Patents

Literature

43results about How to "Automated precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

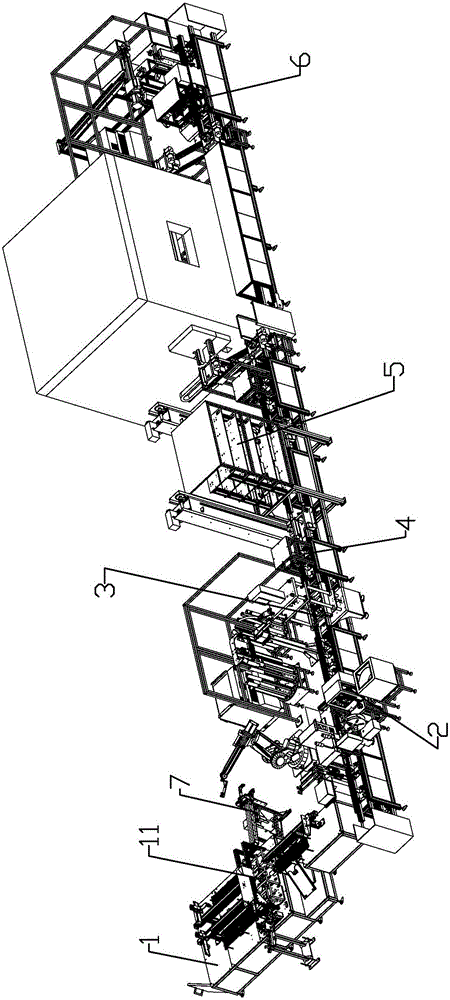

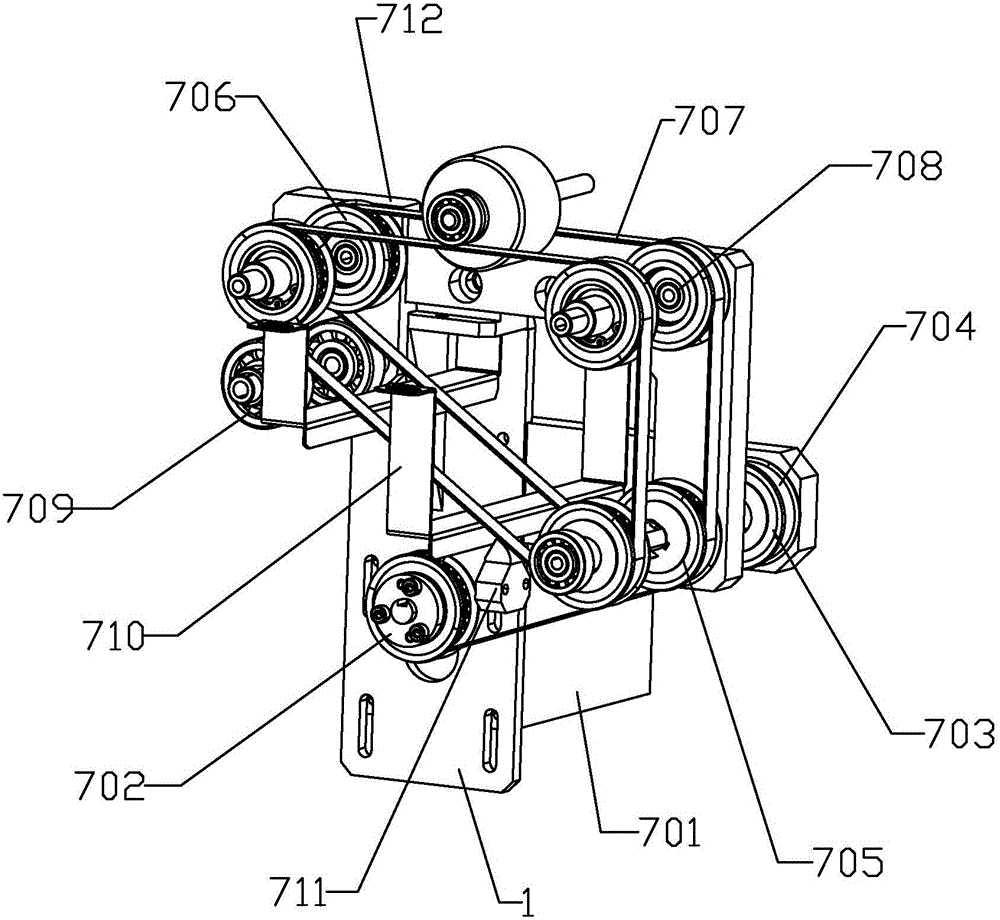

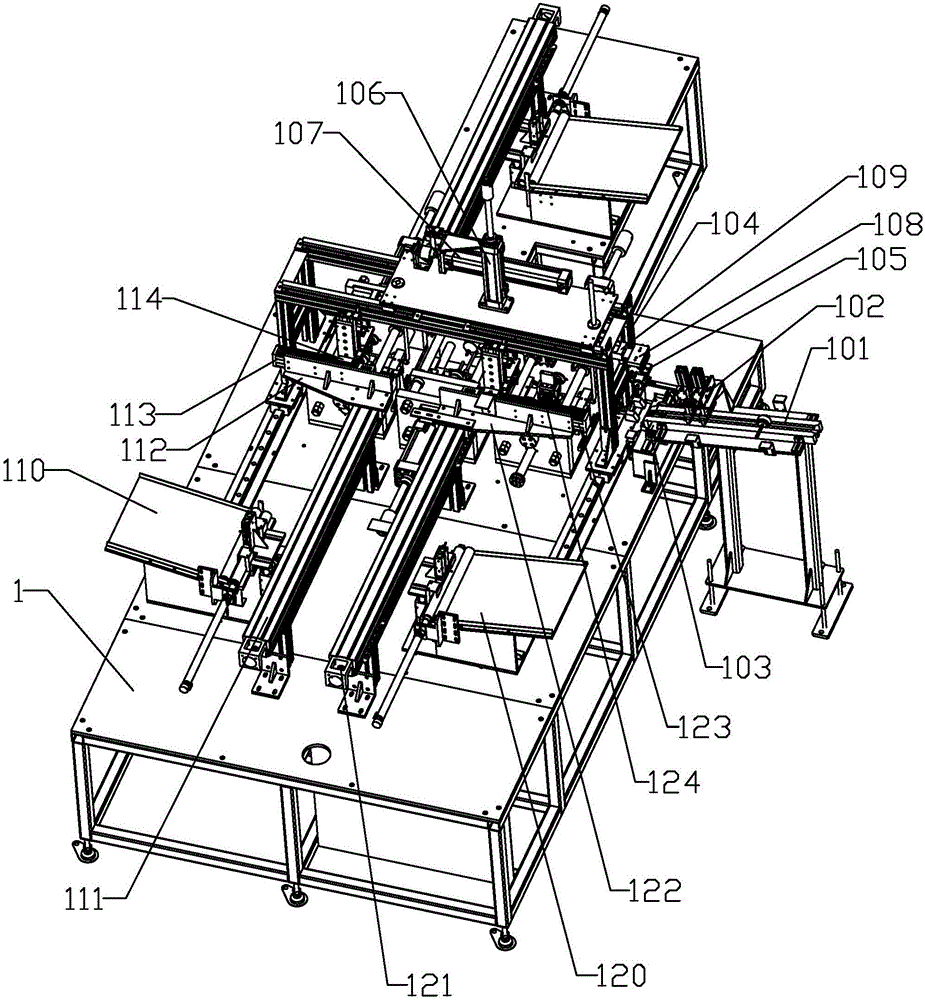

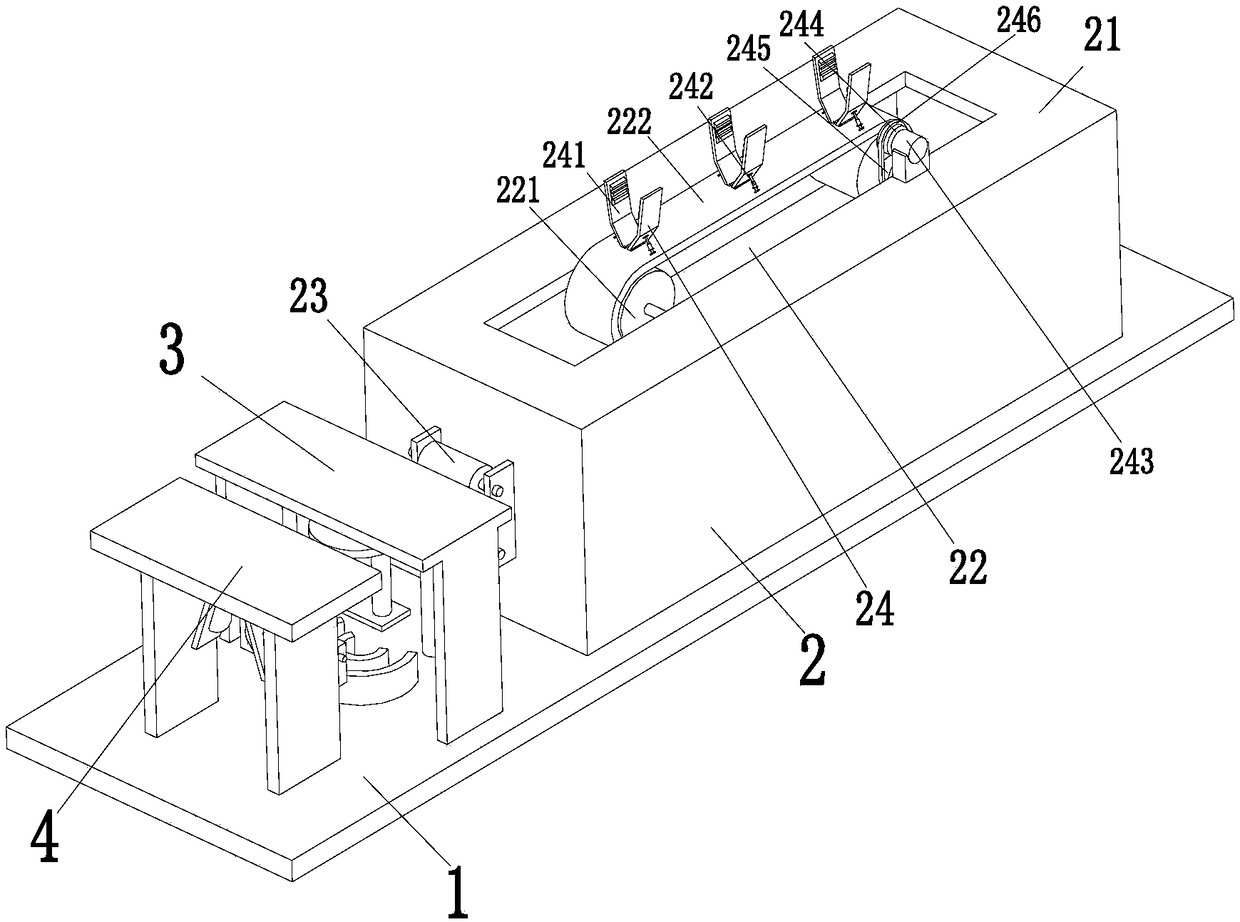

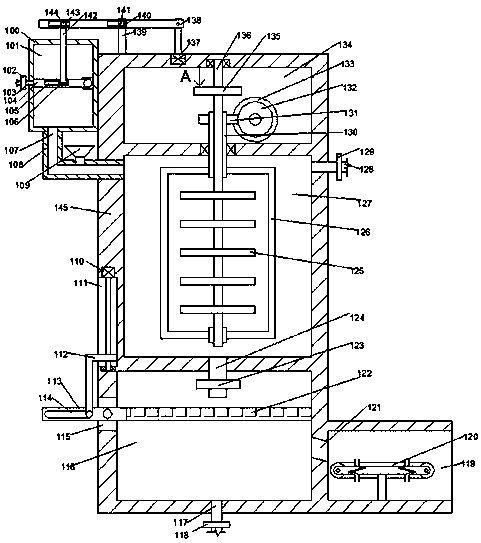

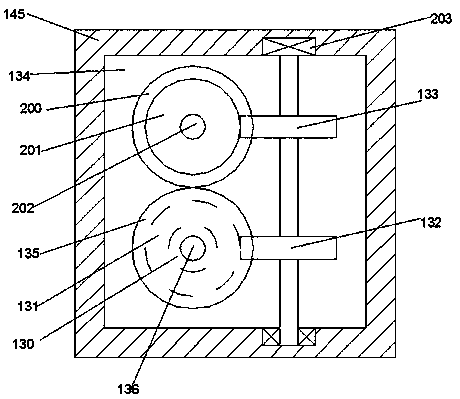

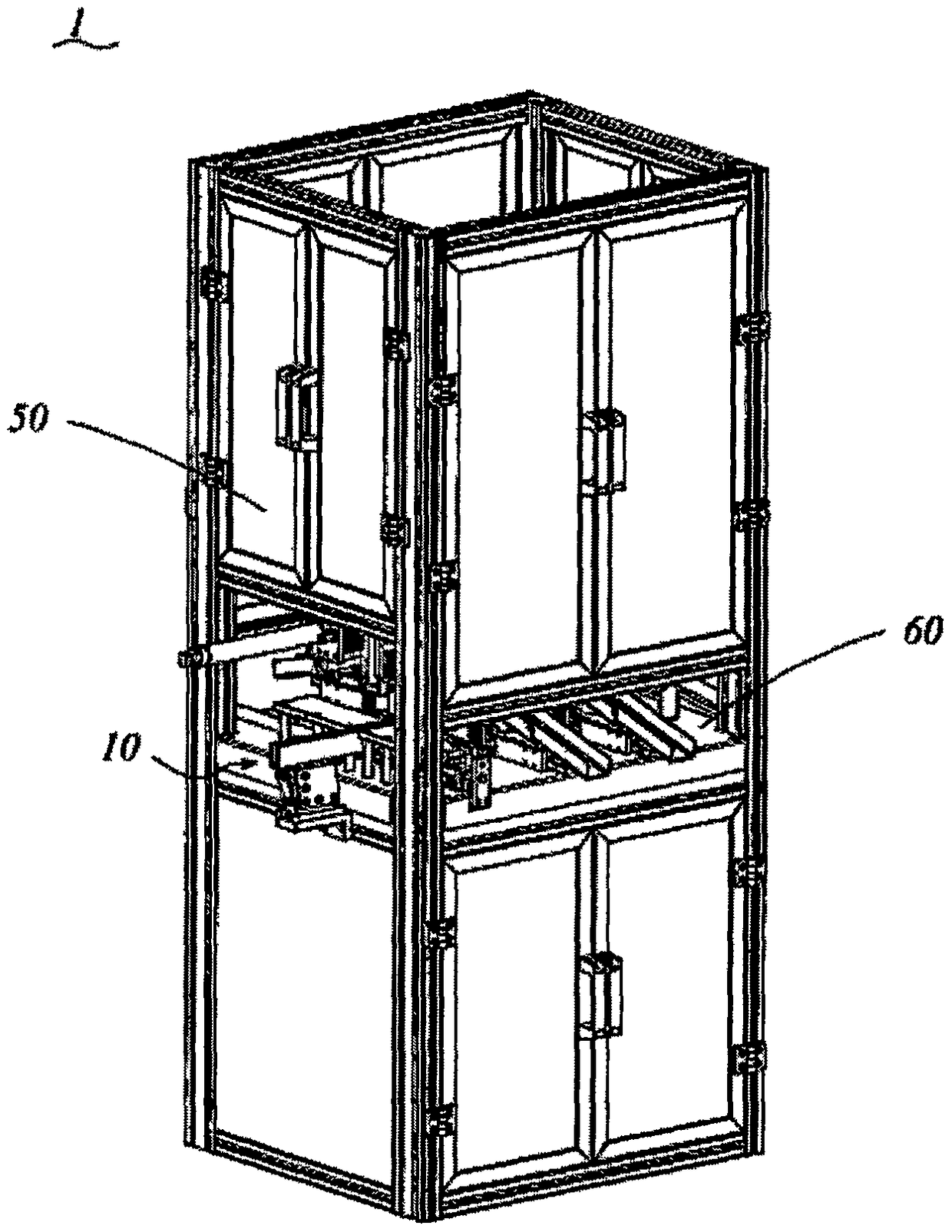

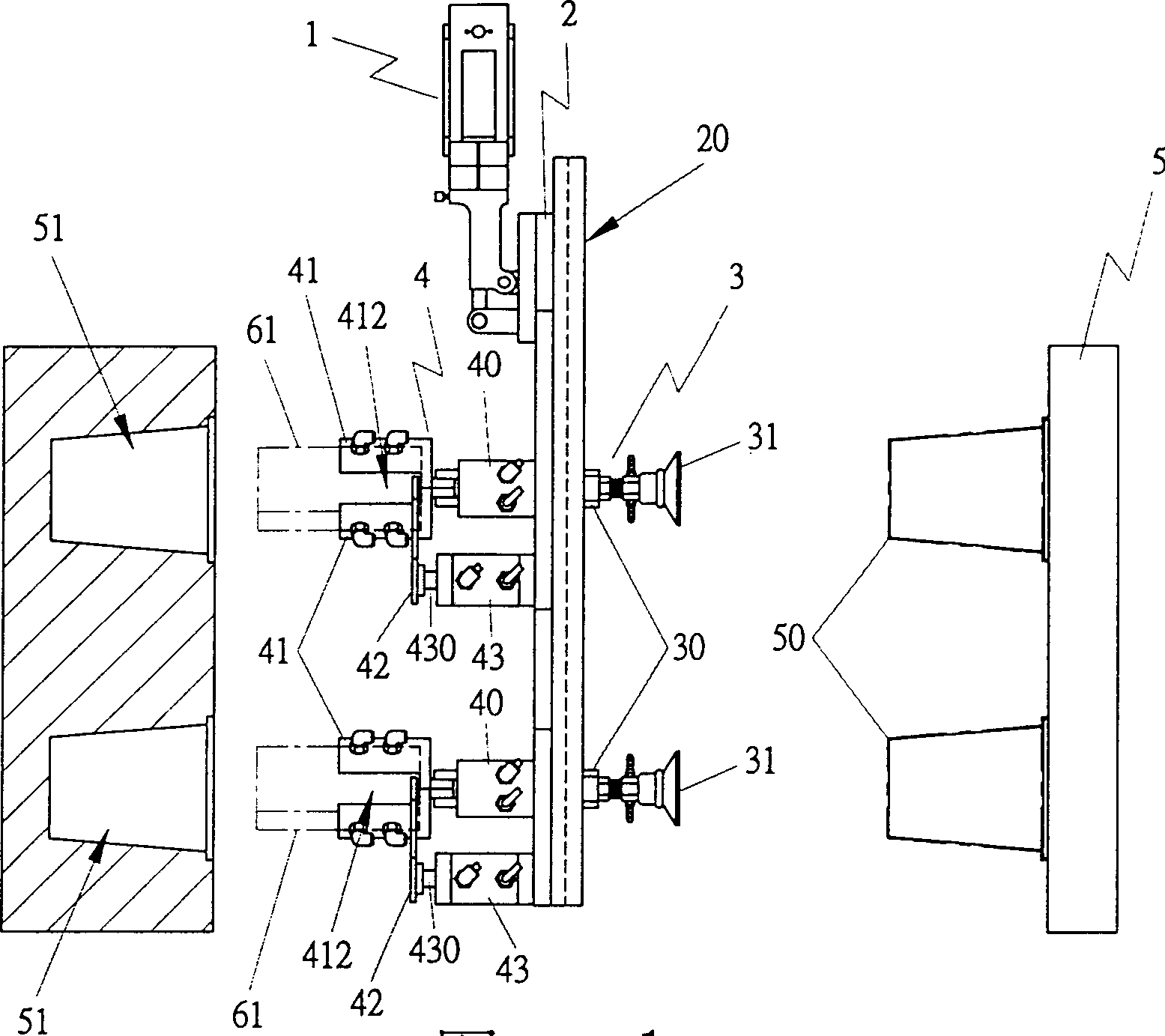

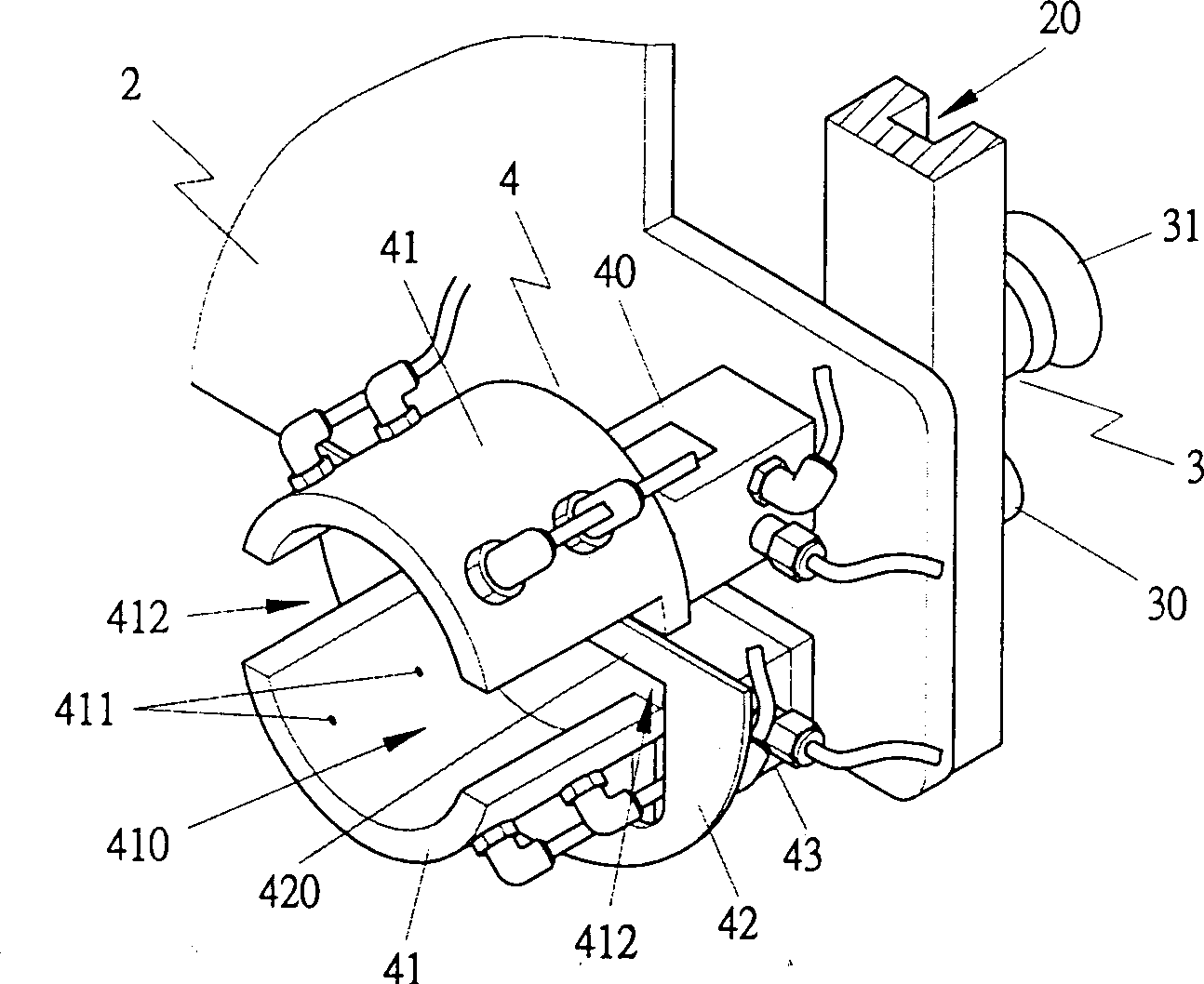

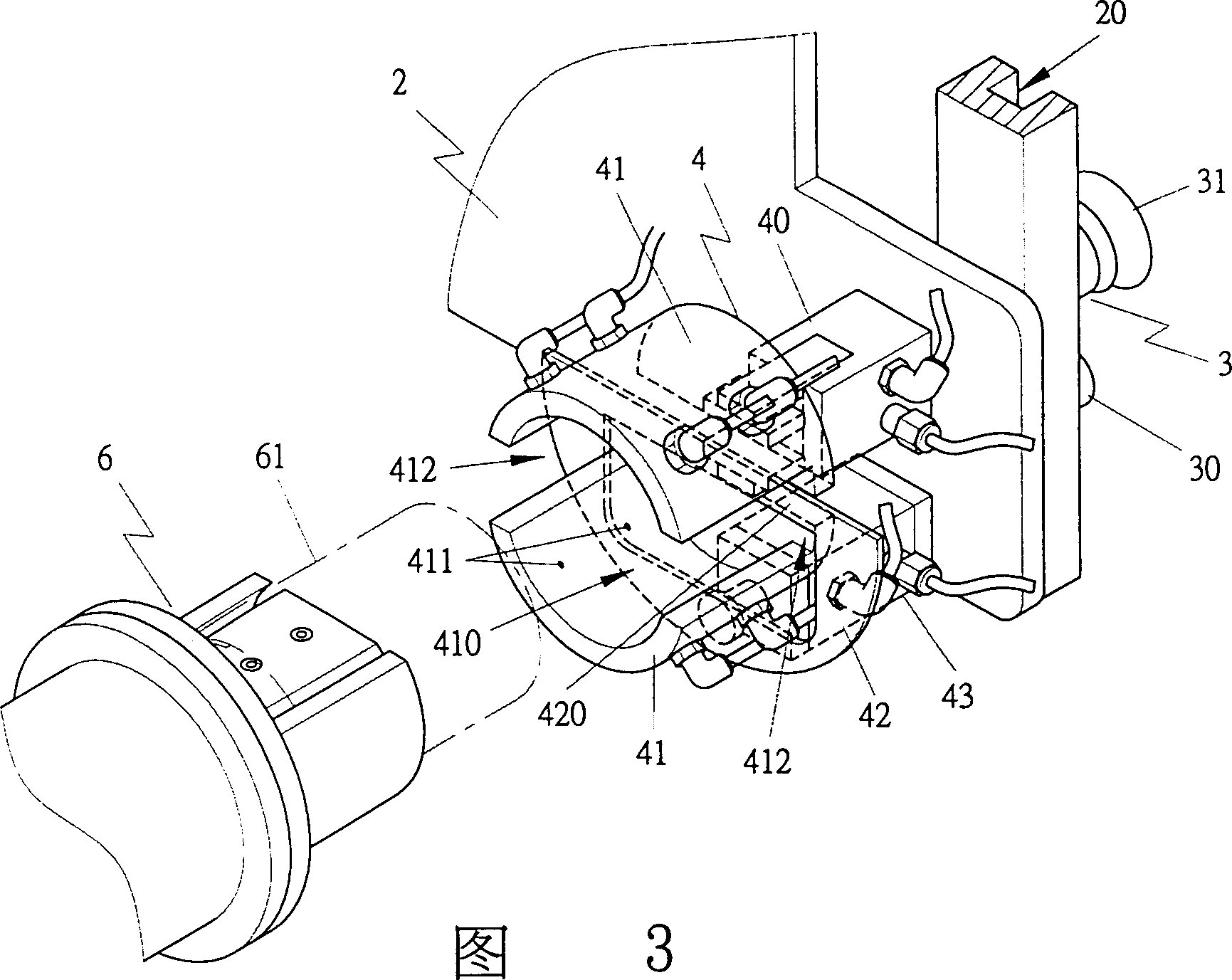

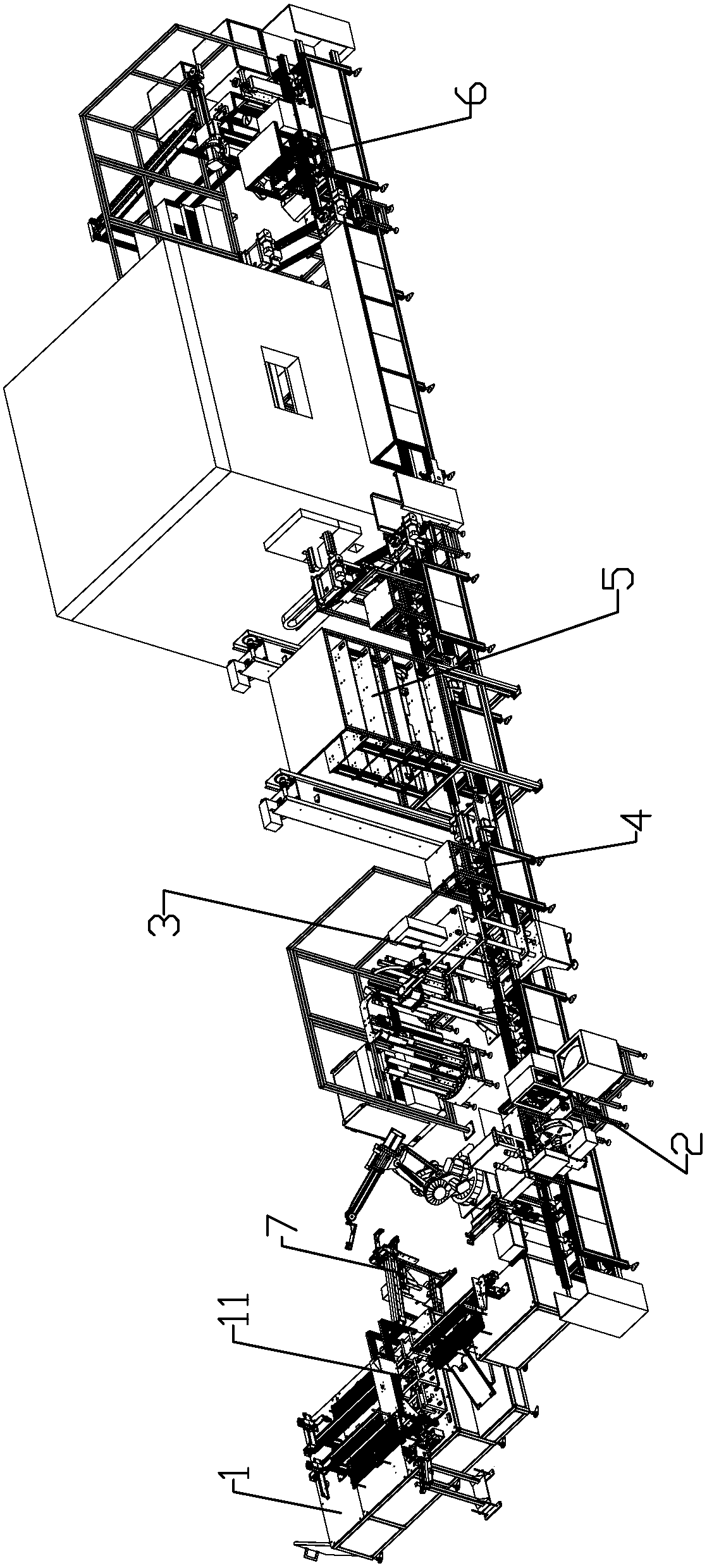

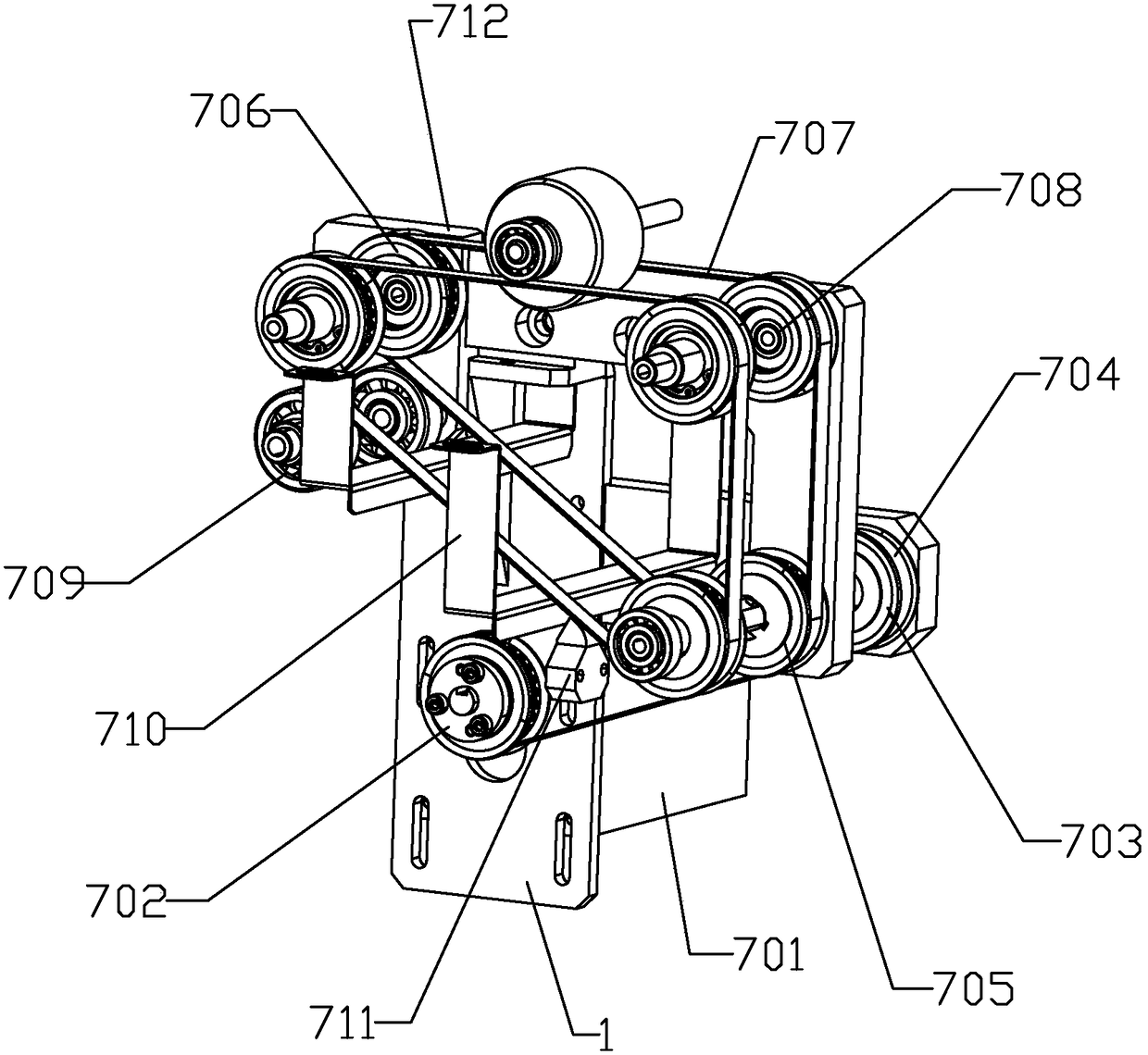

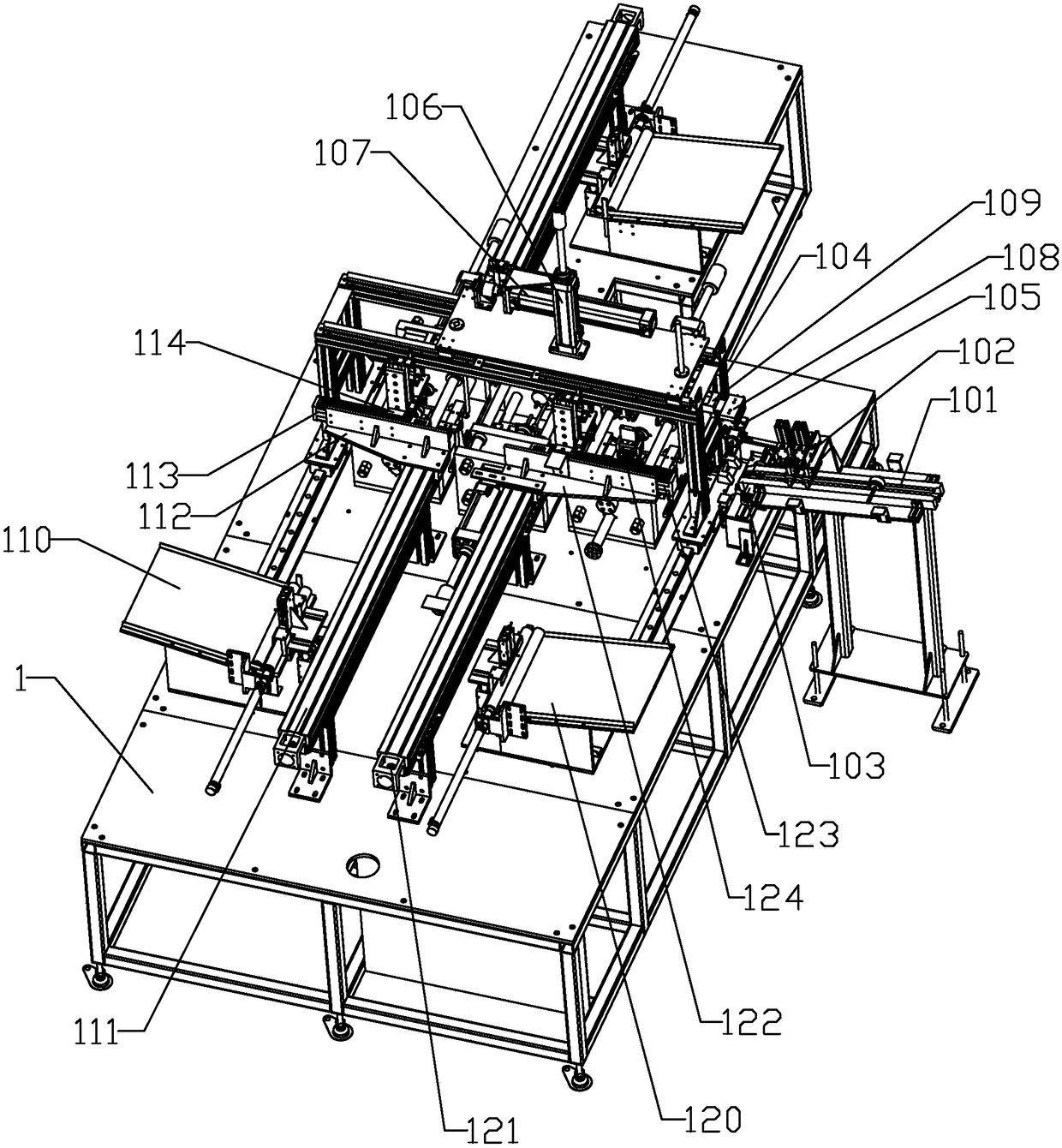

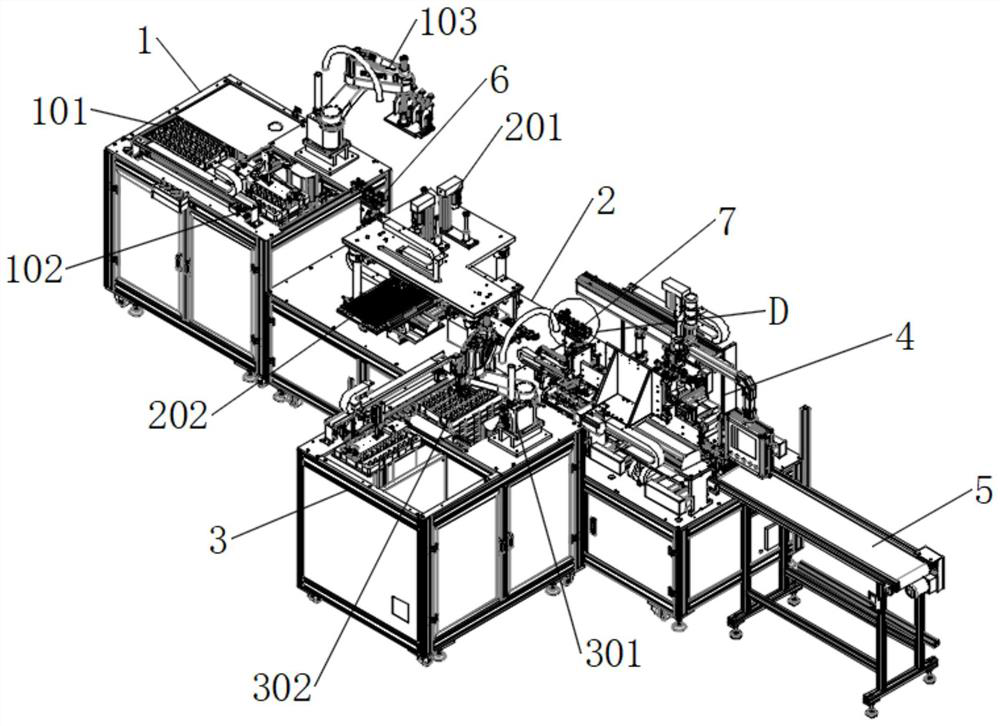

Automatic assembling line for motors

ActiveCN105871129AHigh degree of automationImprove assembly qualityManufacturing dynamo-electric machinesElectricityEngineering

The invention discloses an automatic assembling line for motors. The automatic assembling line for the motors comprises a frame, an automatic conveying belt, a motor rotor bearing bit synchronization oiling device, an automatic motor rotor bearing press-fitting device, an automatic spring washer distributing and detecting device, a motor end cap press-fitting device, an automatic motor bearing gap detecting device, an automatic motor ageing testing device and an automatic gluing air dryer for the motors, wherein the automatic conveying belt which is electrically connected with a circuit controller is arranged on the frame; and the motor rotor bearing bit synchronization oiling device, the automatic motor rotor bearing press-fitting device, the automatic spring washer distributing and detecting device, the motor end cap press-fitting device, the automatic motor bearing gap detecting device, the automatic motor ageing testing device and the automatic gluing air dryer for the motors are successively connected together by the automatic conveying belt and are electrically connected with the circuit controller. The automatic assembling line for the motors is high in assembling stability and good in assembling quality, and testing automation of components of the motors can be realized.

