Pressure regulator for ink-jetting pen

A pressure regulating device and inkjet technology, applied in the field of pressure regulating devices, can solve the problems of many components, high manufacturing cost, and complexity, and achieve the effects of maintaining a negative pressure state, easy manufacturing and assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

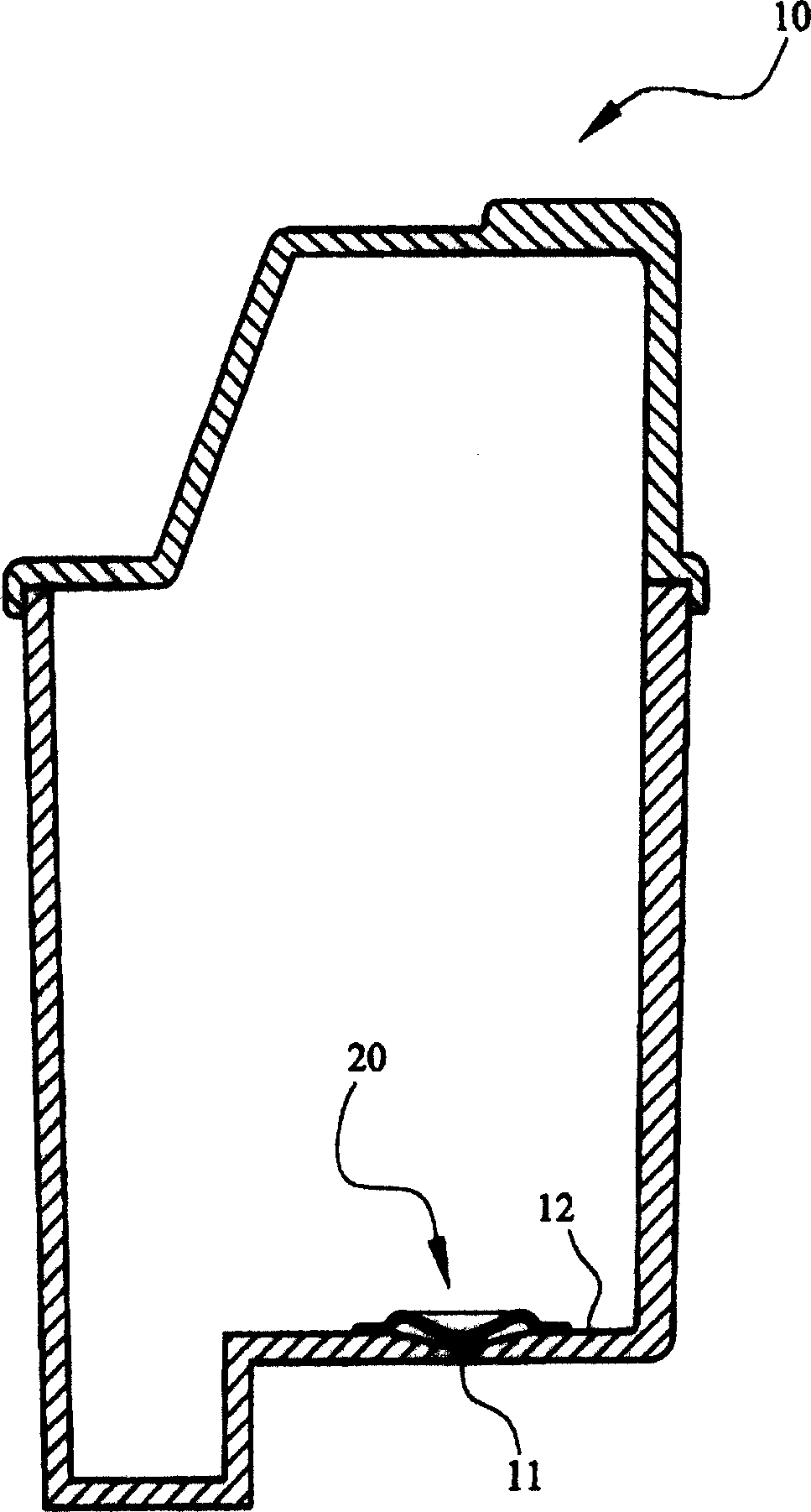

