Fabric suspension three-dimensional tester based on grating stripe method

A technology of grating stripes and testers, which is applied in the field of three-dimensional dynamic and static drape test and fabric drape three-dimensional tester, can solve the problems of inability to fully reflect fabric drape characteristics, inappropriate assumptions, large drape coefficients, etc., and improve the measurement of drape repeatability The effect of high performance and automation, elimination of human error, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

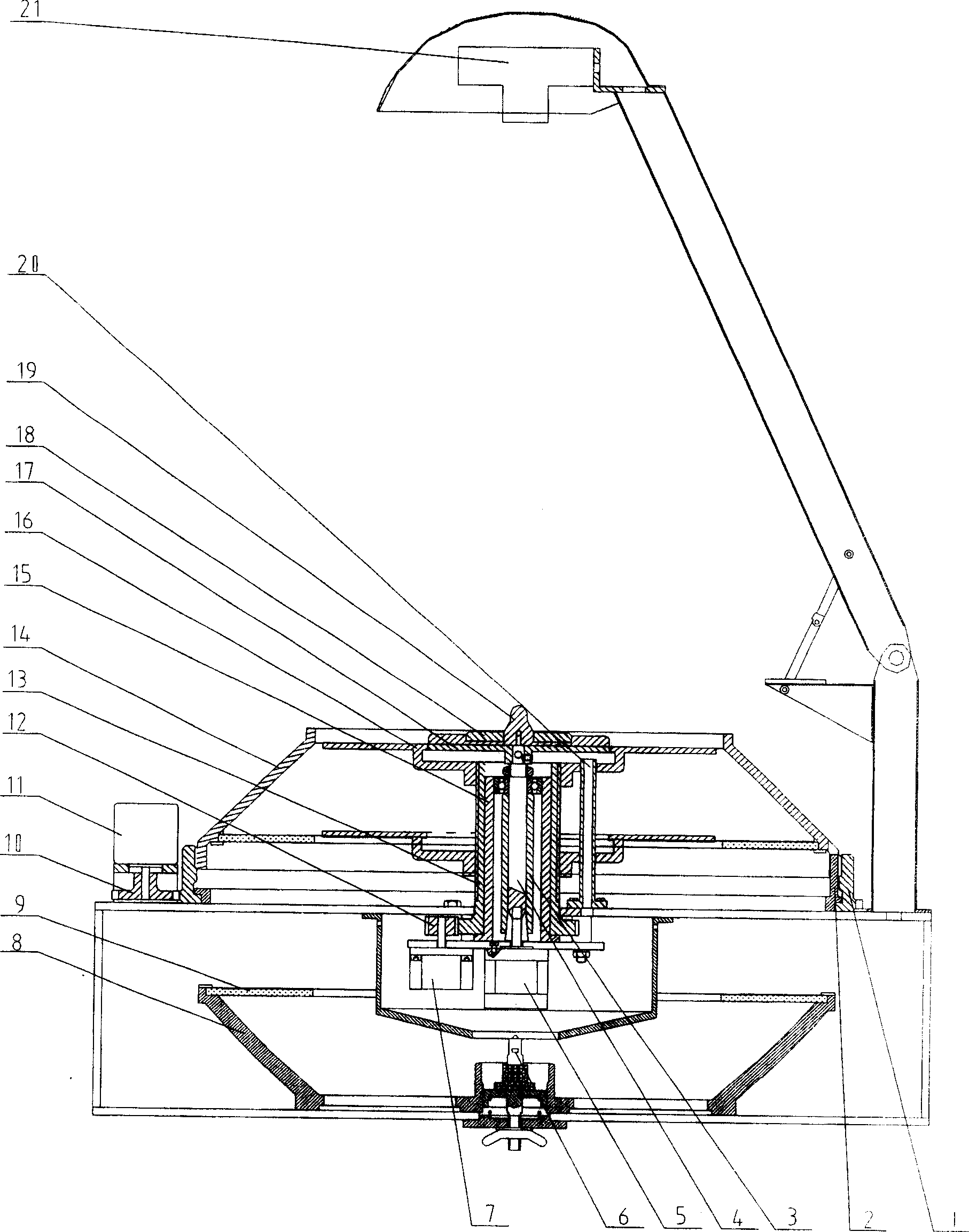

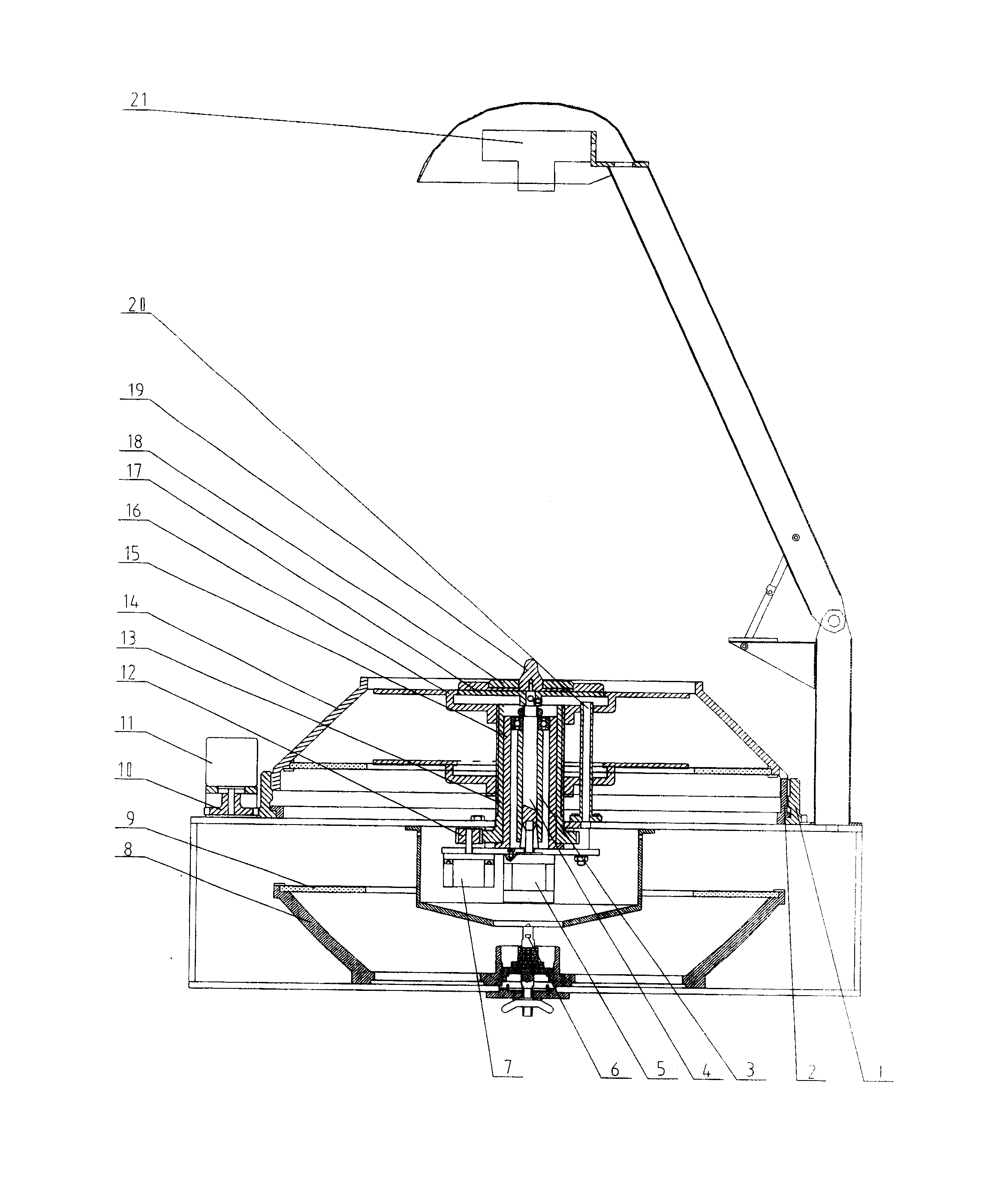

[0016] figure 1 is an embodiment of the present invention. Such as figure 1 As shown, the embodiment of the present invention is: a fabric drape three-dimensional tester based on the grating stripe method, including a toothed nut 1, a stop rod 2, a shaft sleeve 3, a shaft 4, a sample rotation stepping motor 5, and a point light source 6 , lifting platform stepping motor 7, annular paraboloid 8, grating template 9, gear 10, stepping motor 11, gear 12, lifting screw 13, annular reflective cone 14, bearing outer sleeve 15, lifting platform 16, rotating platform 17 , magnet 18, upper cover 19, anti-rotation rod 20, image acquisition device 21, it is characterized in that the present invention is made up of four systems: main transmission system, lifting system, optical system, image acquisition system, main transmission system comprises axle sleeve 3 , shaft 4, sample rotating stepping motor 5, rotating platform 17, magnet 18, upper cover 19, the shaft end of the sample rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com