Pneumatic radial tire

A radial tire, tire technology, applied in the reinforcement layer, tire parts, transportation and packaging of pneumatic tires, etc., can solve problems such as reduced handling stability and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

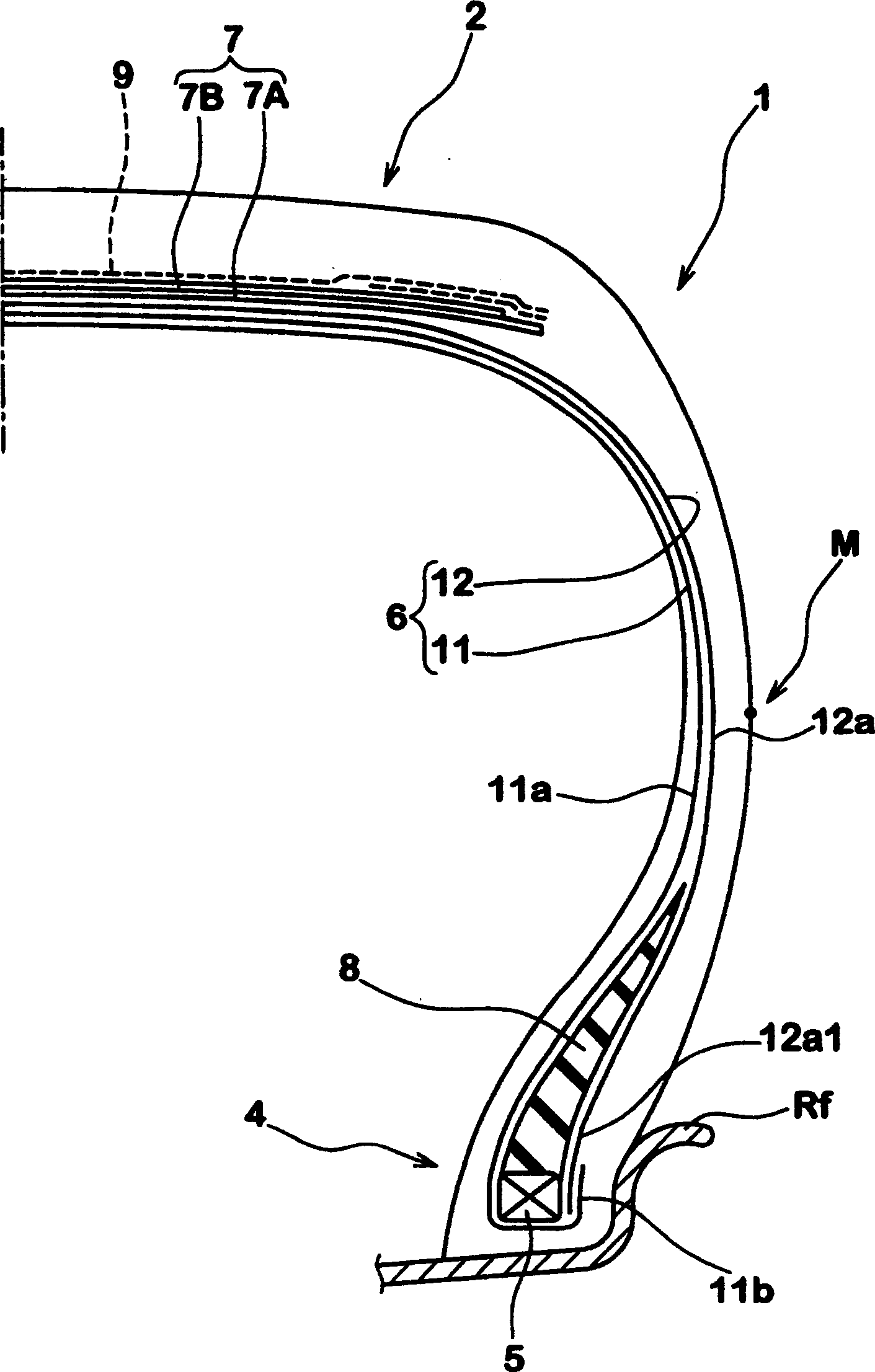

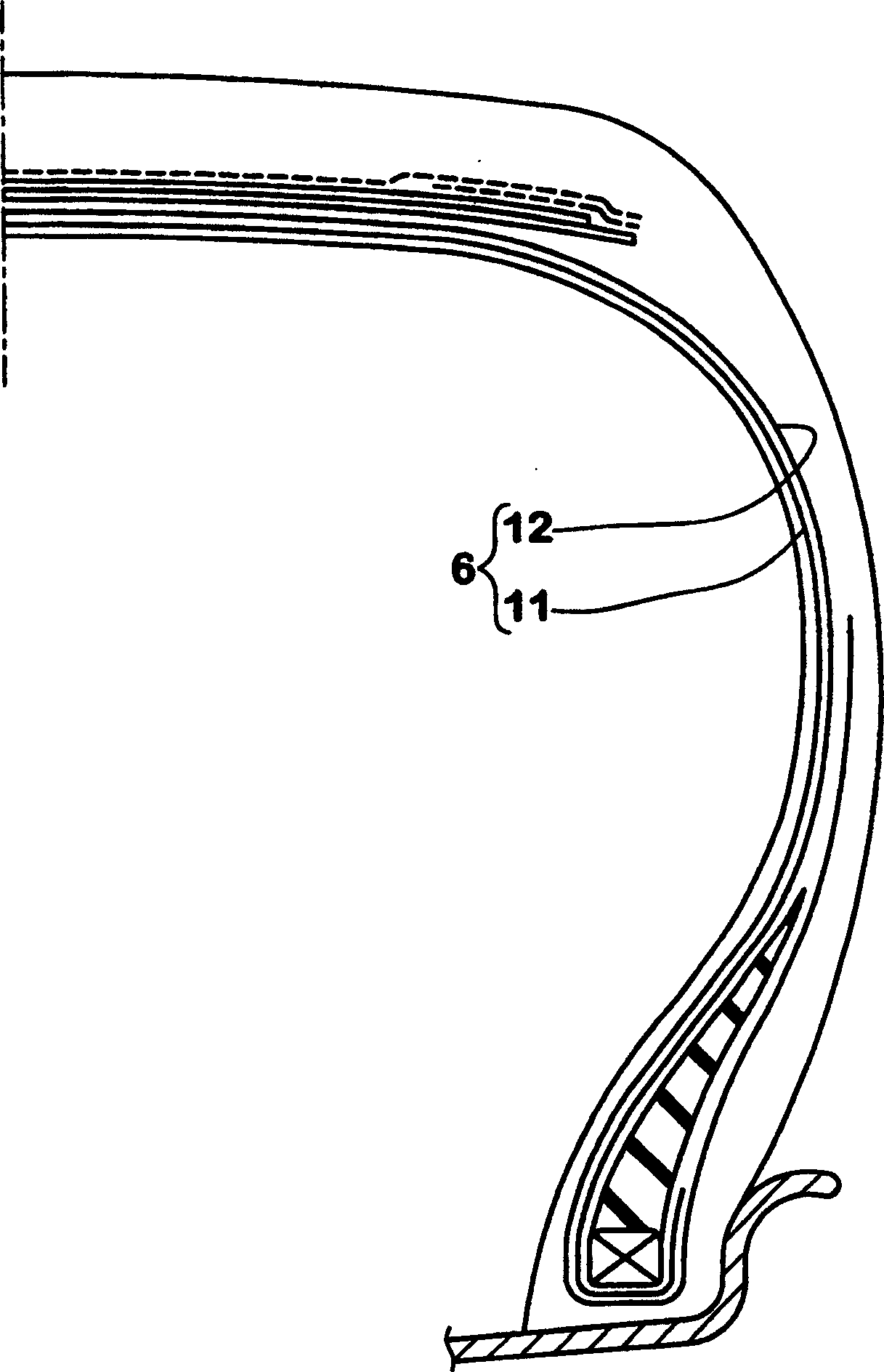

[0048] form figure 1 The tire size of the structure was trial-manufactured according to the specifications in Table 1. 205 / 55R16 car radial tires were trial-manufactured. At the same time, the handling stability, ride feeling and road noise performance of each test tire were tested and compared. All tires are of the same specification except for those listed in Table 1.