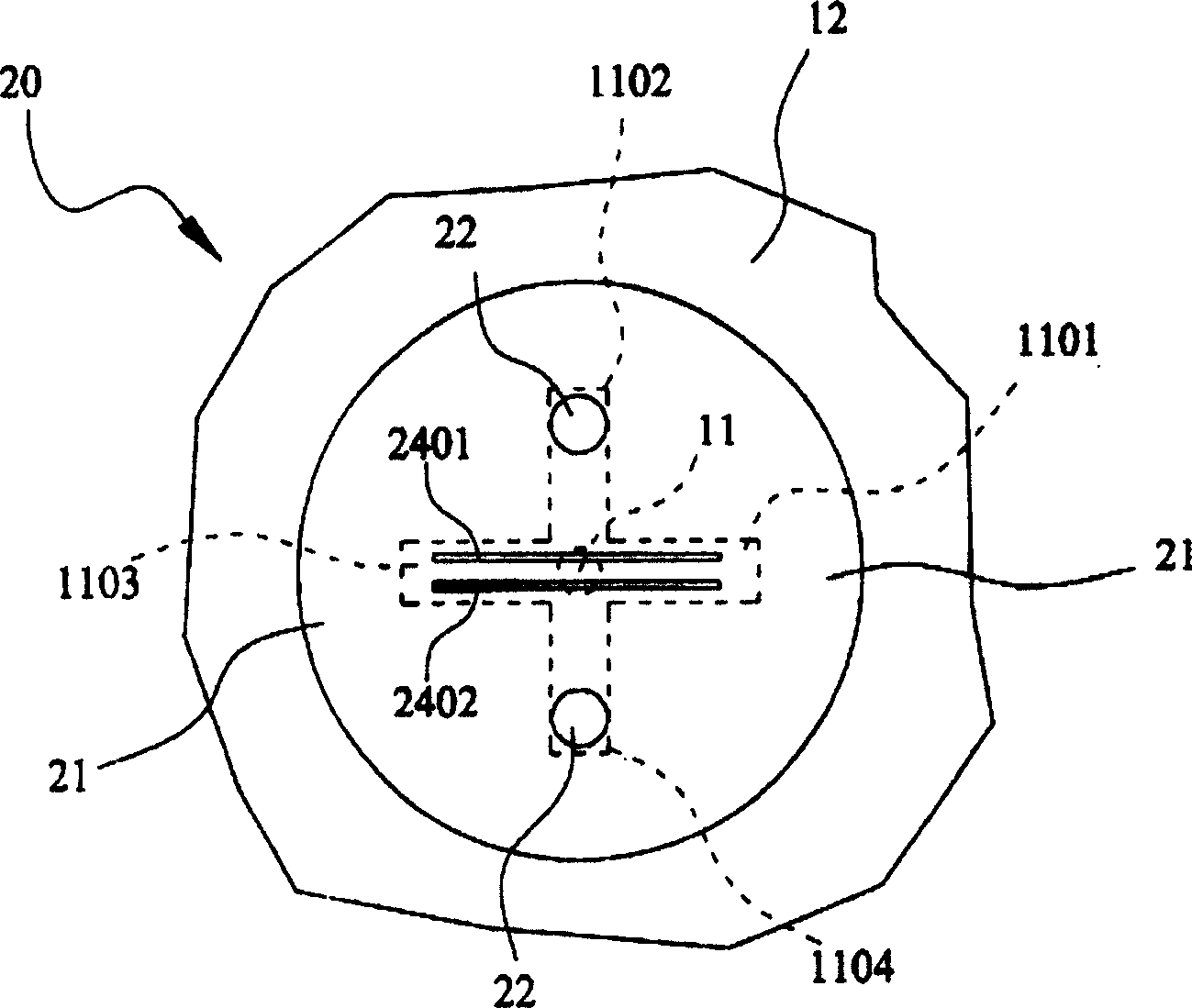

[0021] Ink in a small gap, its boundary is the main factor controlling the movement. When the ink stops moving, the shape of its free liquid boundary is determined by the surface tension of the ink and the pulling force of the ink boundary on the ink. Therefore, the final gas-liquid equilibrium interface can be determined by properly providing the gaps through which the ink flows.

