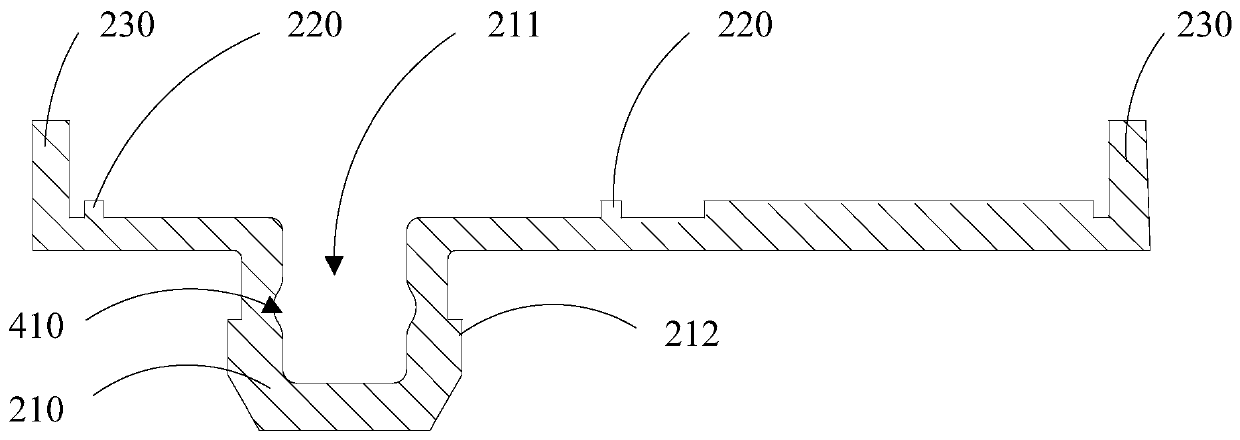

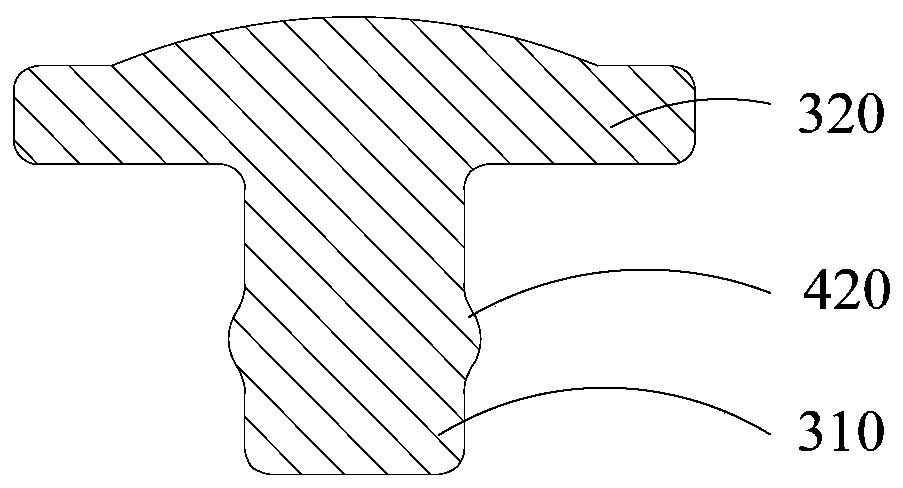

Diaphragm pump and water treatment equipment

ActiveCN108266354ANormal work impactImprove performanceFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpEngineering

The invention discloses a diaphragm pump and water treatment equipment. The diaphragm pump comprises a shell, a diaphragm and a piston, wherein a cavity in the shell forms a diaphragm chamber and a power chamber; the diaphragm is isolated between the power chamber and the diaphragm chamber, part of one side, towards the diaphragm chamber, of the diaphragm is formed a containing part; a containingcavity is formed in the containing part; the piston is arranged in the diaphragm chamber, the piston comprises a connecting part; and the connecting part is accommodated in the containing cavity. According to the technical scheme, the diaphragm pump and the water treatment equipment can improve the performance of the diaphragm pump.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

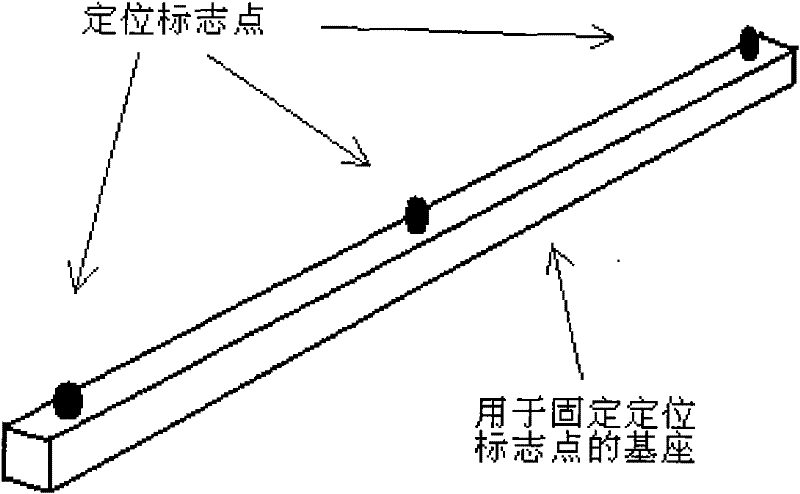

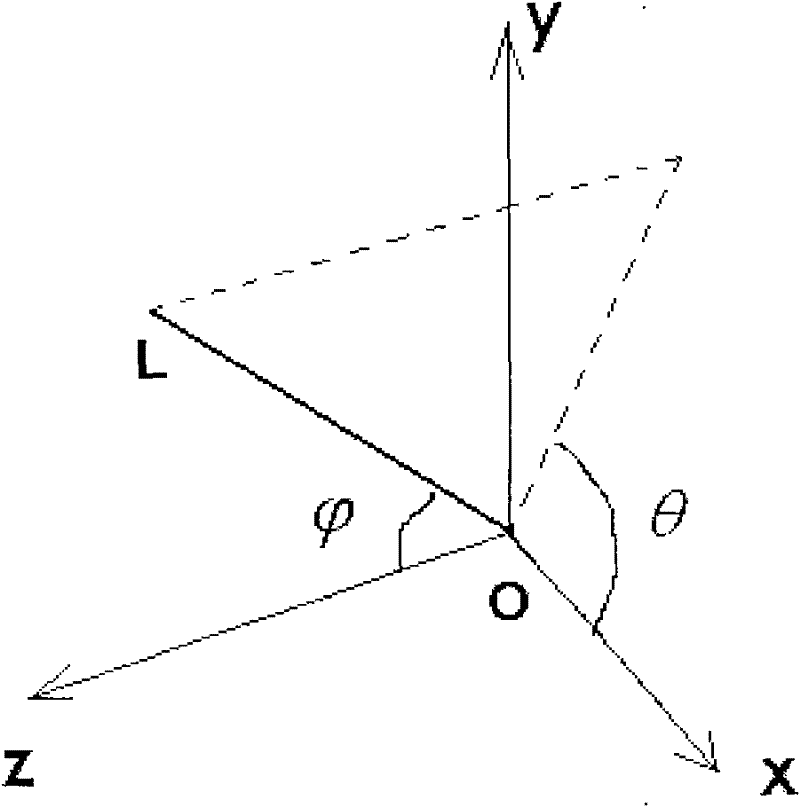

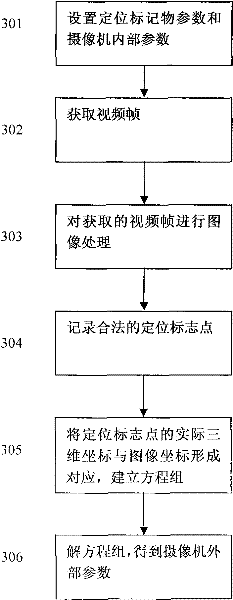

Three-dimension locating method based on three-point collineation marker in video frame

InactiveCN101702233BReasonable experienceFlexible shape designImage analysisThree-dimensional spaceVideo image

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Battery cover structure and mobile terminal

InactiveCN107645035AAffects routingEasy wiringAntenna supports/mountingsAntenna equipments with additional functionsEngineeringPrinted circuit board

The invention provides a battery cover structure and a mobile terminal. The battery cover structure comprises a battery cover body made of metal material, a partition structure and an antenna connection structure, wherein the battery cover body comprises a base plate and a side wall, and the partition structure is arranged on the at the side wall or the joint of the side wall and the base plate, the antenna connecting structure connects the side wall and the antenna circuits of the printed circuit board of a mobile terminal. Since the partition structure is arranged on the at the side wall orthe joint of the side wall and the base plate, the partition structure is staggered with a printed circuit board to avoid the printed circuit board of the mobile terminal, thereby preventing the partition structure from affecting the wiring of the printed circuit board. The problems of full-metal battery cover of a mobile terminal, the position of a plastic strip limiting the modeling design of the whole terminal and the wiring of a printed circuit board are solved.

Owner:VIVO MOBILE COMM CO LTD

A methane sensor for high-pressure hydrothermal system and its preparation method

ActiveCN105067674BGood mechanical strength at high temperatureModerate hardnessMaterial analysis by electric/magnetic meansOcean bottomHigh pressure

The invention discloses a methane sensor for a high-pressure hydrothermal system and a manufacturing method of the methane sensor. The sensor comprises a base, a circular-truncated-cone-shaped high-temperature-resistant insulated taper pad, a high-temperature-resistant insulated taper sleeve, circular-truncated-cone-shaped high-temperature-resistant ceramic, circular-truncated-cone-shaped solid electrolyte ceramic, a spongy active electrode, a spongy inert electrode, a spongy inert metal layer, an inert metal piece, an electrode lead and the like, wherein the parts are combined into a conical self-tightening sealing mechanism; compared with existing various methane sensors, the manufactured methane sensor has the advantages of simple structure, high selectivity, high response speed, stable and reliable performance and the like, can be used for in-situ measurement of methane fugacity in a high-temperature and high-pressure hydrothermal system such as a crater on a seabed, hydrothermal fluid spouts and the like, provides a technological support for exploration of natural gas hydrate resources on the seabed and can also be applied to other high-temperature (300DEG C-700 DEG C) high-pressure (normal pressure-100 MPa) hydrothermal environments requiring on-site detection of methane gas.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

