Modified lignocellulose separator for lithium ion battery and its preparation method and application

A technology of lignocellulose and lithium-ion batteries, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve problems such as high production costs, poor electrochemical performance of batteries, and cumbersome production techniques, and achieve stable Electrochemical properties, overcoming poor thermal stability, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

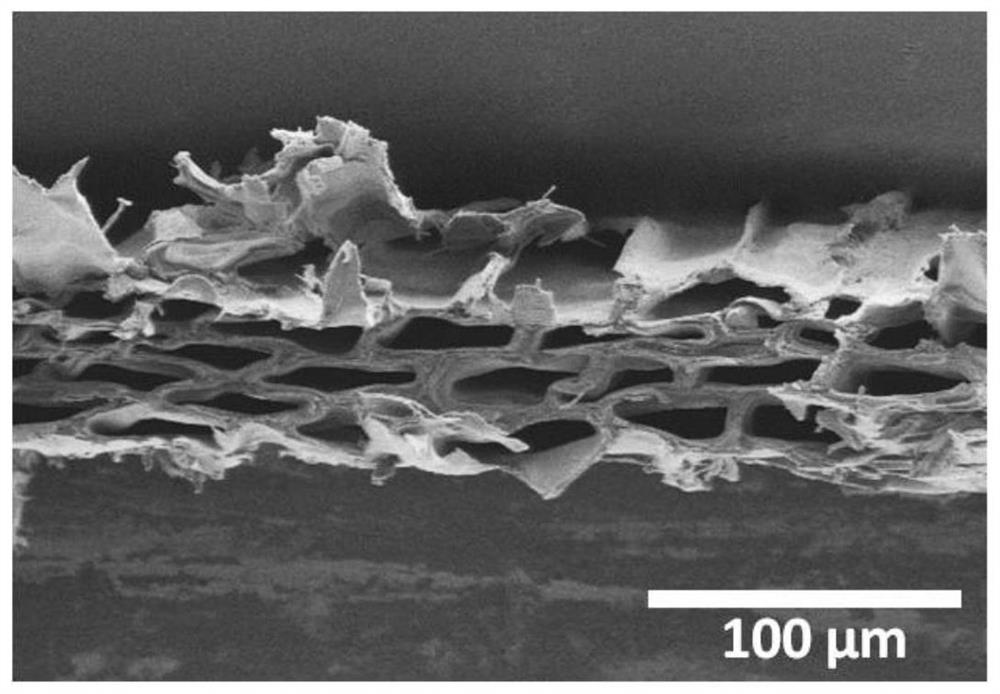

[0041] A lithium ion battery with a modified natural lignocellulose diaphragm, the specific preparation method is as follows:

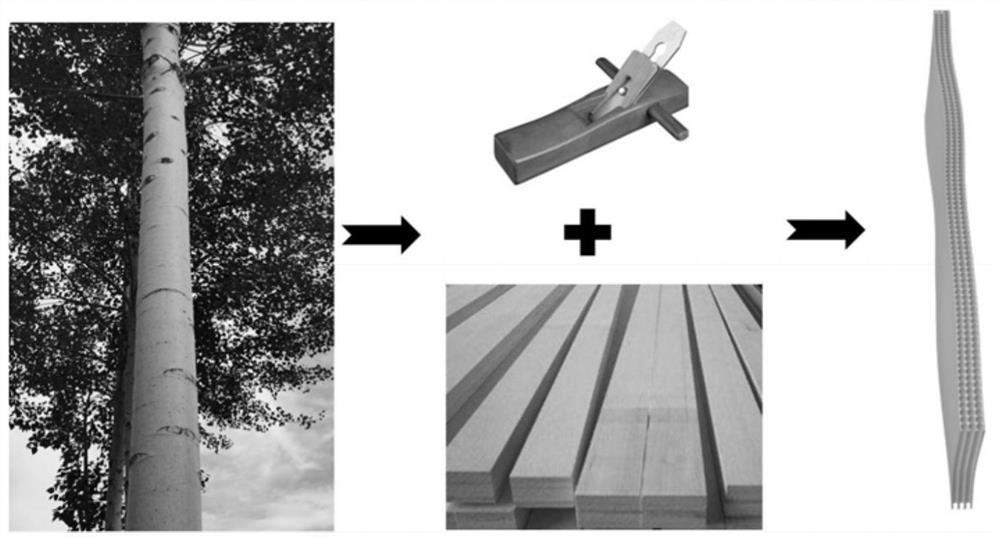

[0042] (1) Thinning the pre-selected poplar wood to a film with a thickness of 50 μm, the schematic diagram of the preparation process is as follows figure 1 shown;

