LED lamp and LED light source module

A technology of LED light source and LED lamp, which is applied in the direction of light source, electric light source, point light source, etc., can solve the problems of rising cost of the whole lamp, unable to realize standardized design of radiator, etc., and achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

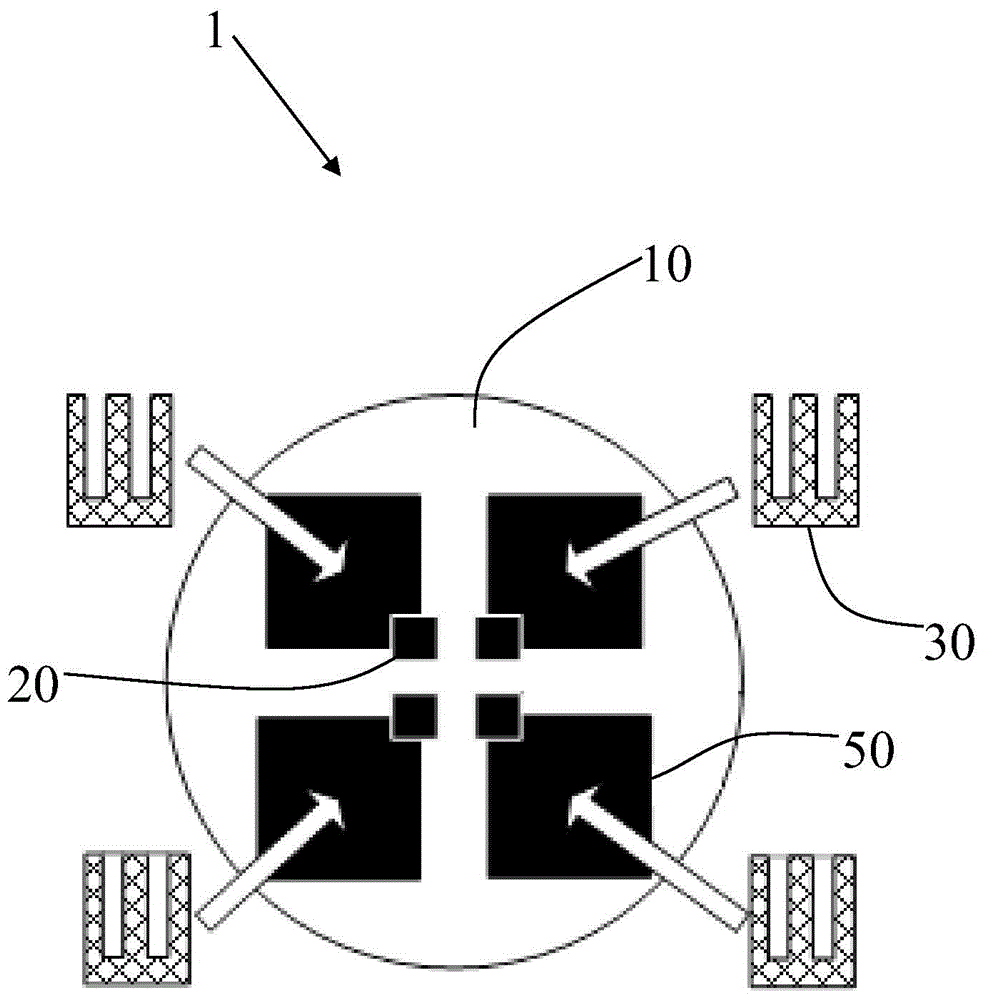

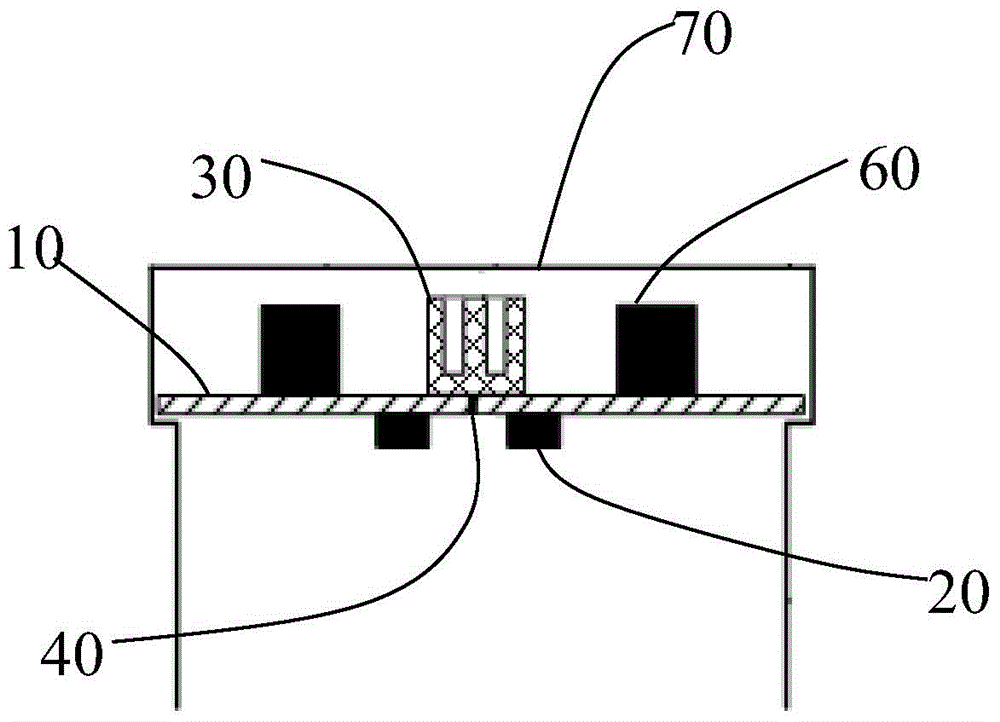

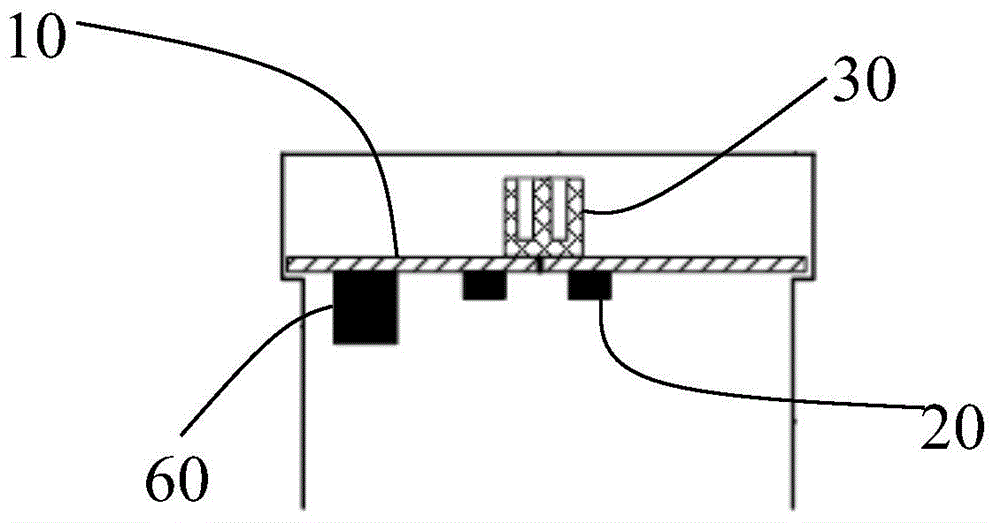

[0033] Please refer to figure 1 As shown, an LED lamp 1 according to the first preferred embodiment of the present invention includes a light source board 10, a number of LED particles 20 mounted on the light source board 10, and a number of heat sinks 30. Each two LED particles 20 correspond to one or more There are two heat sinks 30, and heat conduction is formed between each LED particle 20 and its corresponding heat sink 30. In the present invention, one or more heat sinks 30 are provided for every two LED particles 20, and the heat sinks 30 are dispersed and distributed on each LED particle 20 instead of being a large whole, so that the internal space of the LED lamp 1 can be configured conveniently and flexibly. Reserving a large space for the radiator 30 can effectively reduce the volume of the LED lamp 1 and make the overall shape design of the LED lamp 1 flexible.

[0034] Every two LED particles 20 corresponds to a heat sink 30 or each LED particle 20 corresponds to a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com