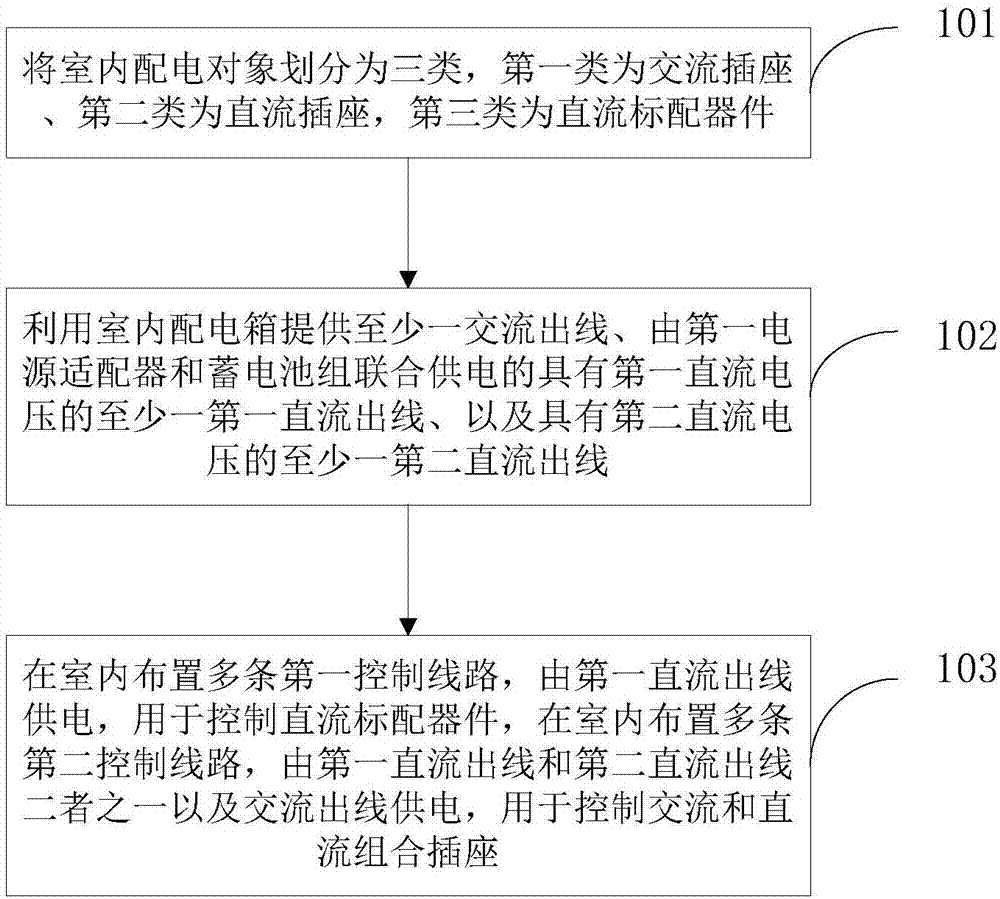

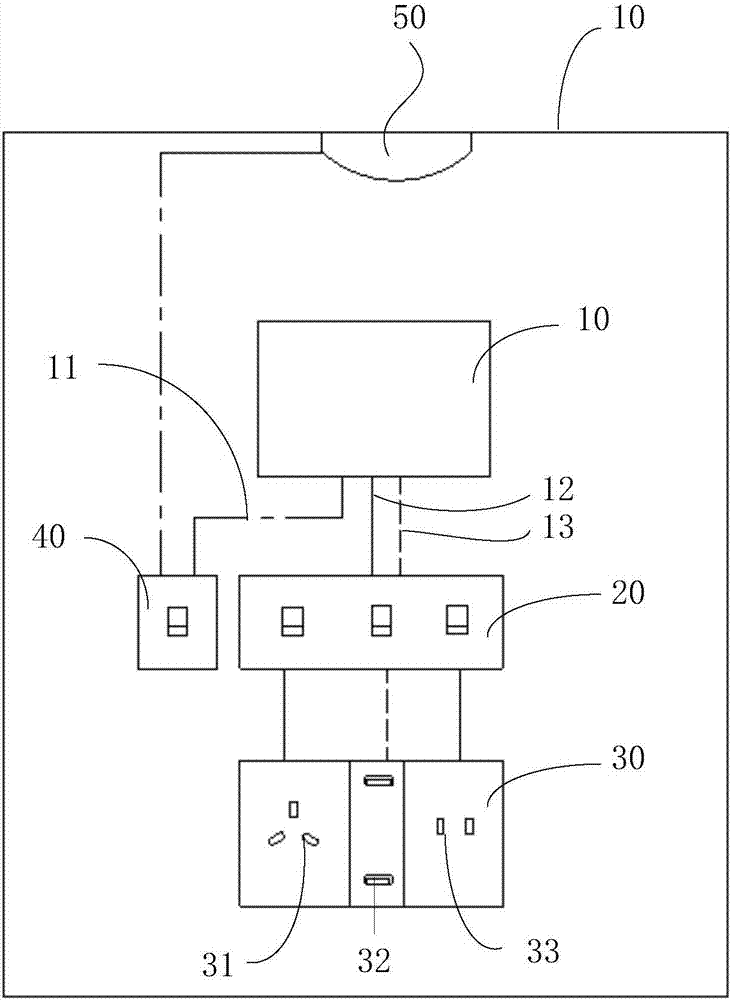

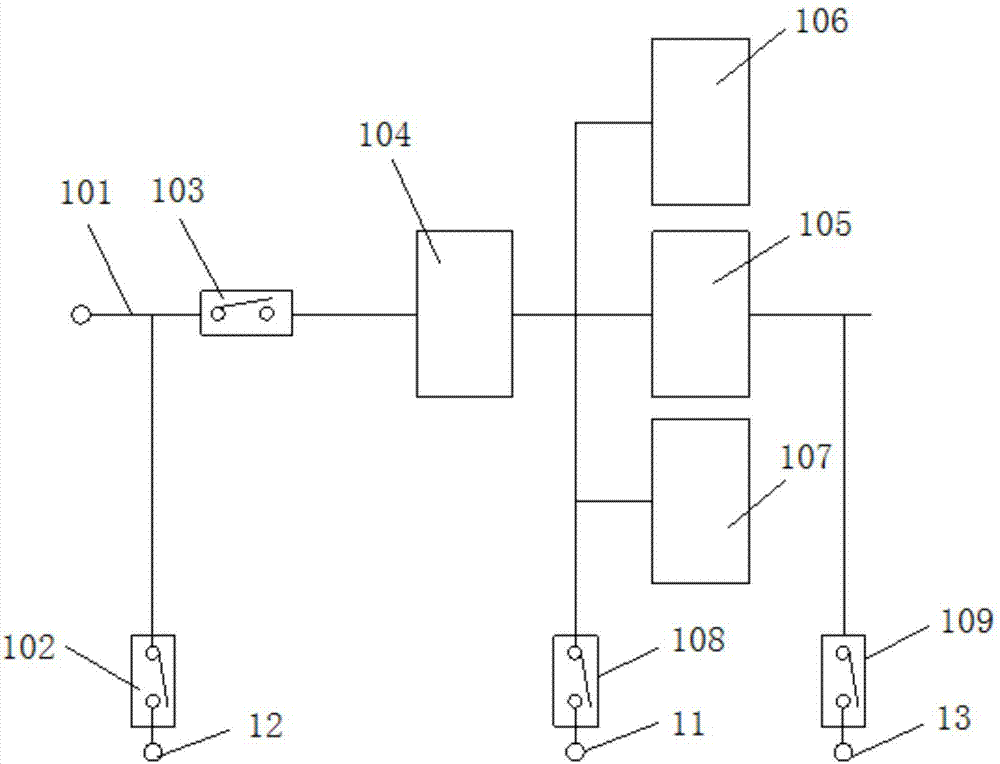

Smart home control system

InactiveCN107145078AReduce throwaway problemsFlexible shape designComputer controlProgramme total factory controlControl systemDistribution method

The invention discloses a smart home control system, comprising an indoors power distribution method and an indoors power distribution system. The indoors power distribution method comprising the following steps: dividing the indoors power distribution objects into three categories with the first category for the alternating current socket, the second category for the direct current socket and the third category for direction current standard components; using an indoors power distribution box to provide at least one alternating current outgoing wire, at least one first direct current outgoing wire co-powered by a power supply adapter and a storage battery and provided with a first direct current voltage as well as at least one second direct current outgoing wire provided with a second direct current voltage; arranging indoors a plurality of first control lines powered by the first direct current outgoing wire and used to control the direct current standard components; and arranging indoors a plurality of second control lines powered by either the first direct current outgoing wire or the second direct current outgoing wire and the alternating current outgoing wire so as to control the alternating current and direct current combining socket. With the system of the invention, the number of adapters can be reduced to a large extent, and the abandoning problem of direct current component caused by the fault of adapters can be reduced, achieving remarkable social economic gains.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

