Method for detecting diesel-engine water-pump flow and preventing from overloading, and apparatus thereof

A technology of water pump flow and diesel engine, applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effect, flow control, etc. The effect of reducing workload and responding accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

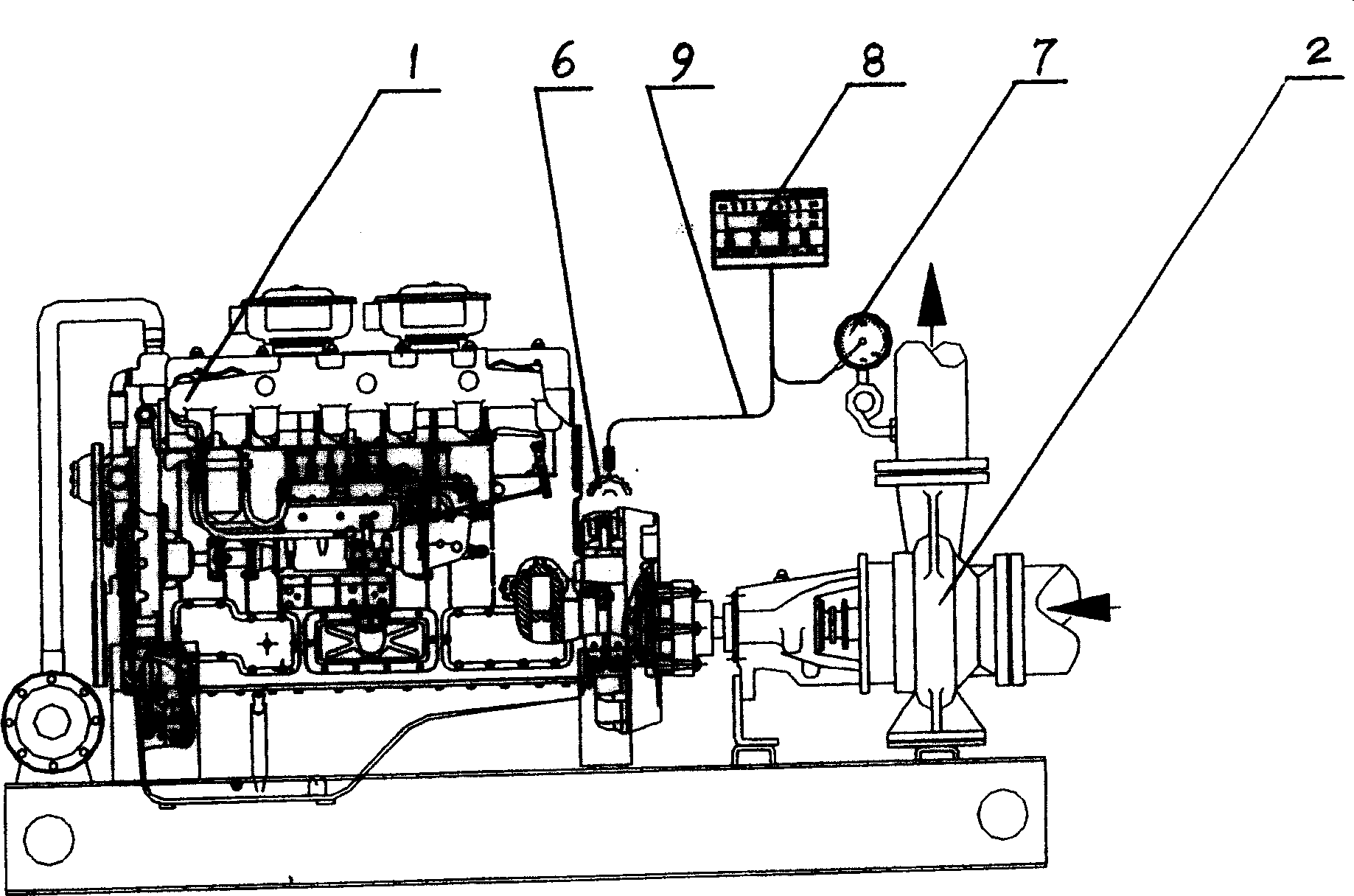

[0025] Such as image 3 As shown, the device of the present invention for detecting the flow rate of a diesel water pump and preventing overload is composed of a control computer 8, a speed sensor 6, and a pressure sensor 7. The speed sensor 6 is installed on the main shaft of the diesel engine 1, and the pressure sensor 7 is installed at the outlet of the diesel engine water pump 2. At , the speed sensor 6 and the pressure sensor 7 are connected to the control computer 8 through the data link 9 .

[0026] When the speed of the device is constant, its head / flow / shaft power will be formed as follows: Figure 4 As shown in the curve, the curve parameters: speed n=1450 rpm, power p=78kw, head H=70 meters, flow Q=70 liters / second, speed n1=1450 revolutions / min, speed n2=1400 revolutions / min; according to the following mathematical relationship: Q 2 =(n 2 / n 1 ) Q 1 、H 2 =(n 2 / n 1 ) 2 h 1 ,P 2 =(n 2 / n 1 ) 3 P 1 Calculate the real-time flow value of the device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com