Vehicle tire

A tire and vehicle technology, applied to vehicle parts, tire parts, tire tread/tread pattern, etc., can solve the problem that it is difficult to predict the maximum sound level of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

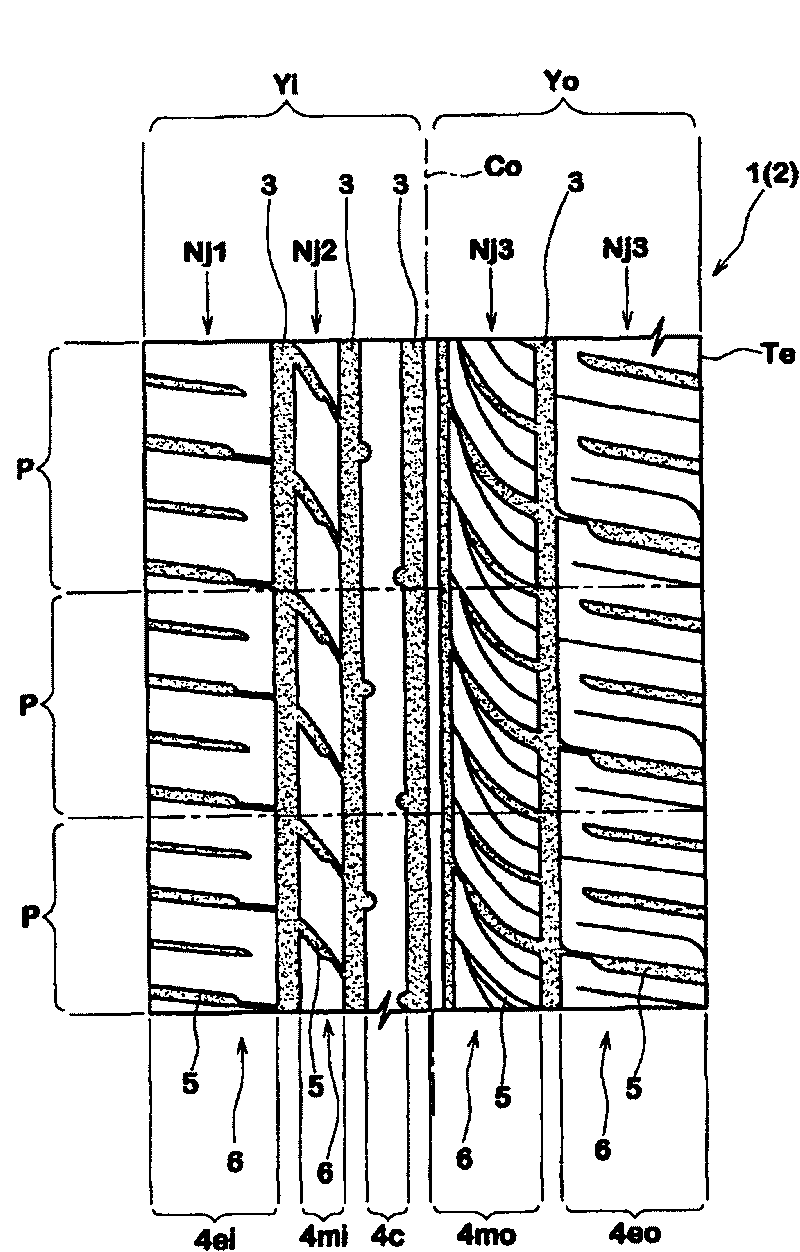

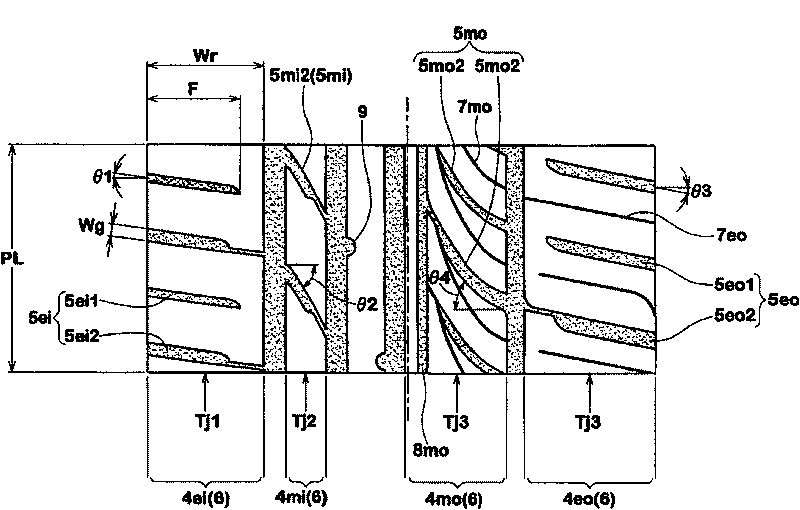

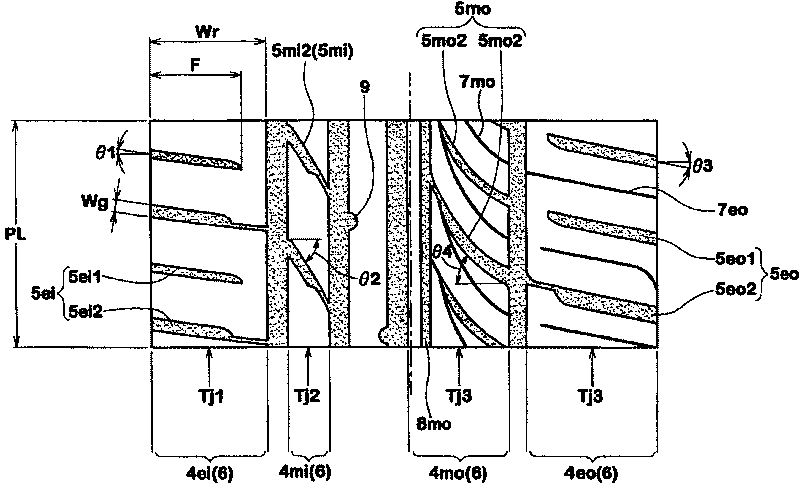

[0018] In the present embodiment, the vehicle tire 1 according to the present invention is a pneumatic radial tire for passenger cars. As is well known to those skilled in the art, a pneumatic tire includes a tread portion, a pair of axially spaced bead portions, and a pair of sidewall portions extending between the tread edge and the bead portion.

[0019] Said tread portion 2 is provided with tread grooves and optional sipes defining the tread pattern. figure 1 An example of a tread pattern is shown, which is suitable for a minivan and is designed to provide low noise and handling stability.

[0020] The tread groove comprises a plurality of main grooves 3 extending continuously in the circumferential direction of the tire, thereby axially dividing the tread portion 2 into at least three annular regions 4 .

[0021] Here, the main groove 3 in the circumferential direction is a groove with a width of not less than 2.0 mm, which is provided for drainage. Therefore, narrow gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com