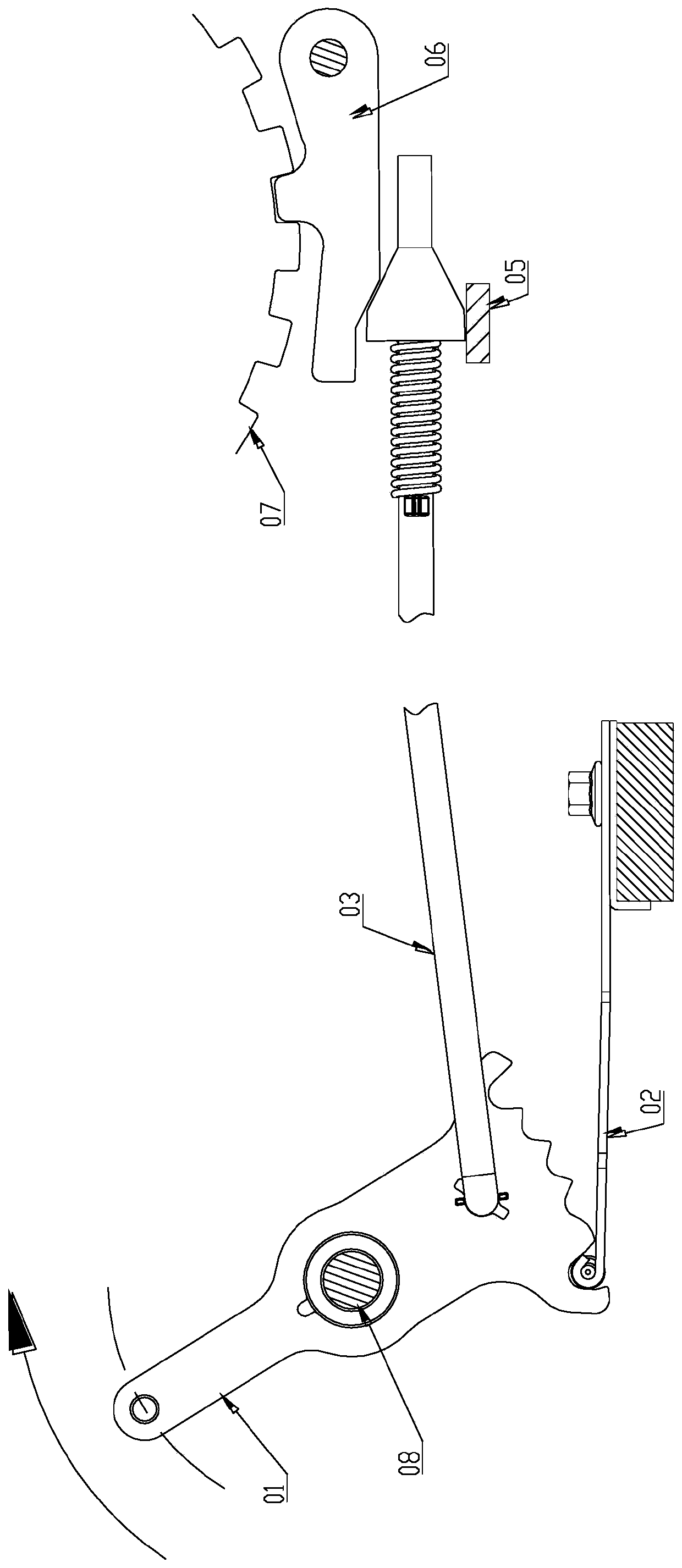

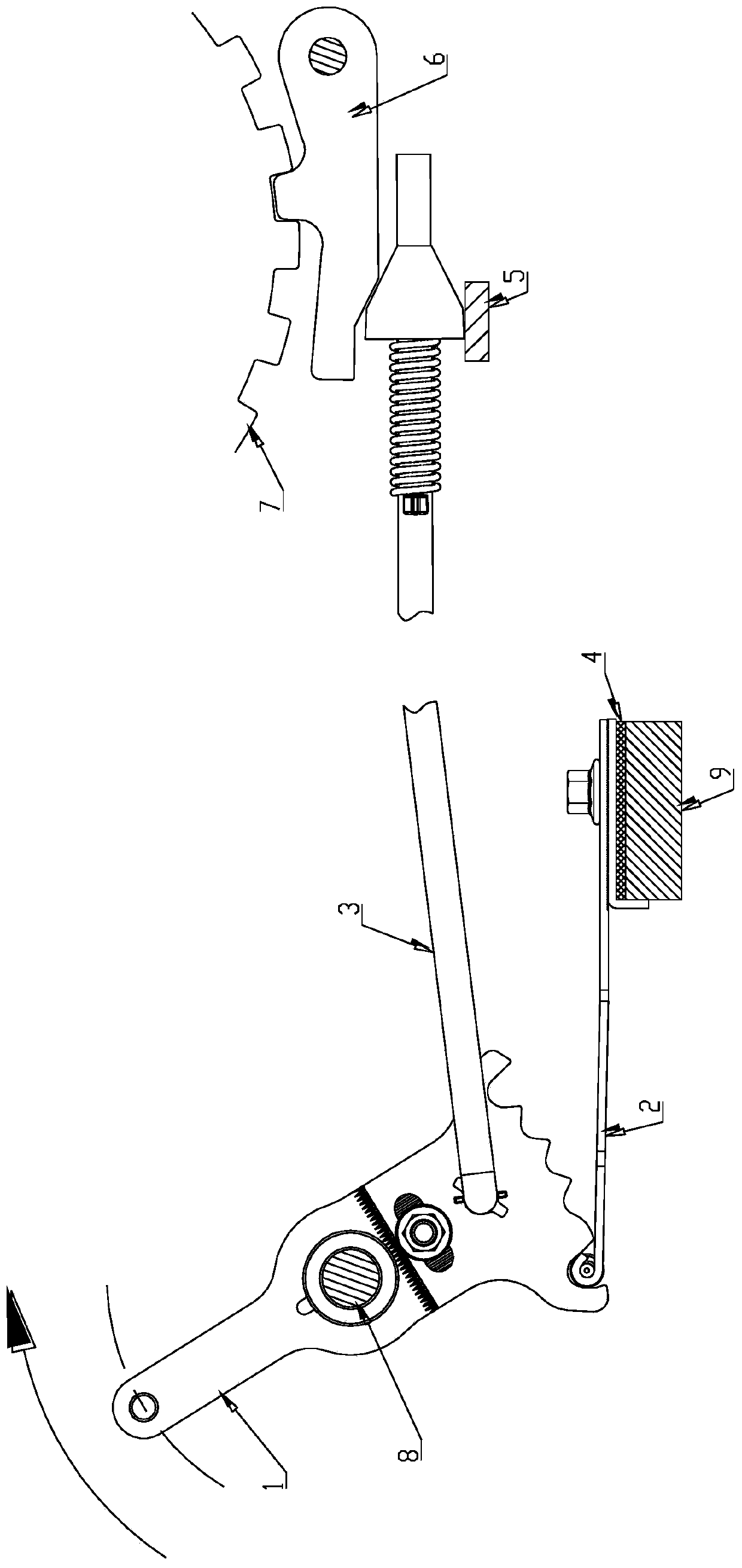

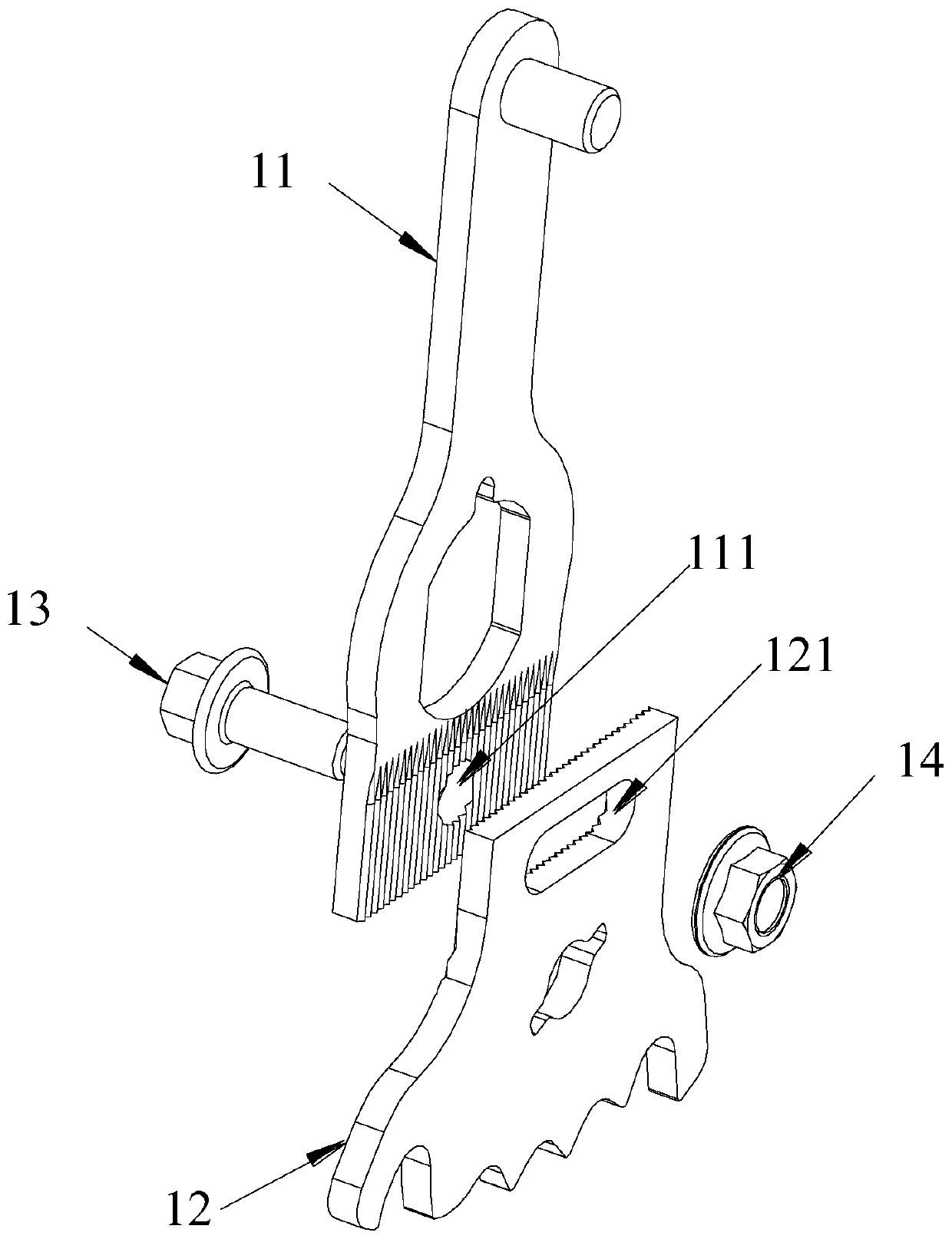

Automatic transmission gear shifting mechanism

PendingCN110219981ALow machining accuracy requirementsLow installation accuracy requirementsGearing controlAutomatic transmissionSelf locking

The invention relates to a gear shifting mechanism, in particular to an automatic transmission gear shifting mechanism. The technical problems that for an existing automatic transmission gear shiftingmechanism, the relative position between a self-locking device and an elastic device cannot be adjusted, so that the requirements on machining precision and installing precision of parts are high, and the production cost of products is high are solved. The automatic transmission gear shifting mechanism comprises a self-locking device, an elastic device, a parking rod, a guide device, a parking pawl and a parking ratchet wheel, wherein the self-locking device is a split piece and comprises a driving component and a locking component, a first through hole is formed in the driving component, a first kidney-shaped hole is formed in the locking component, and a first bolt sequentially penetrates through the first through hole and the first kidney-shaped hole to be connected with a nut; the elastic device comprises an elastic element and a gasket, a second kidney-shaped hole is formed in the elastic element, and a second through hole is formed in the gasket; and a second bolt sequentially penetrates through the second waist-shaped hole and the second through hole to be connected to the shell, and an adjusting pad is arranged between the gasket and the shell.