Owner:GUANGDONG LXD ROBOTICS CO LTD

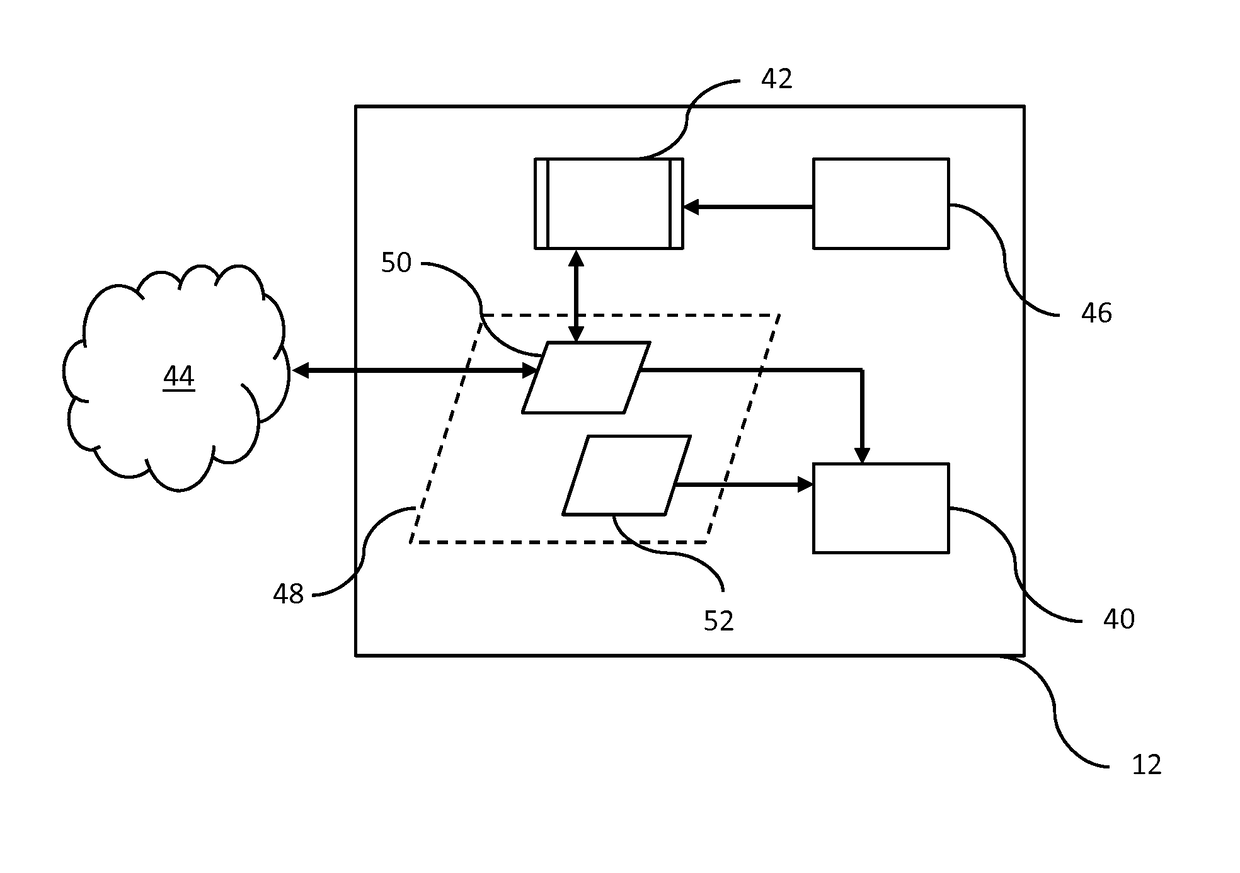

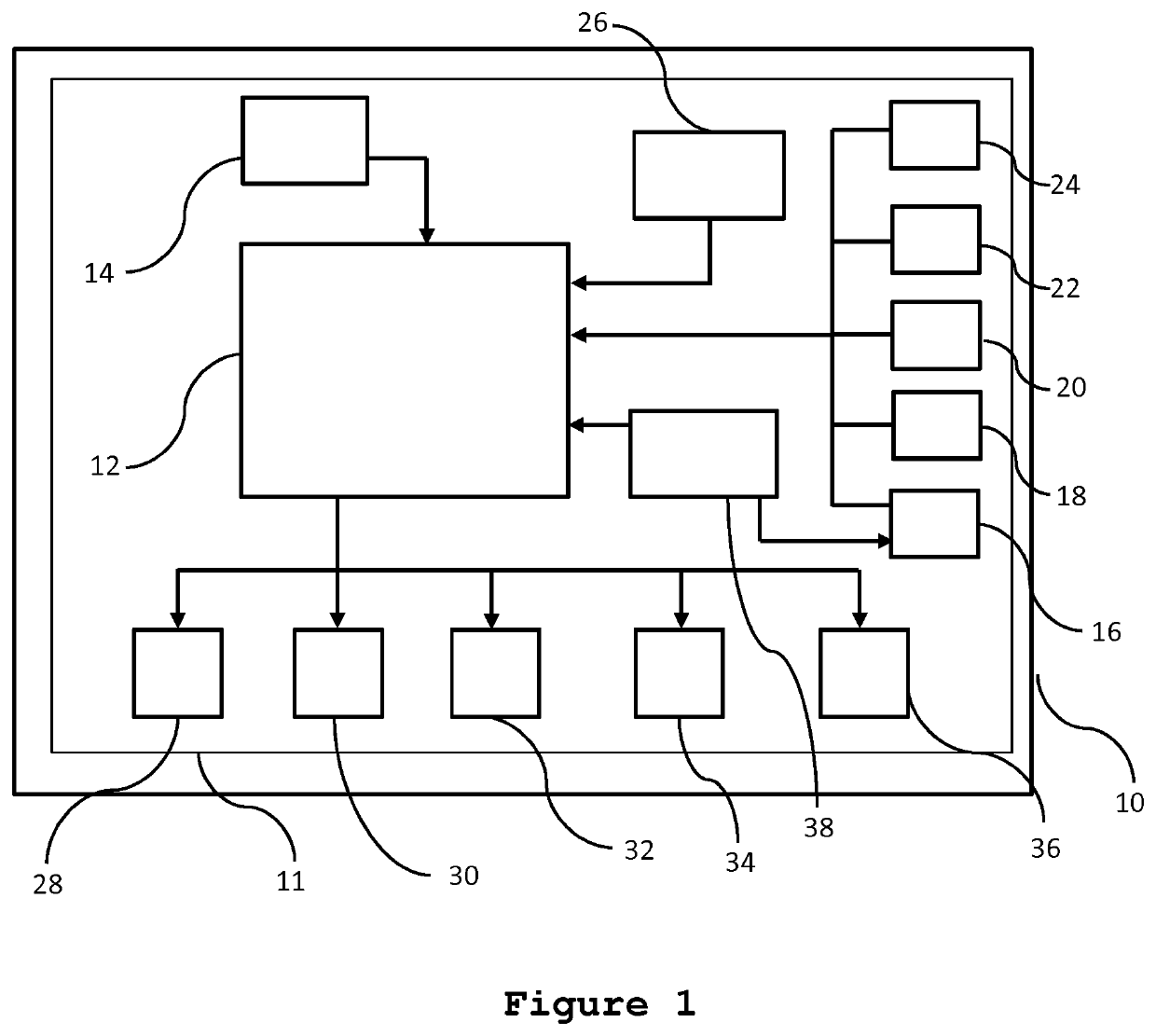

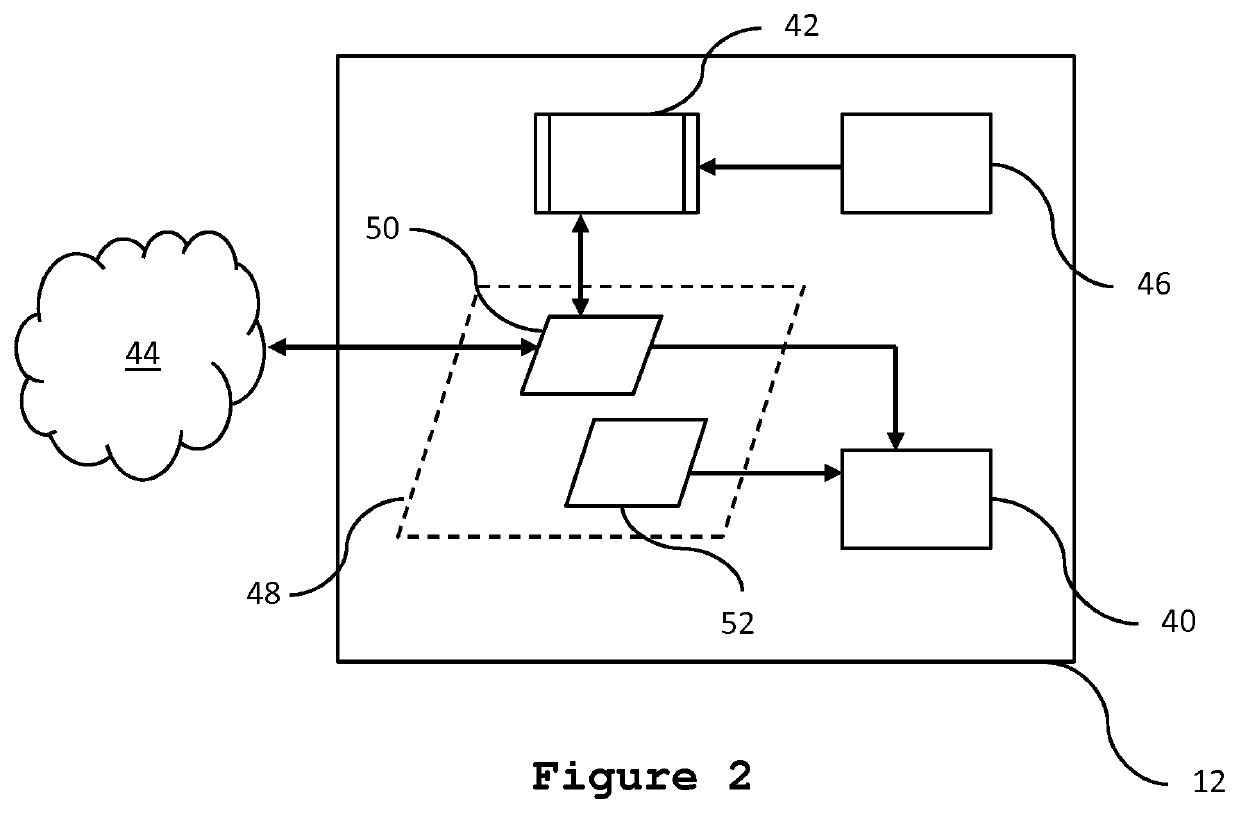

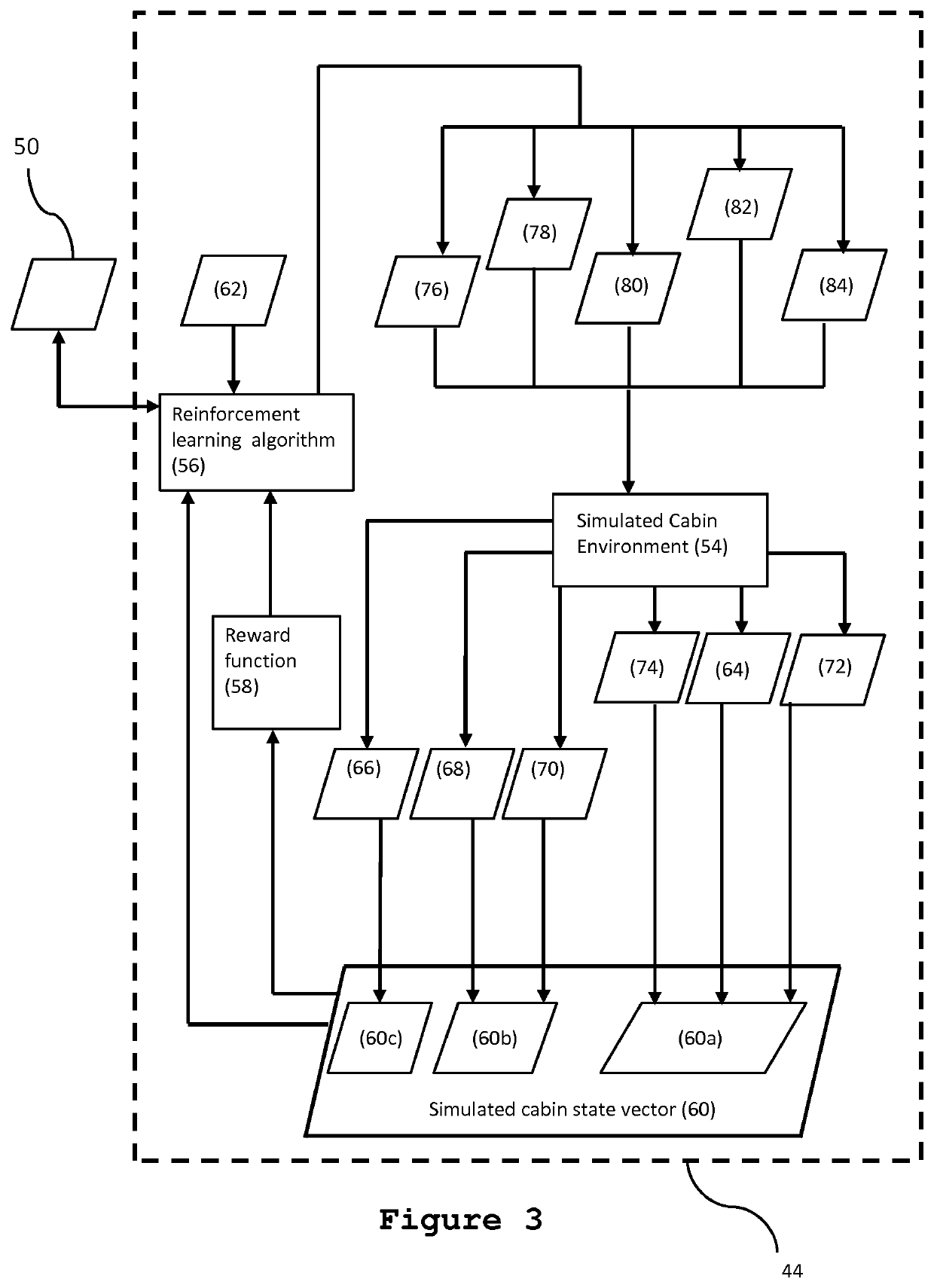

Automated climate control system

ActiveUS20180134118A1Reduce riskReduce the burden onAir-treating devicesVehicle heating/cooling devicesControl systemUser input

A control unit for a climate control system for a vehicle, comprising; a monitoring module arranged to monitor at least one demand representative of an environmental parameter change within the vehicle and / or at least one active user input relating to an environmental parameter within the vehicle; a storage means storing a control policy for configuring at least one climate control element; a feedback module configured to receive the at least one demand from the monitoring module and to receive a simulated control policy from a simulation module; wherein the feedback module is configured to update the control policy, based on the simulated control policy, in response to receiving the at least one demand; and an implementation module for controlling said at least one climate control element in accordance with said control policy.

Owner:JAGUAR LAND ROVER LTD

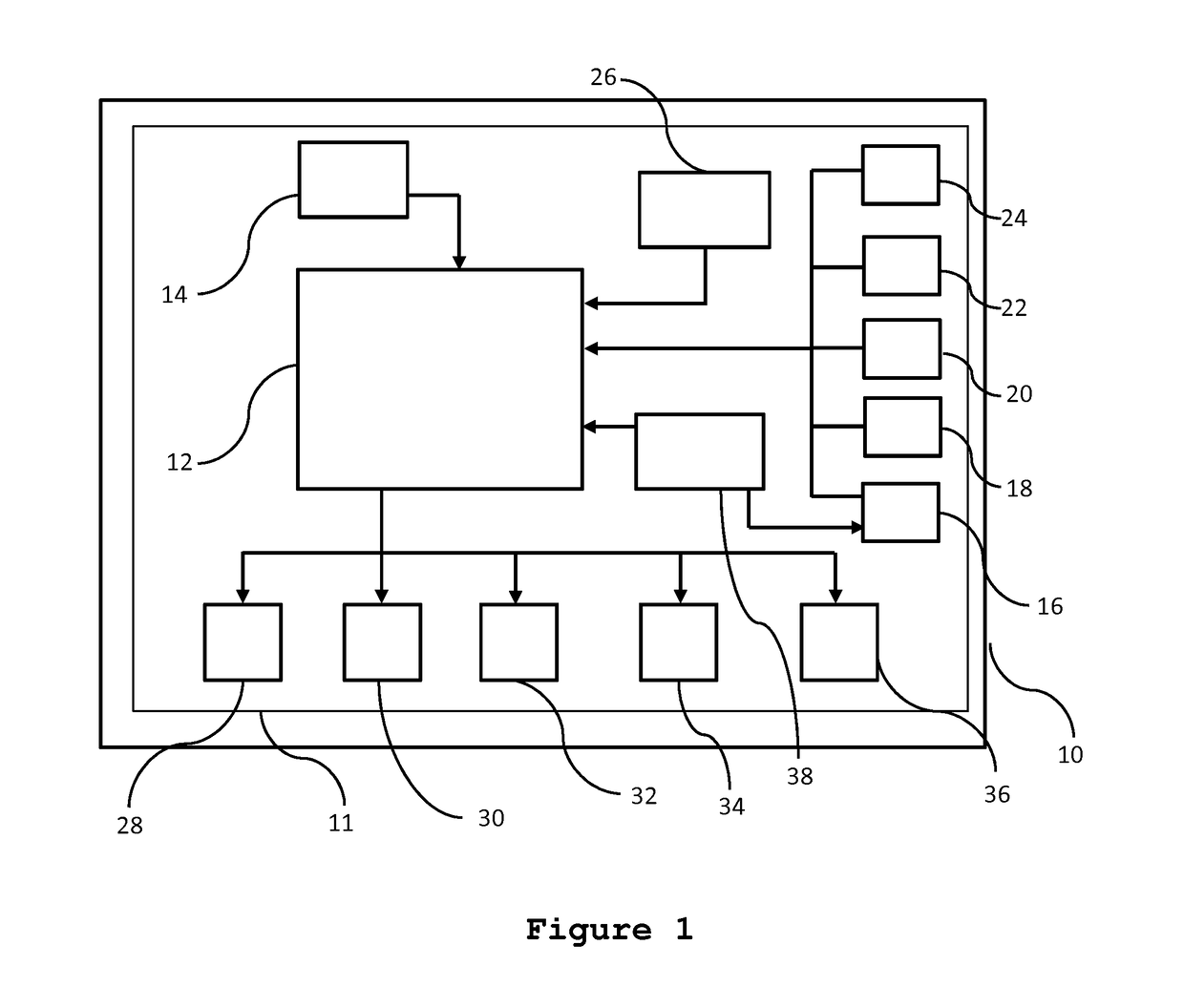

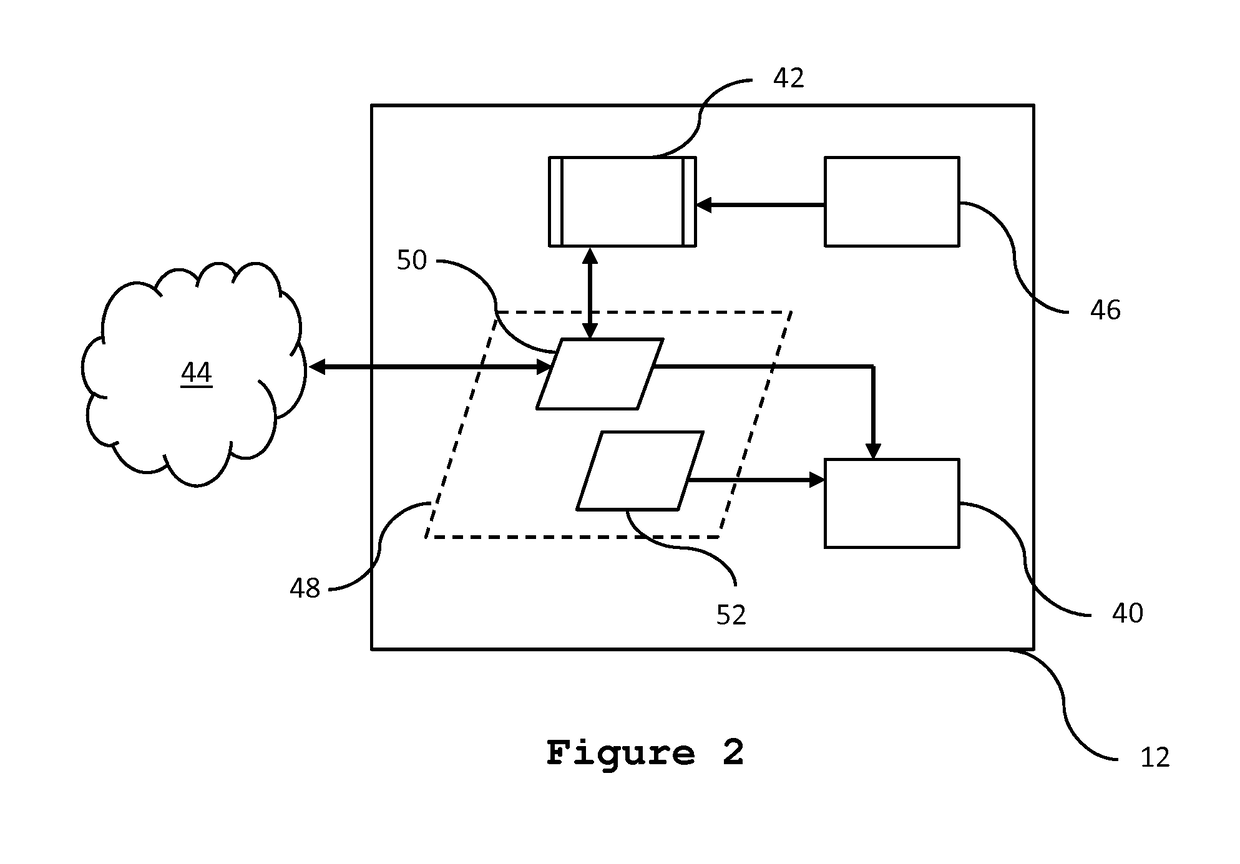

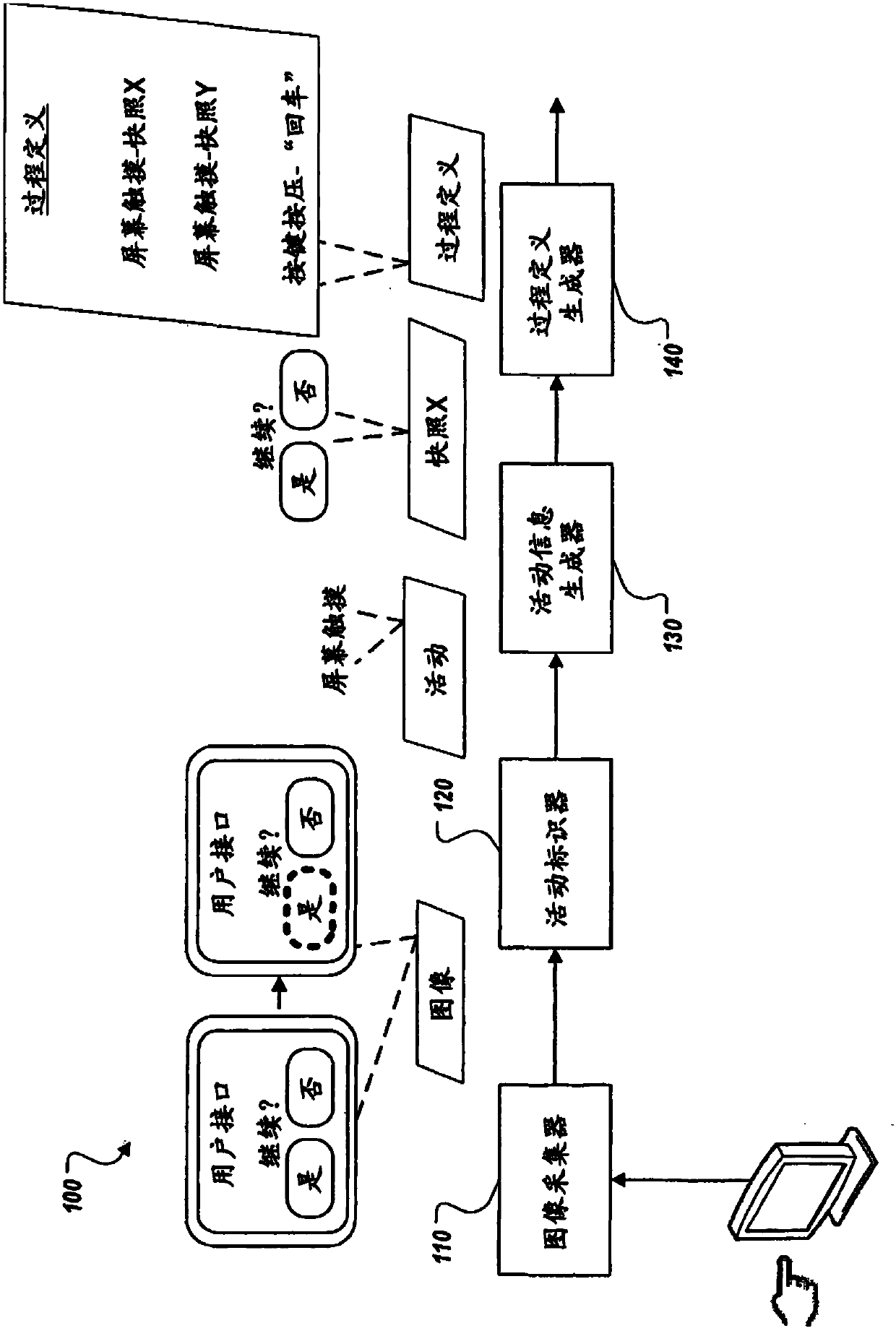

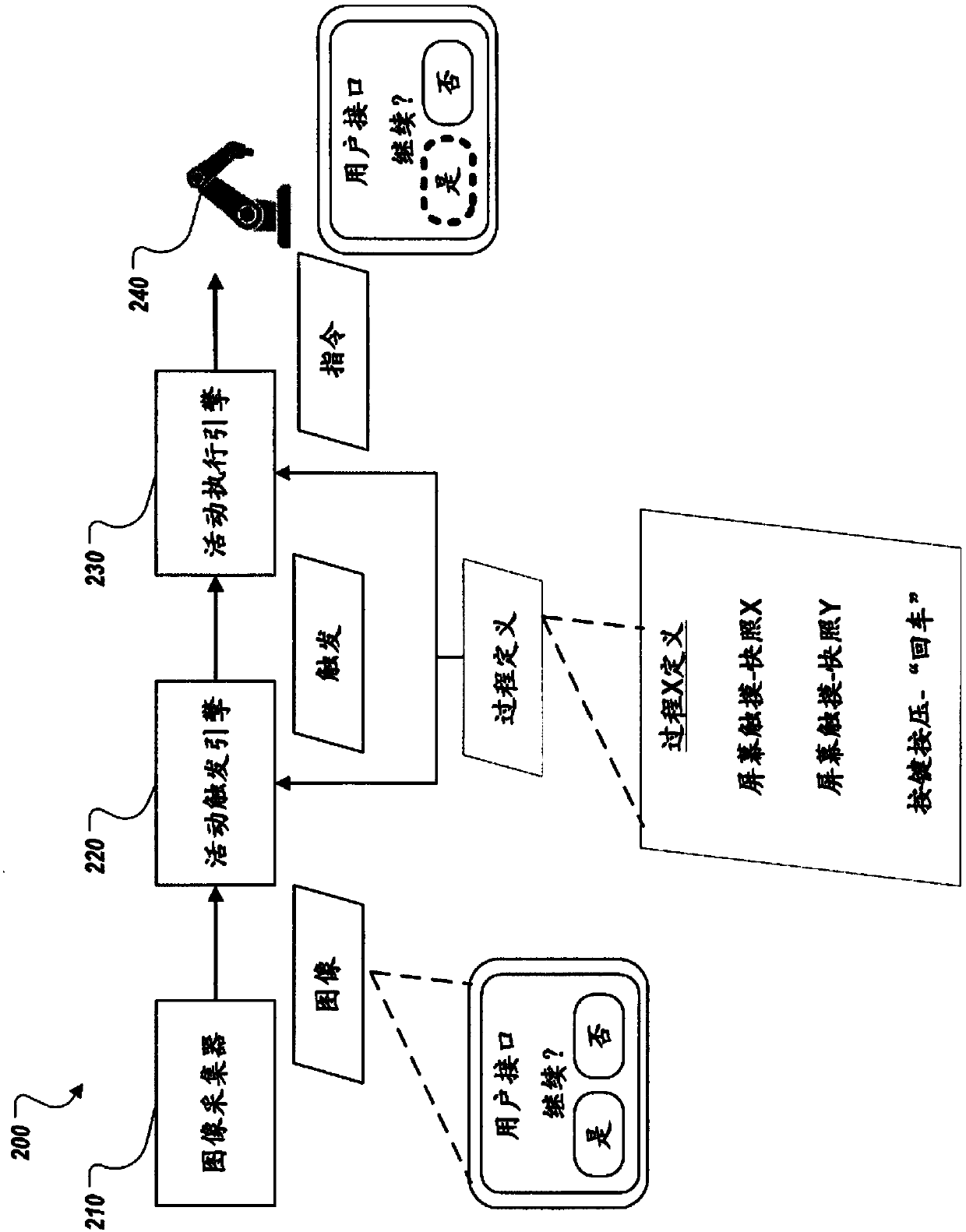

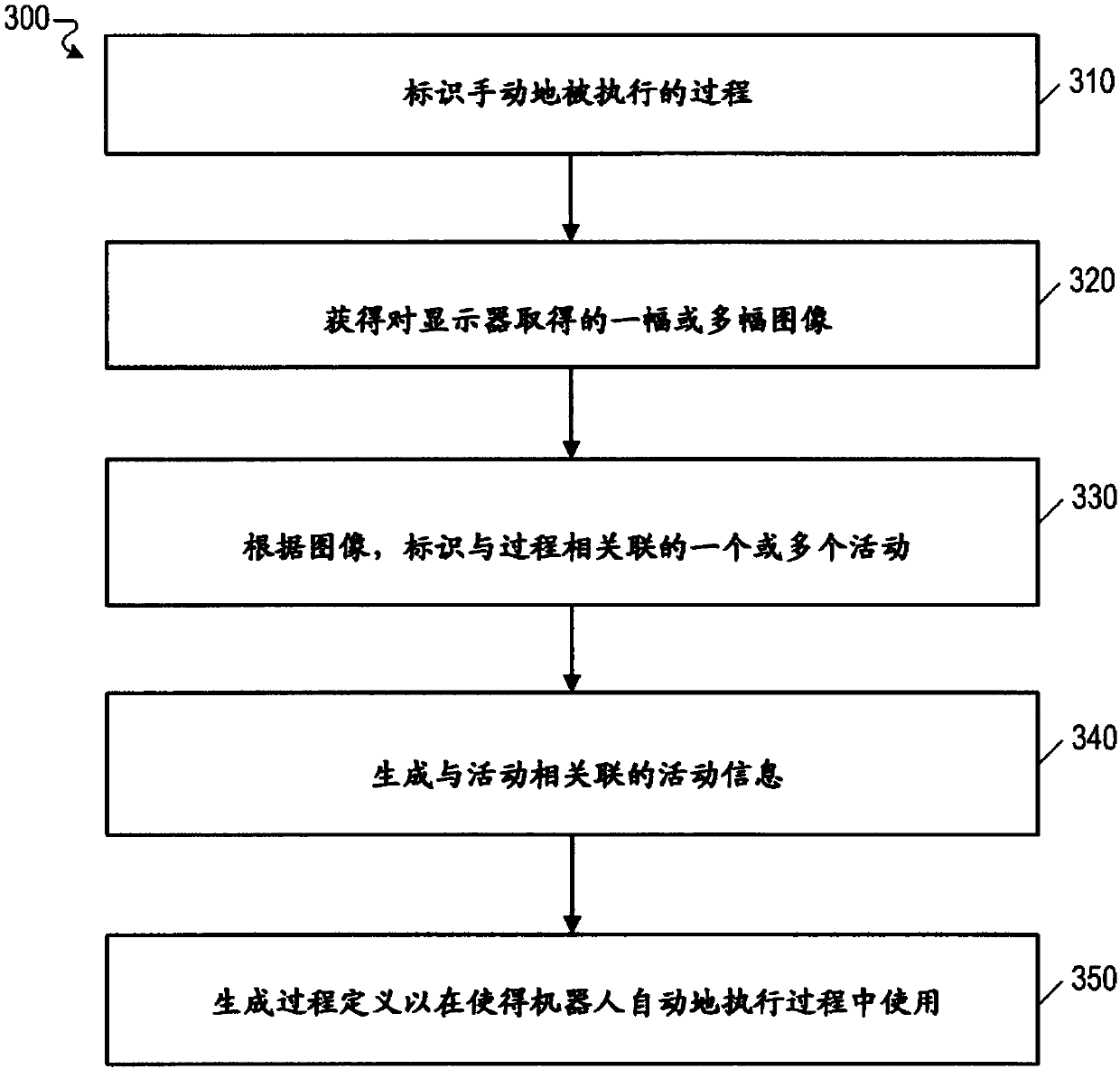

Robotic process automation

ActiveCN107666987AAutomated precisionFully automatedProgramme controlProgramme-controlled manipulatorDisplay deviceProcess definition

Methods, systems, and apparatus, including computer programs encoded on a computer storage medium, for automating a manual process. The methods, systems, and apparatus include actions of identifying aprocess that (i) is manually performed by a user interacting with a computer, and (ii) is to be automated for performance by a robot that is configured to interact with another computer. Additional actions include obtaining one or more images taken of a display of the computer while the user is interacting with the computer in manually performing the process and applying a computer vision technique to identify one or more activities associated with the process. Further actions include, for each of the one or more identified activities, generating activity information associated with the activity and generating a process definition for use in causing the robot to automatically perform the process.

