Heat radiation bipolar plate of fuel battery

A technology of fuel cells and bipolar plates, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of less applicable environments, inconsistencies, and high air requirements, and achieve the effects of flexible shape design, improved performance and life, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

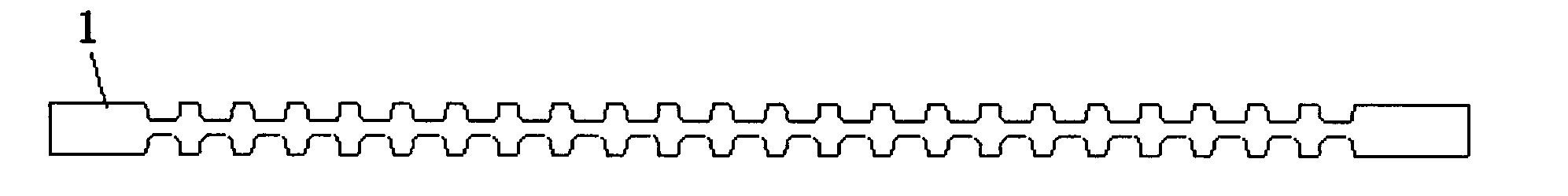

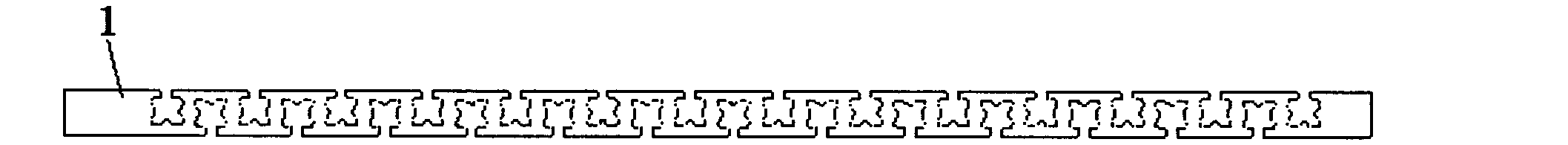

[0032] like Figure 4 As shown, an air-cooled integrated bipolar plate for a fuel cell includes an anode plate 5 and a cathode plate 6. The cathode plate and the anode plate are only provided with fuel inlet and outlet fluid holes and oxidant inlet and outlet fluid holes, without cooling fluid inlet and outlet holes. A heat dissipation section is arranged between the anode plate 5 and the cathode plate 6, and the heat dissipation section is composed of three layers of heat dissipation plates 1-1, 1-2 and 1-3. The heat sink 1 is stamped from an aluminum alloy plate, and is provided with a parallel straight groove 2, that is, a trapezoidal parallel groove with the same upper and lower cross-sections is punched on both sides of the aluminum alloy plate, such as figure 1 shown. The cathode plate 6 is provided with fuel fluid channels, and the anode plate 5 is provided with oxidant fluid channels.

[0033] The cathode plate 6, the heat dissipation section and the anode plate 5 ar...

Embodiment 2

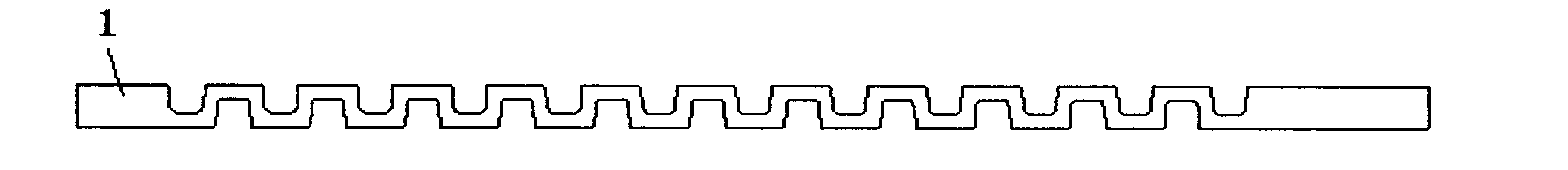

[0037] like figure 2 As shown, an air-cooled integrated bipolar plate for a fuel cell includes an anode plate 5 and a cathode plate 6, and a heat dissipation section is arranged between the anode plate 5 and the cathode plate 6, and the heat dissipation section is superimposed by several layers of heat dissipation plates made. The radiating plate is provided with a single row of staggered parallel straight grooves 2, and the radiating plate 1 is stamped from an aluminum alloy plate, that is, the upper and lower sides of the aluminum alloy plate are staggered and stamped with parallel grooves with trapezoidal cross-sections. The cathode plate 6 is provided with fuel fluid channels, and the anode plate 5 is provided with oxidant fluid channels.

[0038]The cathode plate 6, the heat dissipation section and the anode plate 5 are integrally formed by injection molding to form a bipolar plate. The two ends of the bipolar plate are provided with the fuel inlet and outlet flow chann...

Embodiment 3

[0044] like figure 1 As shown, the cooling plate 1 is provided with fluid channels. The fluid channel is punched from an aluminum alloy plate, that is, a trapezoidal parallel groove with the same upper and lower positions is punched on both sides of the aluminum alloy plate, and a layer of upper heat dissipation plate is arranged between the cathode plate and the anode plate. The rest are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com