Owner:SHAANXI FAST GEAR CO

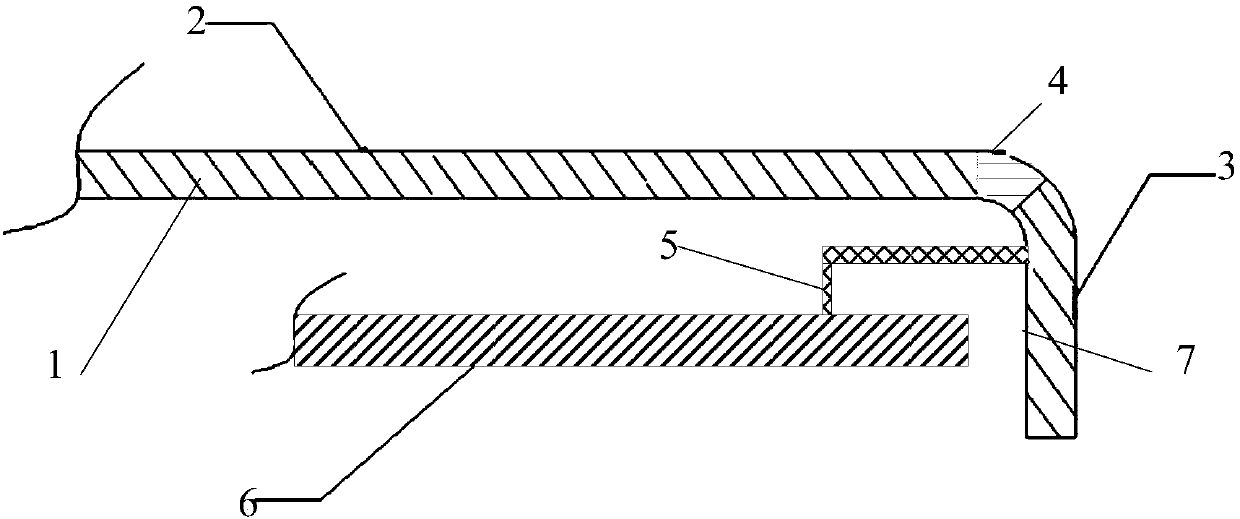

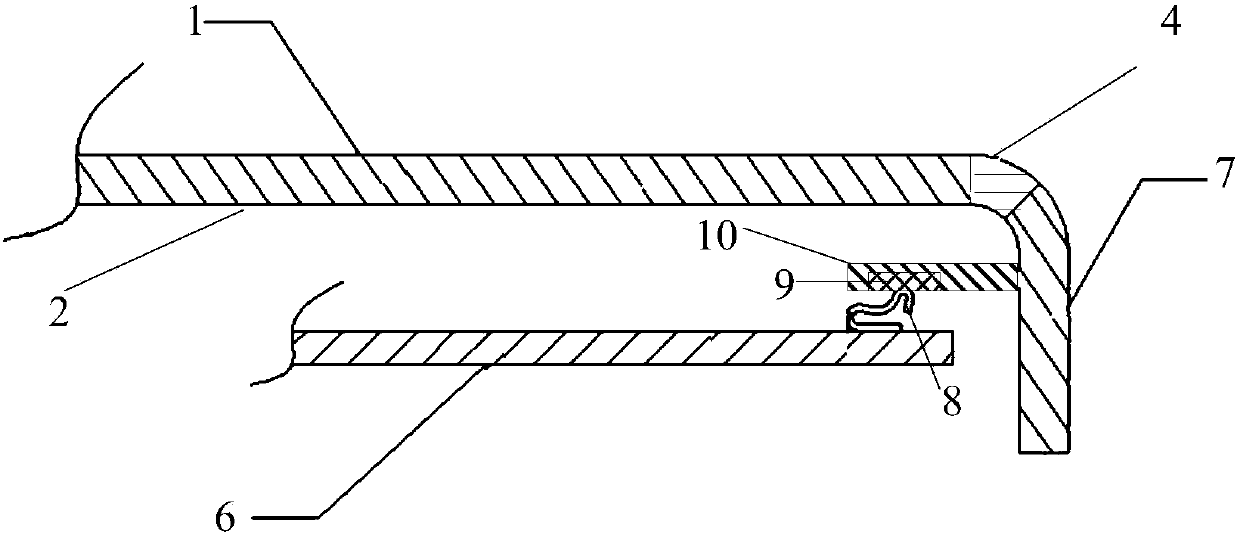

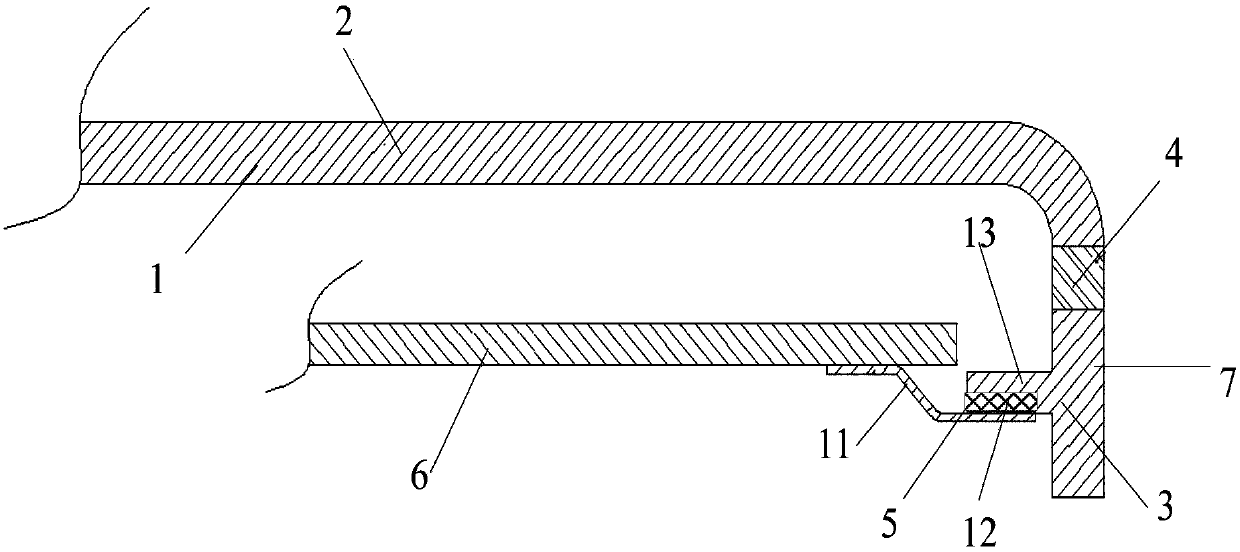

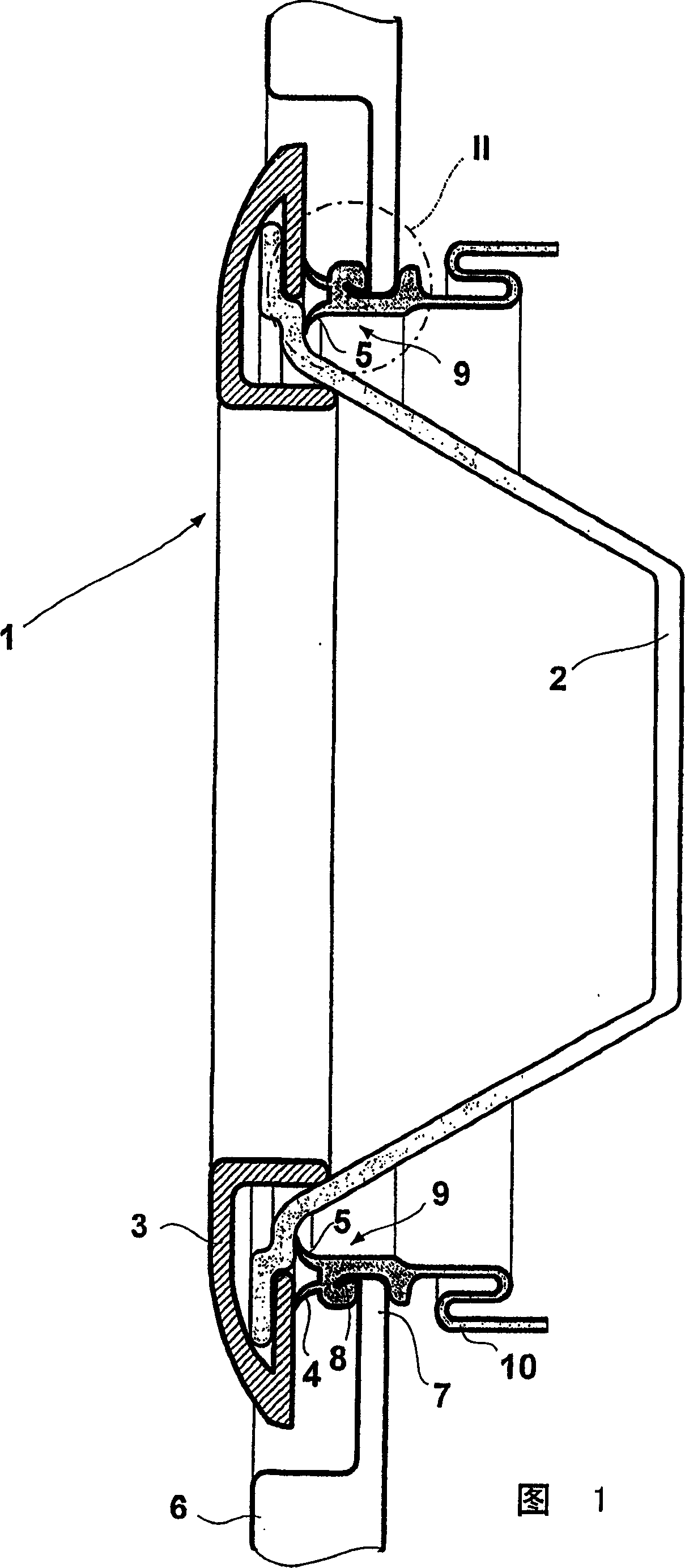

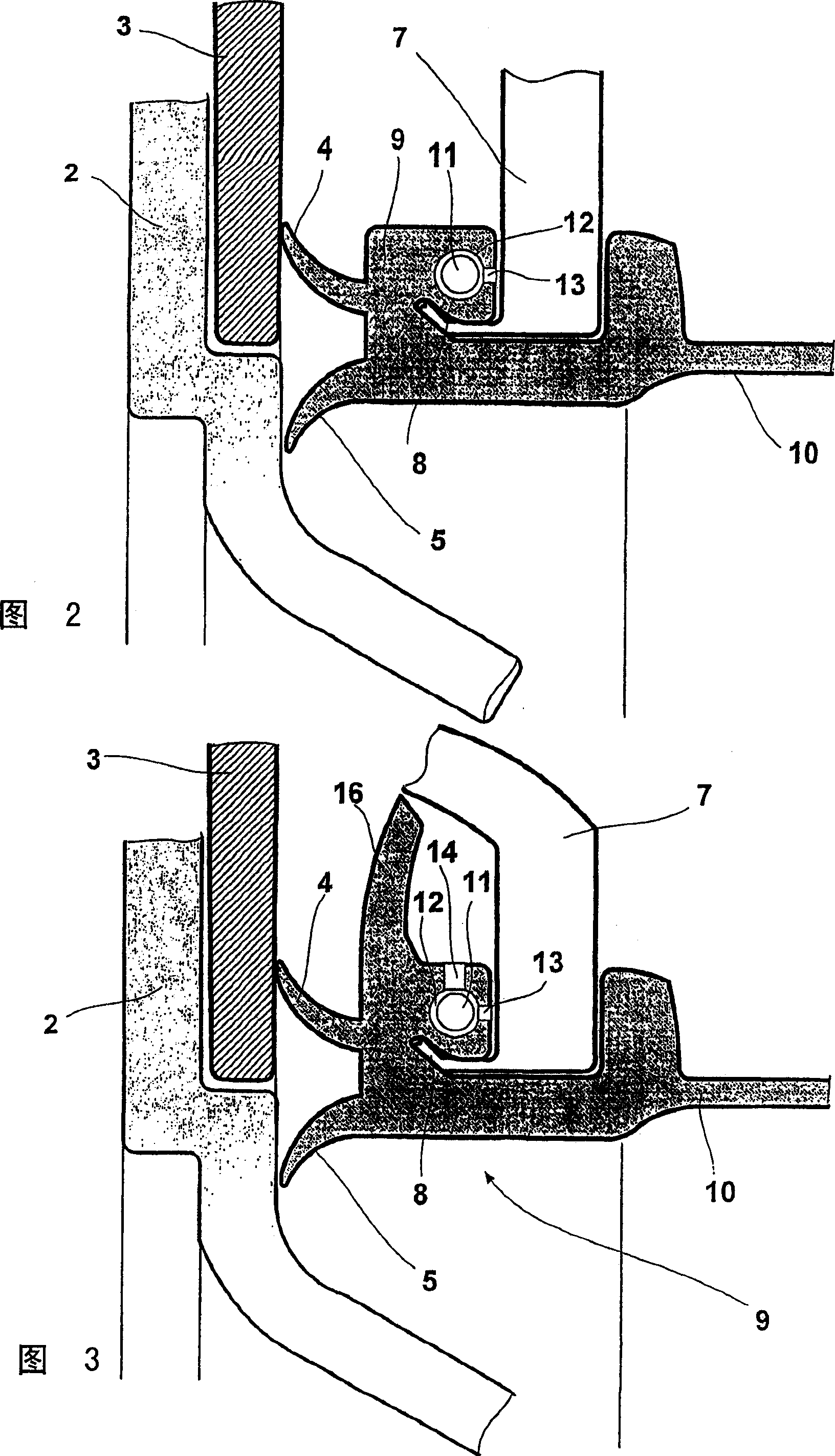

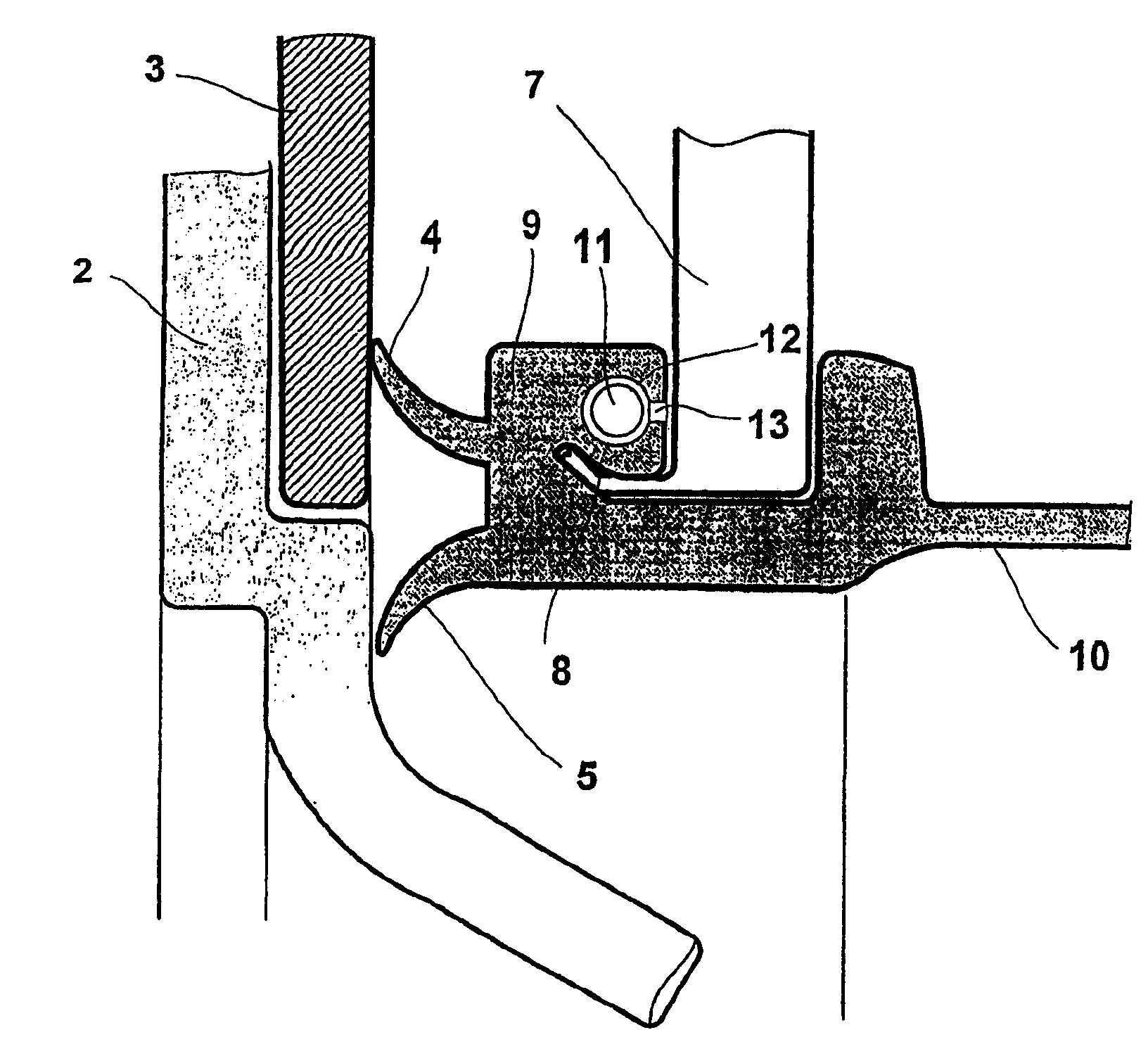

Sealing collar

InactiveCN1211522CFlexible shape designEasy to fixEngine sealsOther washing machinesEngineeringMechanical engineering

