Inflated tire and vulcanized metal die thereof

A technology for pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, tires, etc., and can solve problems such as blade tilt, partial wear, and high stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

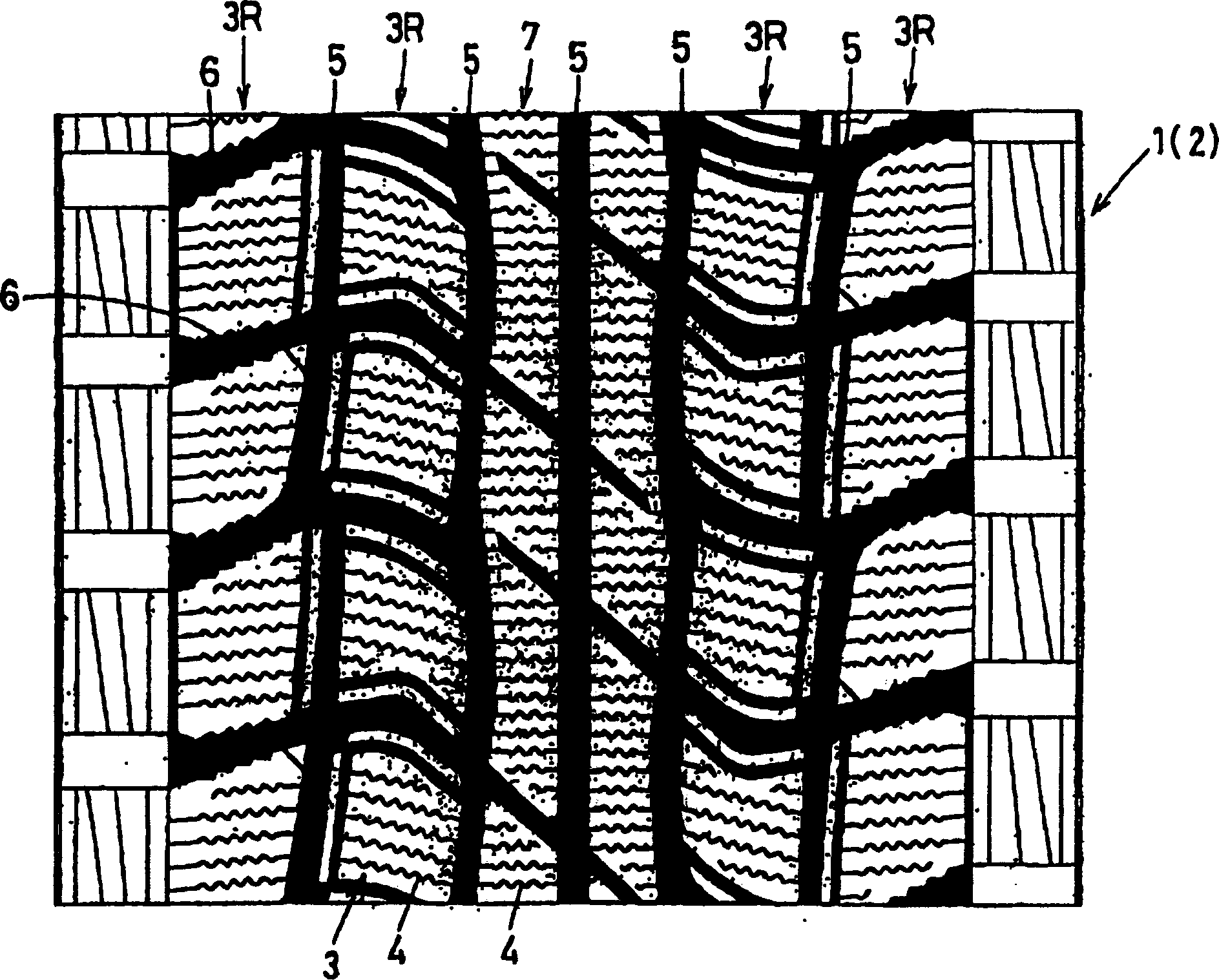

[0030] figure 1 It is a developed view of the tread pattern when the pneumatic tire of the present invention is formed as a studless tire for passenger vehicles.

