Method for regulating underwater gas by superhydrophobic copper cone and its application in pressure sensor

A super-hydrophobic, water-copper technology, applied in the measurement of fluid pressure, instruments, measurement devices, etc., can solve problems such as bubble difficulty, and achieve the effects of simple preparation method, low cost, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

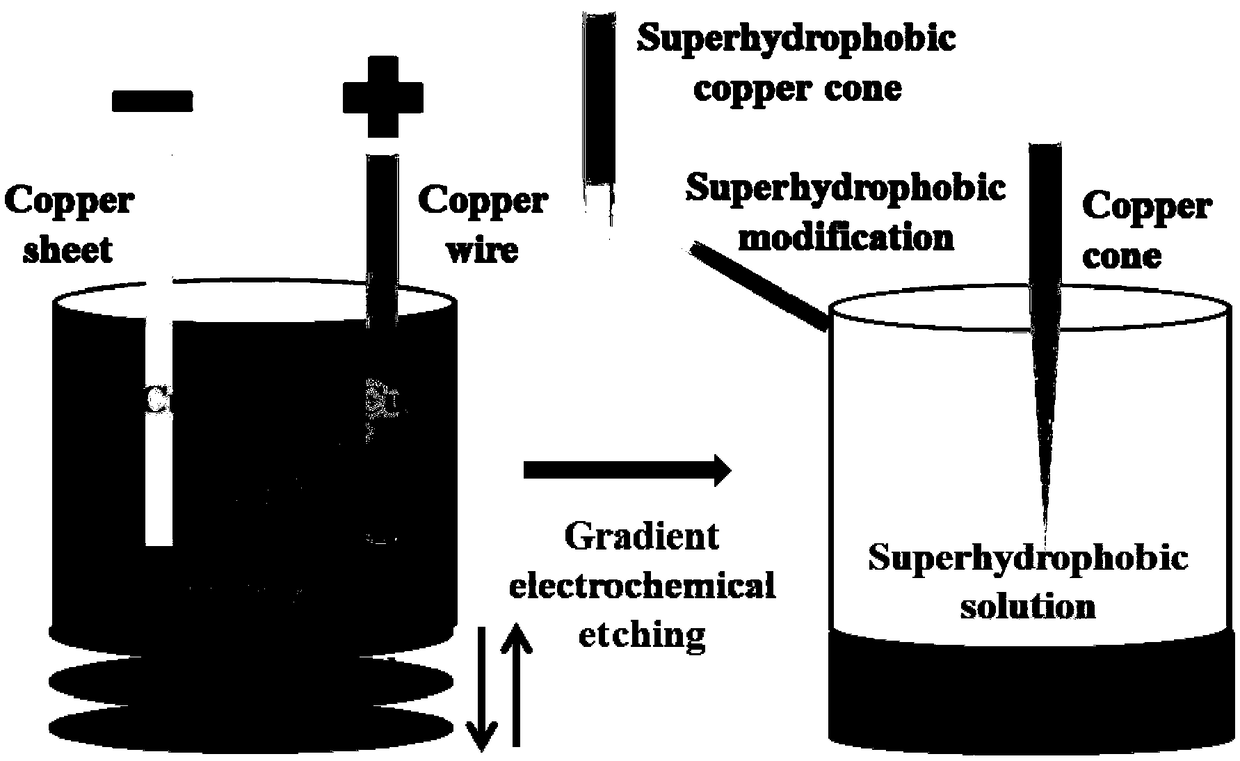

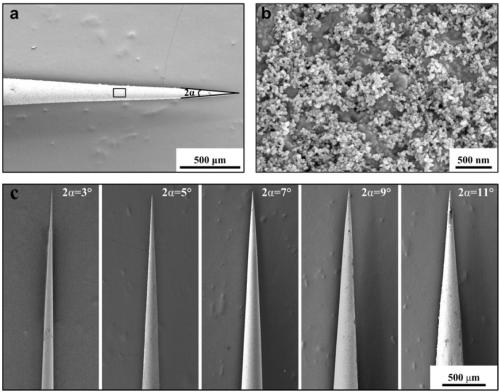

[0030] (2) Preparation of copper cone: Immerse the copper wire in (1) in a small glass tank containing 50 mL of 0.1 mol / L copper sulfate solution, use it as the anode, and use the copper sheet as the cathode, and the electrolysis voltage is 10V , fix the small glass tank on the lifting table (the lifting speed is 1.0mm / s), after about 300 cycles, the copper cone is formed (such as figure 1 shown).

