Interface corrosion electrochemical measurement system and method for realizing interface stripping

A technology of interfacial peeling and measurement system, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve the problem that the theory of interfacial corrosion has not been established, it is impossible to realize the measurement of interfacial corrosion rate, phase interface stability and Insufficient precision control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings.

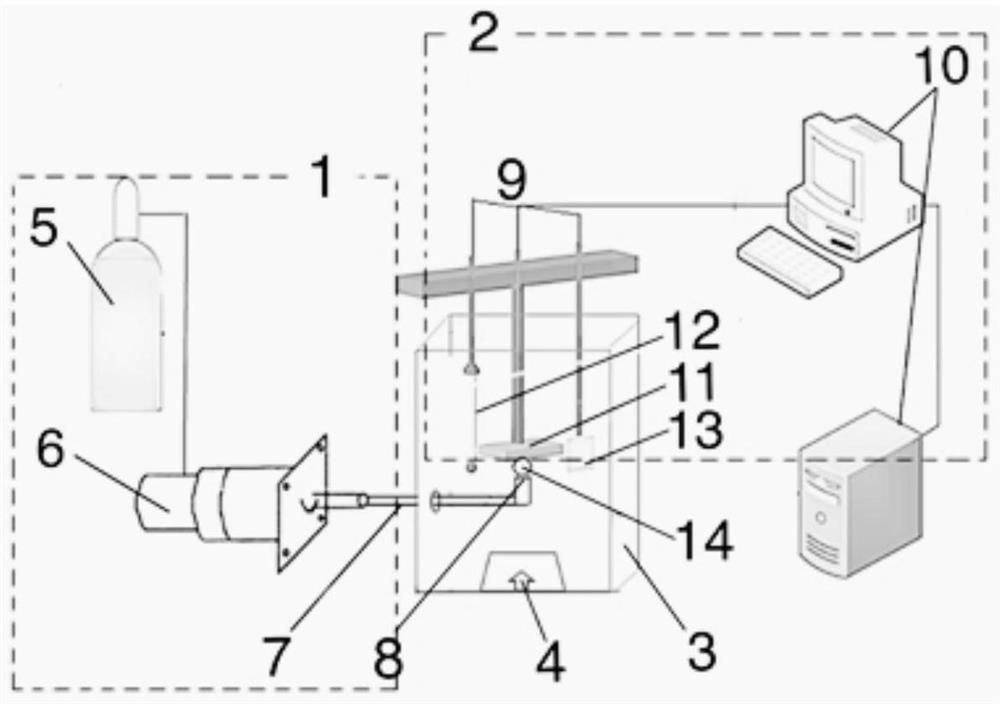

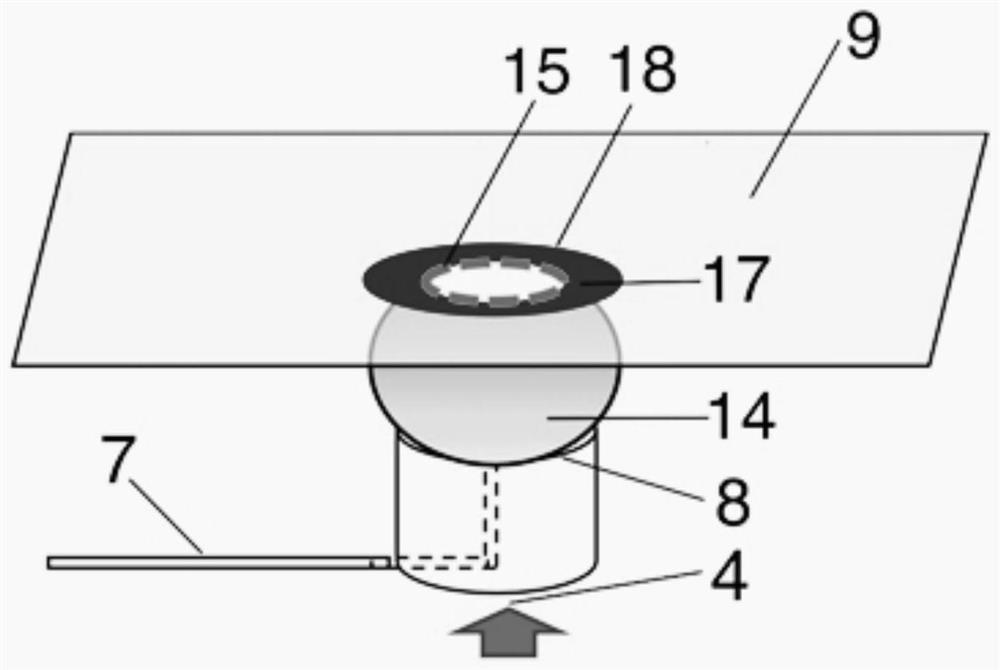

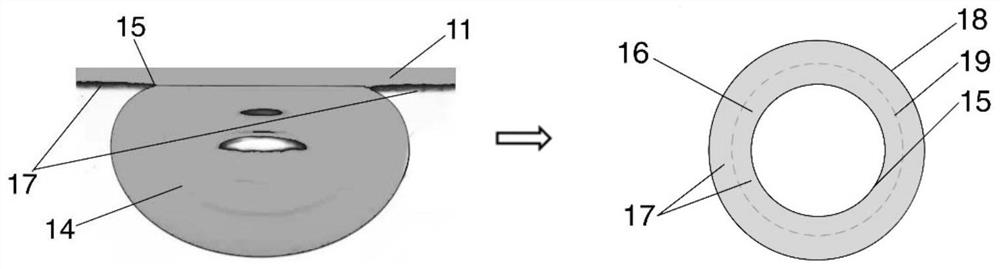

[0044] Such as figure 1 , figure 2 The shown electrochemical measurement system for interfacial corrosion research by bubbling method mainly includes four parts: bubble generation equipment 1, electrochemical measurement equipment 2, liquid storage chamber 3 and high-speed camera equipment 4. Among them, the bubble generating device 1 is composed of four parts: an adjustable pressure gas storage tank 5, a stepping motor system 6, a bubble needle 7, and a bubble contour fixing ring 8. The spacing l is smaller than the diameter of the bubble 14 to prevent the bubble 14 from drifting during the experiment. The electrochemical measurement device 3 is composed of three electrodes 9 and a data acquisition system 10, wherein the three electrodes 9 are made of an inverted metal surface as the working electrode 11, and its size is 2cm×2cm; the reference electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com