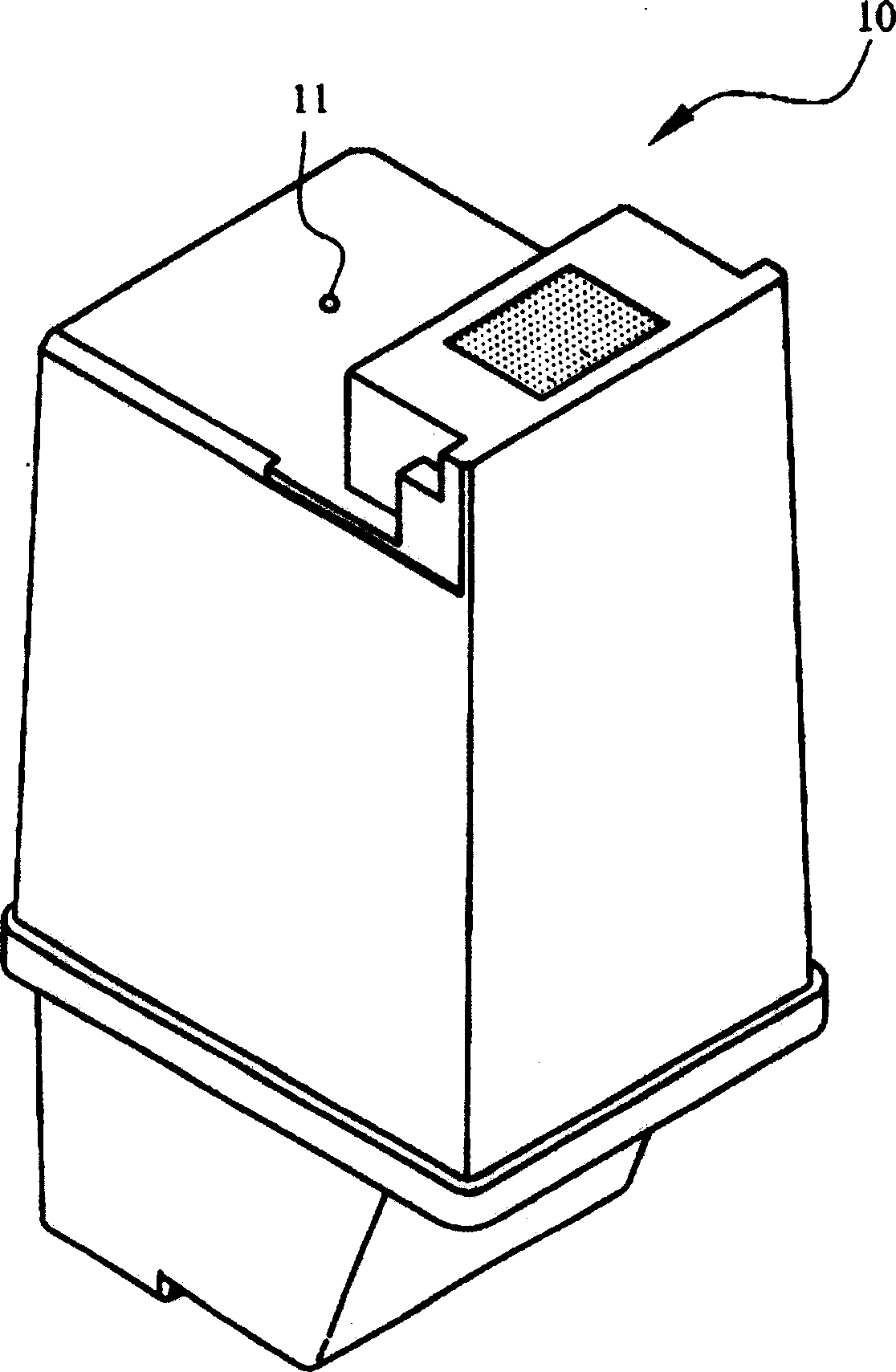

[0022] like figure 1 and figure 2 In the shown inkjet pen 10, a fine hole is provided in the wall 12 of the ink cartridge as an air passage 11 for air to enter. The pressure regulating device 20 implemented according to the present invention is arranged on the inner side of the ink cartridge wall 12 to provide appropriate gaps to guide the flow of ink and to restore the gas-liquid equilibrium interface that is damaged during air intake. When the outside air enters through the air passage 11 due to the increased negative pressure in the inkjet pen 10, the ink that originally stayed in the air pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com