Owner:BOSCH SIEMENS HAUSGERATE GMBH

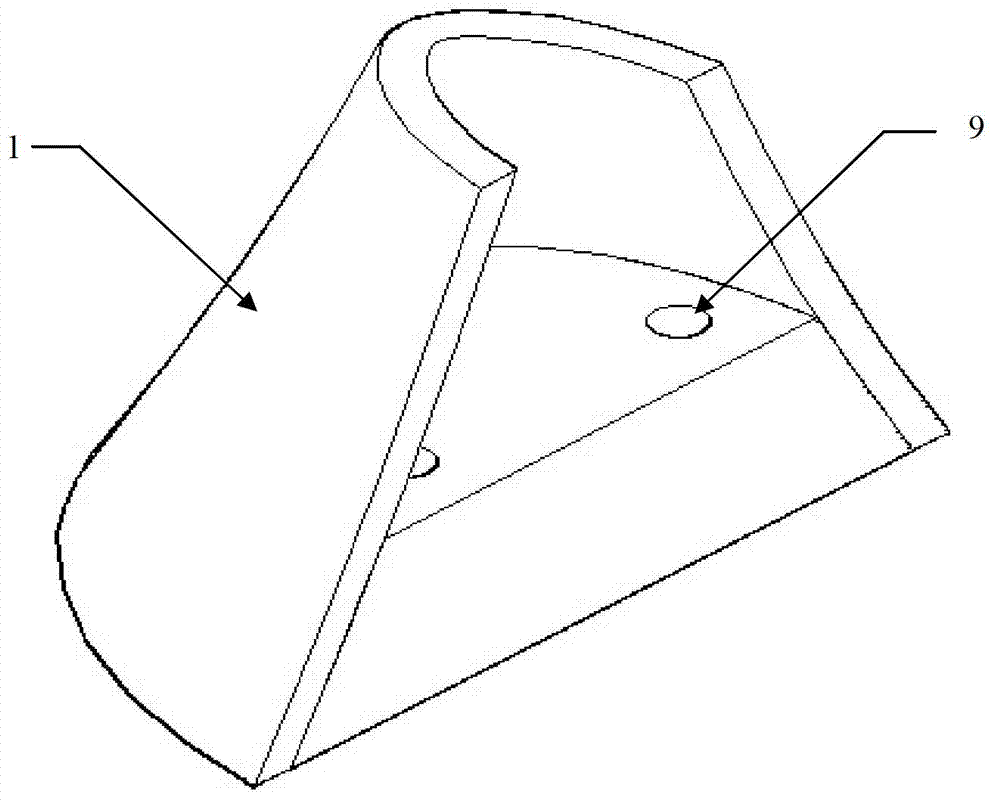

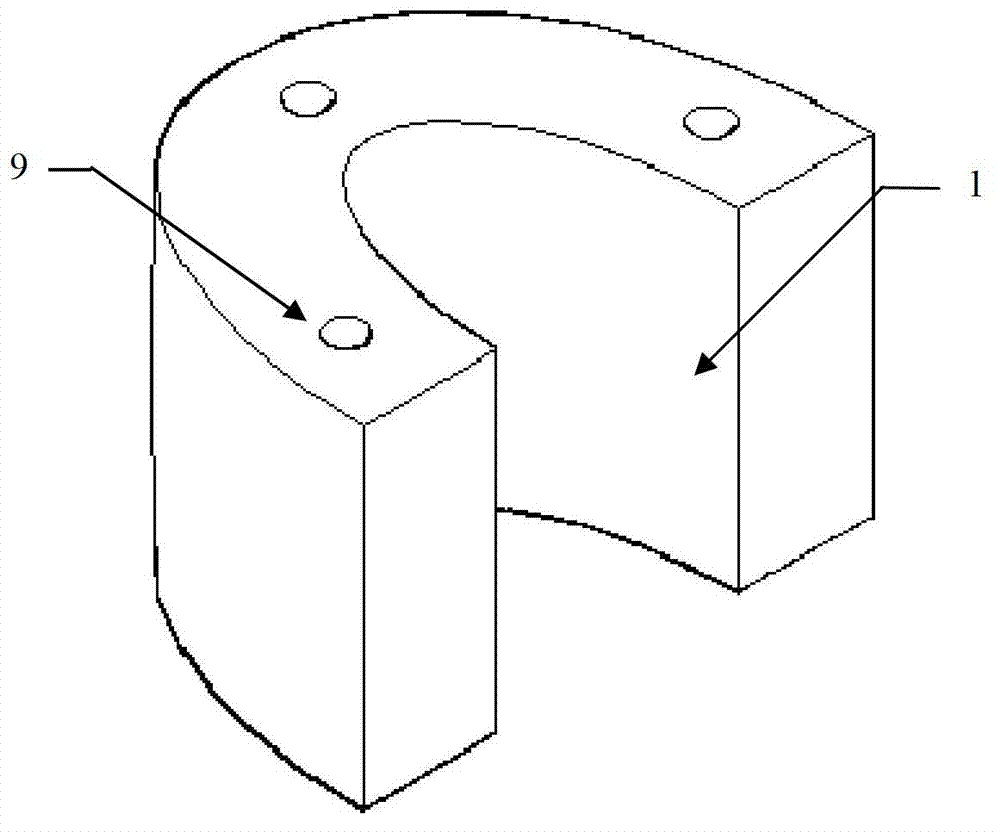

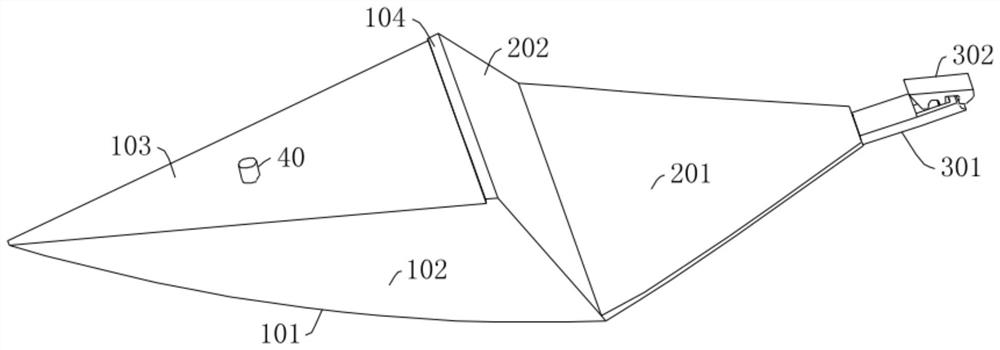

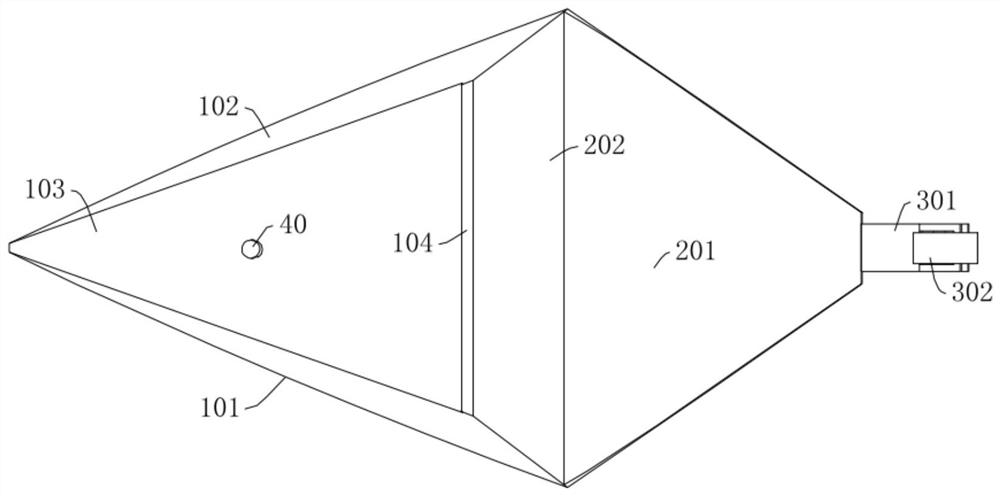

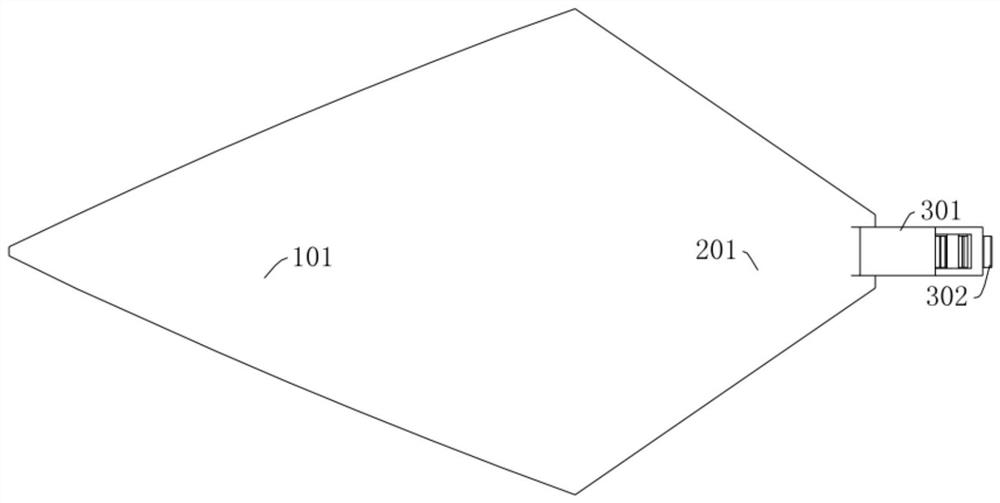

A Hypersonic Inlet Cowling Scheme Using Slit Flow to Realize Separation

ActiveCN113247279BFlexible shape designReduce resistanceAircraft power plant componentsWeight reductionFlight vehicleClassical mechanics

The invention discloses a scheme for a hypersonic air inlet fairing that utilizes slit flow to realize separation, including a drag reducing unit and a blocking unit, and the blocking unit is provided with a blocking structure capable of blocking the inlet of the air inlet; The head of the drag reducing unit is gathered at one point, the tail of the drag reducing unit is connected to the head of the blocking unit, and the drag reducing unit gradually widens and thickens along the direction from the head to the tail, The tail of the blocking unit is detachably fixedly connected to the bottom outer wall of the air inlet through a first connecting structure; the drag reducing unit is connected to the outer wall of the aircraft through a second connecting structure, and the drag reducing unit is connected to the outer wall of the aircraft through a second connecting structure There are gaps between the outer walls of the aircraft. The separation of the fairing can be achieved by providing the pneumatic separation force provided by the slit flow, which effectively solves the contradiction that the reduction of the resistance of the fairing and ensuring sufficient separation torque cannot be taken into account at the same time.

Owner:NAT UNIV OF DEFENSE TECH

Diaphragm pumps and water treatment equipment

ActiveCN108266354BNormal work impactImprove performanceFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpEngineering

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

Methane sensor for high-pressure hydrothermal system and manufacturing method of methane sensor

ActiveCN105067674AGood mechanical strength at high temperatureModerate hardnessMaterial analysis by electric/magnetic meansOcean bottomHigh pressure