Owner:ACCENTURE GLOBAL SERVICES LTD

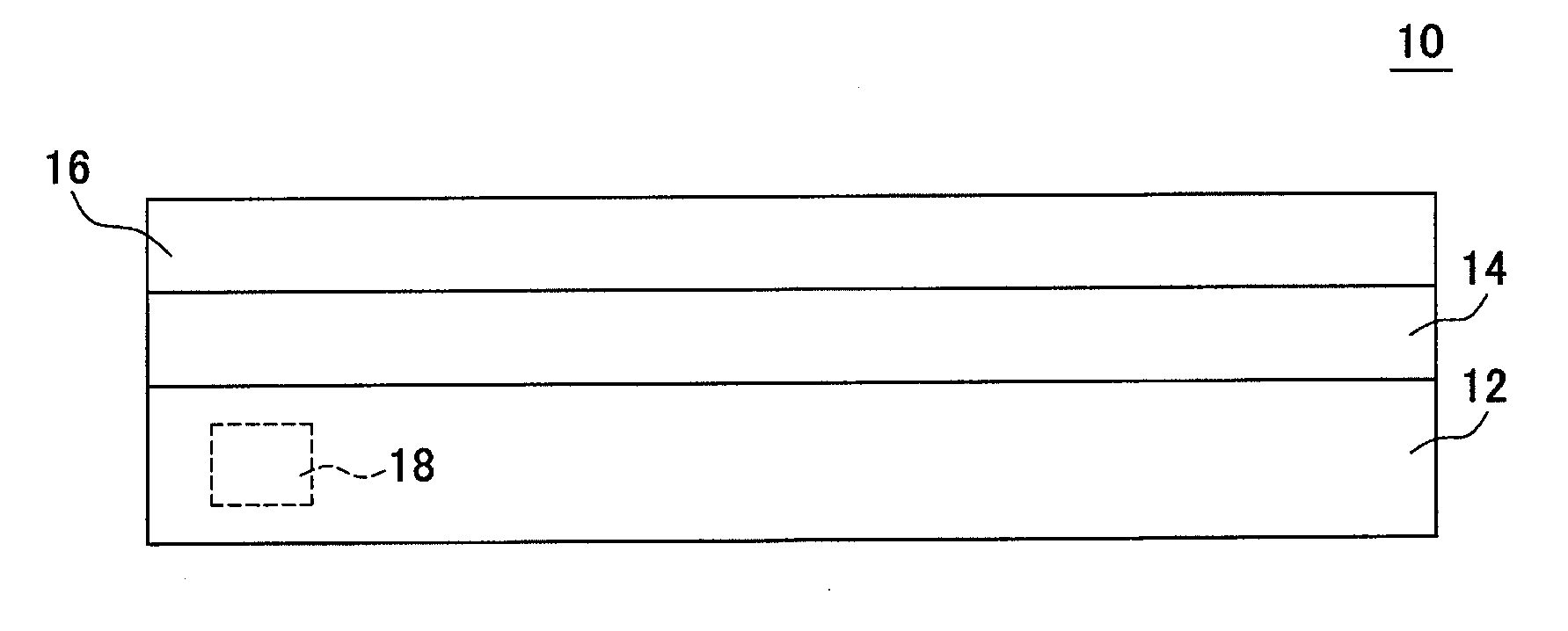

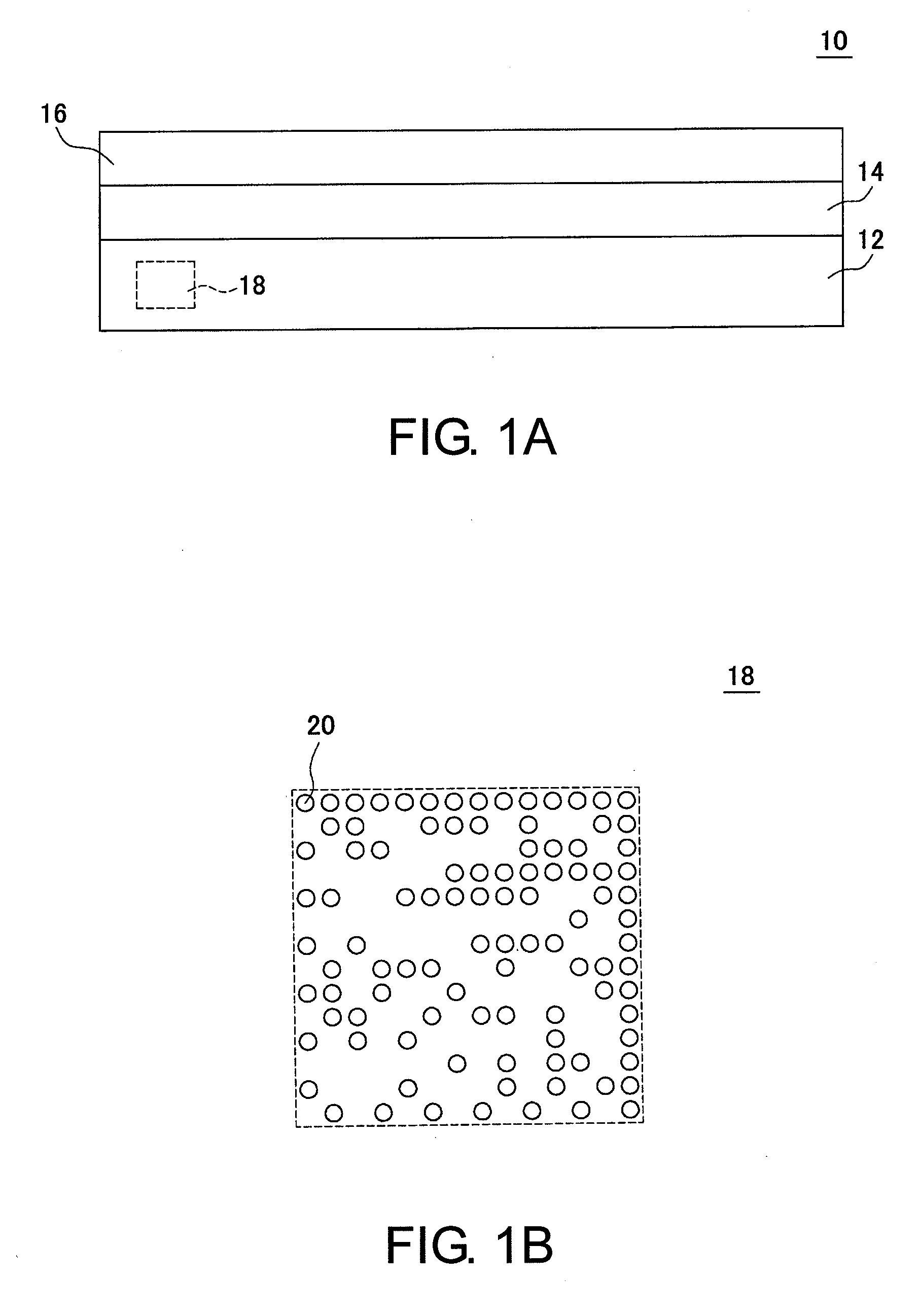

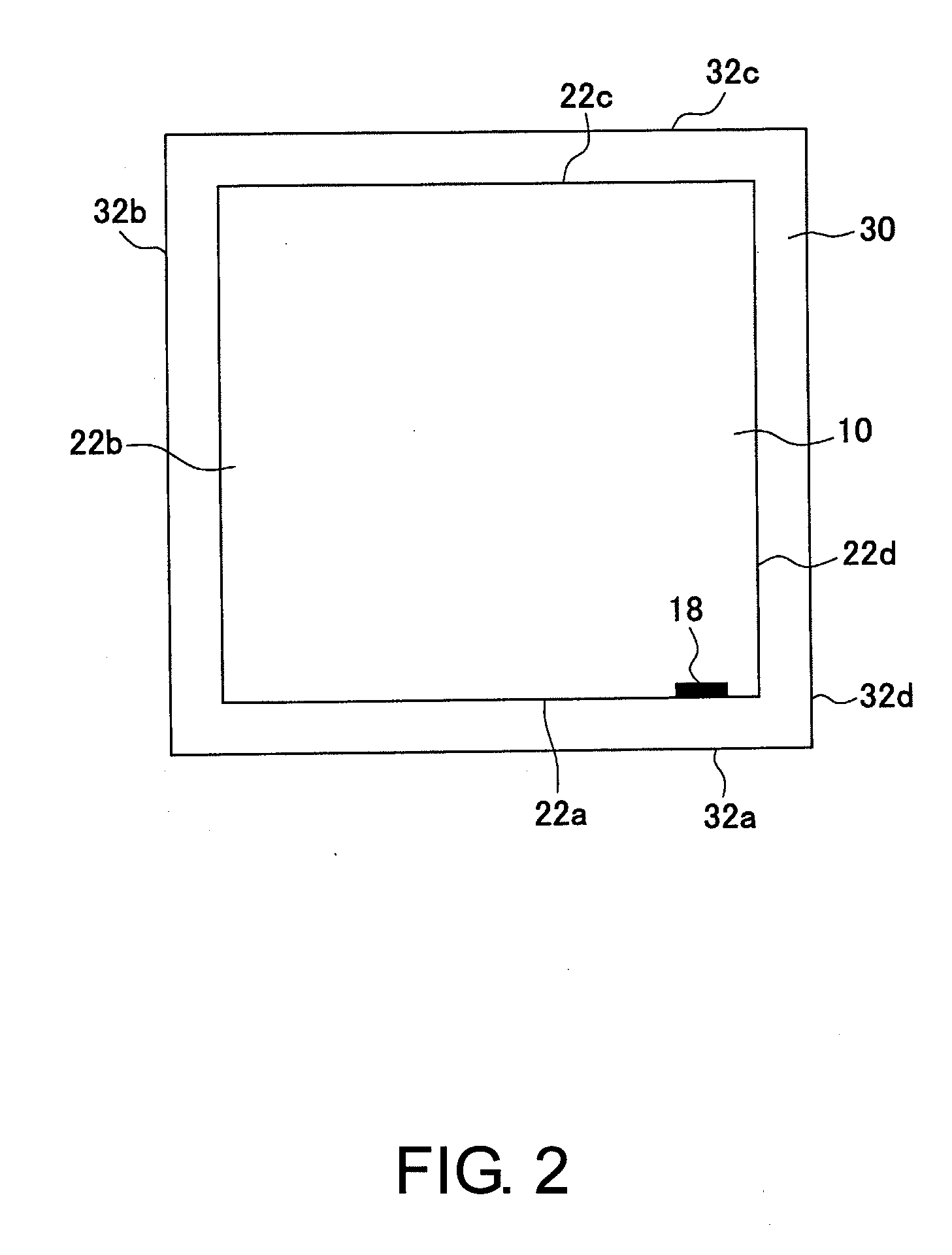

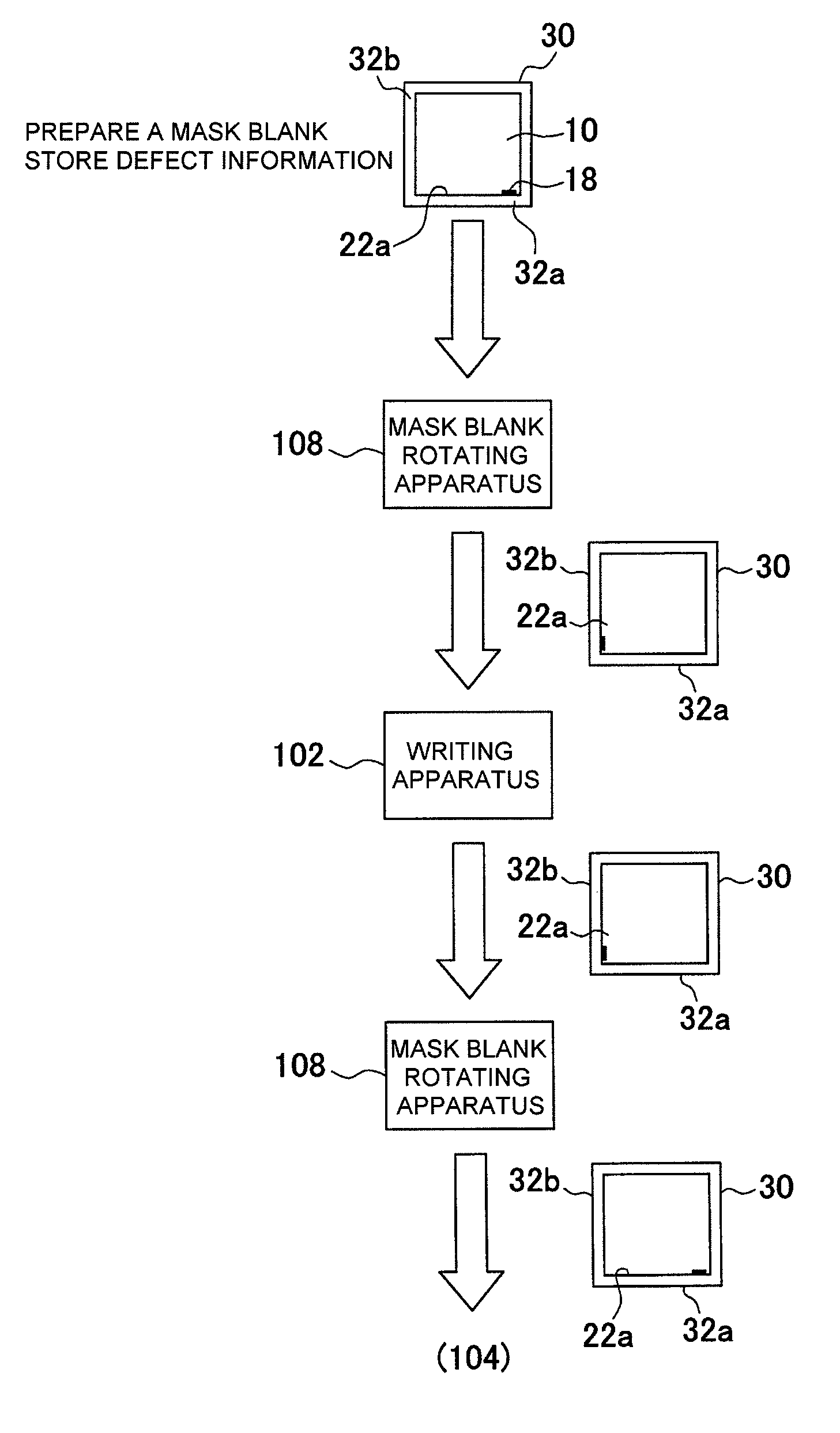

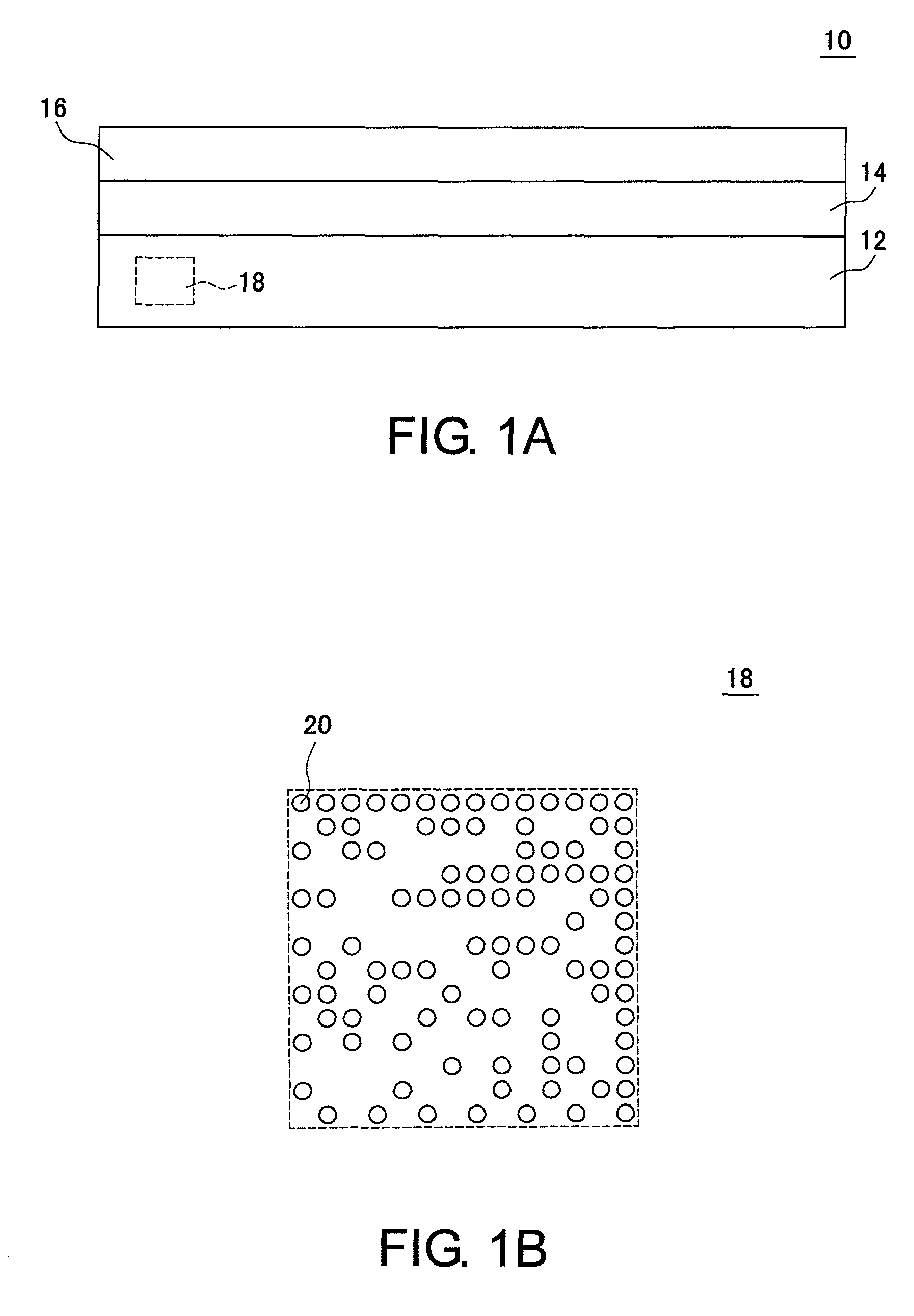

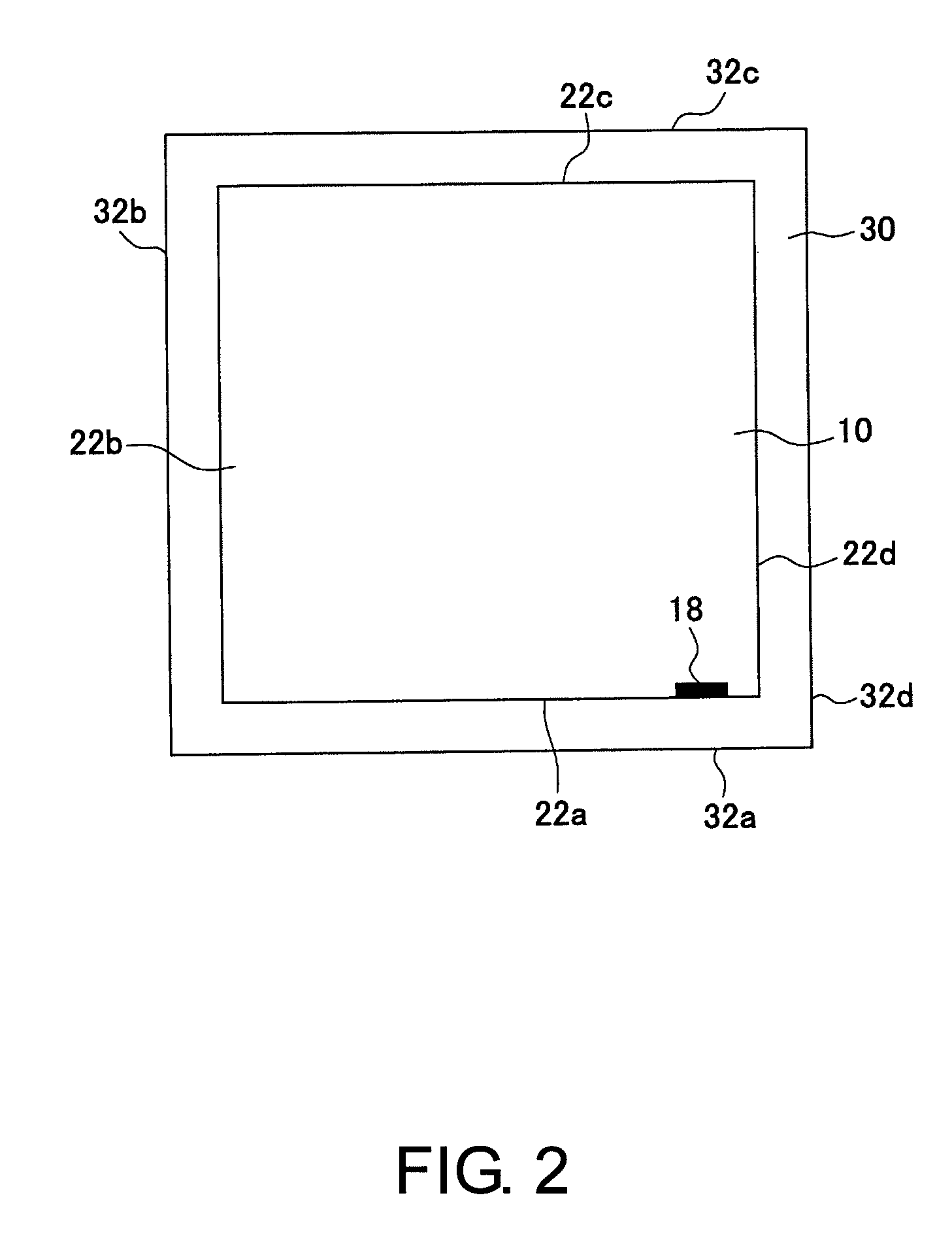

Photomask manufacturing method

ActiveUS20090325083A1Automated precisionDetection securityPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringRotation control

A photomask manufacturing method includes a defect information storage step of storing defect information of a mask blank, provided with an identification marker on an end face thereof, into an information storage device in correspondence to the identification marker, a placing orientation determination step of determining a placing orientation of the mask blank with respect to an exposure / writing apparatus, and an orientation correction step of performing rotation control of a rotating apparatus so that an orientation of the mask blank coincides with the determined placing orientation.

