A new type of bathroom heating device

A technology for heating devices and bathrooms, applied in heating methods, lighting and heating equipment, space heating and ventilation, etc. It can solve the problems of unrealized temperature continuous adjustment, reduce the height of the bathroom room, and long heating time, etc., and achieve thermoelectric conversion efficiency High, flexible shape design, fast heating rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

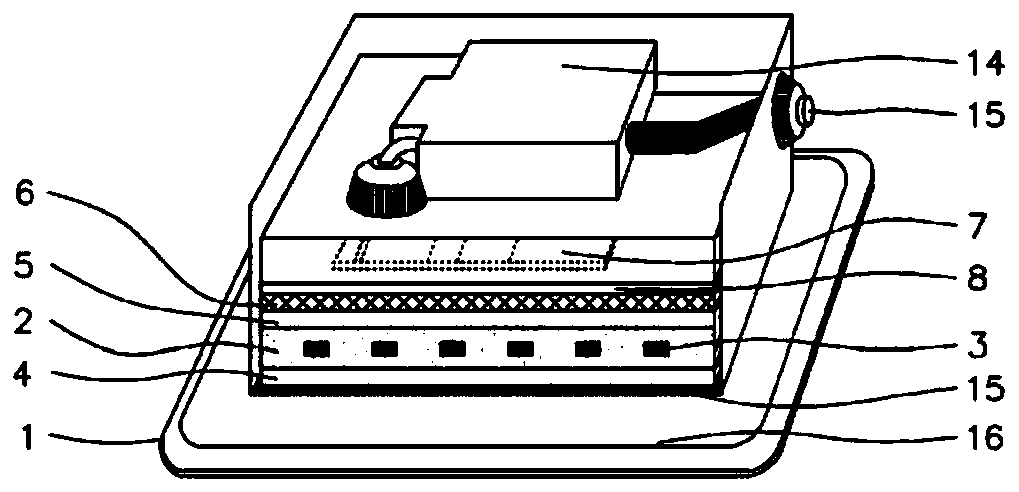

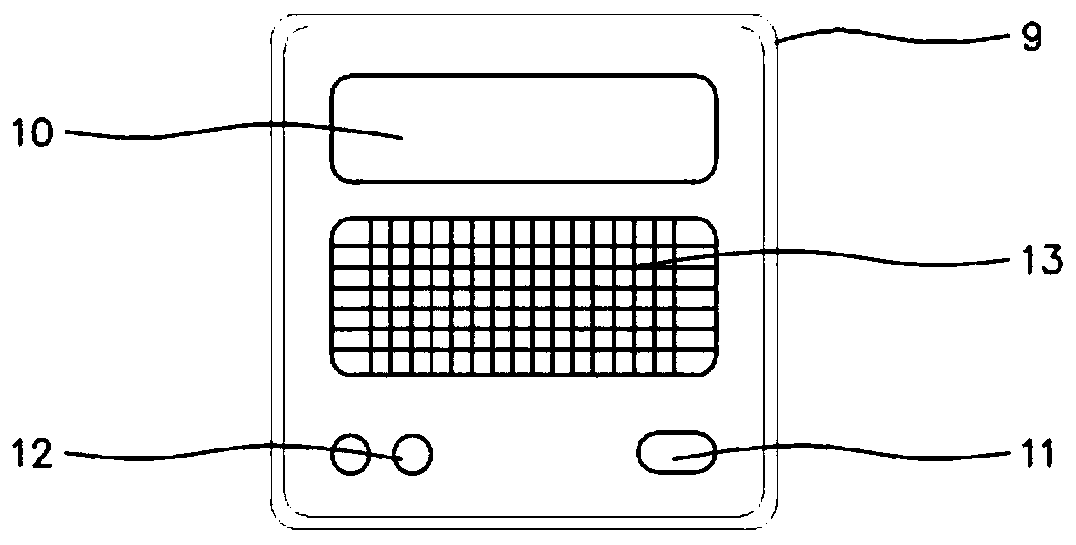

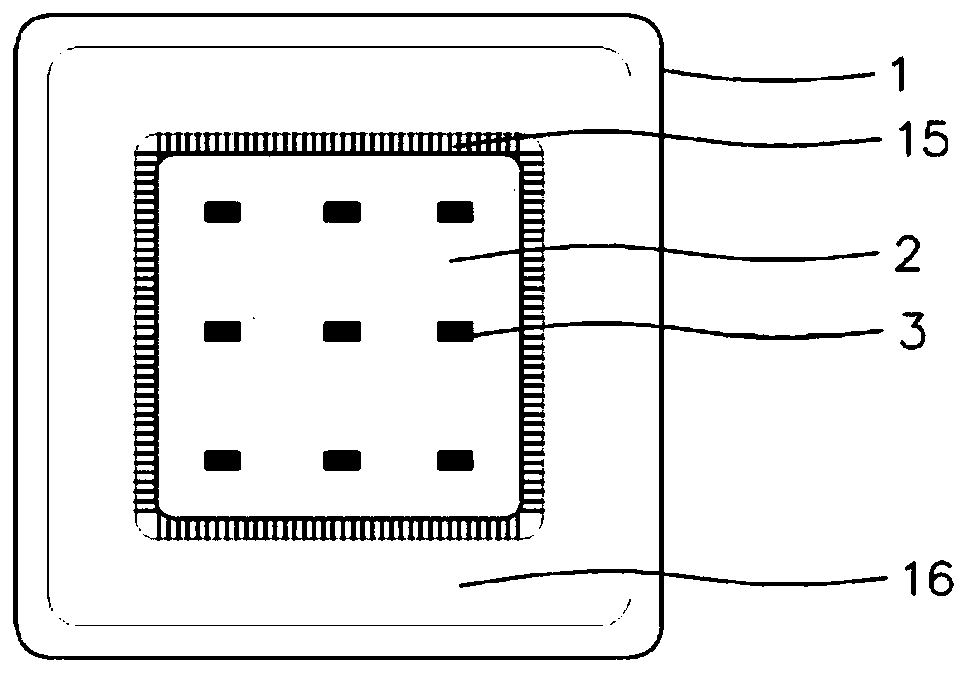

[0028] This embodiment records a new type of bathroom heating device, such as figure 1 As shown, the heating device is installed in the bathroom through the housing 1, and uses the heat radiation generated by the heating element 2 made of flexible carbon material to meet the heating requirements of the bathroom.

[0029] Flexible carbon materials can be carbon fiber heating materials (one-dimensional filaments, two-dimensional membranes), graphene heating materials (including one-dimensional graphene fibers / one-dimensional carbon nanotubes, two-dimensional graphene films (paper), three-dimensional graphene ), a series of carbon-based flexible heating materials such as graphene fibers (one-dimensional filaments and two-dimensional membranes). The heating element 2 prepared by the flexible carbon material has low noise during heating, no harmful electromagnetic wave radiation, and high safety performance.

[0030] Such as figure 1 As shown, the housing 1 includes a top plate, a partit...

Embodiment 2

[0044] In a preferred embodiment, the heating element 2 adopts a new self-made heating element of the present invention, which can obtain a high-performance electrothermal material by directly growing microcrystalline graphite on high-temperature resistant fibers.

[0045] Specifically, the novel heating element of the present invention includes a high temperature resistant fiber layer and a microcrystalline graphite layer coated on the high temperature resistant fiber layer.

[0046] The preparation method of electrothermal material usually includes the following steps:

[0047] Step 1: Prepare clean fiber materials;

[0048] Step 2: Perform surface coating treatment on the fiber material, and the coating layer contains the carbon source cracking catalytic material;

[0049] Step 3: Place the coated fiber material in a vacuum reaction chamber;

[0050] Step 4: Pass protective gas and reducing gas into the vacuum reaction chamber, and then pass in a carbon source to grow microcrystalline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com