Powder distributor

A powder and object technology, applied in the field of powder dispersing devices, can solve the problems of reducing the powder dispersing effect, falling powder, polluting the surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

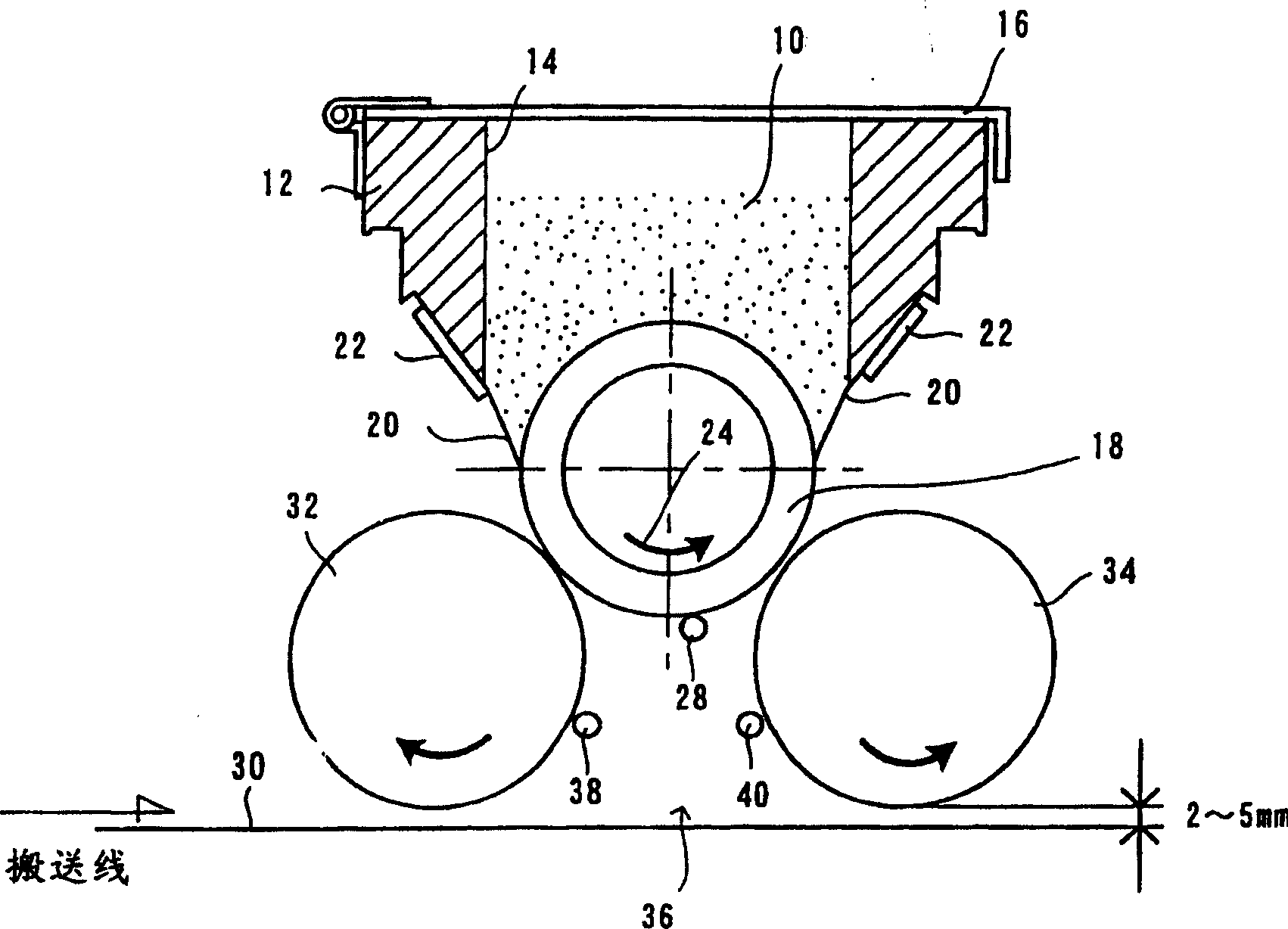

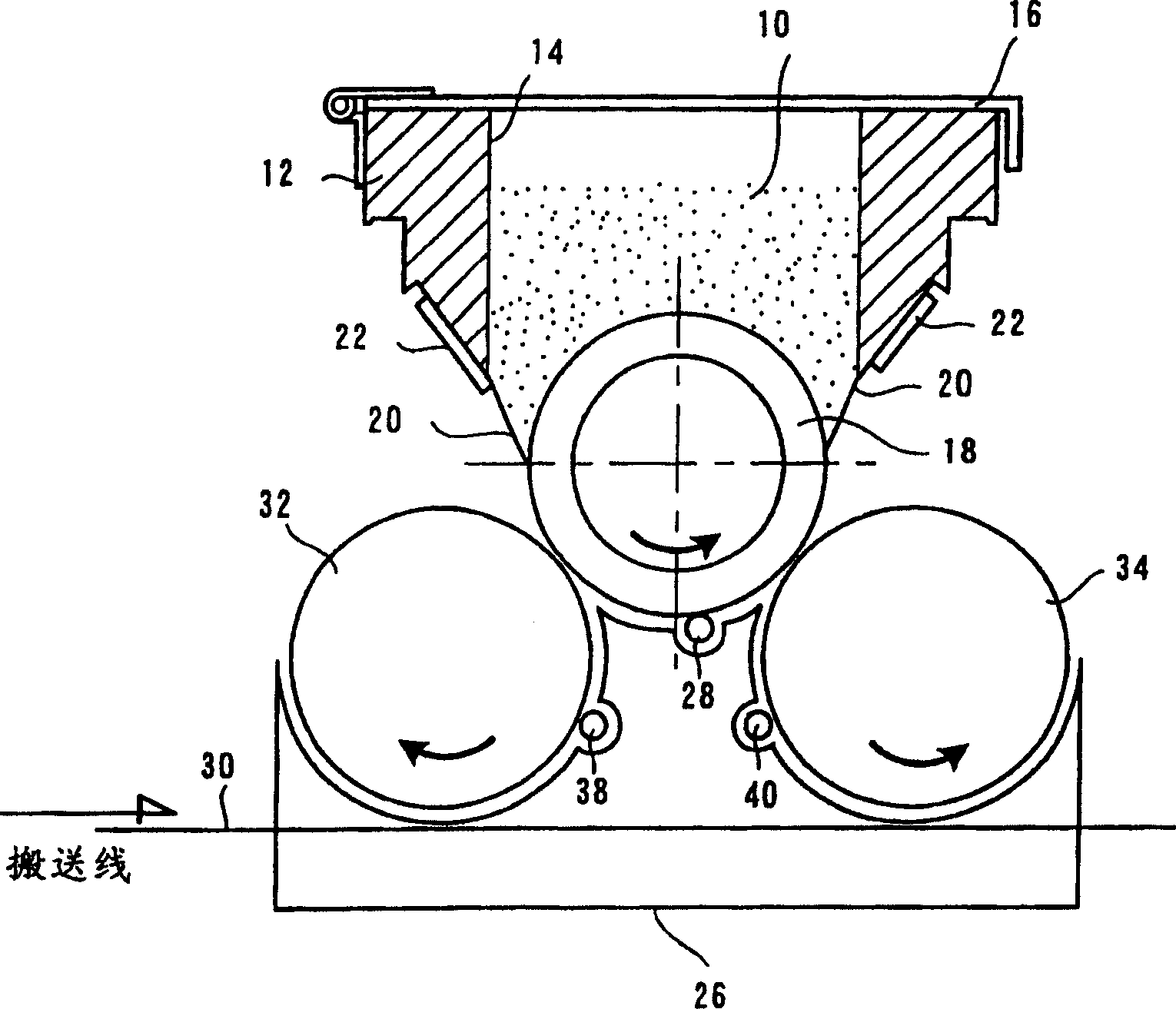

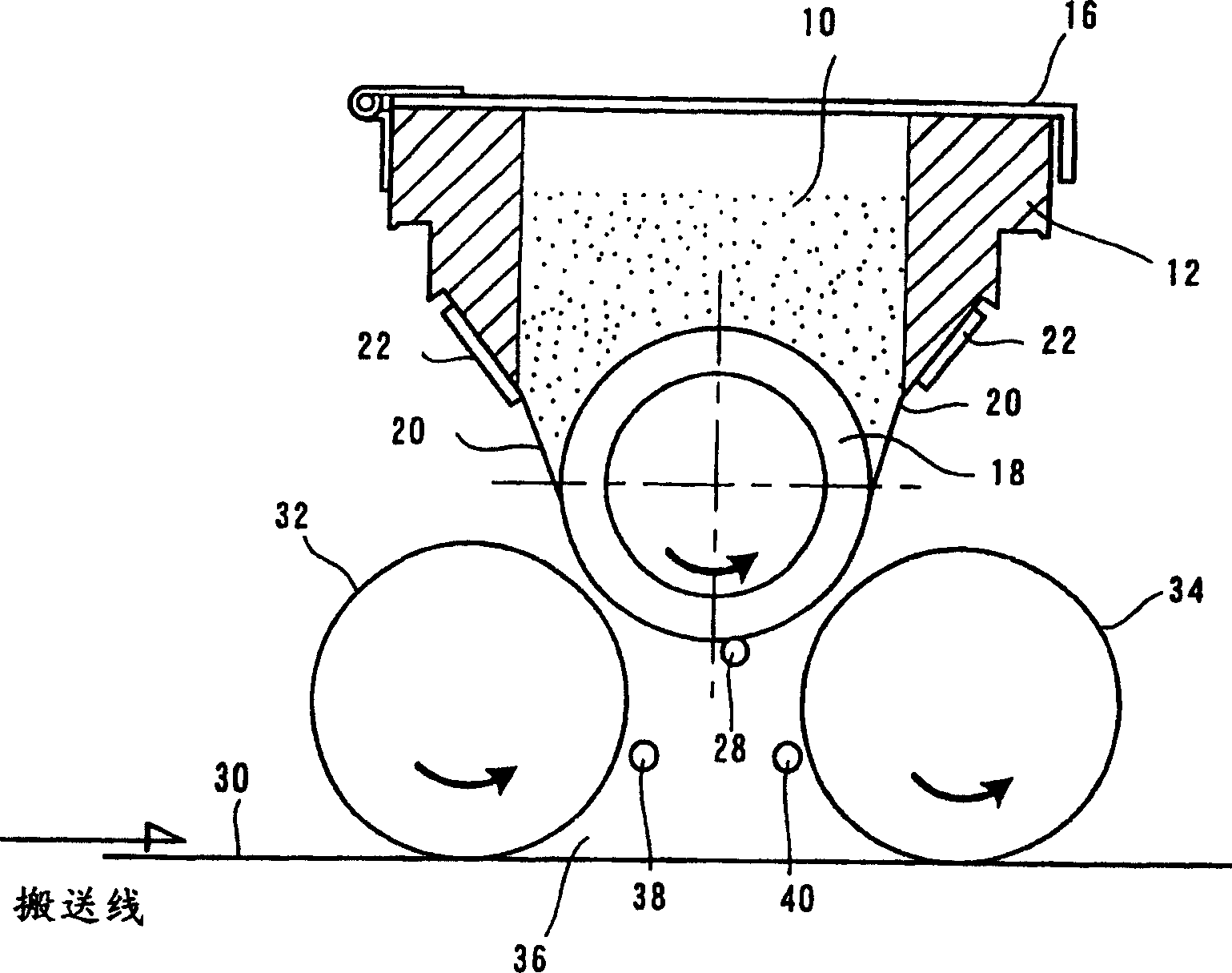

[0012] Hereinafter, specific embodiments of the powder dispersion device of the present invention will be described in detail with reference to the drawings.

[0013] Figure 1 ~ Figure 2 It is a sectional view and an end view of the powder dispersion device according to the first embodiment of the present invention. As shown in the figure, the powder dispersing device of this embodiment has a powder storage tank 12 capable of storing powder 10 such as starch and dispersing the stored powder 10 from the lower part thereof. More specifically, the inside of the powder storage tank 12 is formed with a receiving space 14 with a rectangular cross-section, and a cover 16 is provided on the top thereof so as to prevent the placed powder 10 from flying outside. In addition, a spreading roller 18 having a diameter smaller than the width of the storage space 14 is horizontally provided at the lower rectangular opening of the storage tank 12 so that the lower half thereof is exposed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com