Cooling method and device for high-temperature discharge gas and combustion treating device

A technology for exhausting gas and cooling device, which is applied in the field of combustion treatment device, can solve the problems of not being large, the cooling device cannot, and cannot allow the gas to circulate and drain the structure, etc., and achieve the effect of improving the gas-liquid contact efficiency and the cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

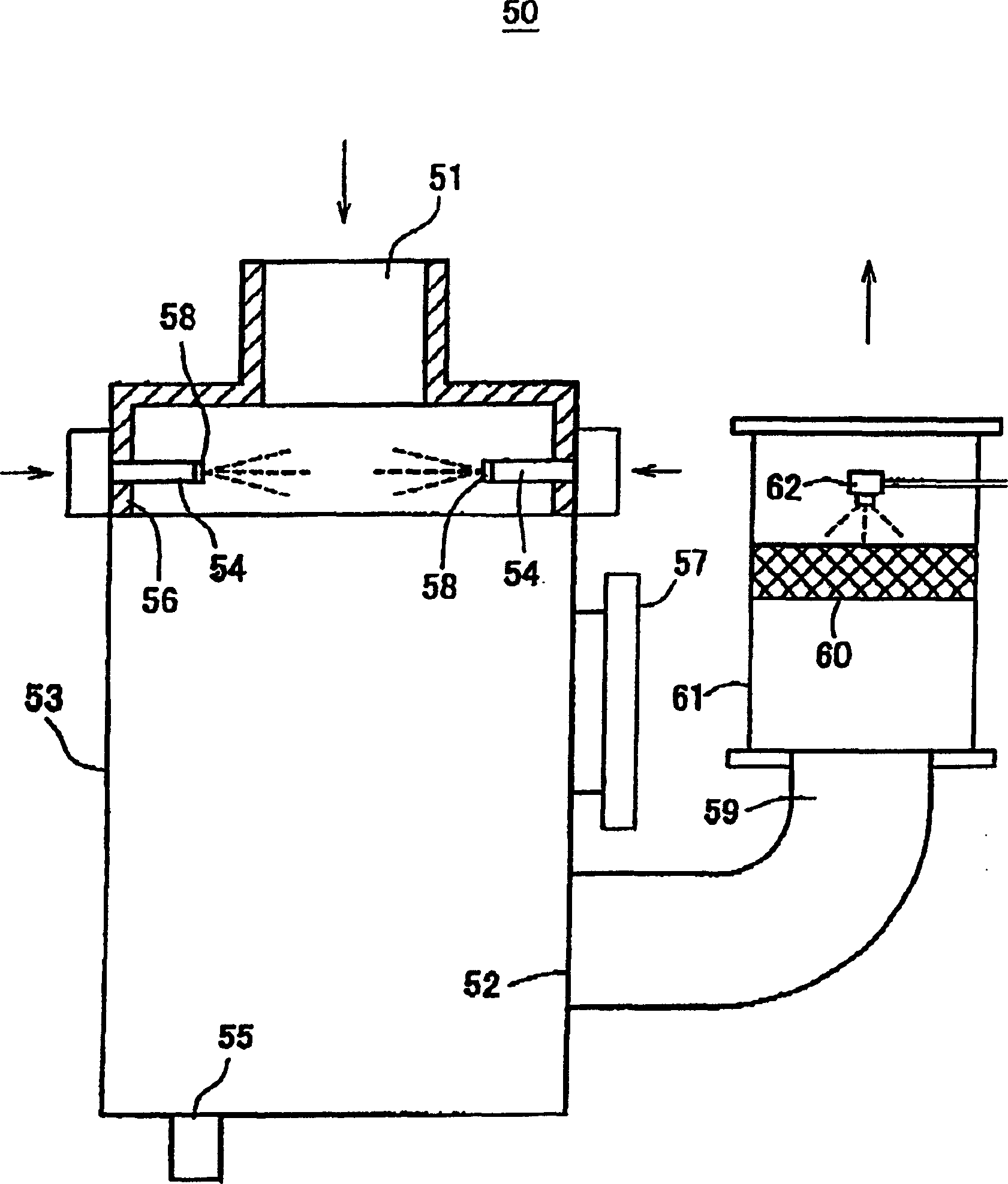

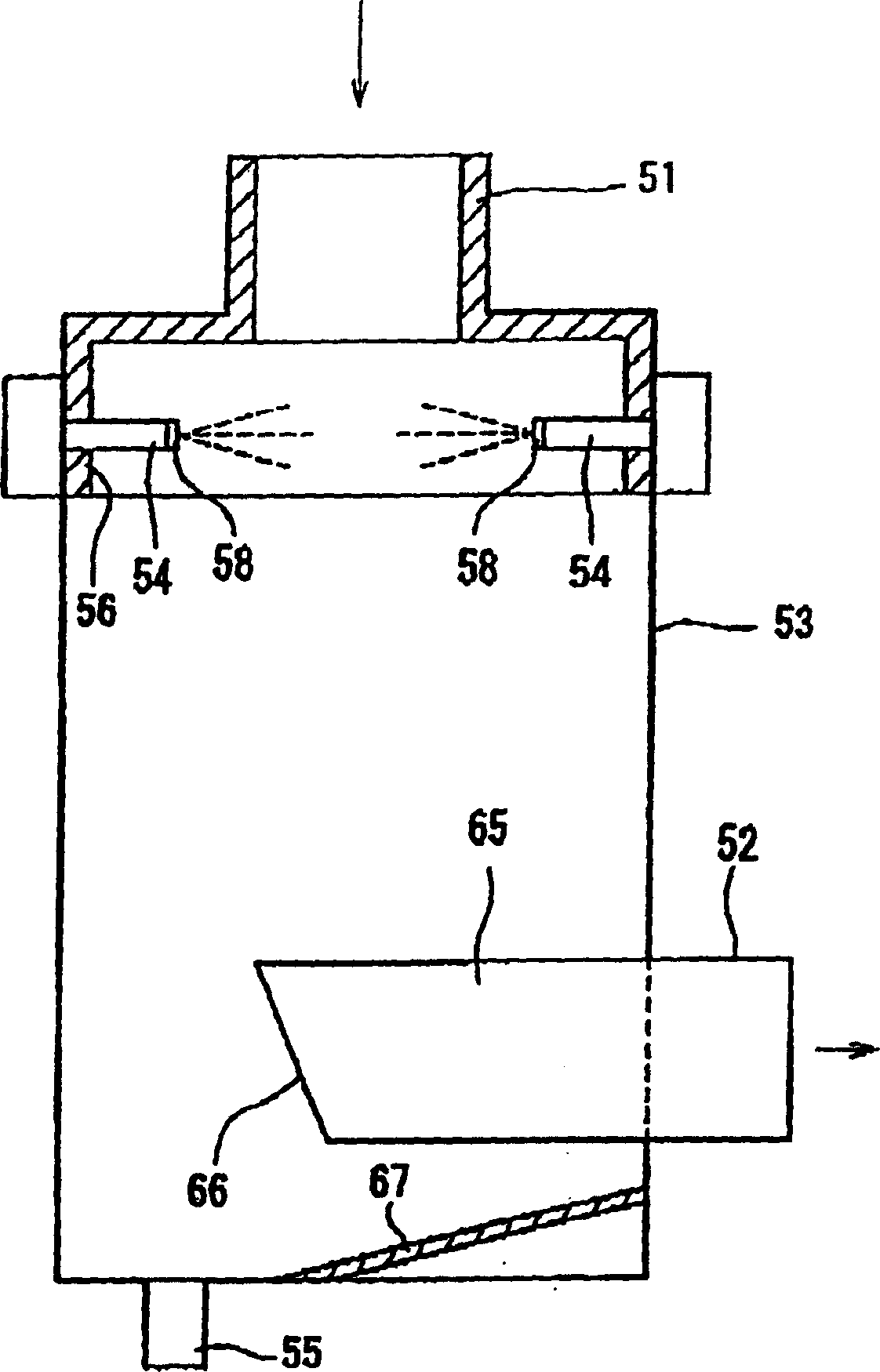

[0076] use Figure 5 The combustion chamber of the structure shown will be composed of 3% silane (silane, SiH 4 ) Combustion treatment target gas composed of nitrogen gas is introduced into the combustion chamber from the gas introduction pipe at a rate of 200 liters (litter) per minute, and a flat flame formed by using LPG as fuel and air as a combustion-supporting gas in the burner, Burn silane for detoxification treatment. At this time, a high-temperature exhaust gas of about 1000 degrees Celsius occurs from the combustion chamber at a rate of 800 liters per minute.

