Device for fetching/putting volume label of sticking mark inside module

A technology of in-mold labeling and volume labeling, which is applied in the field of in-mold labeling, can solve problems such as product defects, finished product yield, deviation or deviation, and poor quality, and achieve the effect of increasing equipment utilization and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable your examiner to fully understand the industrial application value of this invention, the explanation is as follows according to the accompanying drawings:

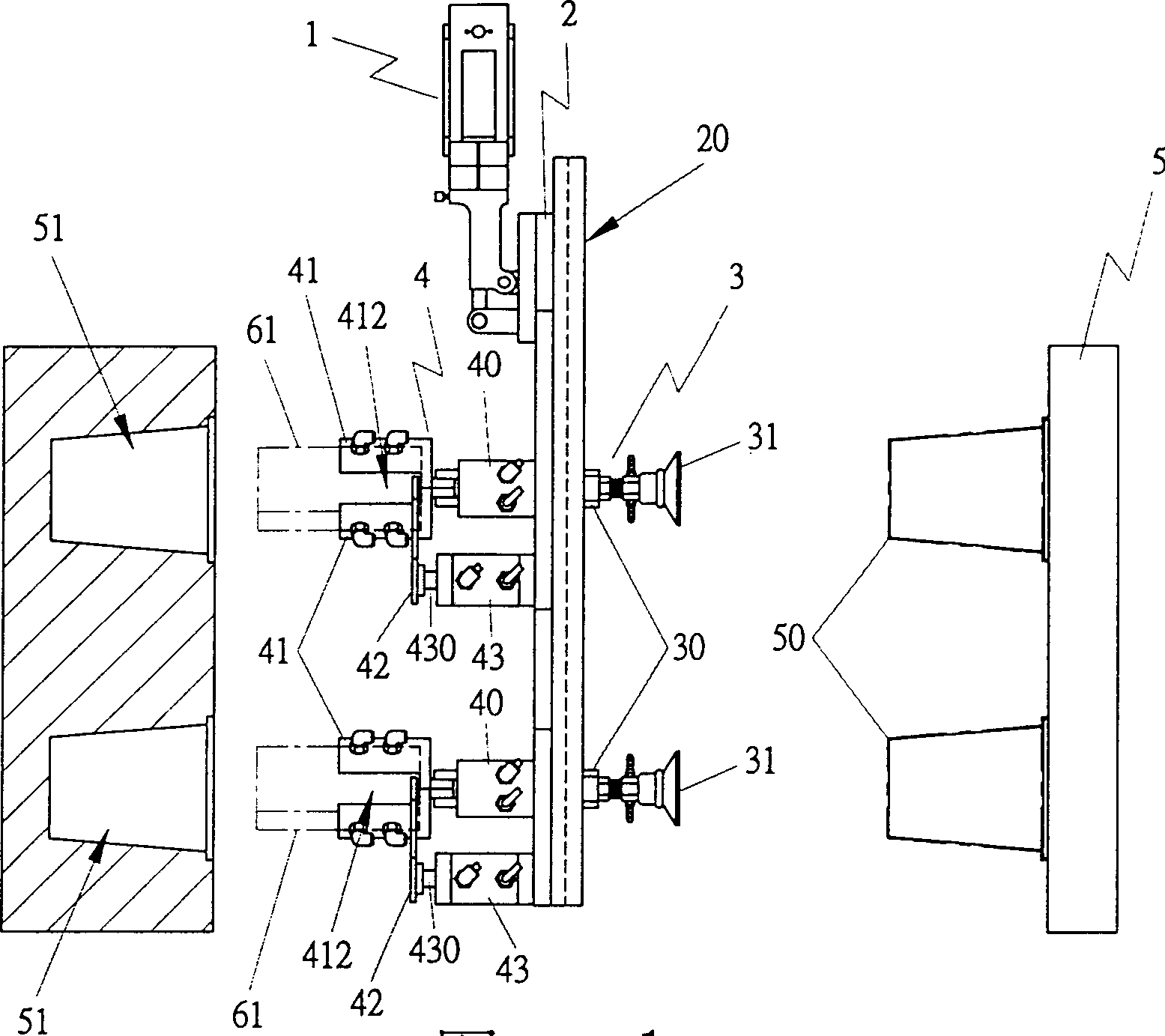

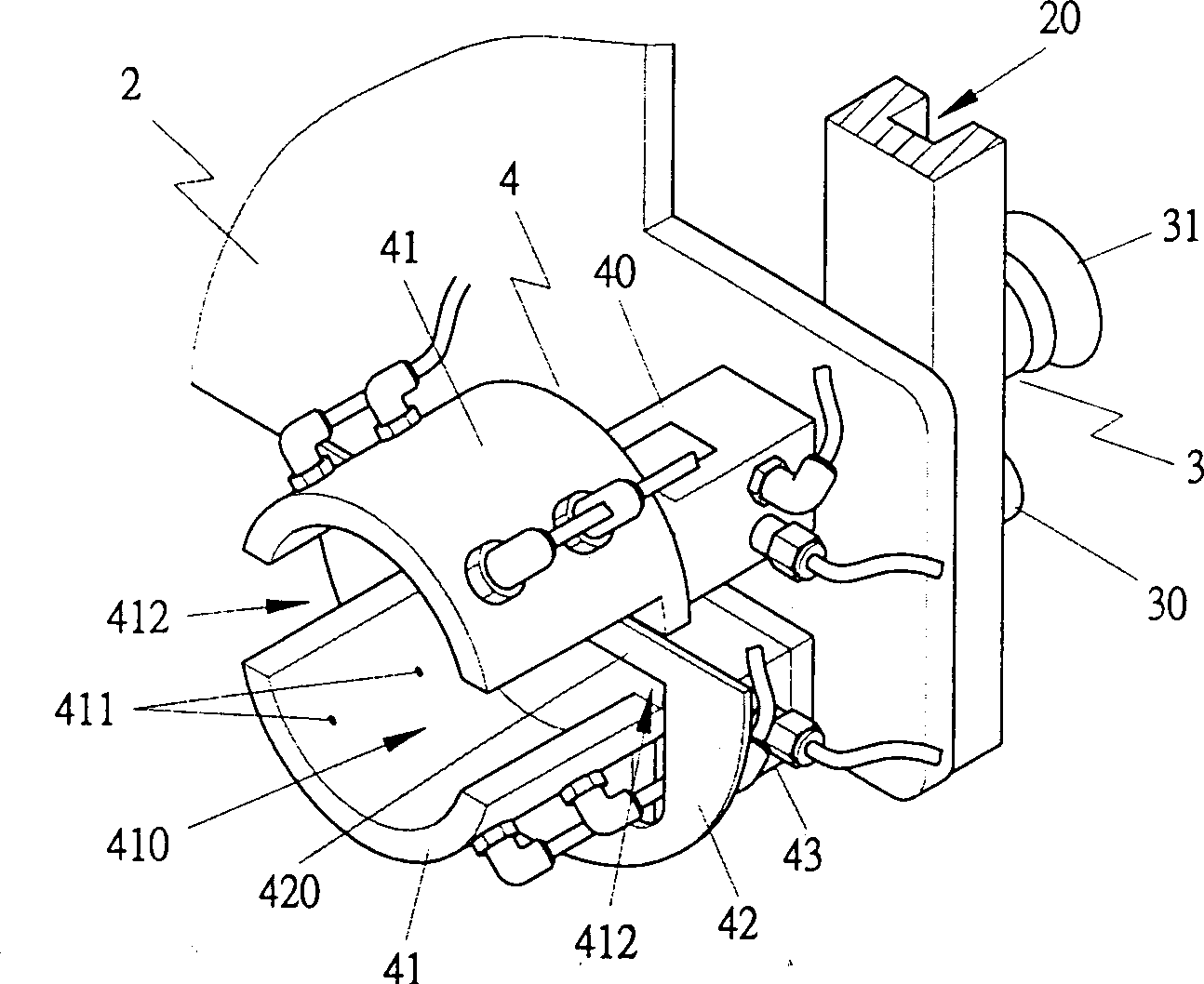

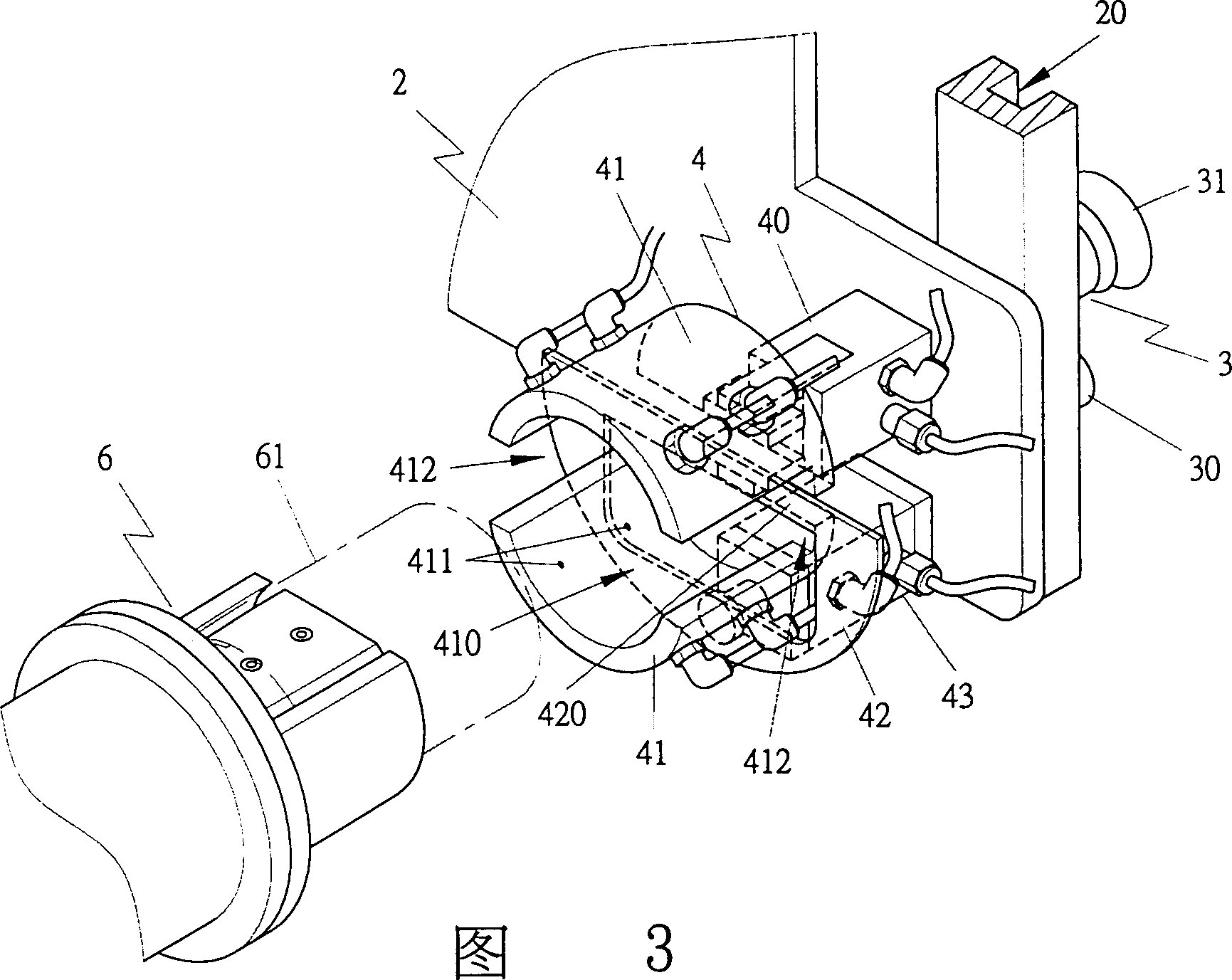

[0042] Such as figure 1 As shown in ~3, it is the embodiment (1) of the present invention. As shown in the figure, the in-mold labeling and labeling equipment of this embodiment (1) includes:

[0043] Mechanical arm 1, the mechanical arm 1 uses computer numerical control to operate its basic operations such as up, down, left, right, front and back. Since it is a common known technology, its computer numerical control method will not be repeated here. and process.

[0044] The fixed seat 2, the fixed seat 2 is fixed under the aforementioned mechanical arm 1, and is driven by the mechanical arm 1 to operate according to its action. The fixed seat 2 is provided with a chute 20, and the chute 20 can be used for setting the finished product take-out device 3 Suction cup seat 30, and utilize the sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com