The invention discloses a methane sensor for a high-pressure hydrothermal system and a manufacturing method of the methane sensor. The sensor comprises a base, a circular-truncated-cone-shaped high-temperature-resistant insulated taper pad, a high-temperature-resistant insulated taper sleeve, circular-truncated-cone-shaped high-temperature-resistant ceramic, circular-truncated-cone-shaped solid electrolyte ceramic, a spongy active electrode, a spongy inert electrode, a spongy inert metal layer, an inert metal piece, an electrode lead and the like, wherein the parts are combined into a conical self-tightening sealing mechanism; compared with existing various methane sensors, the manufactured methane sensor has the advantages of simple structure, high selectivity, high response speed, stable and reliable performance and the like, can be used for in-situ measurement of methane fugacity in a high-temperature and high-pressure hydrothermal system such as a crater on a seabed, hydrothermal fluid spouts and the like, provides a technological support for exploration of natural gas hydrate resources on the seabed and can also be applied to other high-temperature (300DEG C-700 DEG C) high-pressure (normal pressure-100 MPa) hydrothermal environments requiring on-site detection of methane gas.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Integrated multi-system combining platform

ActiveCN105489992BReduce volumeImprove space utilizationWaveguide type devicesSystem integrationCoupling

The invention provides an integrated point of interface (POI). The integrated POI comprises an upper cover having a first combining function, a cavity body that has a bridge circuit coupling function and is arranged below the upper cover, and a bottom cover that has a second combining function and is connected with the bottom of the cavity body. The integrated POI provided by the invention has the characteristics of small size and high space utilization rate.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

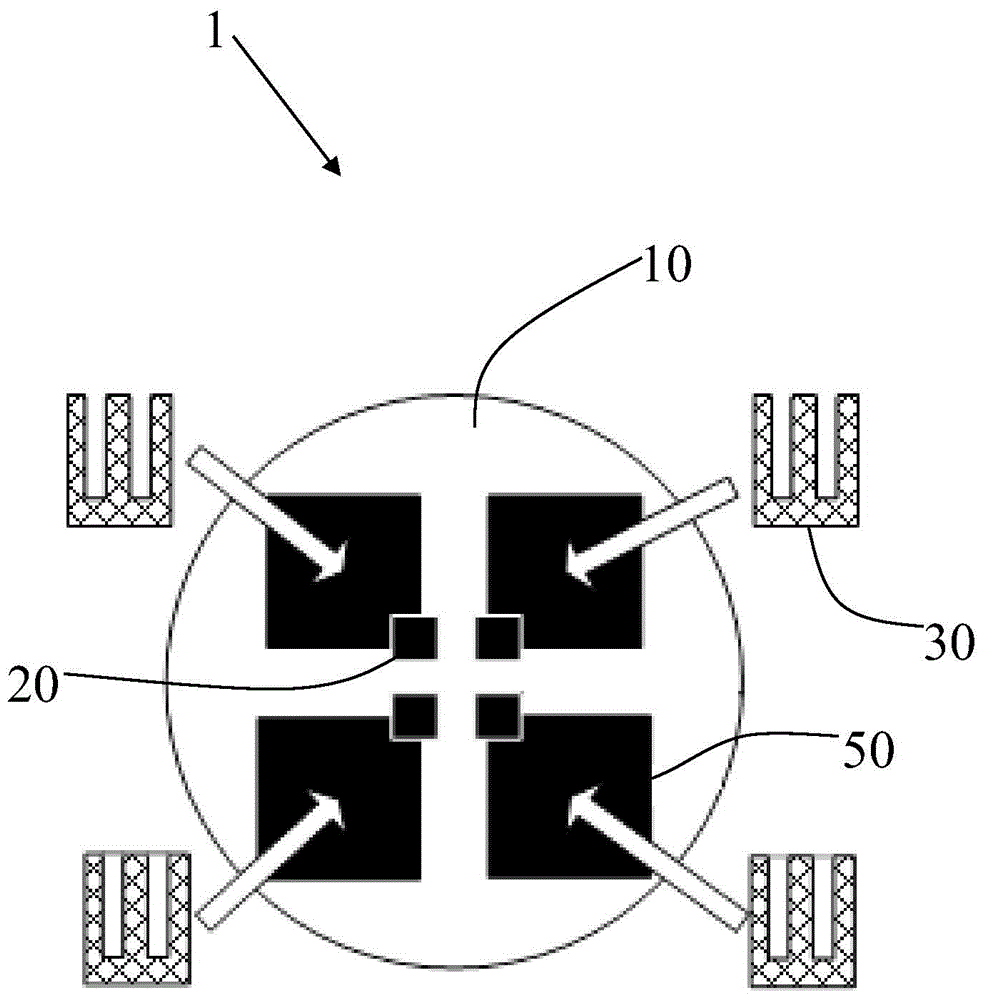

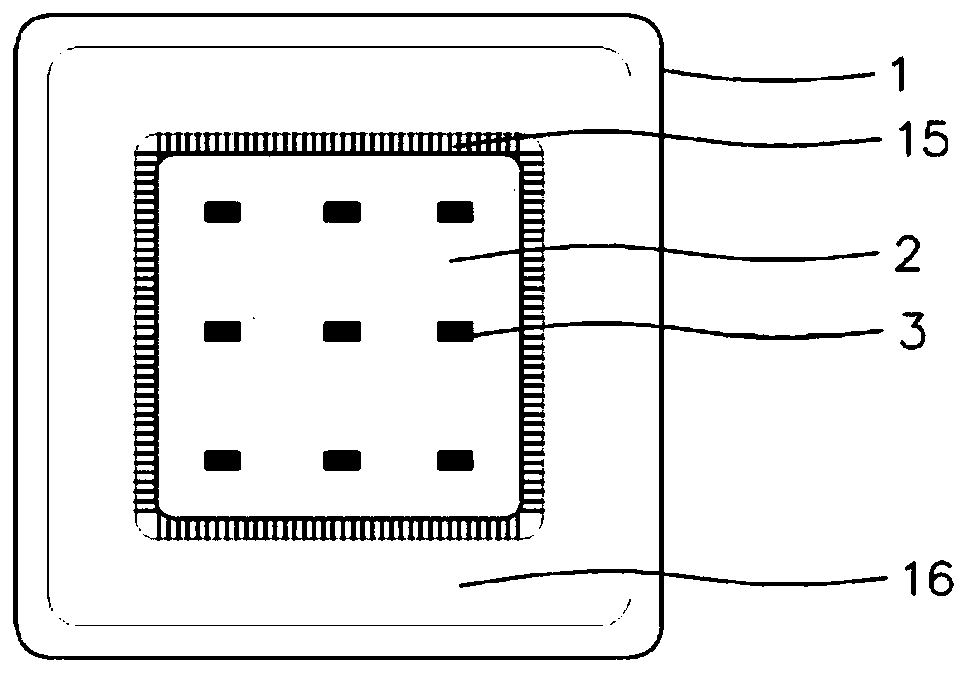

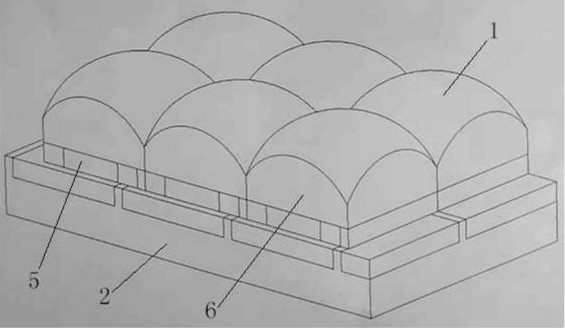

An array focused laser energy transmission photoelectric receiving device

ActiveCN109659301BImprove reliabilityAchieve isolationFinal product manufactureSolid-state devicesLaser lightLight Cell