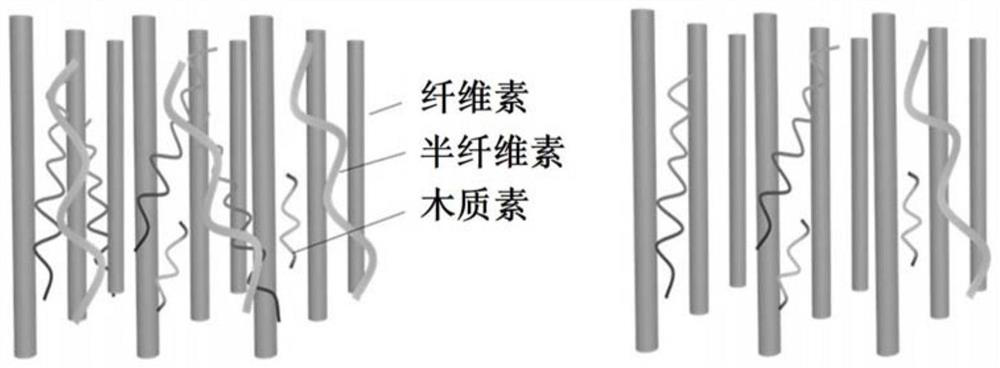

[0043] (2) The natural wood film obtained above is pretreated in an alkaline solution, and the specific process is as follows: 3 g of potassium hydroxide is dissolved in 60 mL of deionized water, stirred for 10 min to obtain a uniform solution; then 2 g of sodium sulfite is weighed and added to the above solution , after stirring for 10 min, a homogeneous solution was obtained. Then immerse the natural wood film in the above solution, place it in a vacuum oven, and under negative pressure, make the mixed alkali solution fully soak the wood film, take it out after half an hour, transfer it to the reaction kettle, and take it out after reacting at 100°C for 5 hours. Wash with deionized w...

Embodiment 2

[0056] A lithium ion battery with a modified natural lignocellulose diaphragm, the specific preparation method is as follows:

[0057] (1) Thin the pre-selected basswood to about 150μm.

[0058] (2) The basswood film obtained above is pretreated in alkaline solution, and the specific process is as follows: in 90ml deionized water, add 6g potassium hydroxide and dissolve in 90mL deionized water, stir for 30min to obtain a uniform solution; then weigh Add 4.5 g of sodium sulfite to the above solution, and stir for 30 minutes to obtain a homogeneous solution. Then submerge the natural wood film in the above solution, place it in a vacuum oven, and under negative pressure, make the mixed alkali solution fully soak the wood diaphragm, take it out after half an hour, transfer it to the reaction kettle, and take it out after reacting at 120°C for 12 hours , repeatedly washed with deionized water until neutral. Clamp it with a glass sheet at room temperature, and gradually dry it sl...

Embodiment 3

[0063] A lithium ion battery with a modified natural lignocellulose diaphragm, the specific preparation method is as follows:

[0064] (1) Thinning the pre-selected natural pine wood to about 300μm.

[0065] (2) The above-mentioned natural wood film is pretreated in an alkaline solution, and the specific process is as follows: 8g of potassium hydroxide is dissolved in 120mL of deionized water, stirred for 60min to obtain a uniform solution; then 8g of sodium sulfite is weighed and added to the above solution, stirred After 60 min, a homogeneous solution was obtained. Then submerge the natural wood film in the above solution, place it in a vacuum oven, and under negative pressure, make the mixed alkali solution fully soak the wood diaphragm, take it out after half an hour, transfer it to the reaction kettle, and take it out after reacting at 140°C for 24 hours , repeatedly washed with deionized water until neutral. Clamp it with a glass sheet at room temperature, and graduall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com