Thermally insulating housing for cooling device

A refrigeration device and shell technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve problems such as unfavorable formation of shrinkage holes, uneven filling of thermal insulation materials, and reduced thermal insulation capacity of shells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

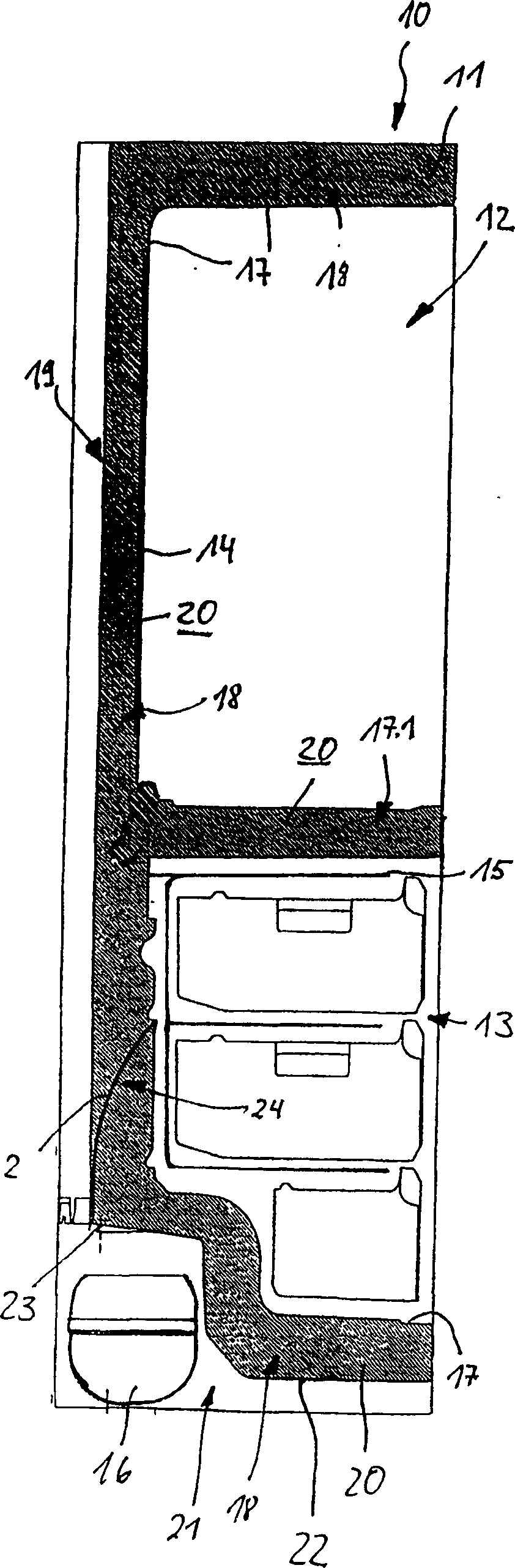

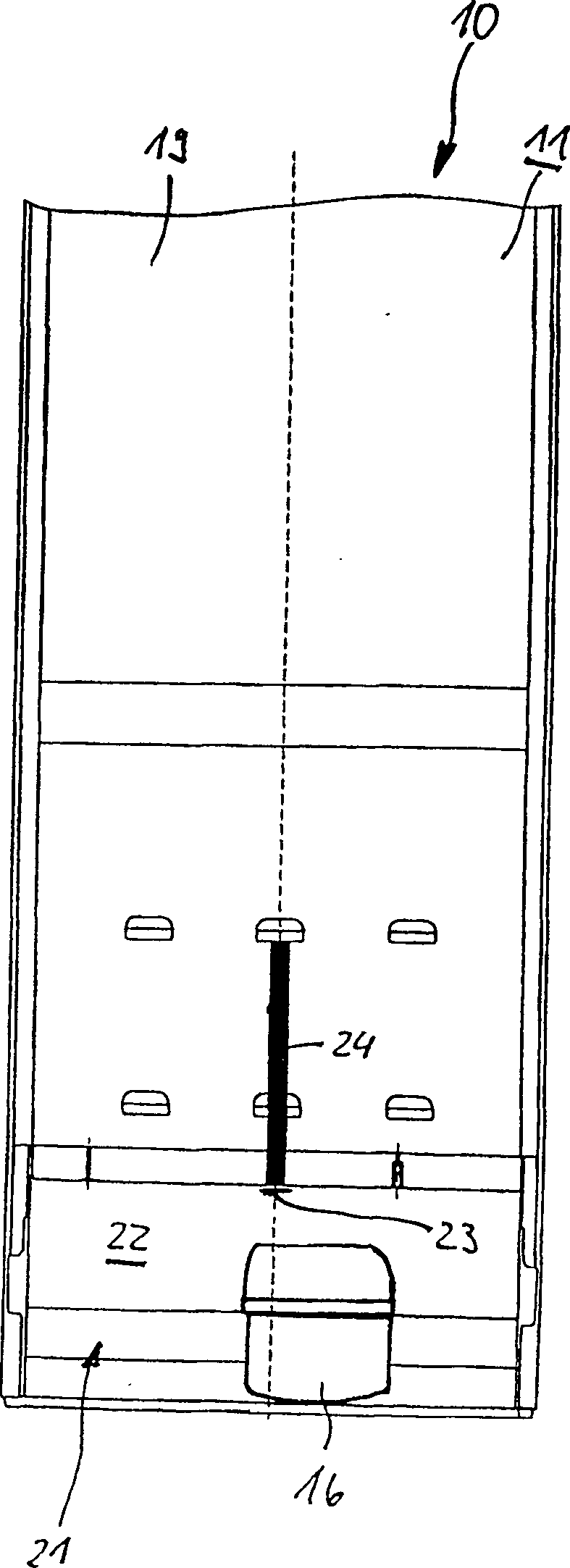

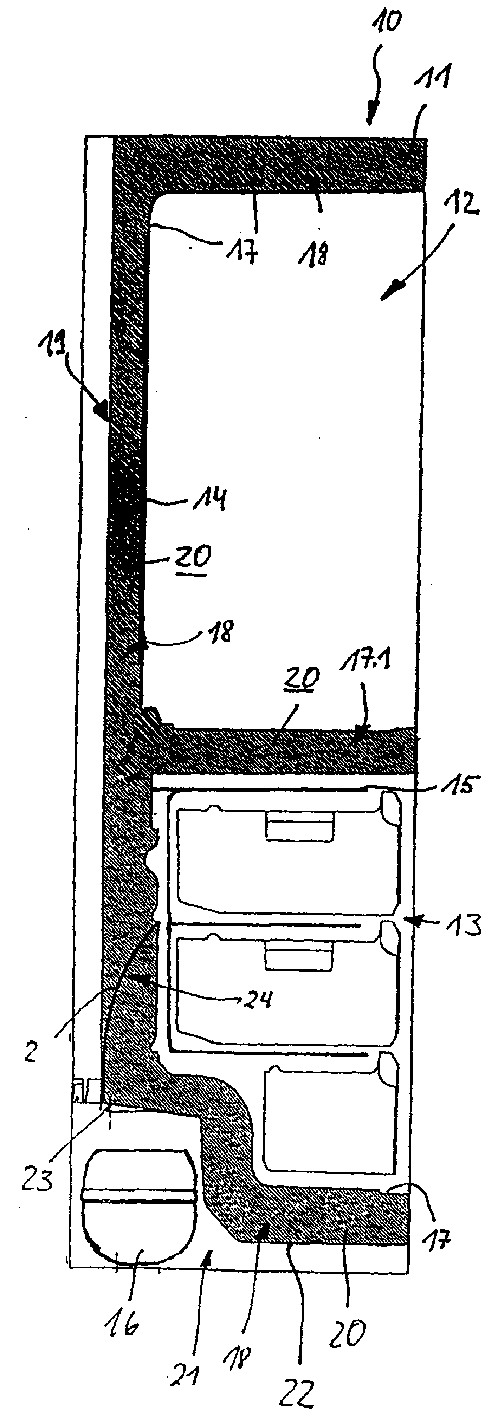

[0022] figure 1 The shown combined cooling-freezing unit 10 has a thermally insulated housing 11 in which a refrigerator compartment 12 and a freezer compartment 13 are arranged below the refrigerator compartment. Whether it is the refrigerator compartment 12 or the freezer compartment 13, they are respectively cooled by an evaporator, wherein the evaporator for cooling the refrigerator compartment 12 is in the form of a so-called cold wall plate evaporator 14; The evaporator is a coiled tube evaporator 15 with a plurality of evaporator planes, and like the cold wall plate evaporator 1, a refrigerant compressor 16 is used to input fluid refrigerant. To cover the refrigerating compartment 12 and the freezing compartment 13, an inner lining 17 formed by chip-free molding of a plastic sheet and serving as an inner cladding is provided, which in this example covers the two refrigerating compartments 12, 12, 13. Between the inner linings for the refrigerating chamber 12 or the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com