The invention belongs to the field of laser wireless energy transmission, and discloses an array-focused laser energy transmission photoelectric receiving device, which includes a photon power supply unit and a lower substrate. The photon power supply unit is arranged on the lower substrate and arranged tightly without gaps. The photon power supply unit array form; the photon power supply unit includes a laser battery chip, a diode, an upper substrate and a focusing lens, the laser battery chip is mounted on the upper substrate through conductive glue, and the laser battery chip and the diode are connected in antiparallel connection, the laser battery chip, diode, and upper substrate are packaged inside the focusing lens, and the upper substrate is welded on the pad of the lower substrate. The invention enables the laser light on the gap between the battery chips to be focused on the photosensitive surface of the battery, thereby improving the utilization efficiency of the surface of the photocell and improving the overall conversion efficiency.

Owner:SHANDONG INST OF AEROSPACE ELECTRONICS TECH

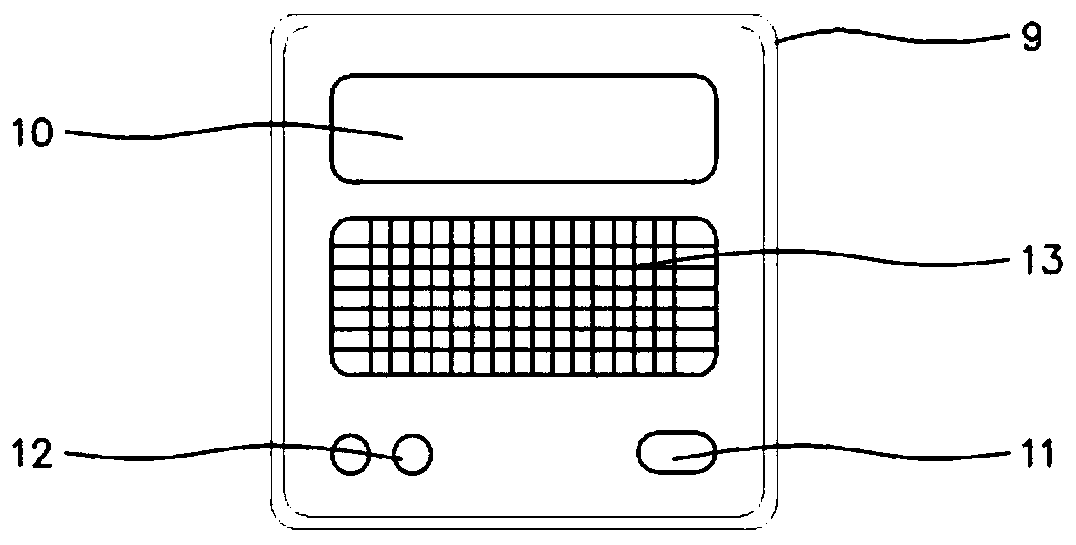

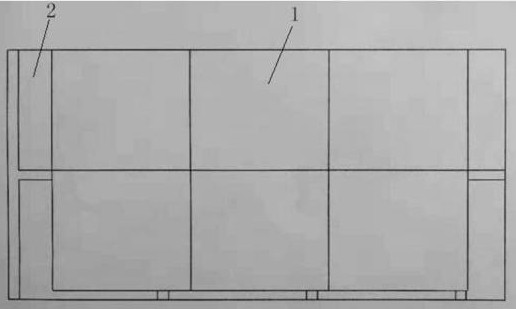

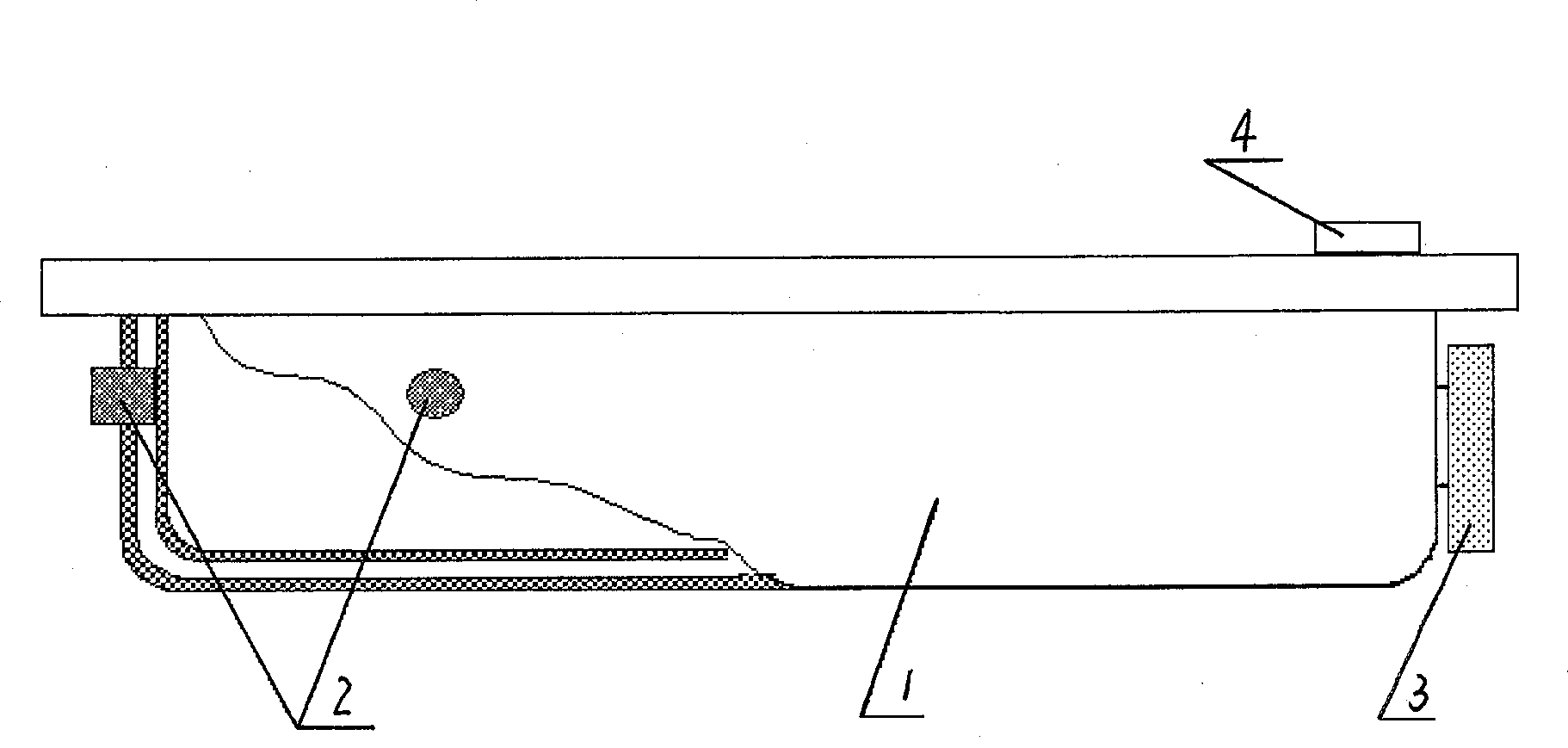

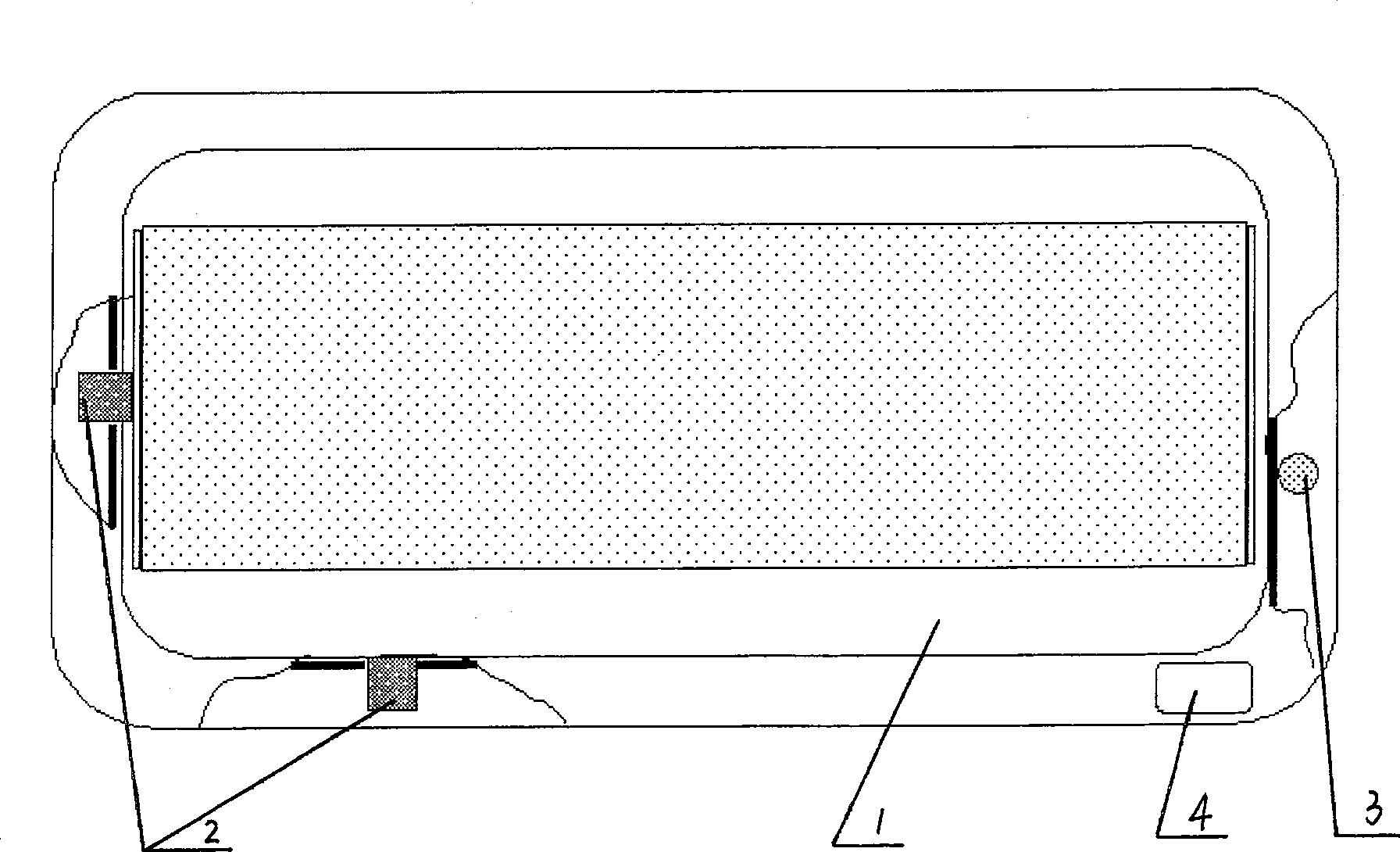

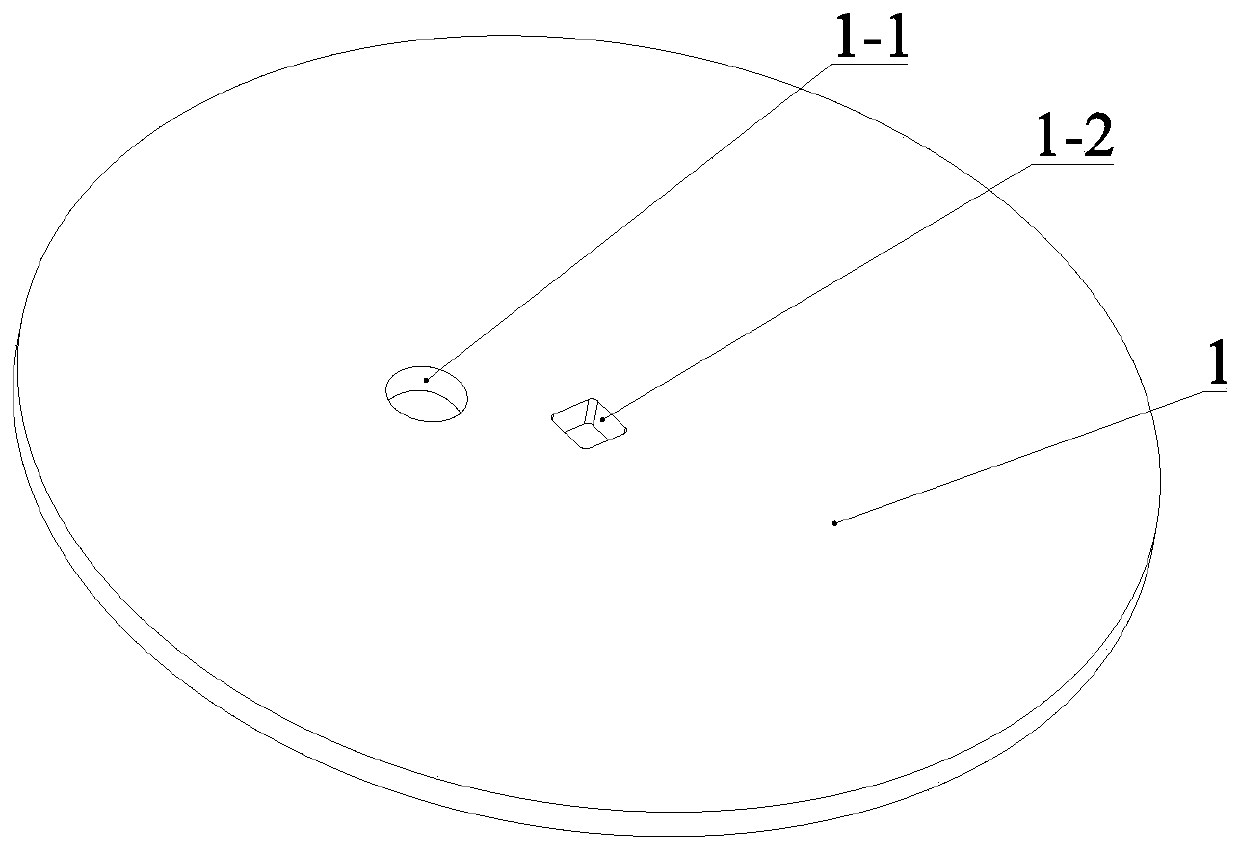

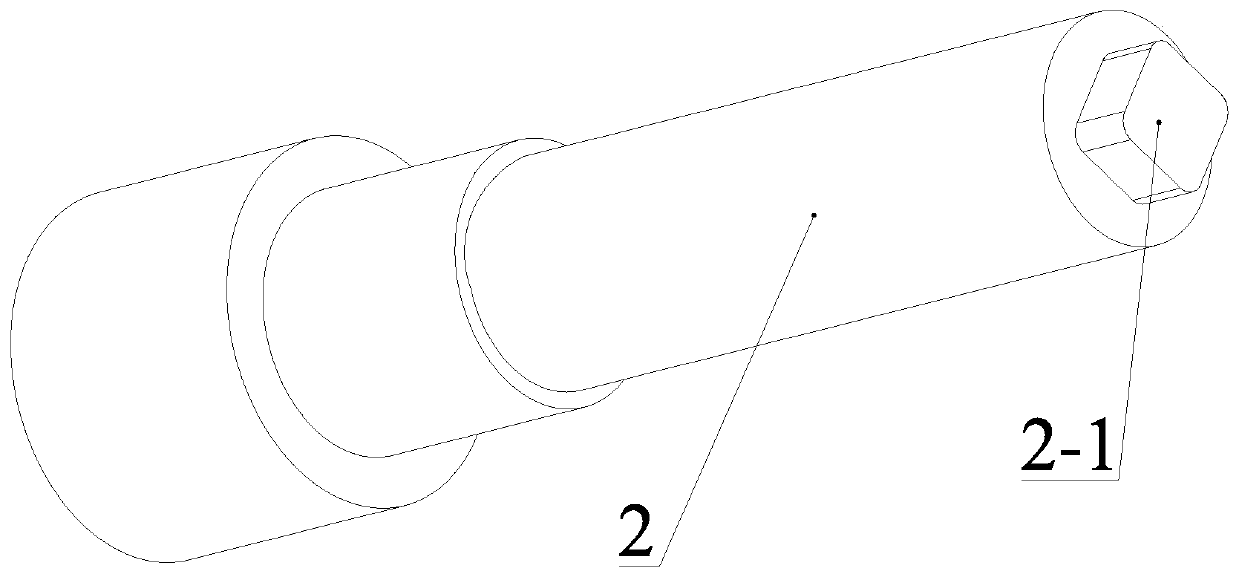

Four-dimensional body sensing music bathtub

InactiveCN100531699CWide selection of materialsImprove transient characteristicsBathing devicesLife careSomatosensory system

The invention relates to bathing equipment, in particular to a four-dimensional somatosensory music bathtub with health care function, comprising a bathtub body, an audio vibrator assembly and a playback controller. components to form a two-channel stereo; the playback controller is arranged on the upper surface of the bathtub body, the audio vibrator component is connected to the playback controller, and the playback controller is connected to an external sound source; a water quality activation booster is added at the water inlet of the bathtub body. The audio vibrator assembly includes a fixed seat, an audio vibrator, a fixed cover, a rubber pad, and a lead wire; the fixed seat is fixed on the bathtub body, the audio vibrator is arranged in the fixed seat, and one end of the audio vibrator is abutted on the bathtub