Dust collector

A technology of dust collection device and dust collection chamber, which is applied in the direction of exhaust diffusion device, vacuum cleaner, suction nozzle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A plurality of embodiments of the present invention will be specifically described below with reference to the drawings.

[0024] first embodiment

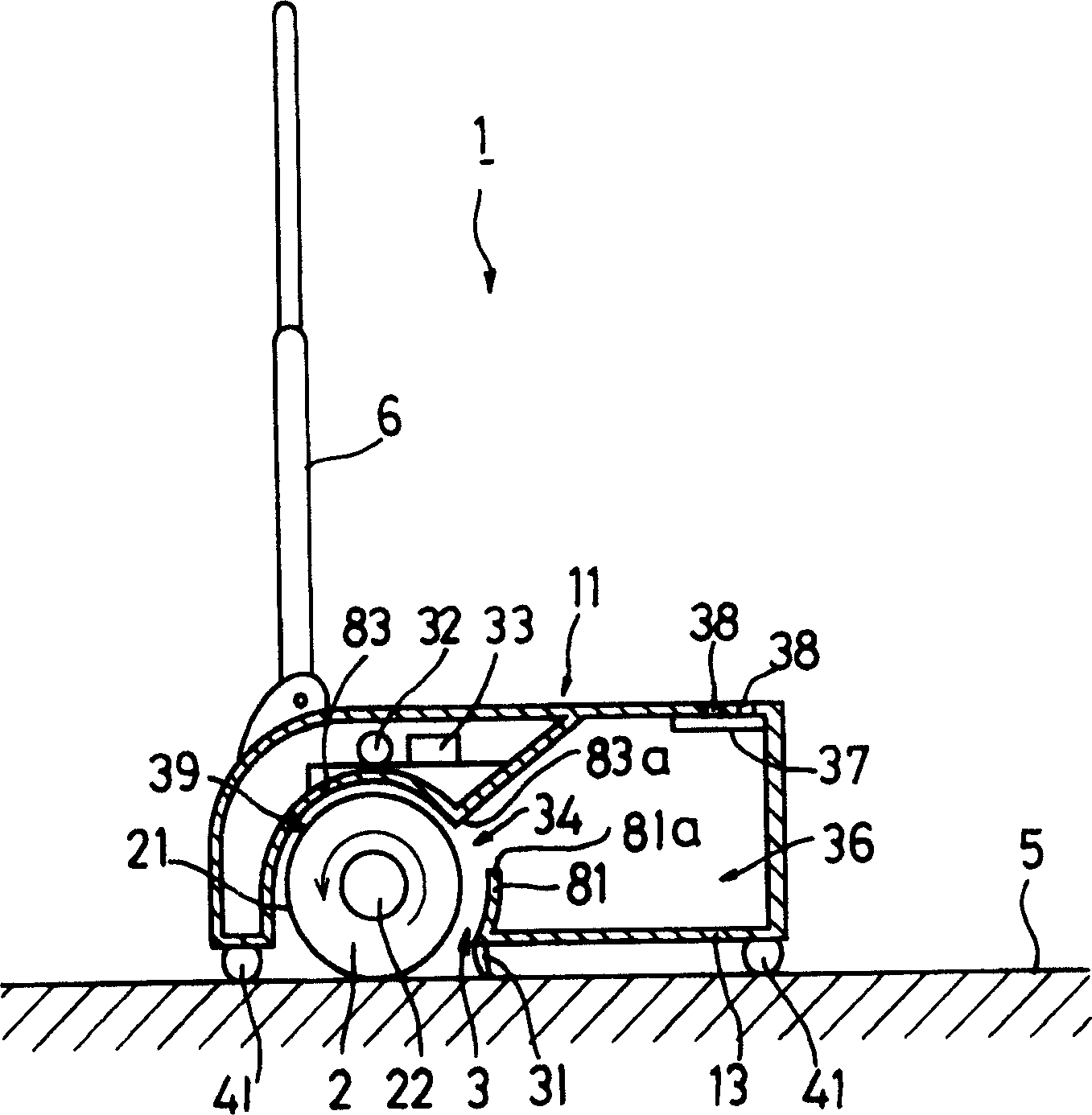

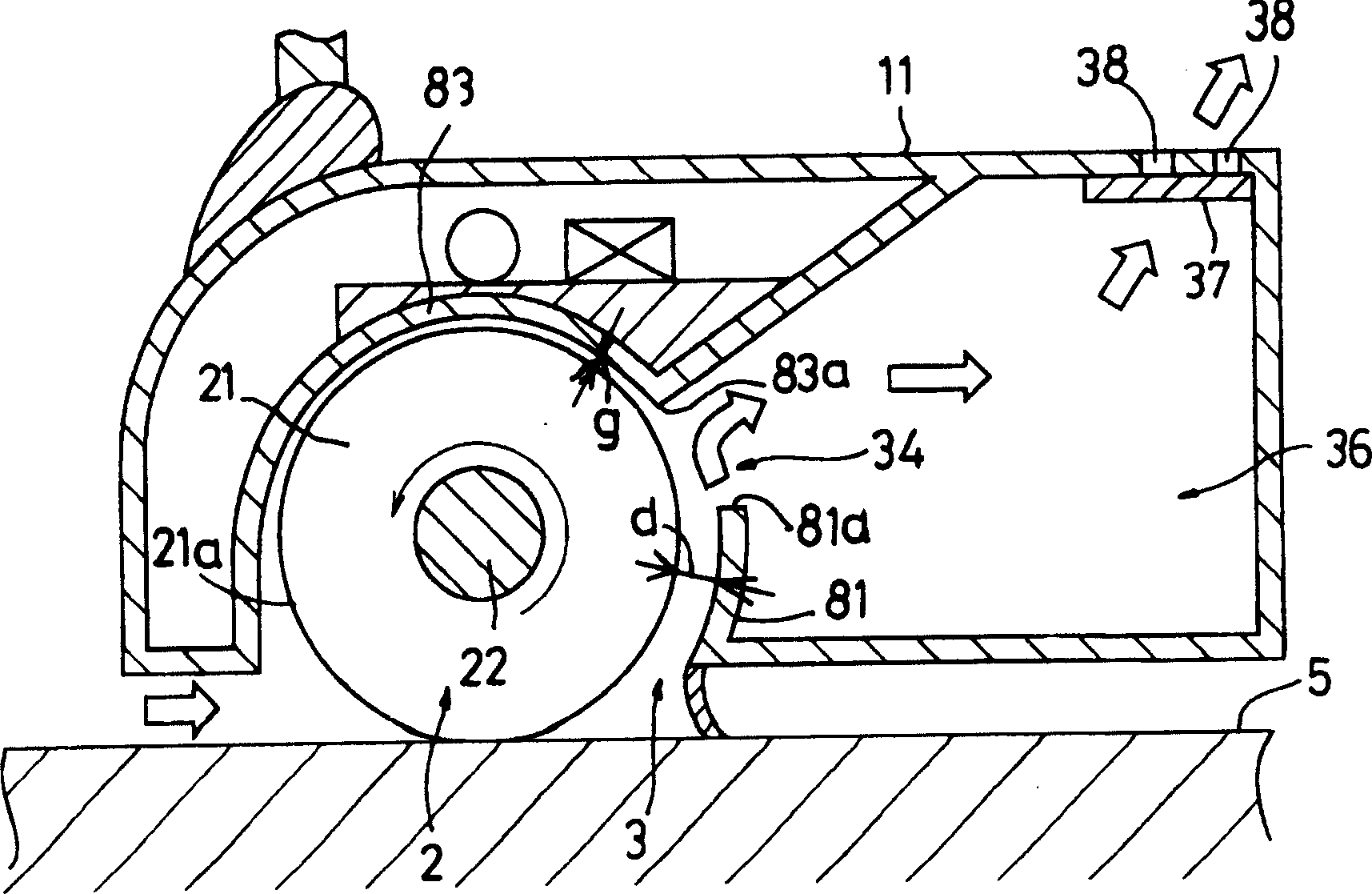

