Mother crimp terminal

A technology of crimping terminals and terminal cavities, which is applied in the direction of connections, contact parts, parts of connection devices, etc., which can solve the problems of increased insertion resistance and inability to insert the shell, and achieve shortened front and rear lengths, ensure strength, and prevent bending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

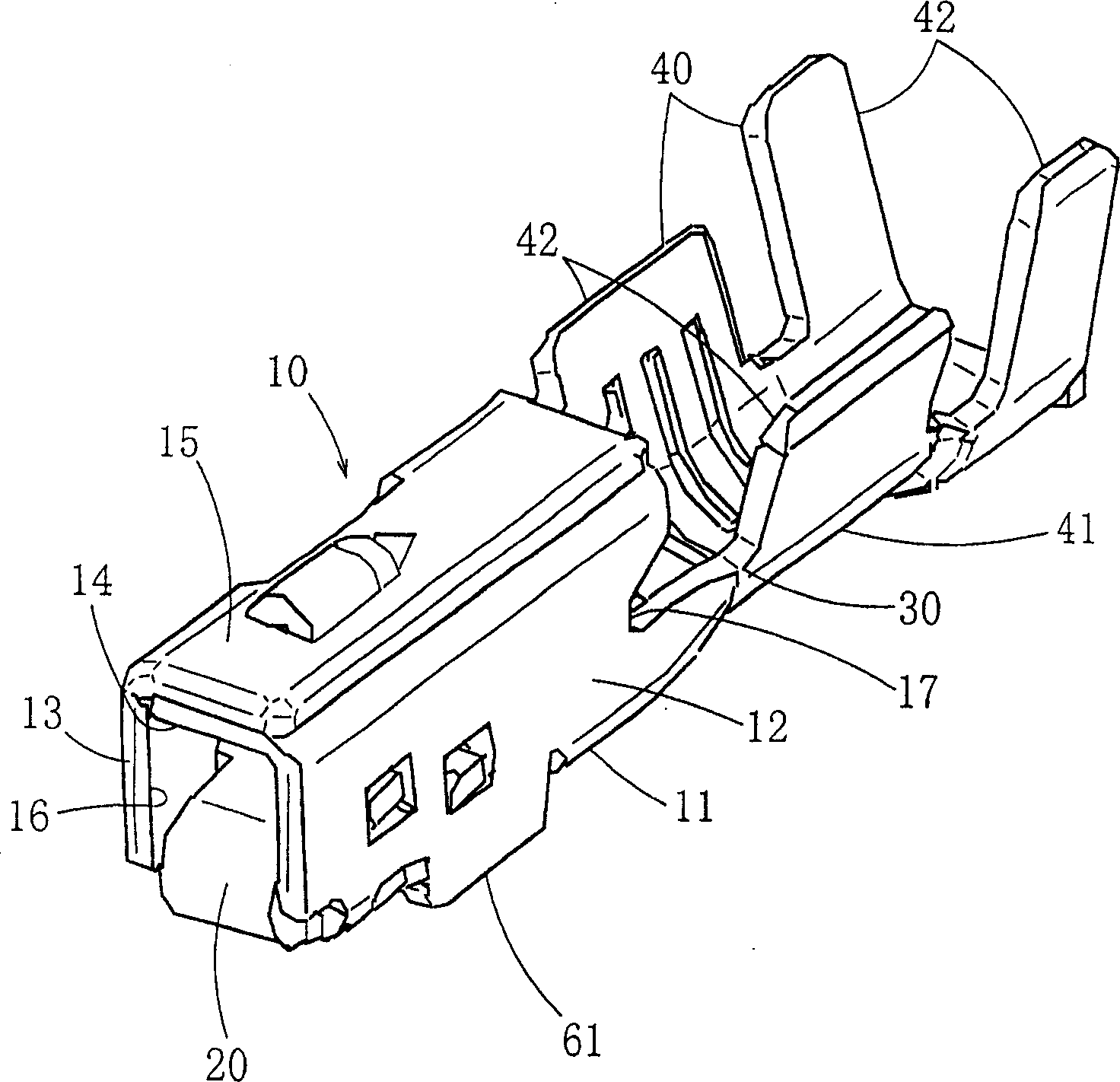

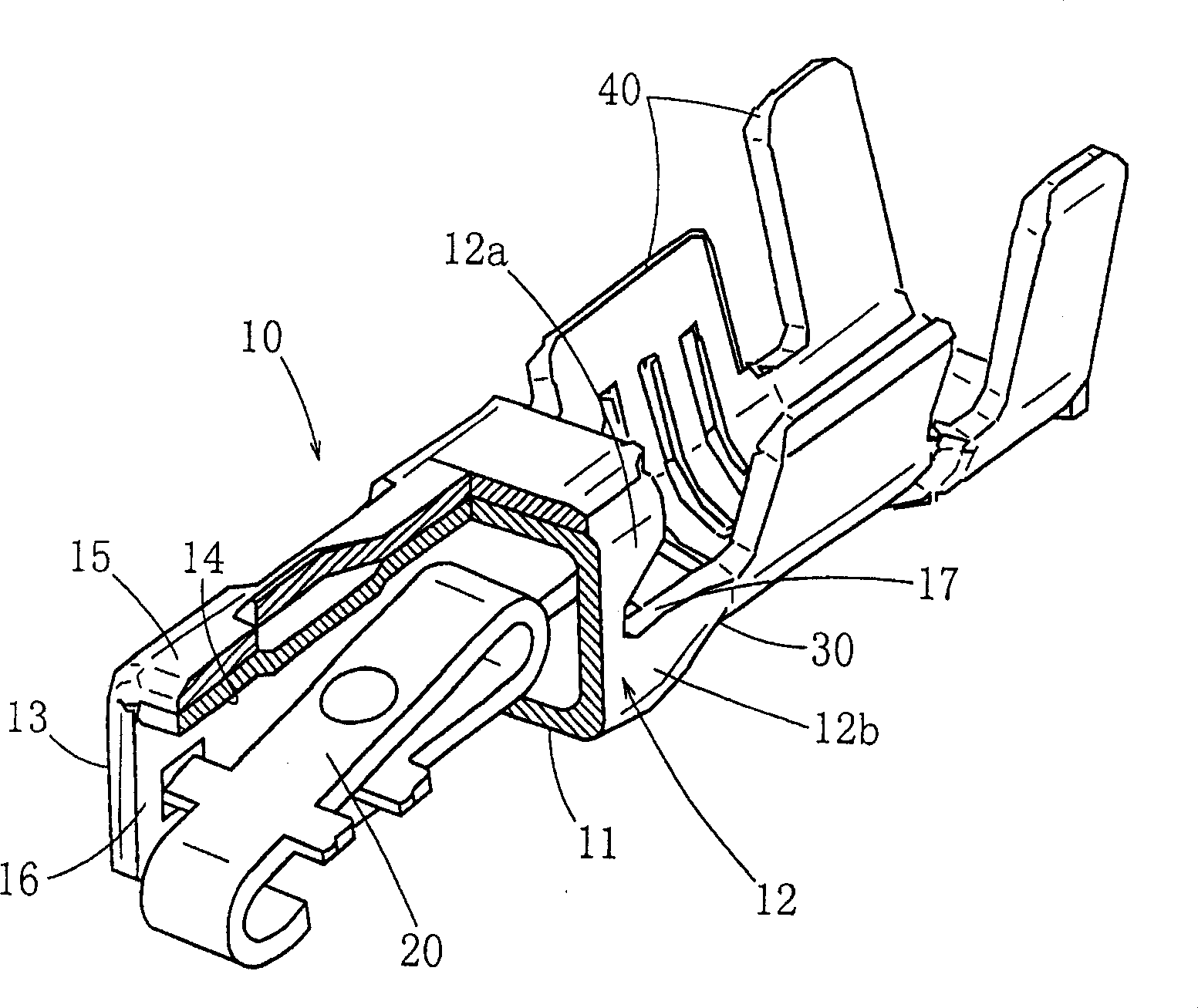

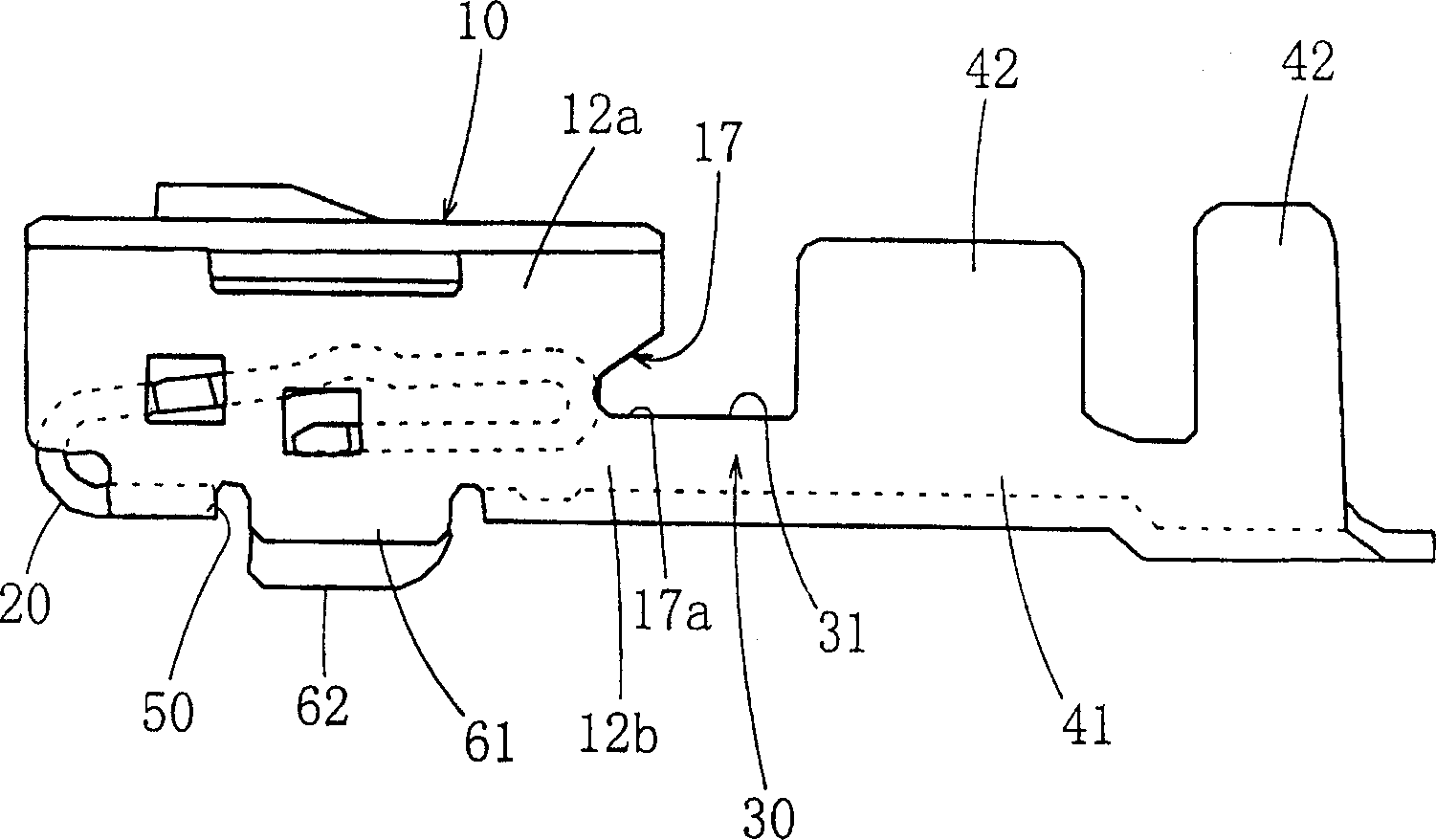

[0013] Embodiments of the present invention will be described below with reference to the drawings. Figure 1 ~ Figure 4 is the female crimp terminal of the shown example.

[0014] This female crimp terminal includes a cylindrical case 10 into which a male terminal is inserted through a front opening 16 , and a leaf spring 20 arranged inside the case 10 . The casing 10 has: a bottom wall portion 11, side wall portions 12, 13 standing up from both ends in the width direction of the bottom wall portion 11, and an upper wall extending sideways from the upper ends of the side wall portions 12, 13. Section 14, 15. The opening 16 is formed at the front end by each wall portion 1115 . In the case of this embodiment, the housing 10 is formed by bending a sheet. The first upper wall portion 14 extends sideways from the upper end of the side wall portion 12 on one side, and the second upper wall portion 15 extends sideways from the upper end of the side wall portion 13 on the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com