Owner:HOYA CORP

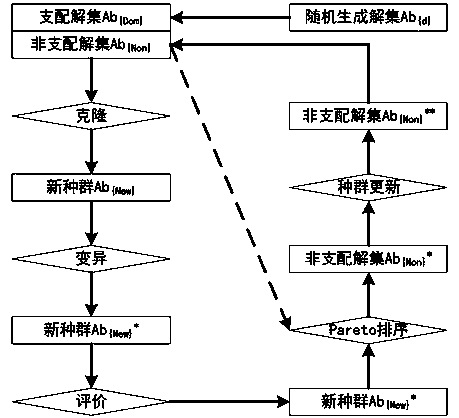

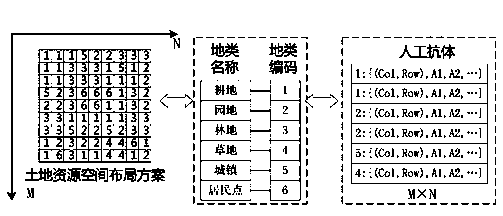

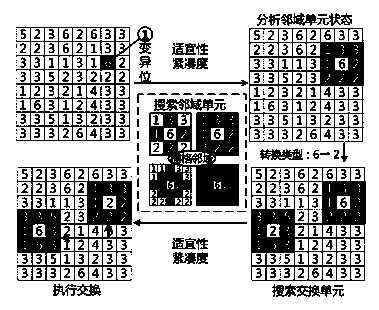

Method for optimizing spatial layout of land resources based on multi-target artificial immunization system

ActiveCN103473465AAutomated precisionAccurate and intelligentSpecial data processing applicationsArtificial immune systemLand resources

The invention provides a method for optimizing the spatial layout of land resources based on a multi-target artificial immunization system. The method comprises the following steps: storing the evaluation result of the land suitability of a planned region in a base year by a grid file; encoding namely mapping the spatial layout scheme of the land resources into the antibodies of the artificial immunization system through integer coding, and representing one actual plot of land by one grid unit, which corresponds to one gene bit in each artificial antibody, in the planned region; setting a target function, setting constraint conditions, initiating an antibody population, calculating the target value vector quantities of the antibodies, then iterating, carrying out cloning, mutation, calculation on the target value vector quantities of the antibodies, population updating and judgment on terminal conditions until iteration is over, and decoding to obtain a Pareto optimizing scheme.

Owner:WUHAN UNIV

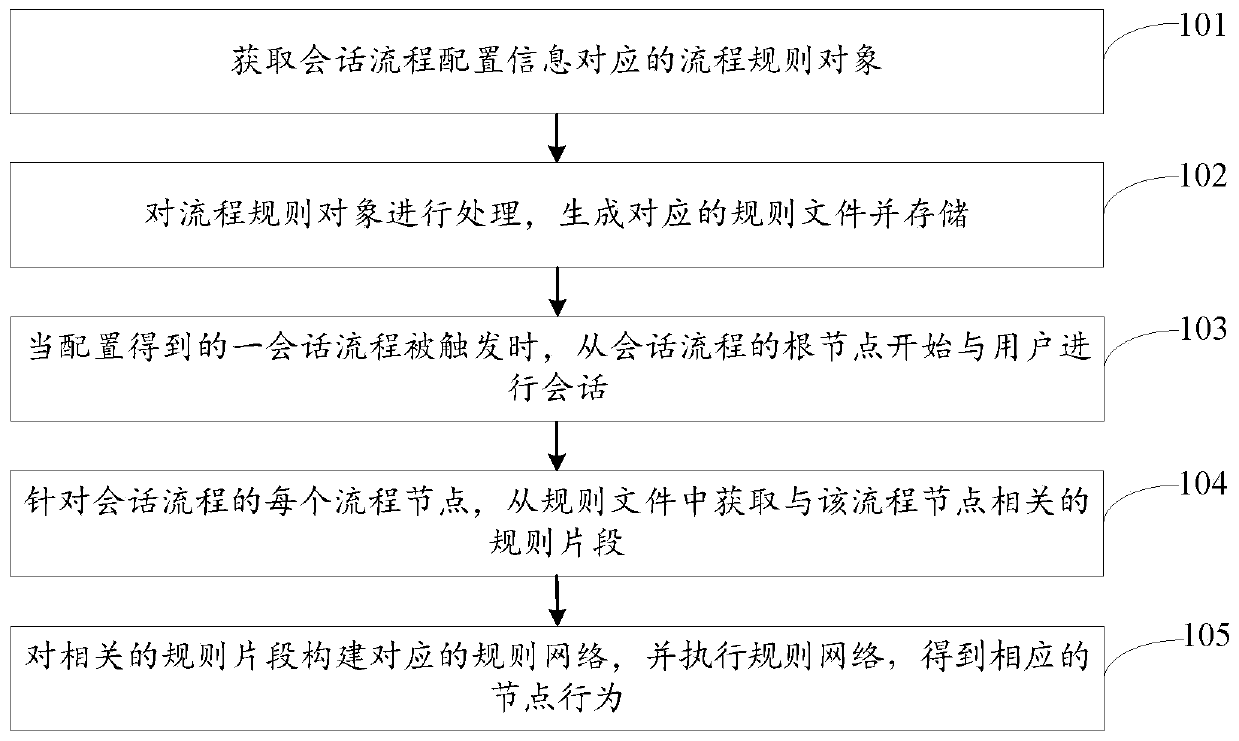

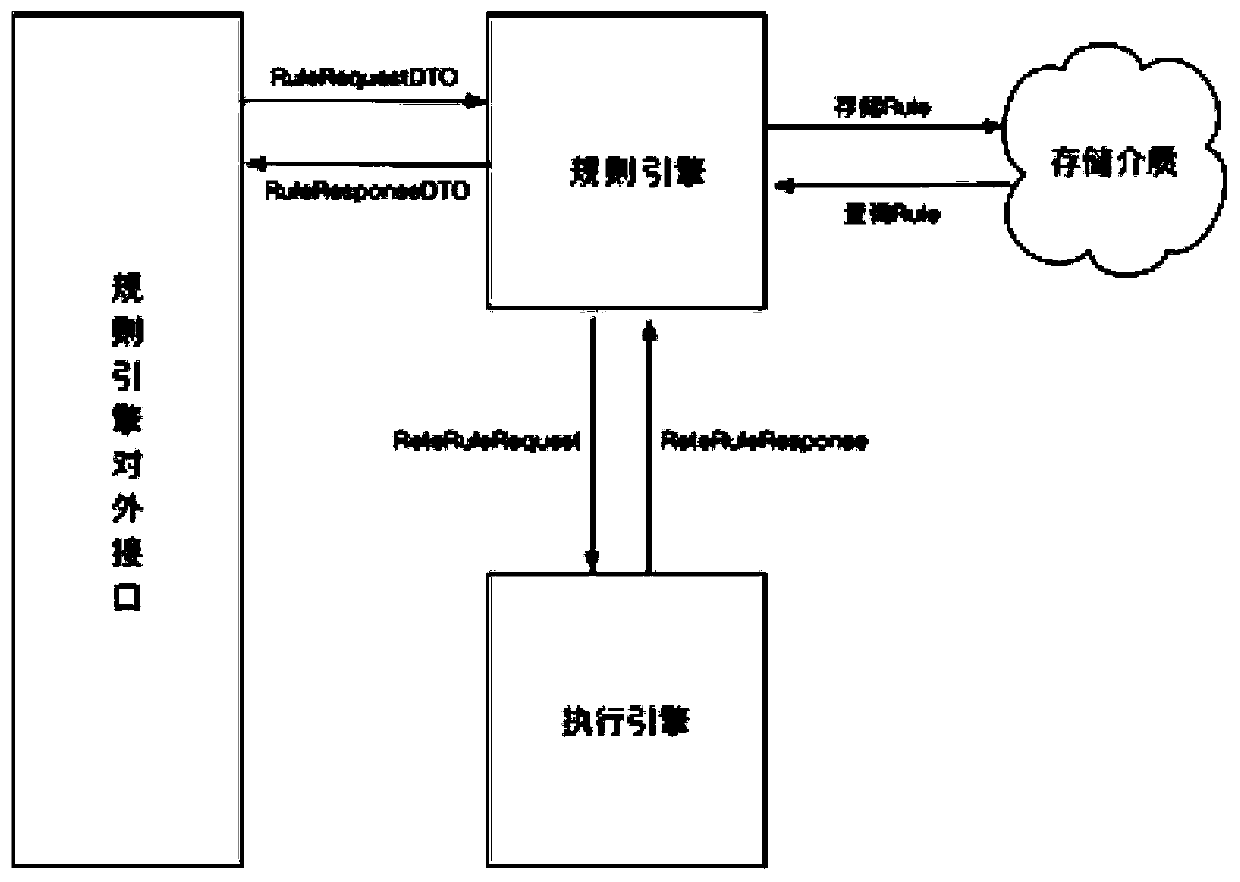

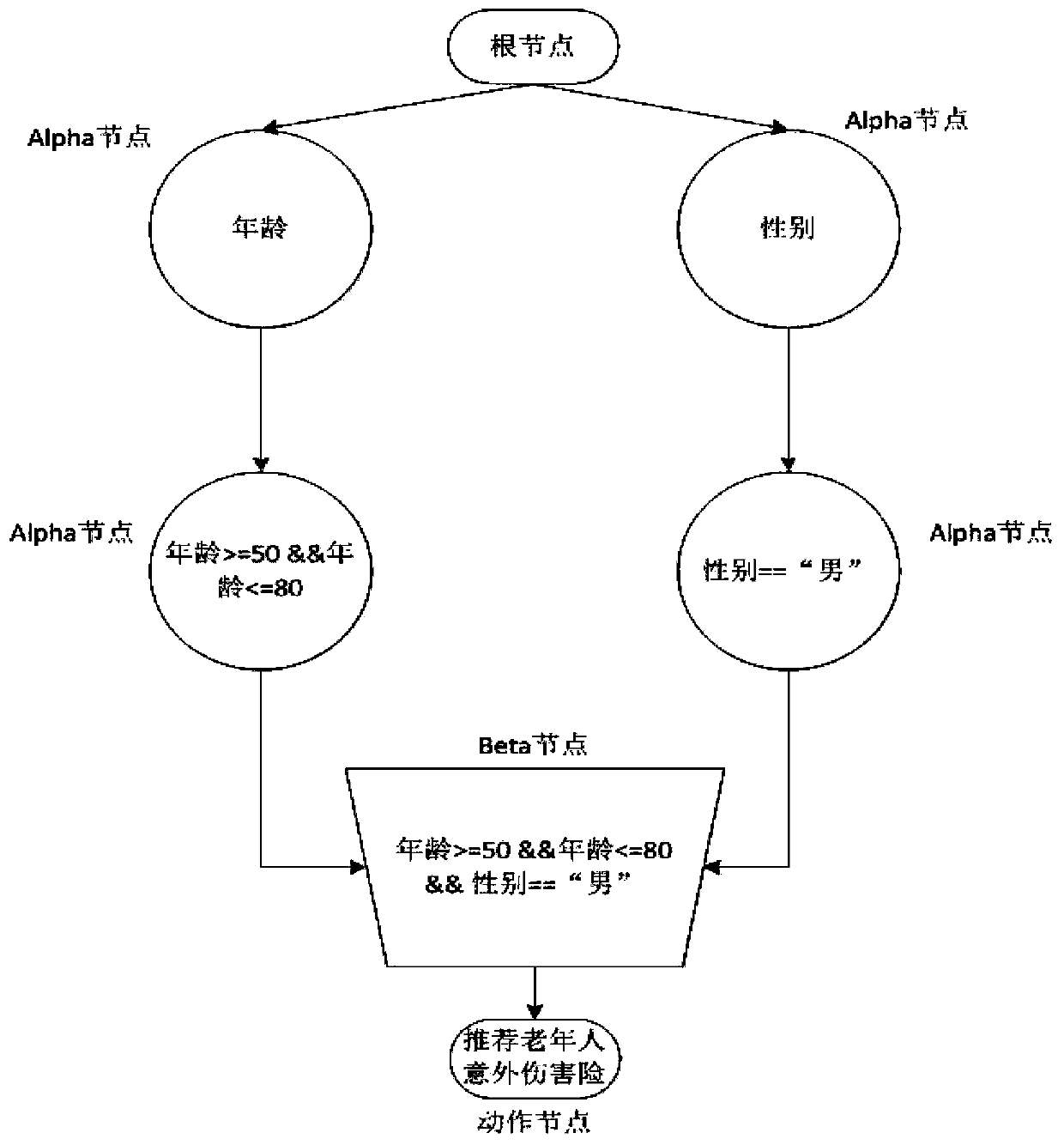

Session flow configuration method and device and computer readable storage medium

ActiveCN109743346AAvoid duplication of development workSave development costTransmissionFully automaticDistributed computing

The invention discloses a session flow processing method and device and a computer readable storage medium, and belongs to the technical field of computers. The method comprises the steps of obtaininga flow rule object corresponding to session flow configuration information; Processing the flow rule object, generating a corresponding rule file and storing the rule file; When a session flow obtained through configuration is triggered, starting to carry out session with a user from a root node of the session flow; For each process node of the session process, executing the following operations:obtaining a rule fragment related to the process node from a rule file; And constructing a corresponding rule network for the related rule fragment, and executing the rule network to obtain a corresponding node behavior. According to the embodiment of the invention, an accurate, flexible and fully automatic session flow can be realized.