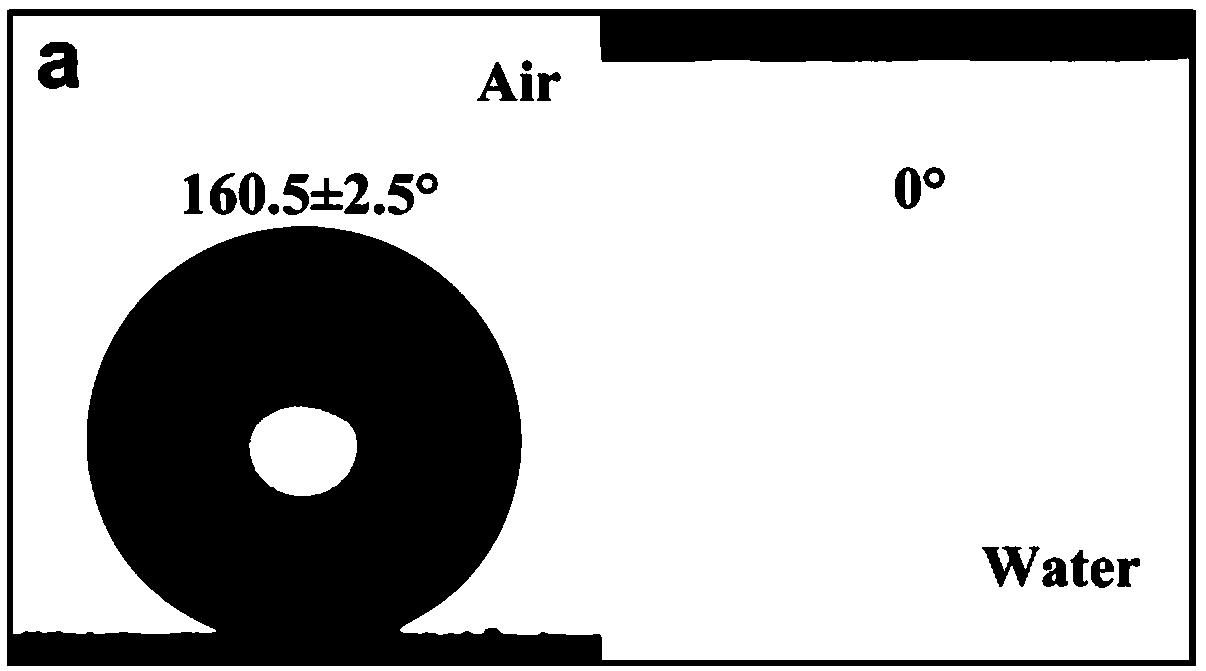

[0031] (3) Preparation of superhydrophobic copper cones: the copper cones prepared in (2) were washed sequentially with 0.1 mol / L hydrochloric acid and deionized water, and dried with nitrogen. followed by superhydrophobic SiO 2 The nanoparticle solution modified the copper cone with a gradient, thus successfully preparing the superhydrophobic copper cone. Its morphology and partial enlargement (such as figure 2 shown)

[0032] (4) Superhydrophobic copper cone to regulate underwater gas: fix the bottom end of the superhydrophobic copper cone successfully prepared in (3) on a 2...

Embodiment 1

[0036] The method proposed in this embodiment to regulate underwater gas by using the superhydrophobic copper cone prepared by the present invention includes the following steps;

[0037](1) Copper wire pretreatment: Polish a commercially available copper wire with a diameter of 1mm with P1500 sandpaper, and then ultrasonically wash it with sodium hydroxide, hydrochloric acid, ethanol, acetone, and deionized water for 15 minutes, and then dry it with nitrogen for use .

[0038] (2) Preparation of copper cone: Immerse the copper wire in (1) in a small glass tank containing 50 mL of 0.1 mol / L copper sulfate solution, use it as the anode, and use the copper sheet as the cathode, and the electrolysis voltage is 10V , fix the small glass tank on the lifting platform (the lifting speed is 1.0mm / s), and after about 300 cycles, the copper cone is formed.

[0039] (3) Preparation of superhydrophobic copper cones: the copper cones prepared in (2) were washed sequentially with 0.1 mol / L...

Embodiment 2

[0043] The method proposed in this embodiment to regulate underwater gas by using the superhydrophobic copper cone prepared by the present invention includes the following steps;

[0044] (1) Copper wire pretreatment: Polish a commercially available copper wire with a diameter of 1mm with P1500 sandpaper, and then ultrasonically wash it with sodium hydroxide, hydrochloric acid, ethanol, acetone, and deionized water for 15 minutes, and then dry it with nitrogen for use .

[0045] (2) Preparation of copper cone: Immerse the copper wire in (1) in a small glass tank containing 50 mL of 0.1 mol / L copper sulfate solution, use it as the anode, and use the copper sheet as the cathode, and the electrolysis voltage is 10V , fix the small glass tank on the lifting platform (the lifting speed is 1.0mm / s), and after about 300 cycles, the copper cone is formed.

[0046] (3) Preparation of superhydrophobic copper cones: the copper cones prepared in (2) were washed sequentially with 0.1 mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com