[0031] exist figure 1 In the pneumatic tire 1 , a pattern 4 extending from one side edge of the block 3 to the other side edge is formed on a block 3 provided on a tire tread portion 2 .

[0032] In this example, by providing the tread portion 2 with longitudinal main grooves 5 extending in the circumferential direction of the tire and transverse main grooves 6 intersecting therewith, the tread portion 2 is divided into, for example, two ribs on the tire equator side. 7, and on both outer sides thereof, for example, four block rows 3R in which the blocks 3 are arranged at intervals in the circumferential direction. Meanwhile, on the aforementioned blocks 3 (in this example, on both the blocks 3 and the ribs 7 ), the patterns 4 are provided at intervals in the tire circumferential direction.

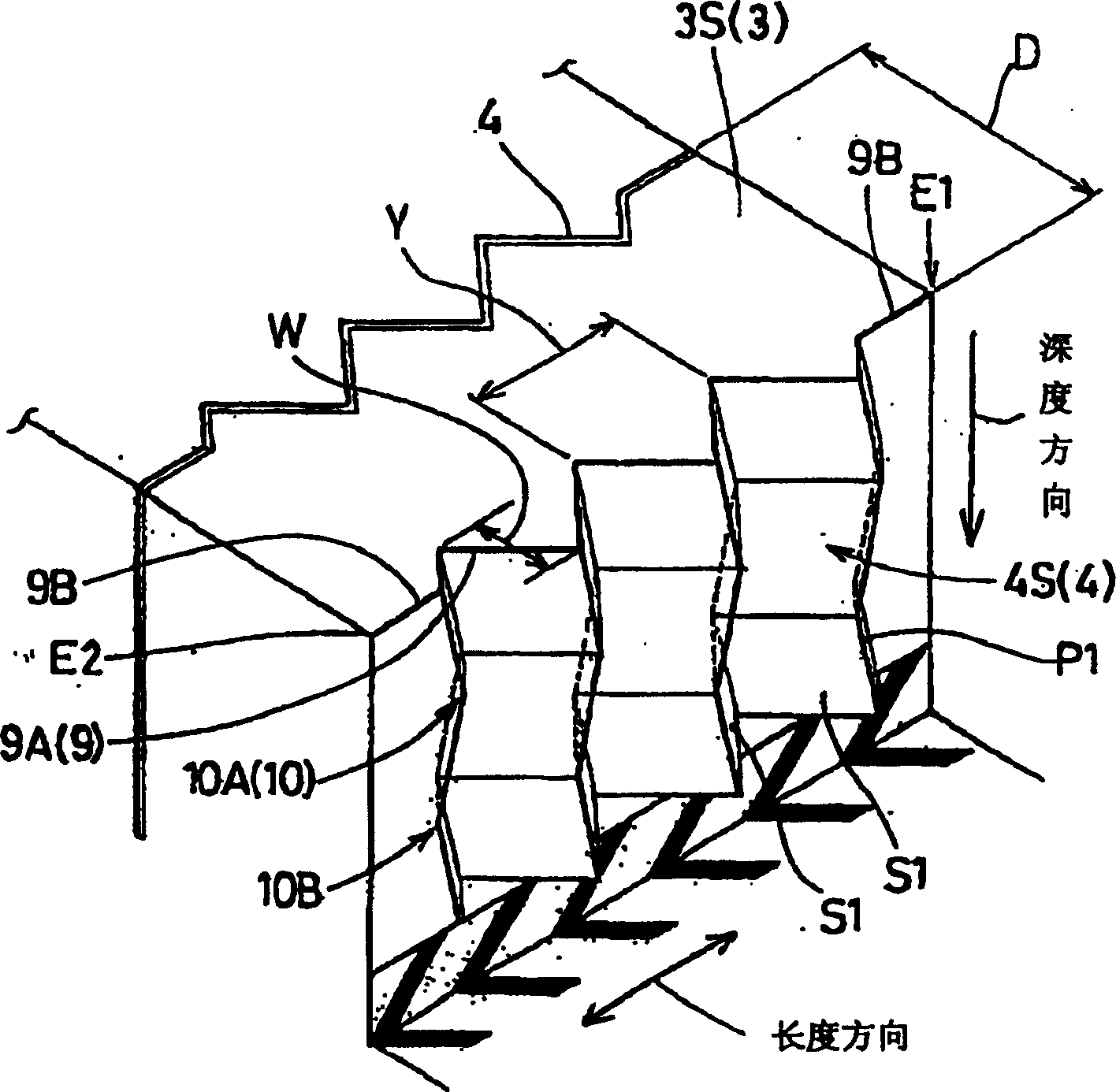

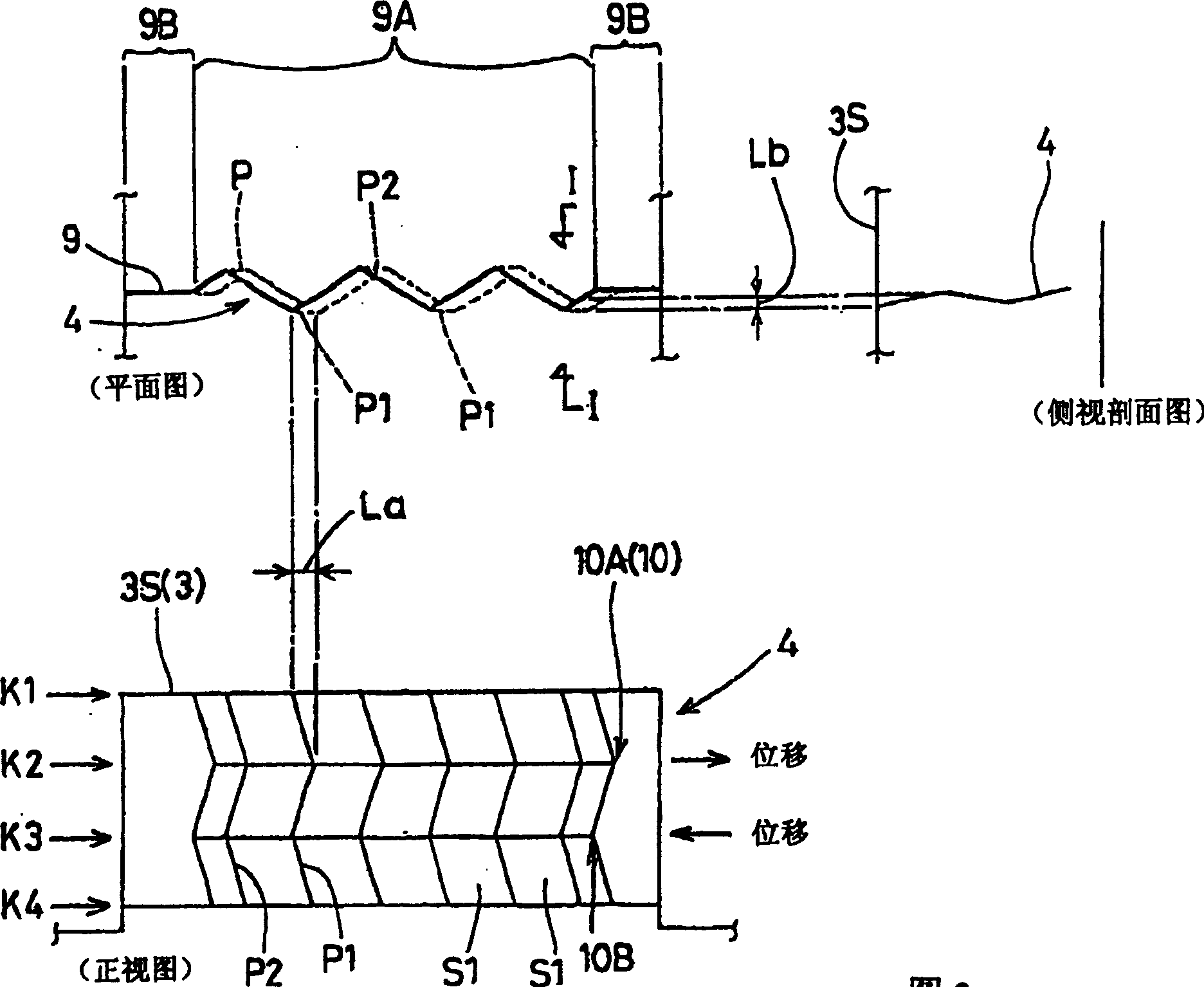

[0033] Secondly, on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com