Owner:ZHONGAN INFORMATION TECH SERVICES CO LTD

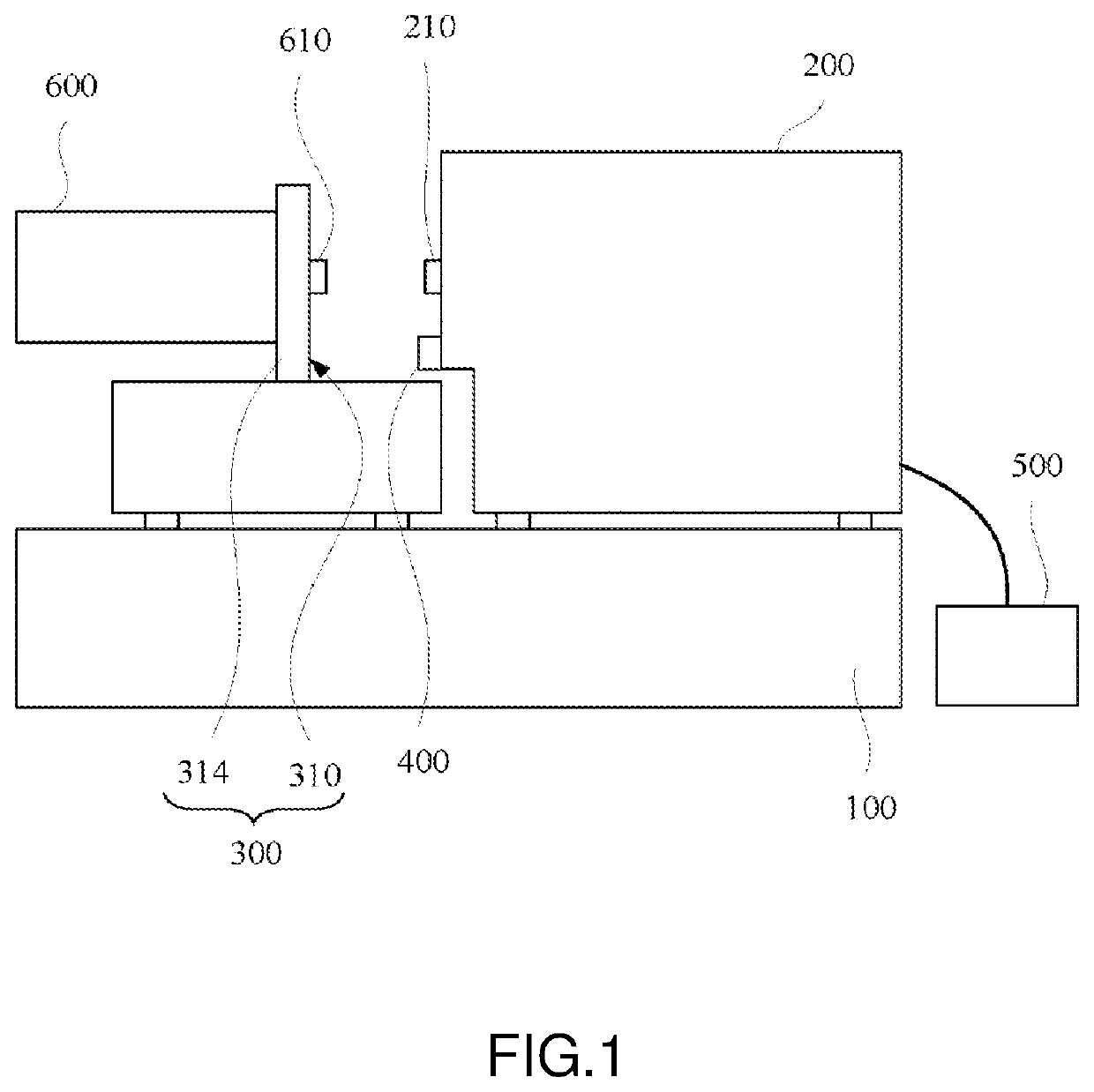

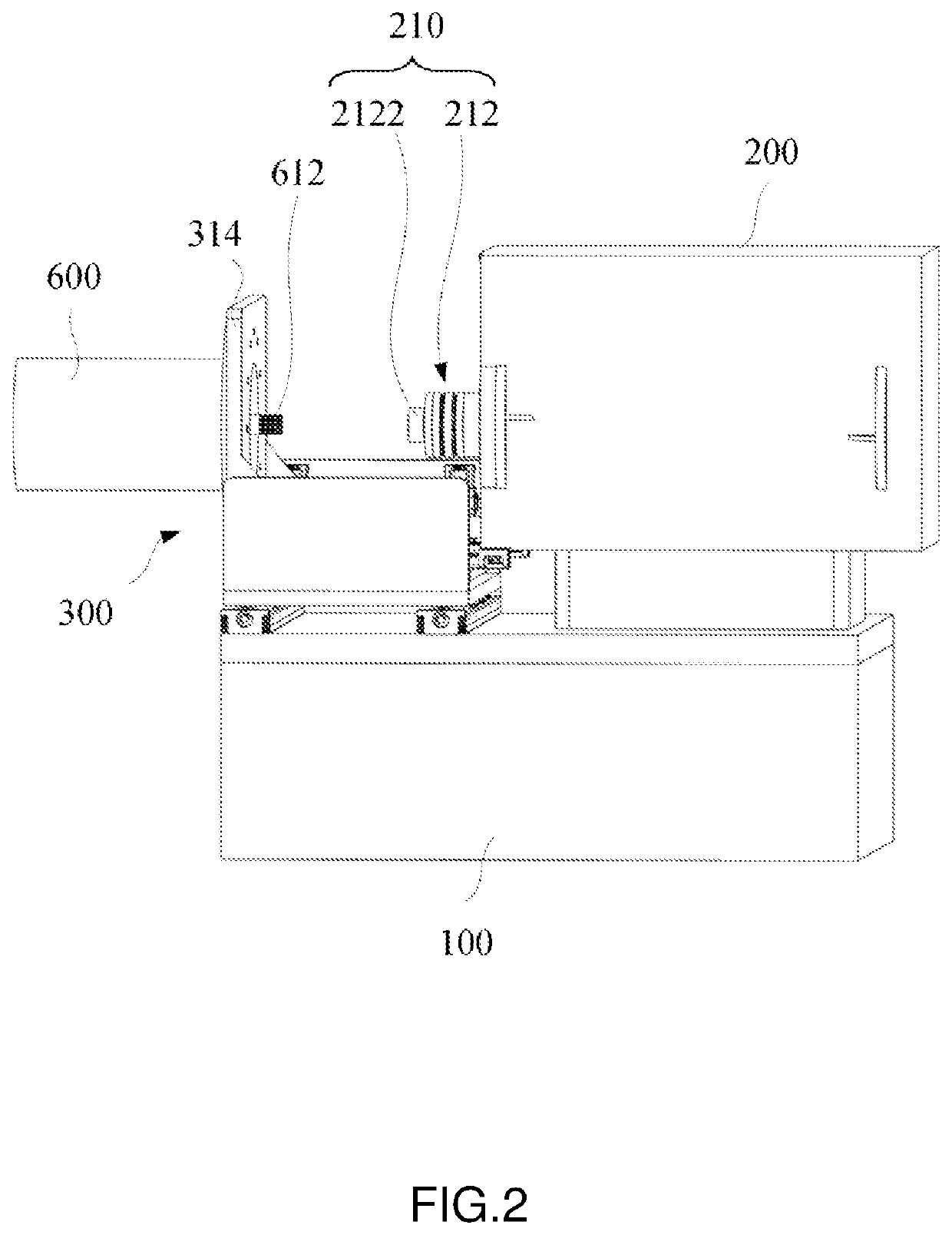

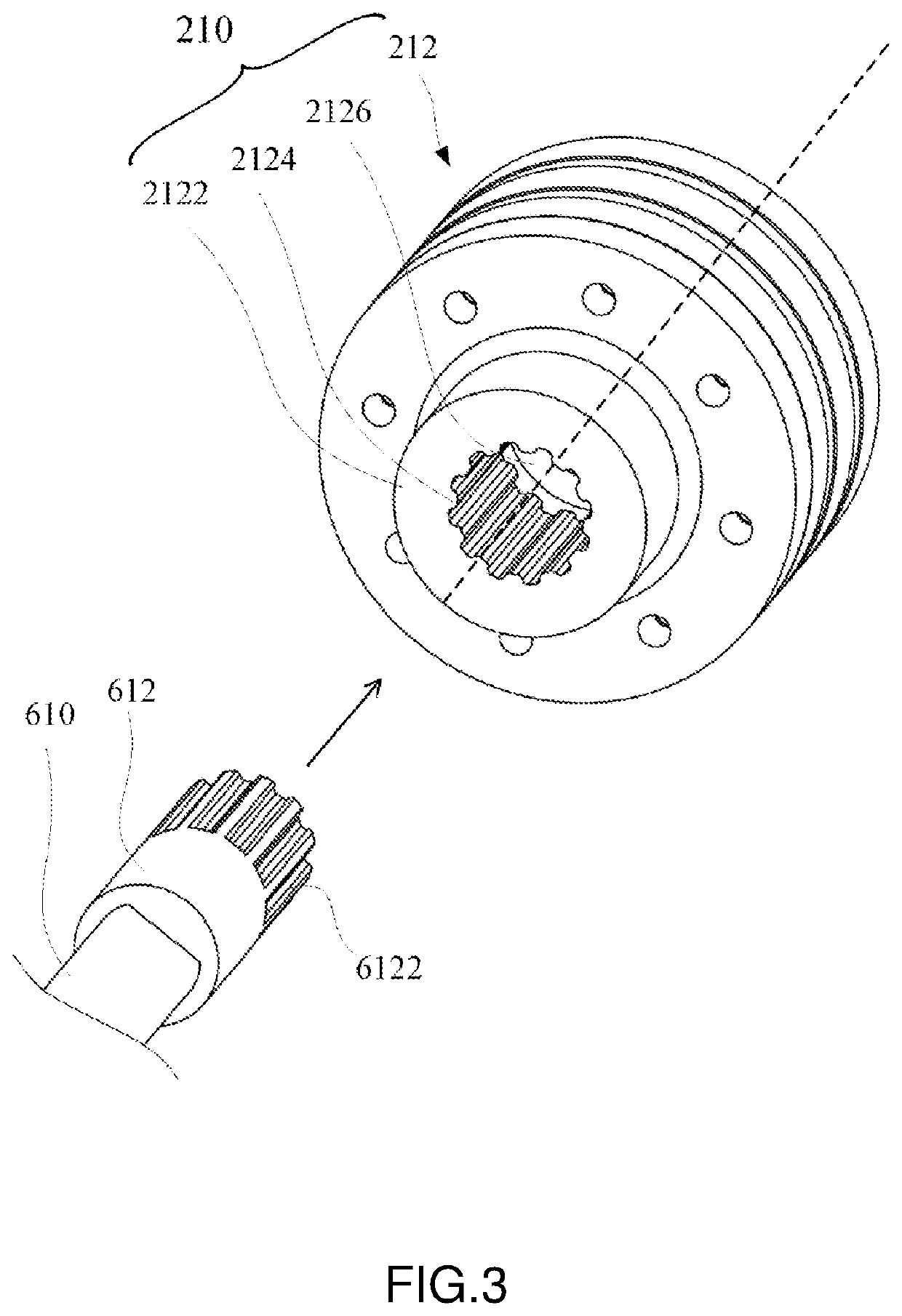

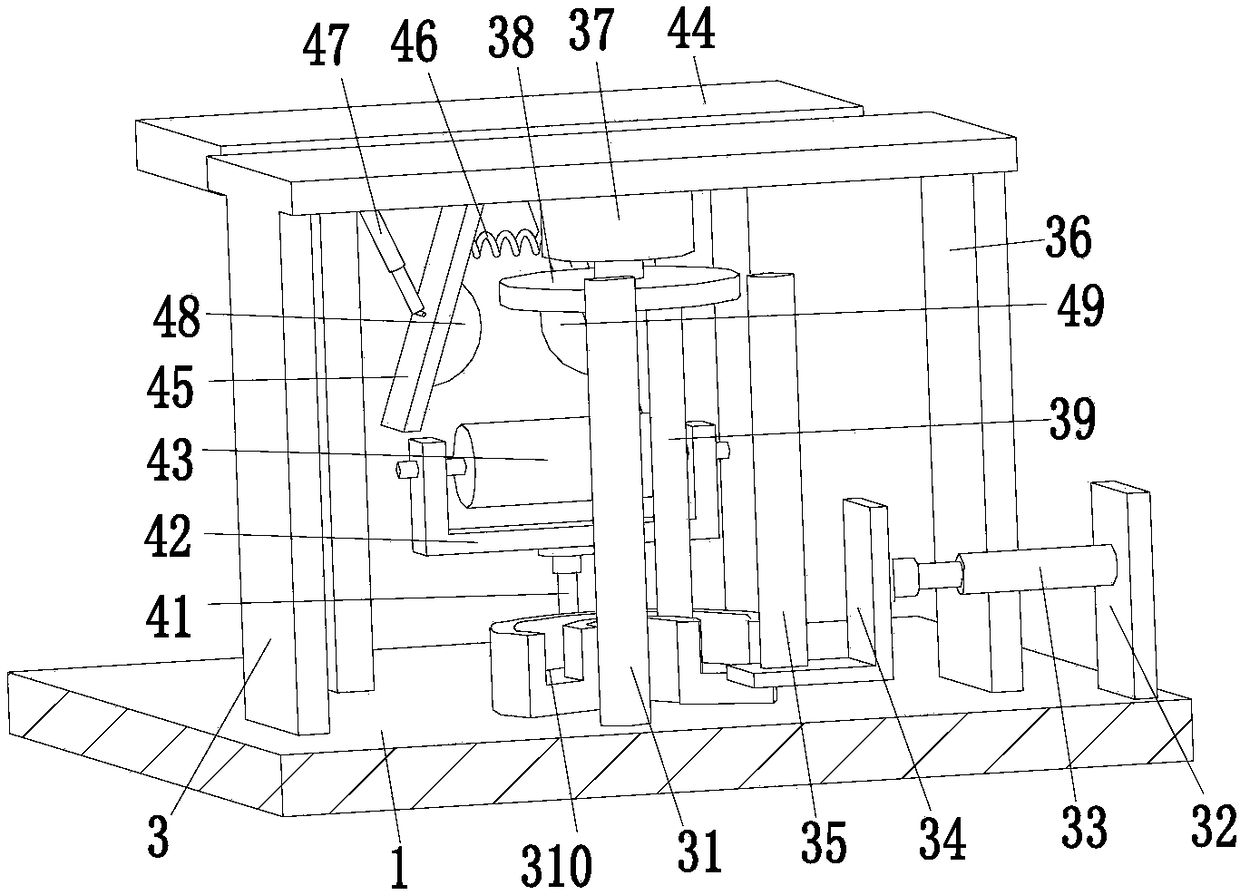

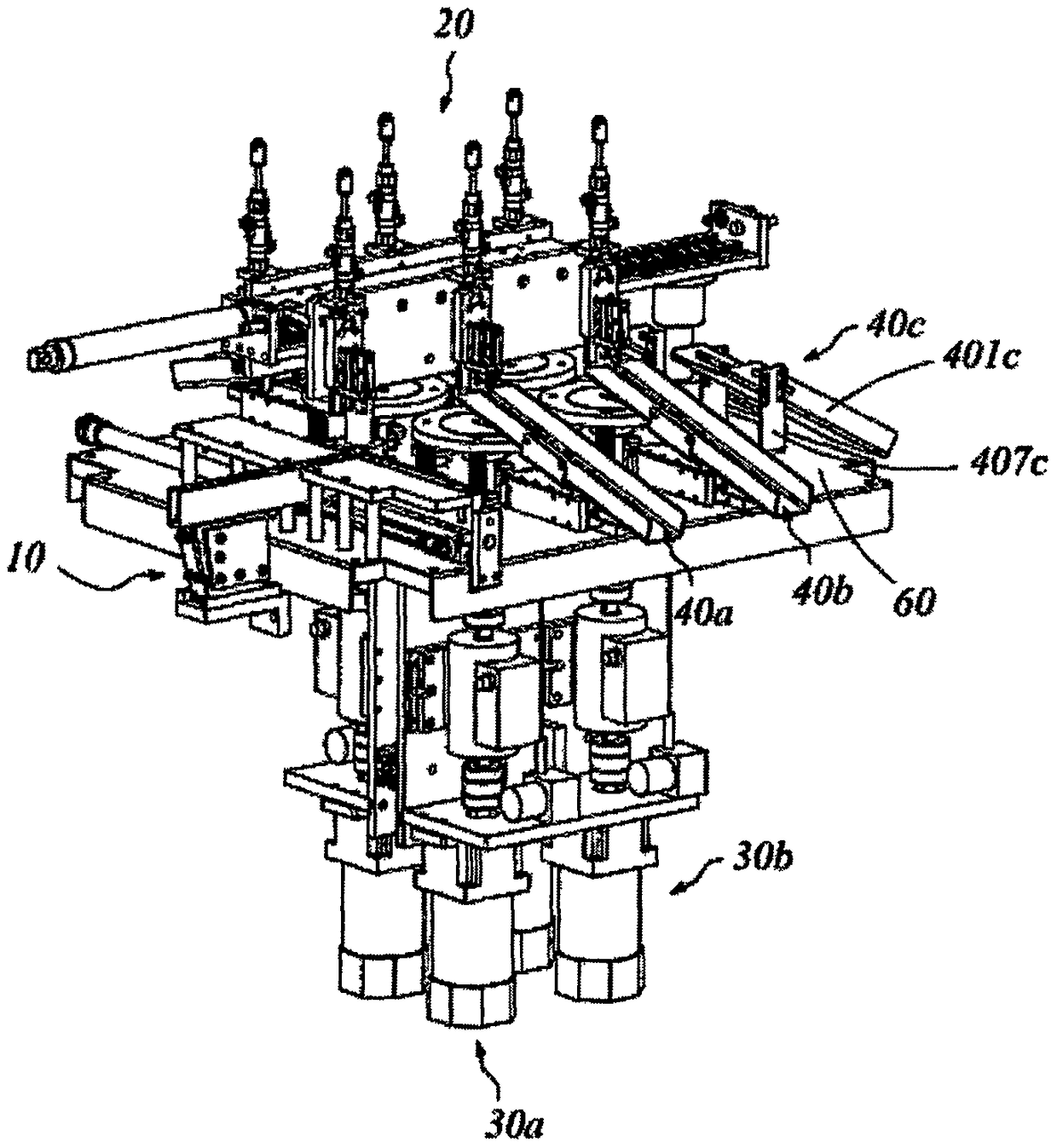

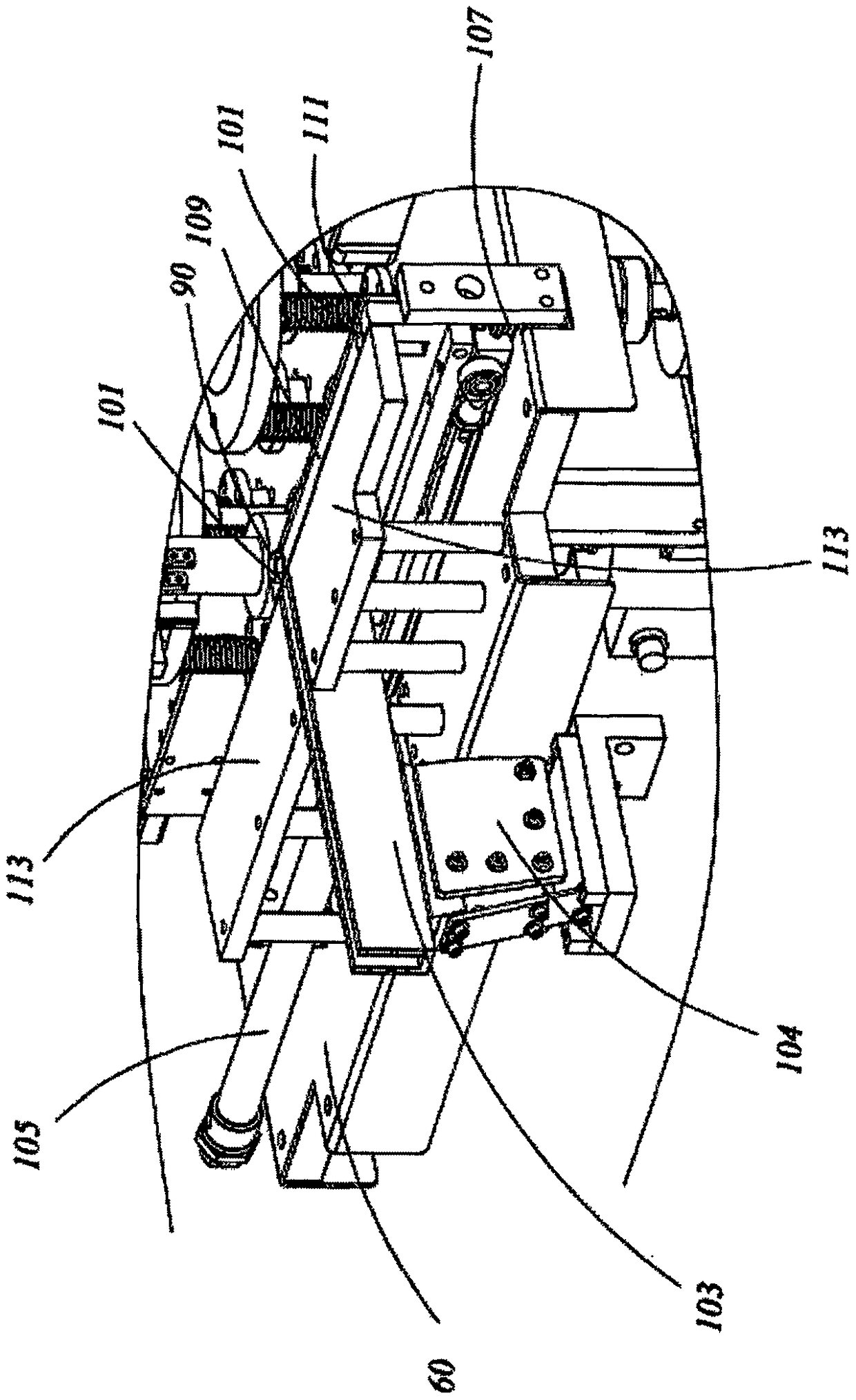

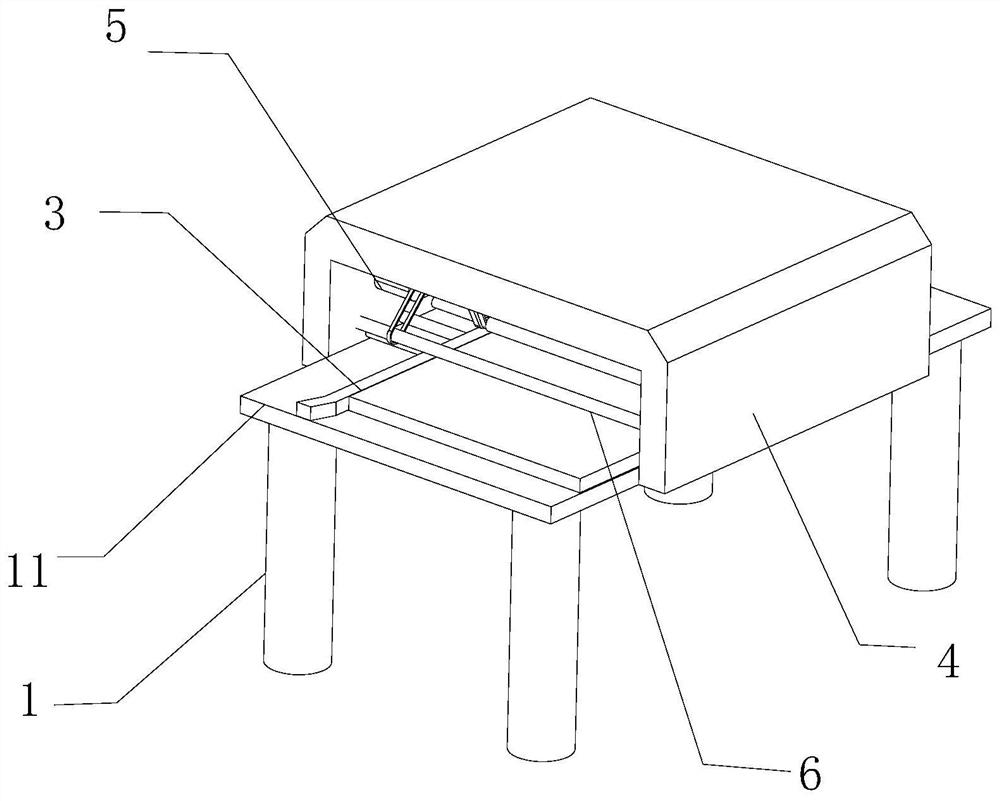

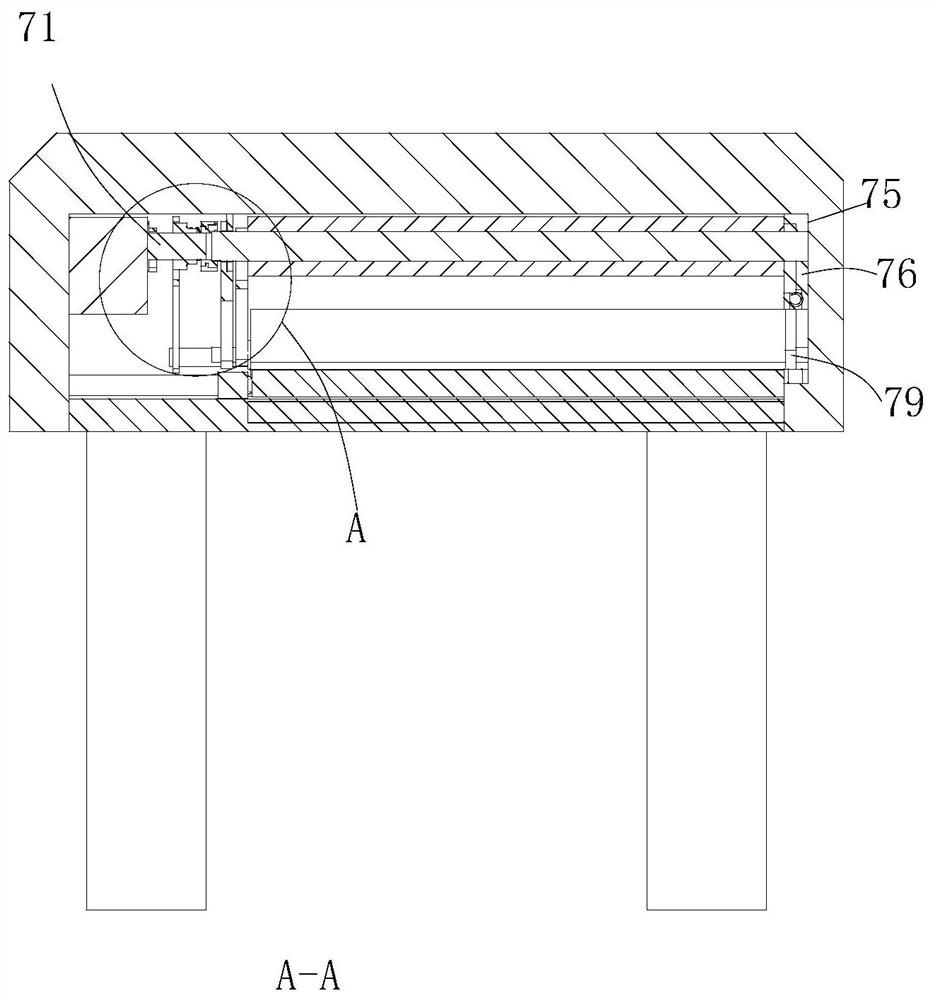

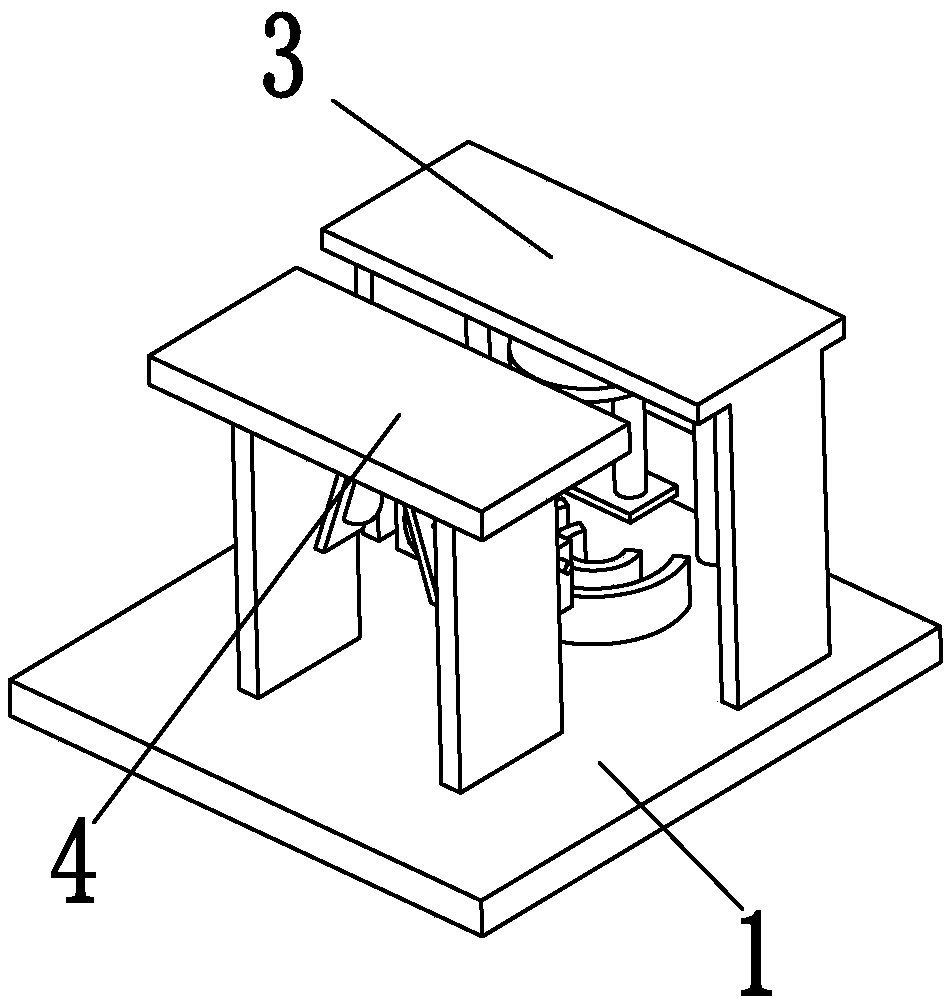

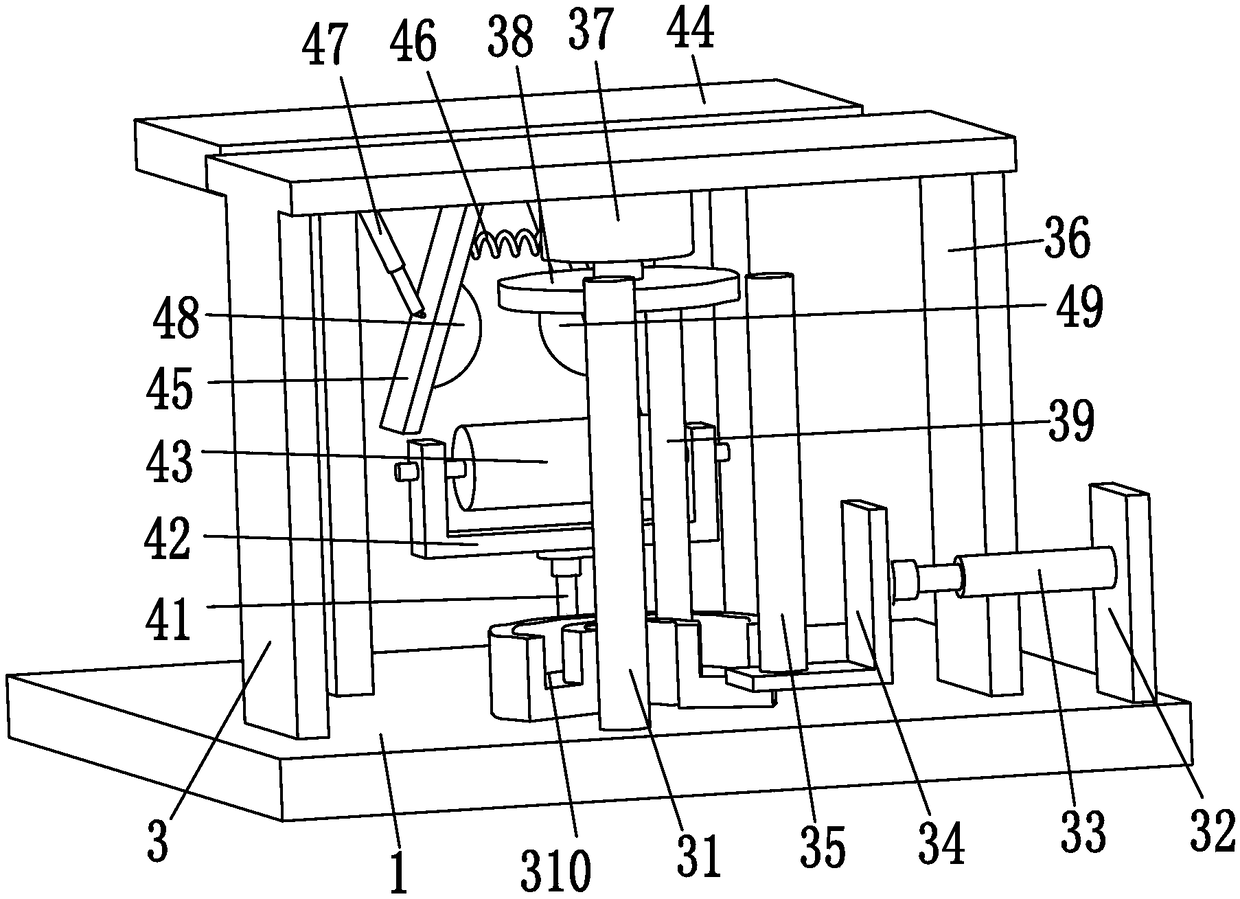

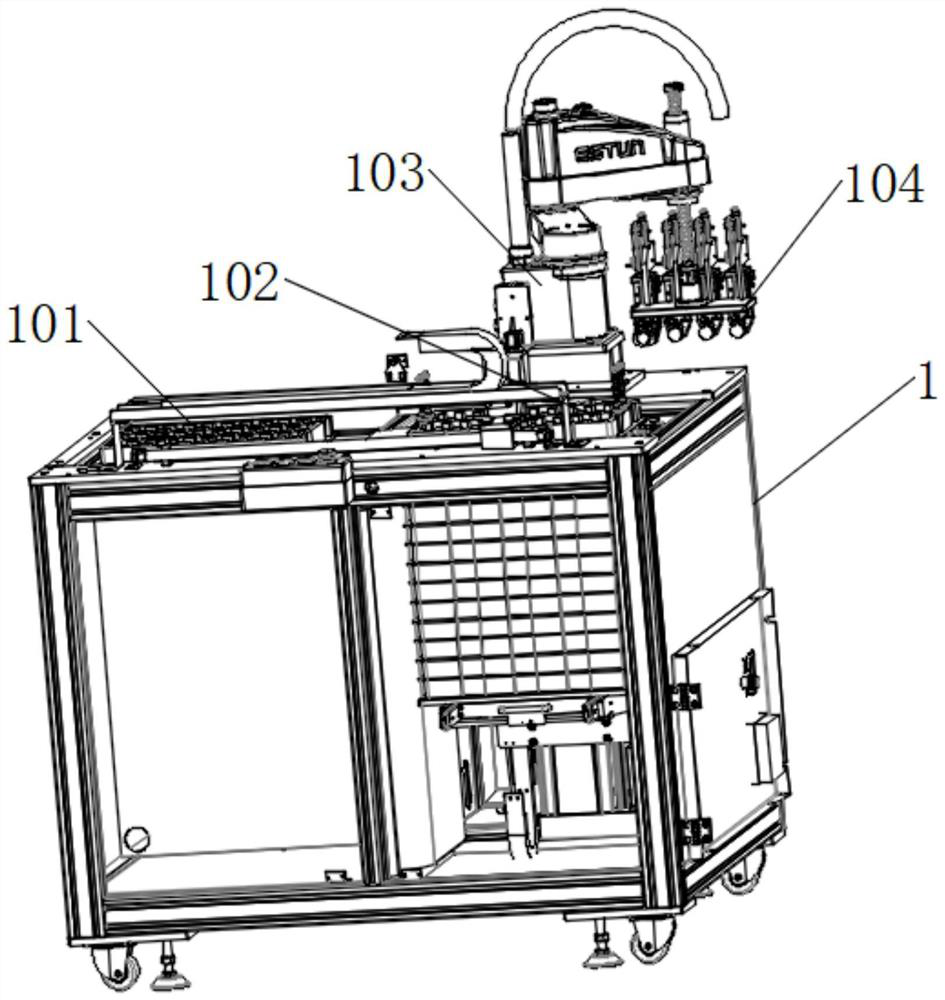

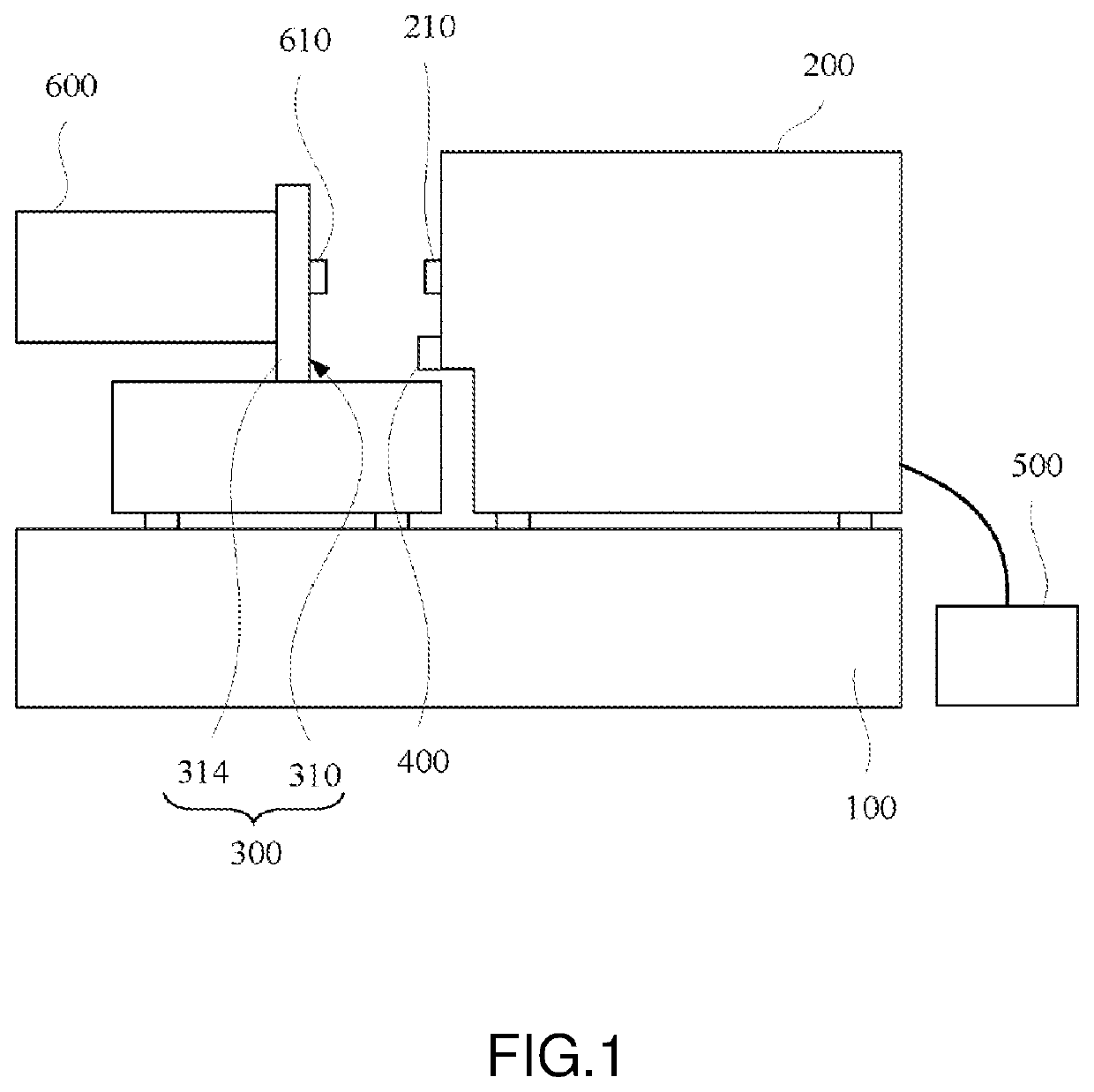

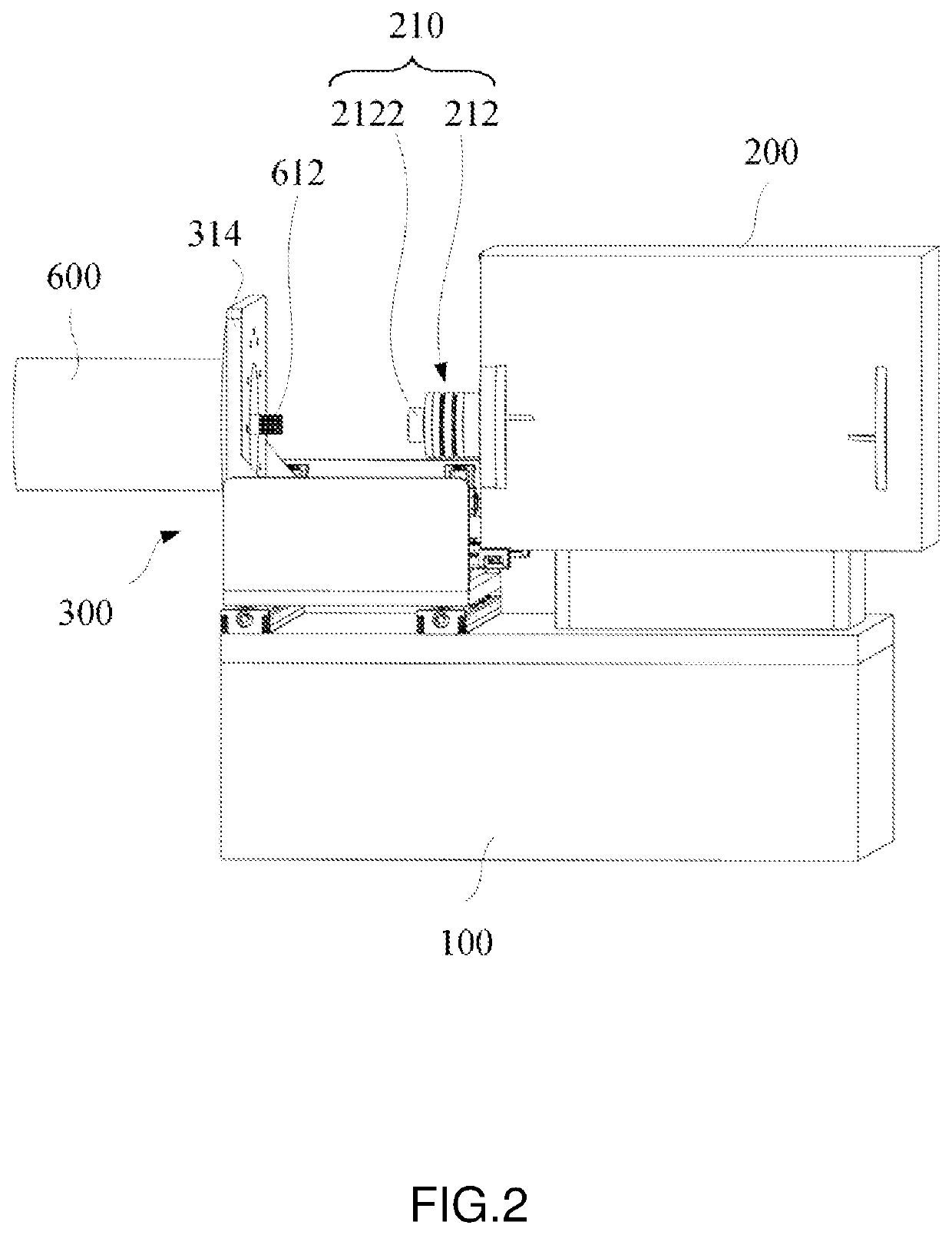

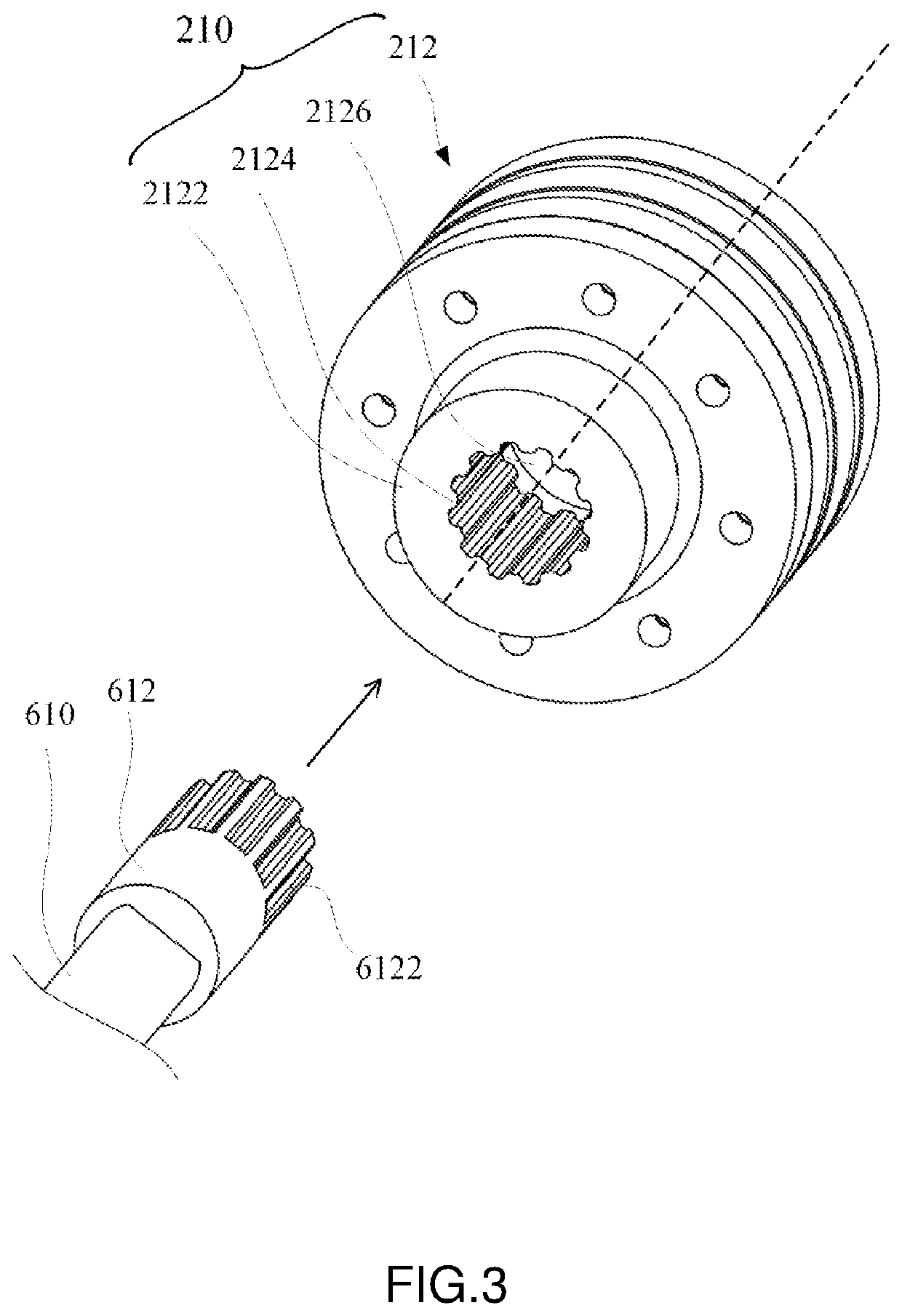

Automatic mounting and demounting device and system for motor testing platform

An automatic mounting and demounting device and system for a motor testing platform, adapted to enable a control host to control automatic mounting and demounting between an axle of a motor under test and an axle of a testing apparatus, includes a mobile platform and a positional information sensing member. The control host controls the mobile platform according to positional information generated by the positional information sensing member, such that a carrier for carrying the motor under test is automatically driven to a corresponding position to thereby effect alignment and connection or separation of the axle of the motor under test and the axle of the testing apparatus. Therefore, preparation for the motor dynamics testing is automatically carried out effectively and correctly, thereby reducing the time and manpower required for testing-related preparation.

Owner:CHROMA ATE

Photomask manufacturing method

ActiveUS8021804B2Detection securityImprove manufacturing yieldPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringRotation control