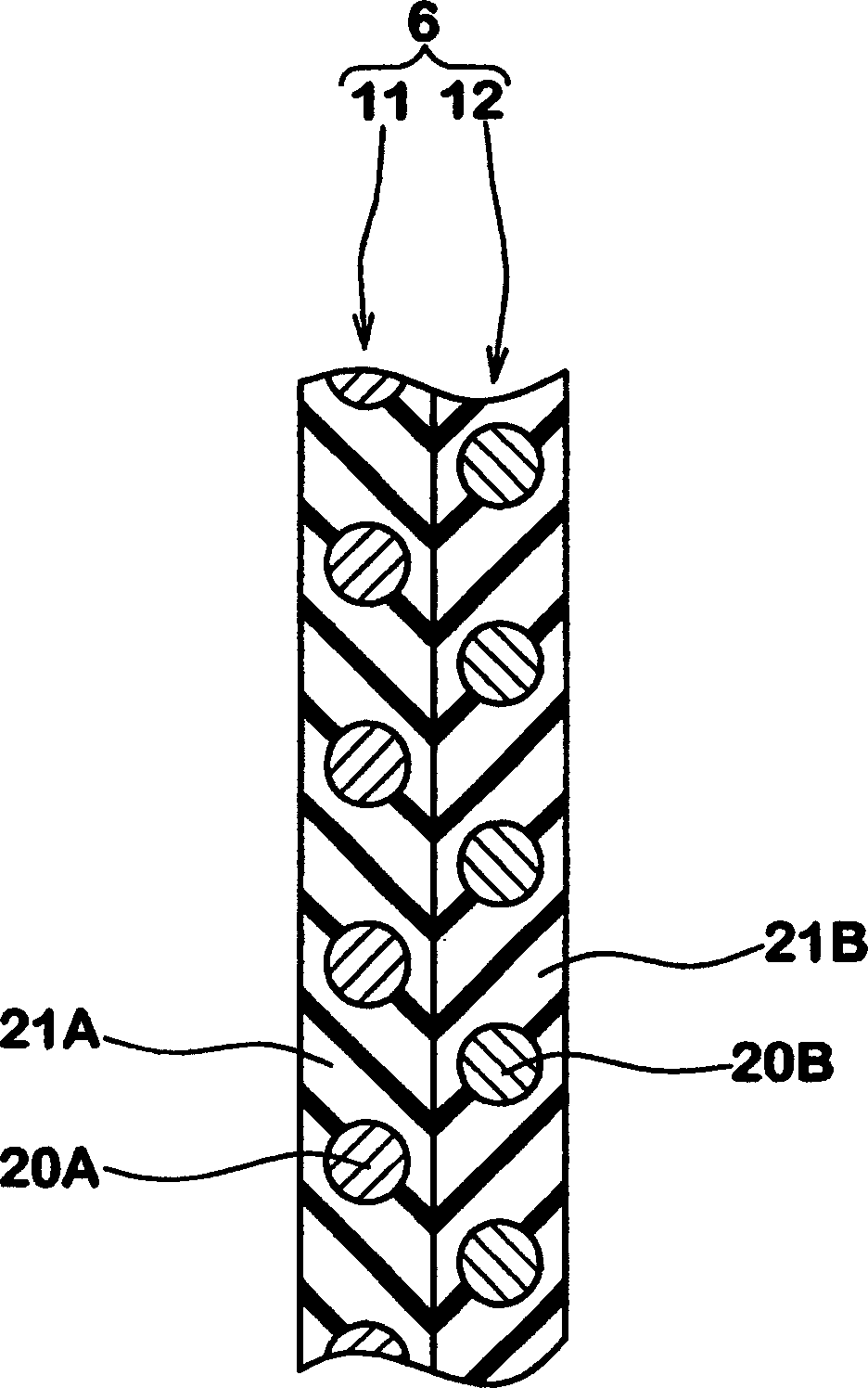

[0049] In addition, the belt layer is the number of plies (2 sheets), belt cords (steel cords), cord angle (22 degrees), and the number of cord implants (40 cords / 5cm).

[0050] (1) Handling stability and ride feeling:

[0051] Under the conditions of rim (16×6.5JJ) and internal pressure (220kPa), install the test tire on all the wheels of the vehicle (2000CC, FF vehicle), and run it on the test road according to the driver's feeling evaluation The handling stability and ride feeling at the time of the test were evaluated on a 10-point scale, while the past example was rated as 6 points. The larger the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com