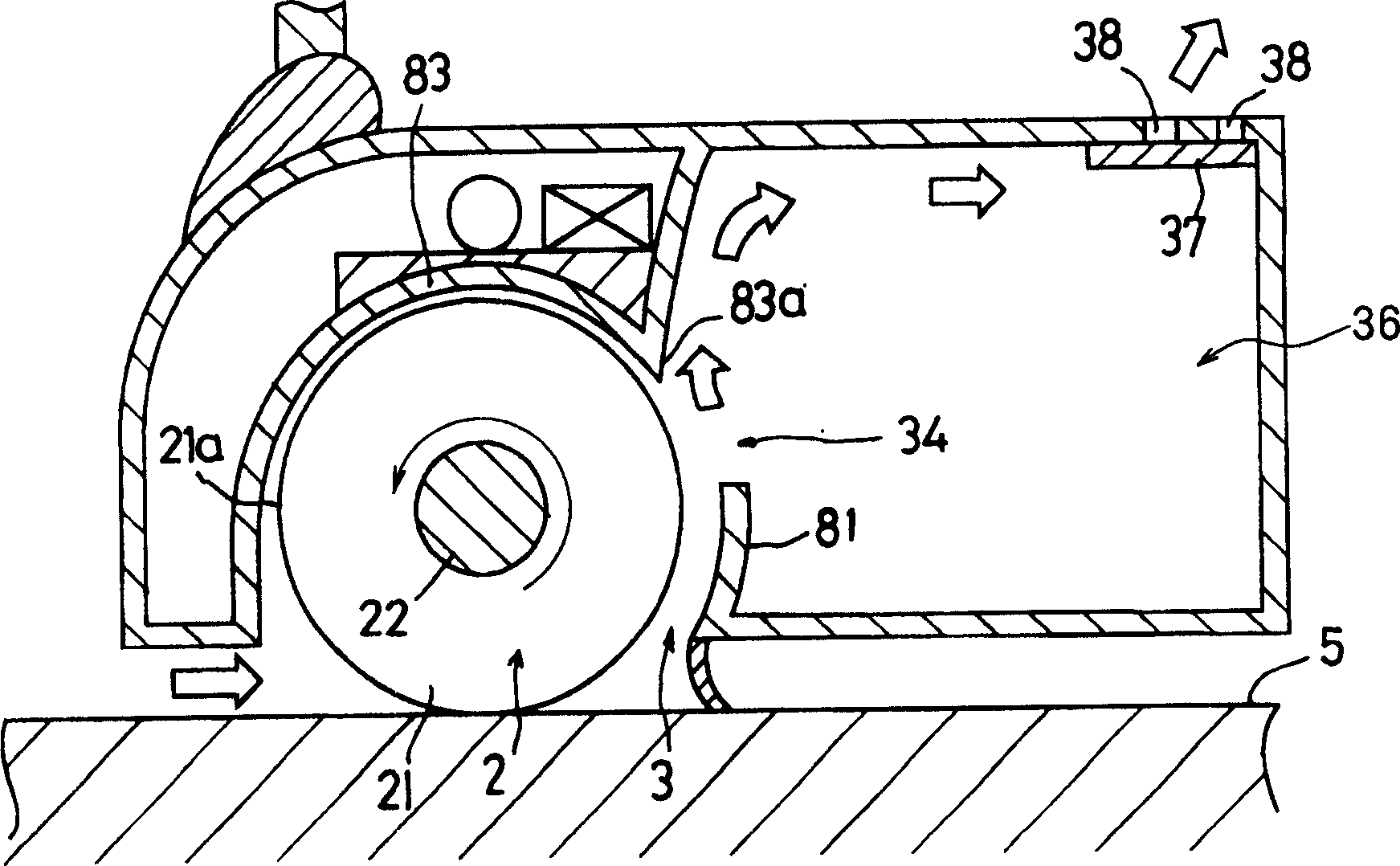

[0025] Such as figure 1 As shown, the dust collecting device of this embodiment has a housing (11) and a rotating brush (2) accommodated in the housing (11), and an operating handle (6) is installed on the upper surface of the housing (11). In the inside of the casing (11), a rotating brush housing chamber (39) for accommodating the rotating brush (2), a dust collection chamber (36) for accumulating dust, and accommodating and generating power for rotating the rotating brush (2) are formed. A motor (32), and a secondary battery (33) that supplies electric energy to the motor (32). The rotating brush (2) has a rotating shaft (22) and a brush portion (21) formed on the outer peripheral surface of the rotating shaft (22), and one end of the rotating shaft (22) is connected to the motor (32) to the motor (32) via a belt in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com