A photomask manufacturing method includes a defect information storage step of storing defect information of a mask blank, provided with an identification marker on an end face thereof, into an information storage device in correspondence to the identification marker, a placing orientation determination step of determining a placing orientation of the mask blank with respect to an exposure / writing apparatus, and an orientation correction step of performing rotation control of a rotating apparatus so that an orientation of the mask blank coincides with the determined placing orientation.

Owner:HOYA CORP

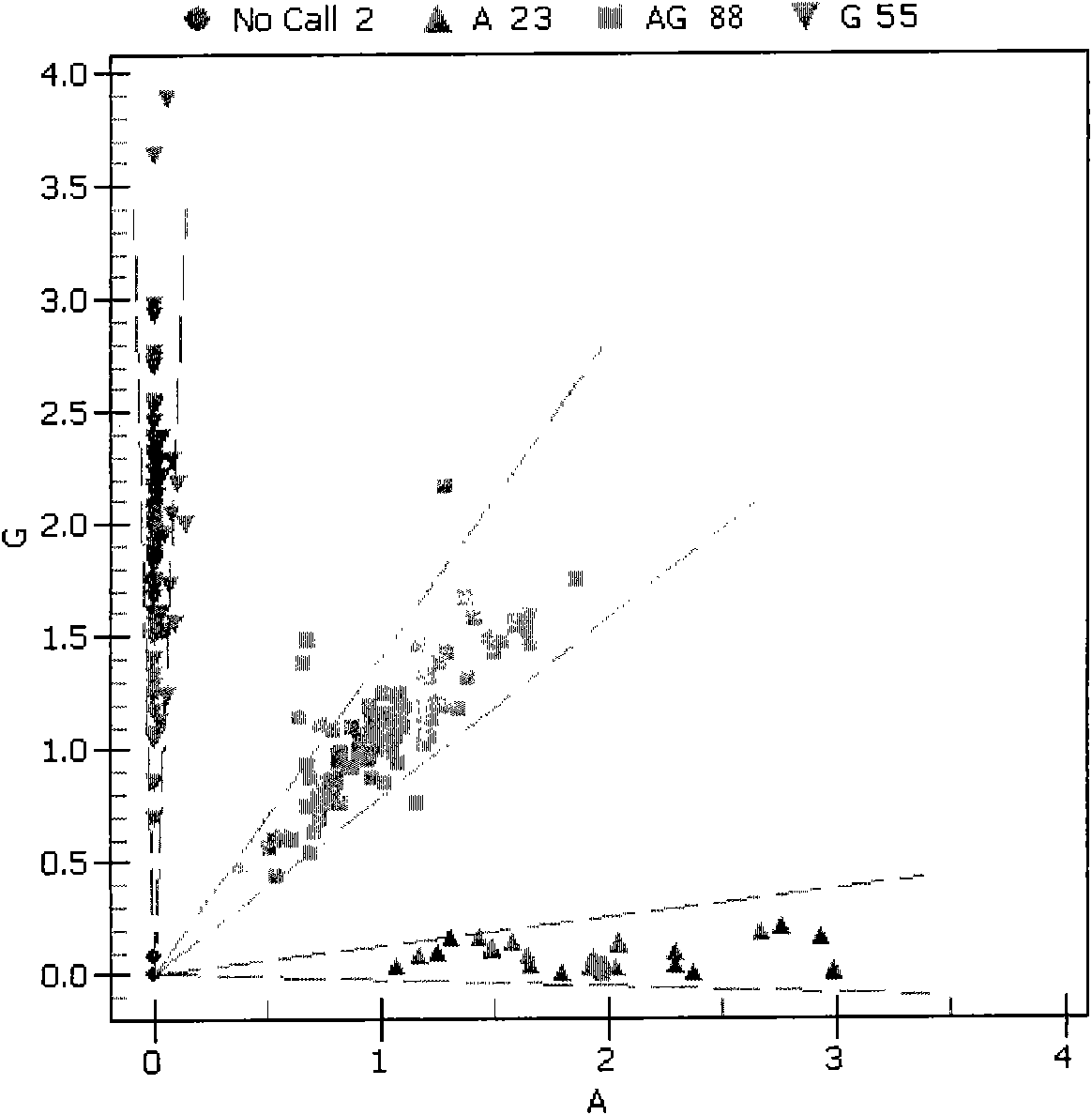

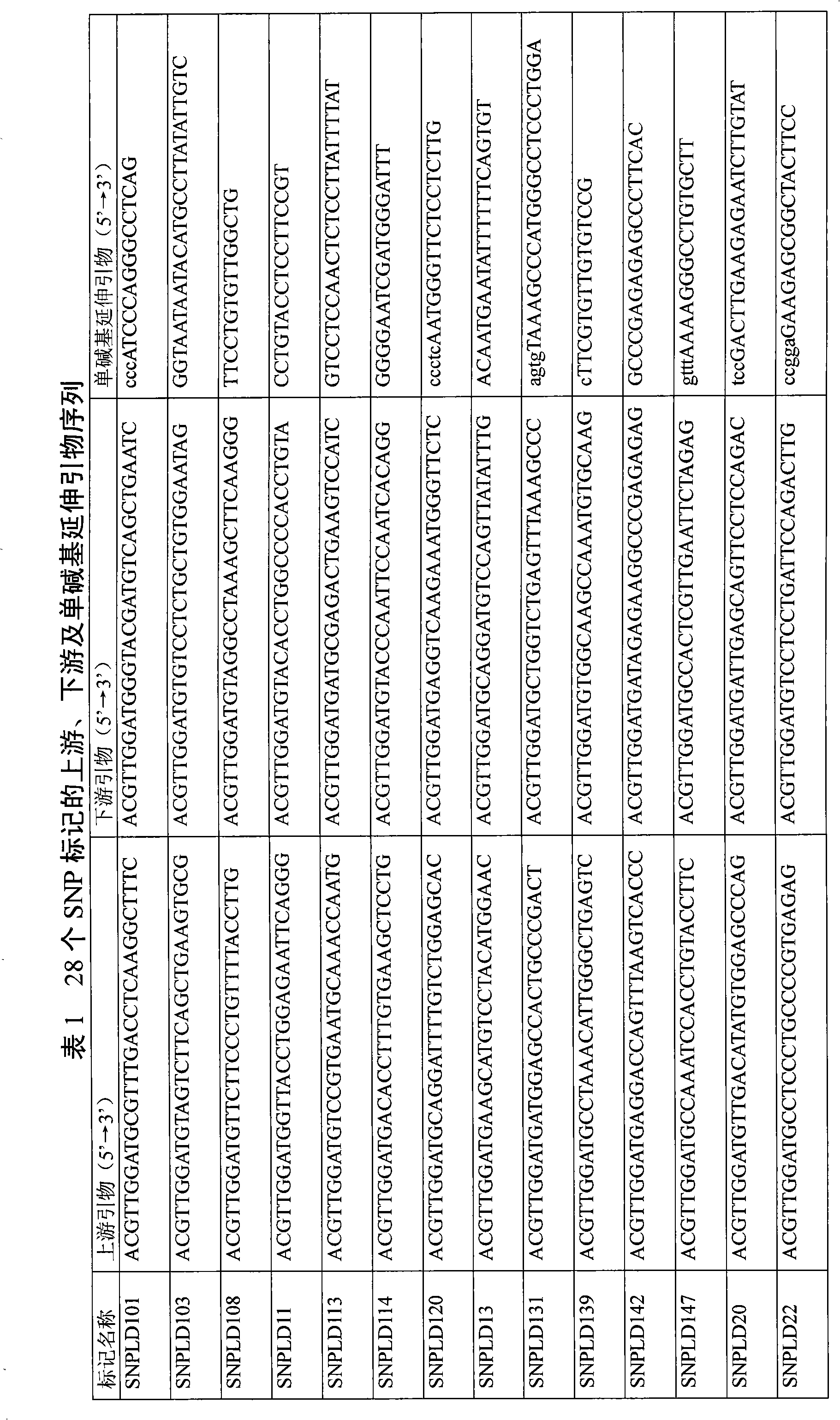

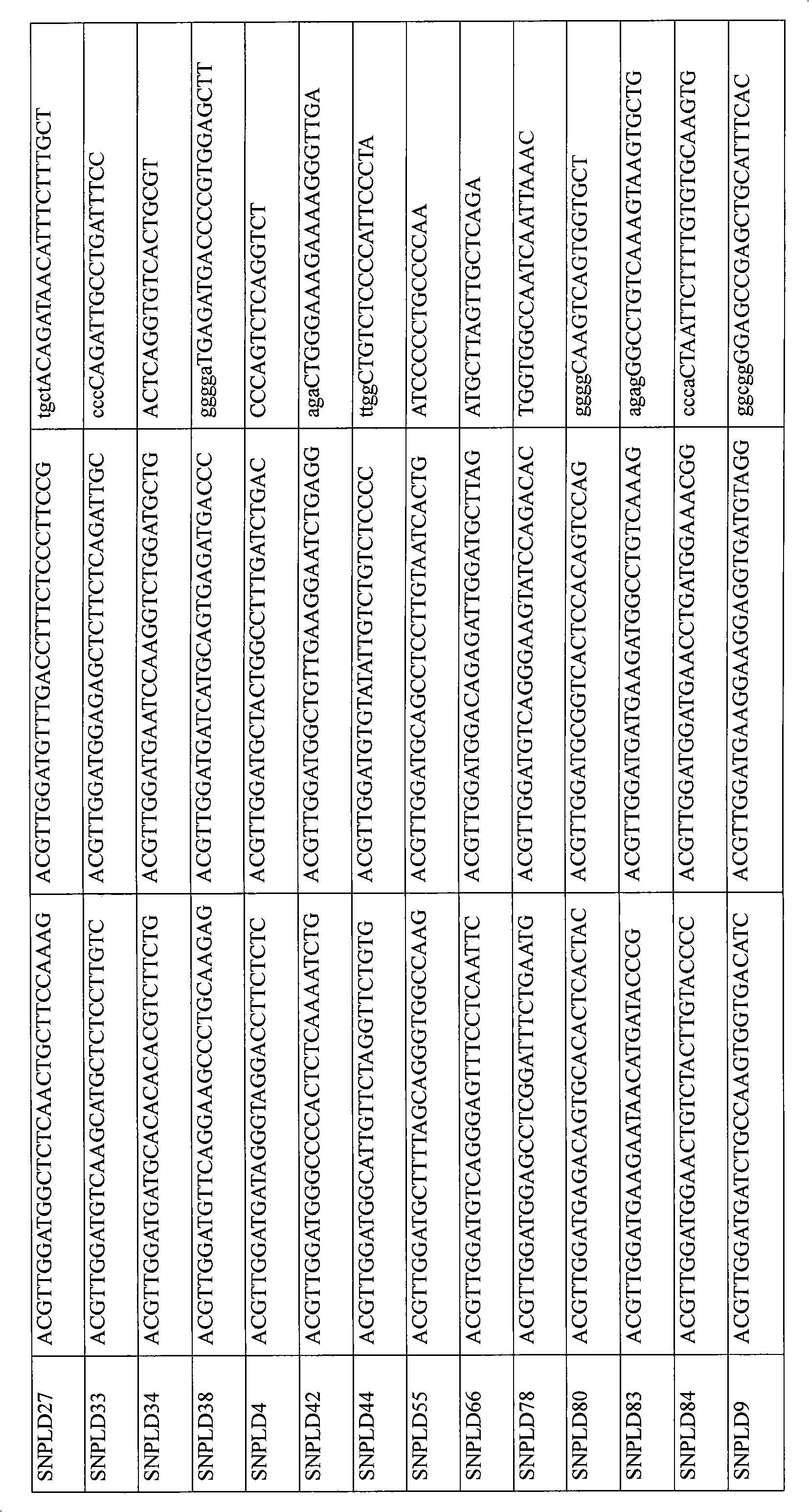

Paternity testing single nucleotide polymorphism (SNP) label combinations and detection method for Holstein cattle group

ActiveCN101984077AEasy to detectImprove automationMicrobiological testing/measurementMaterial analysis by electric/magnetic meansForward primerNucleotide

The invention discloses paternity testing single nucleotide polymorphism (SNP) label combinations for a Holstein cattle group, and one of the combinations contains 28 SNP labels, and the other of the combinations contains 50SNP labels. In the combination, the nucleotide sequences of the forward primers of the 28 SNP labels are shown as SEQ ID NO.23-50 in turn, the nucleotide sequences of the reverse primers of the 28 SNP labels are shown as SEQ ID NO.73-100 in turn, and the nucleotide sequences of the single base extension primers of the 28 SNP labels are shown as SEQ ID NO.123-150 in turn; the nucleotide sequences of the forward primers of the 50 SNP labels are shown as SEQ ID NO.1-50 in turn, the nucleotide sequences of the reverse primers of the 50 SNP labels are shown as SEQ ID NO.51-100, and the nucleotide sequences of the single base extension primers of the 50 SNP labels are shown as SEQ ID NO.101-150. The SNP label combinations used for the Holstein cattle group have accurate results, optimally utilizes a flight mass spectrometry method, can quickly and conveniently detect SNP label polymorphisms with high-flux so as to conclude the parenthood of the cattle group.