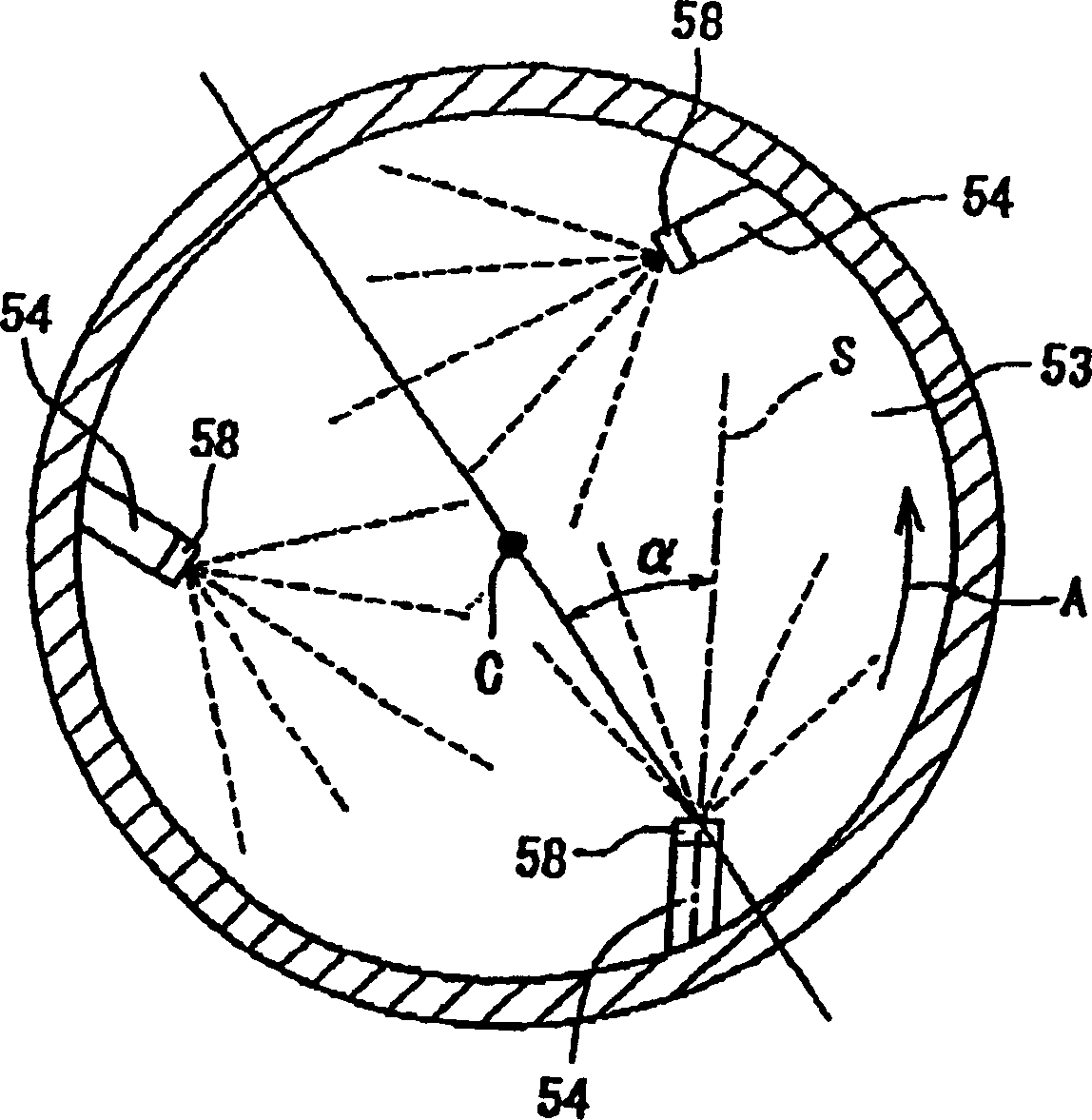

[0077] Here, using the cooling device of the aforementioned first preferred embodiment in which the spray axis of the spray nozzle 54 is arranged toward the center of the cooling chamber, the aforementioned high-temperature exhaust gas is cooled with 5 liters of water per minute, and discharged from the cooling chamber. The temperature of the gas discharged from the gas discharge unit is about 73 degrees Celsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com