body. The other end is provided with a lead wire, the fixed cover is sleeved on the audio vibrator, and is tightened by fixing bolts, and a rubber pad is added between the audio vibrator and the fixed cover. The present invention can be used for clinical treatment and rehabilitation after illness, and is an ideal bathing and sanitary ware for people's daily life health care.

Owner:王文有

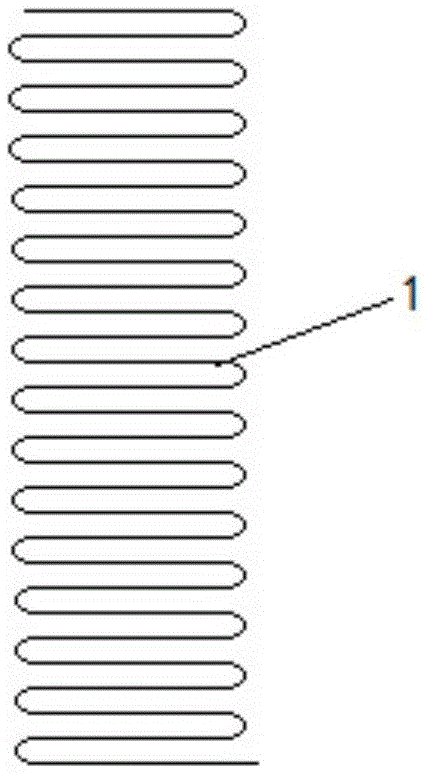

A multi-stator multi-rotor motor system based on flexible pcb winding

ActiveCN110350741BImprove consistencyGood workmanshipDynamo-electric machinesElectric machineMiniaturization

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A fuel cell cooling bipolar plate

Owner:QINGDAO HANHE HYDROGEN ENERGY EQUIP TECH CO LTD

A wearable electric field therapy device

ActiveCN103638603BAchieve strengthNo discomfortElectrotherapyMagnetotherapy using coils/electromagnetsVoltage sourceUltimate tensile strength

Owner:GENERAL HOSPITAL OF PLA

An electrochemical oxygen control device for high-pressure hydrothermal system and its preparation method

ActiveCN105159343BImprove corrosion resistanceGood mechanical strength at high temperatureControlling ratio of multiple fluid flowsChemical variable controlHigh pressureOxygen

The invention discloses an electrochemical oxygen control device applied to a high pressure hydrothermal system and a preparation method thereof. The electrochemical oxygen control device is composed of a pedestal, a truncated cone-shaped high temperature-resistant insulated cone pad, high temperature-resistant insulated cone sleeves, truncated cone-shaped high temperature-resistant insulated ceramics, truncated cone-shaped solid electrolyte ceramic pipes, spongy inert metal layers, an inert metal piece, electrode leads and the like. Components are assembled to form a cone self-energized seal mechanism. Compared with various types of direct or indirect oxygen control devices applied to the high temperature high pressure hydrothermal system in the prior art, the electrochemical oxygen control device of the invention is faster in response speed, more reliable in performance stability and higher in reuse rate, and can be widely applied to the hydrothermal system of a wider temperature pressure range (250-700 DEG C, and normal pressure of 100Mpa).

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com