Owner:CHINA AGRI UNIV

Copper tube bending and cutting machine for connecting and installing indoor and outdoor units of air conditioner

InactiveCN108213977AAutomated precisionExact lengthOther manufacturing equipments/toolsEngineeringVisual inspection

The invention relates to a copper tube bending and cutting machine for connecting and installing indoor and outdoor units of an air conditioner. The copper tube bending and cutting machine comprises abottom plate, wherein a precise conveying device is arranged on the front end of the bottom plate, a controllable bending device is installed in the middle of the bottom plate, a cutting device is installed on the back end of the bottom plate, and the precise conveying device, the controllable bending device and the cutting device are matched so as to complete the copper tube bending and cuttingprocess. According to the copper tube bending and cutting machine, the problems that the length of a copper tube needs to be manually measured, the copper tube needs to be manually bent and processed,the copper tube needs to be manually cut by virtue of a pair of tool scissors, the length of the copper tube is not accurate due to manual measurement, materials are easy to waste, the bending and processing angle is not accurately controlled due to manual operation, the manual visual inspection error is large, the copper tube cutting operation is complex due to manual operation by virtue of thepair of tool scissors, the labor intensity is high and the working efficiency is lower when an existing air conditioner is installed and debugged can be solved.

Owner:卢伟涛

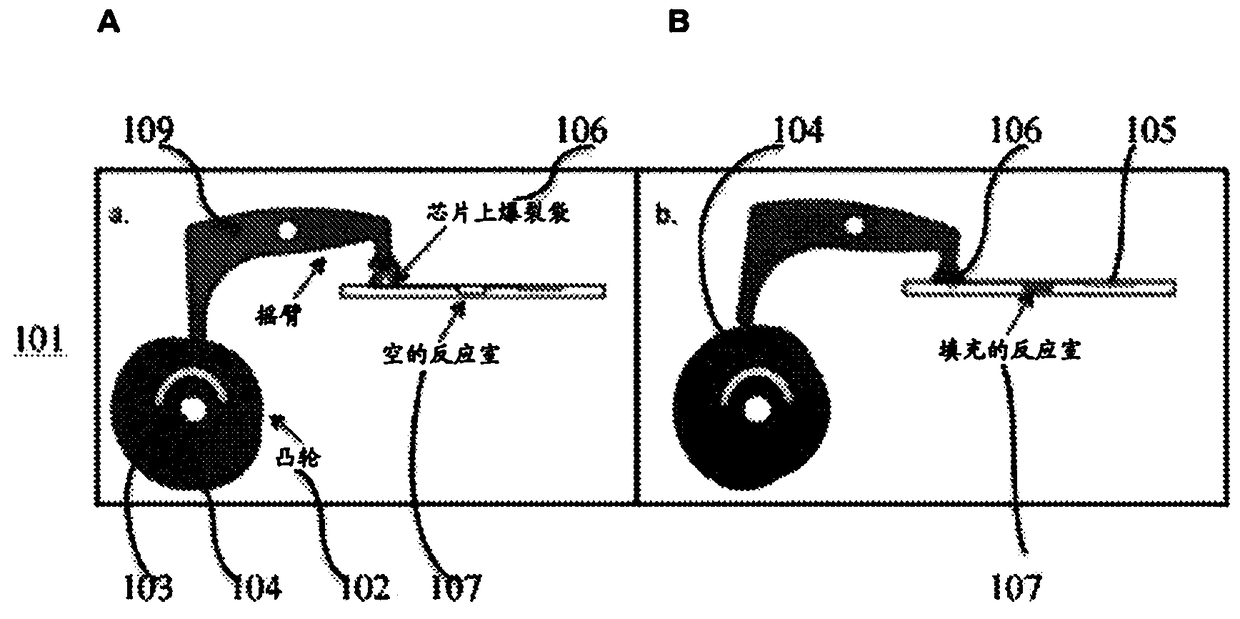

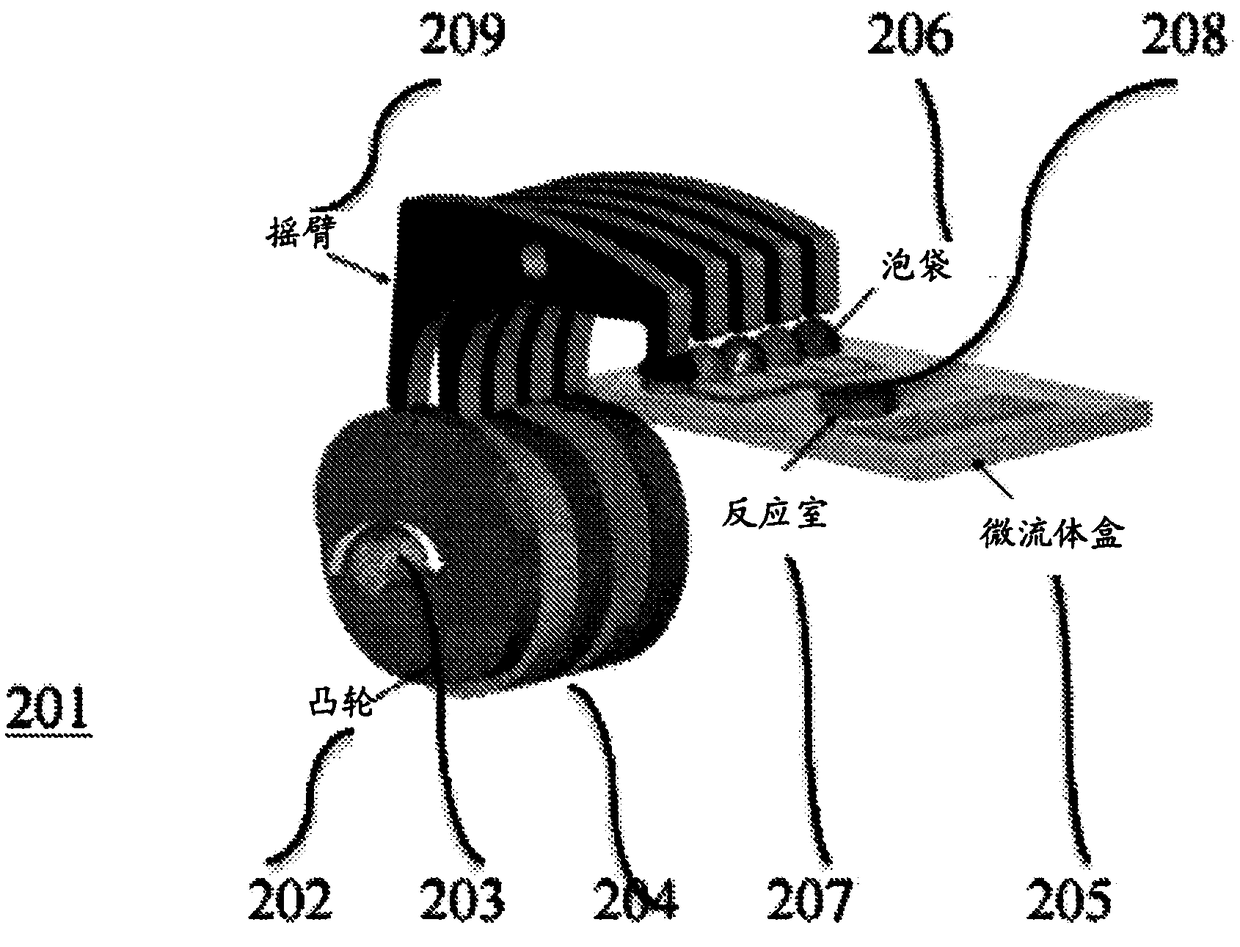

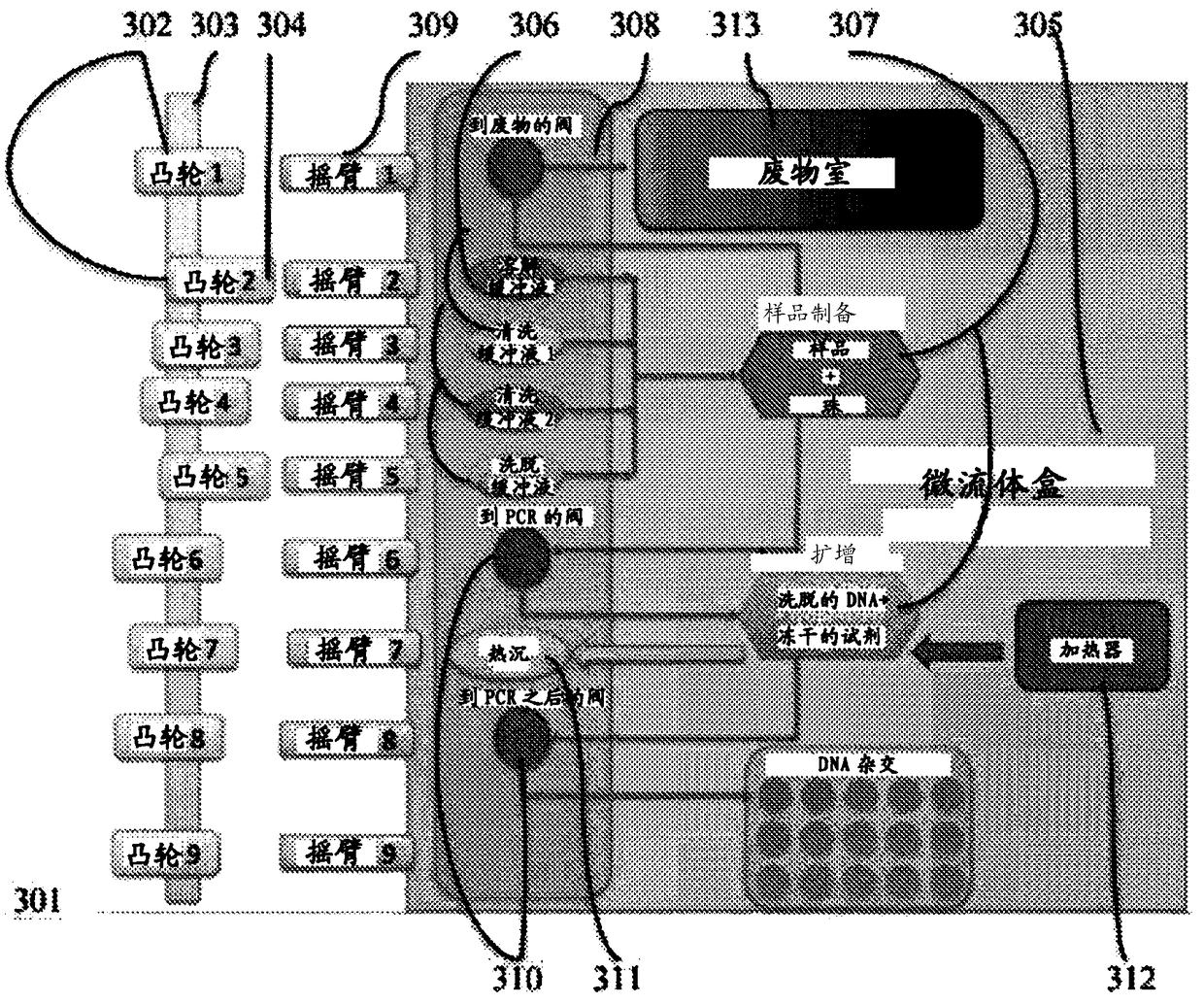

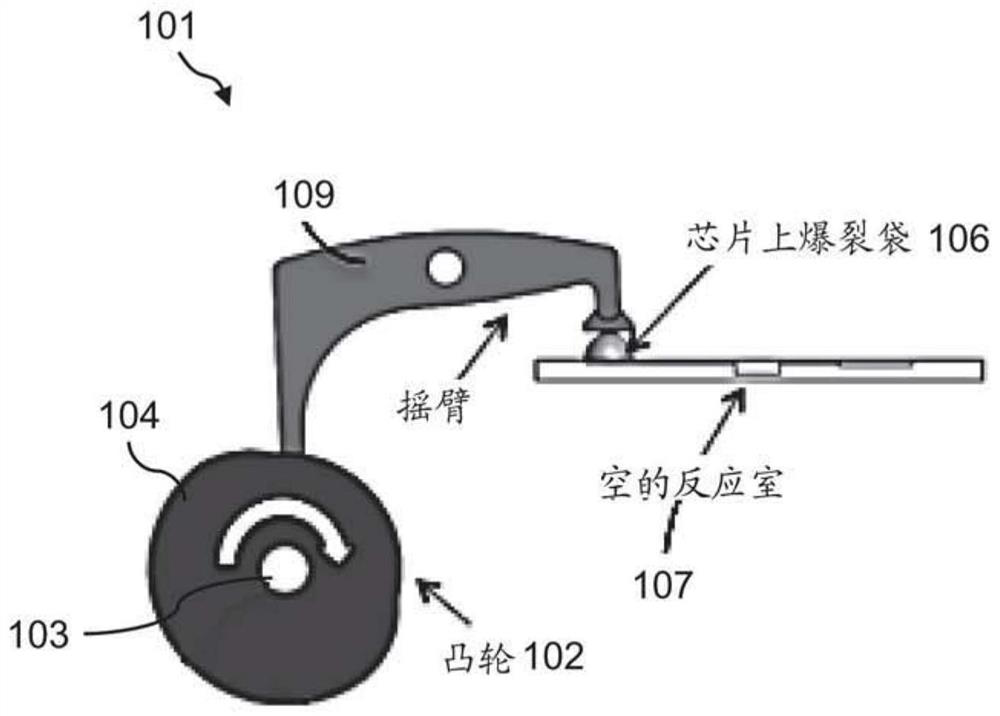

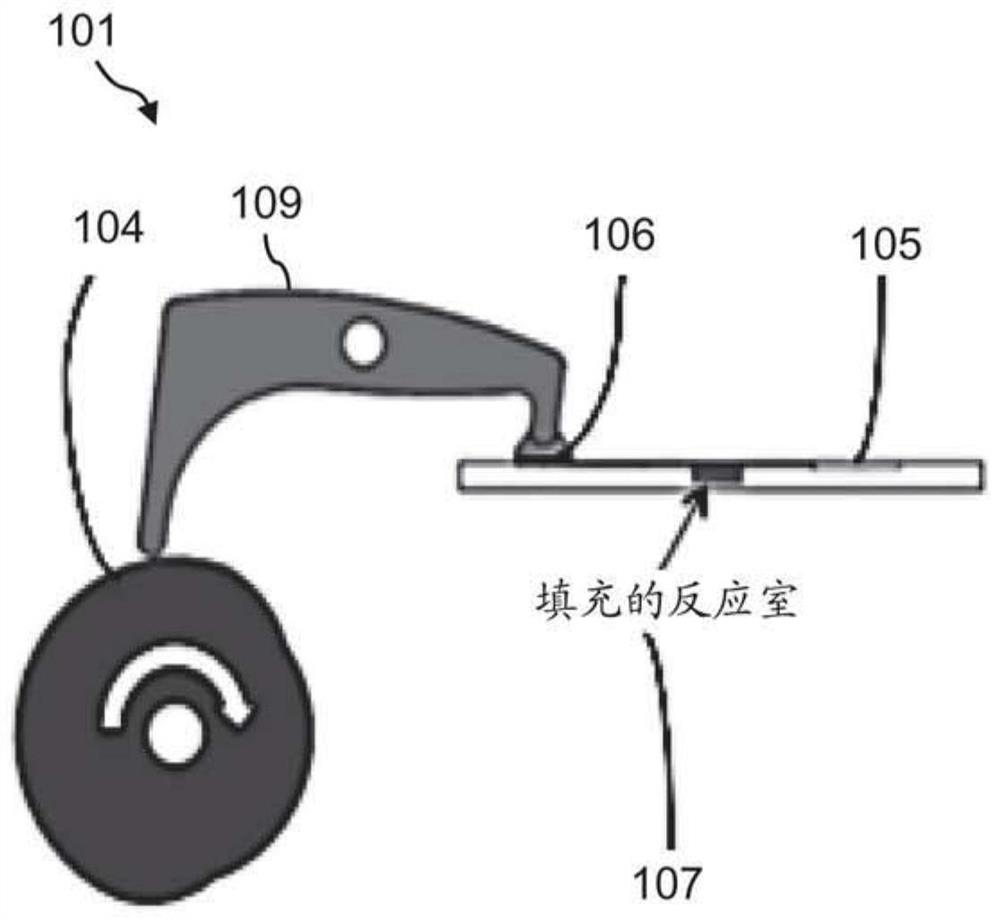

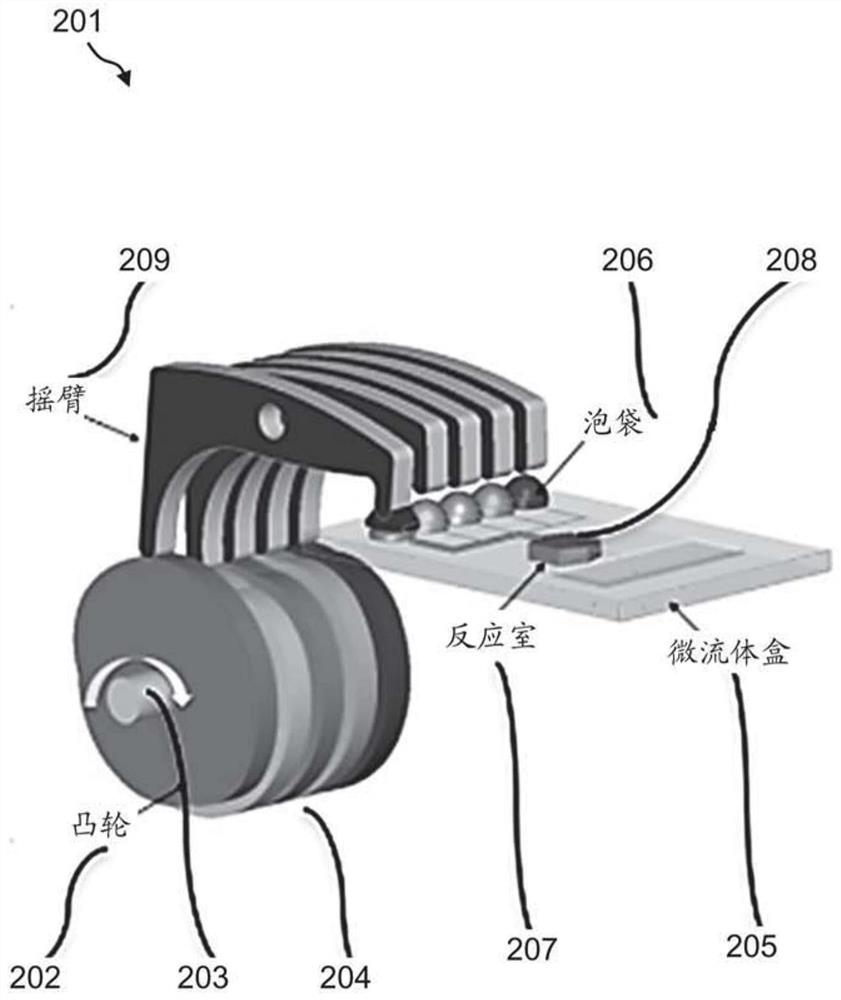

Sample processing device comprising magnetic and mechanical actuating elements using linear or rotational motion and methods of use thereof

ActiveCN108136392ASimple designReduce manufacturing costShaking/oscillating/vibrating mixersHeating or cooling apparatusNuclear physicsNuclear magnetic resonance

The present invention provides methods and devices for simple, low power, automated processing of biological samples through multiple sample preparation and assay steps. The methods and devices described facilitate the point-of-care implementation of complex diagnostic assays in equipment-free, non-laboratory settings.

Owner:NOVEL MICRODEVICES LLC

Method for carrying out slag fishing work through slag fishing treatment equipment

InactiveCN109264882AFast adsorptionSave waterSpecific water treatment objectivesTreatment involving filtrationSlagSewage

Owner:台州市路桥跃盛环保科技有限公司

Sorting equipment

PendingCN108773663AReduce time consumptionImprove utilizationSortingConveyor partsEngineeringAssembly line

The invention provides sorting equipment comprising a sorting device and a loading device. The sorting device is used for loading material boxes and comprises a plurality of material box mounting stations. The loading device is arranged on the side face of the sorting device and used for loading the material boxes and comprises a loading platform, a material box positioning assembly and a loadingassembly. The loading platform and one of the material box mounting stations are located on the same horizontal line. The material box positioning assembly is arranged at one end of the loading platform. The loading assembly is arranged on the loading platform. Compared with the mode that the material boxes are manually loaded to the mounting stations, the sorting equipment can achieve precise automation of loading, time consumption of material box loading is reduced, and the utilization rate of a photovoltaic chip detecting and sorting assembly line is increased.

Owner:SHANDONG ZIBO HANERGY THIN FILM SOLAR CELL CO LTD

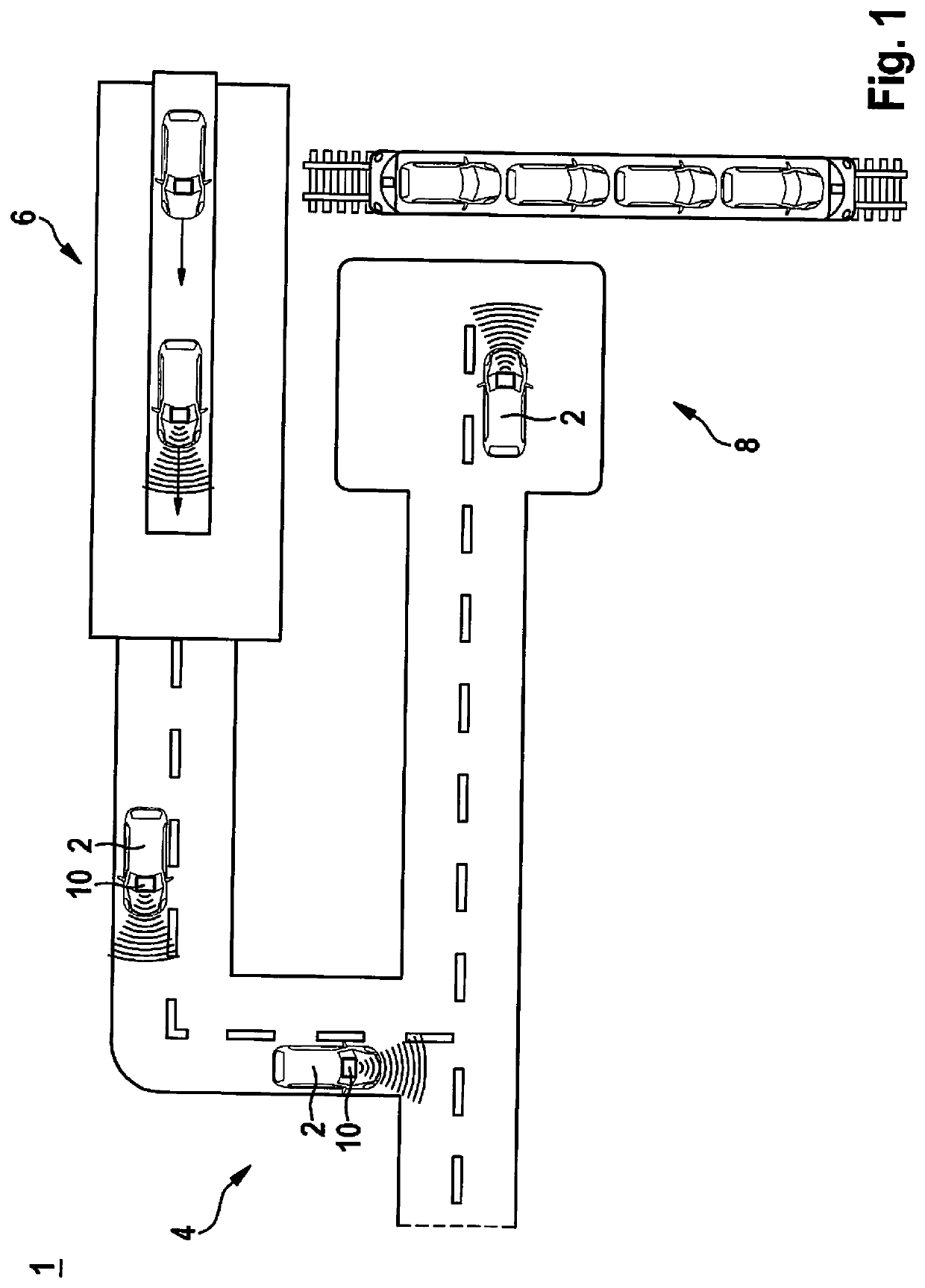

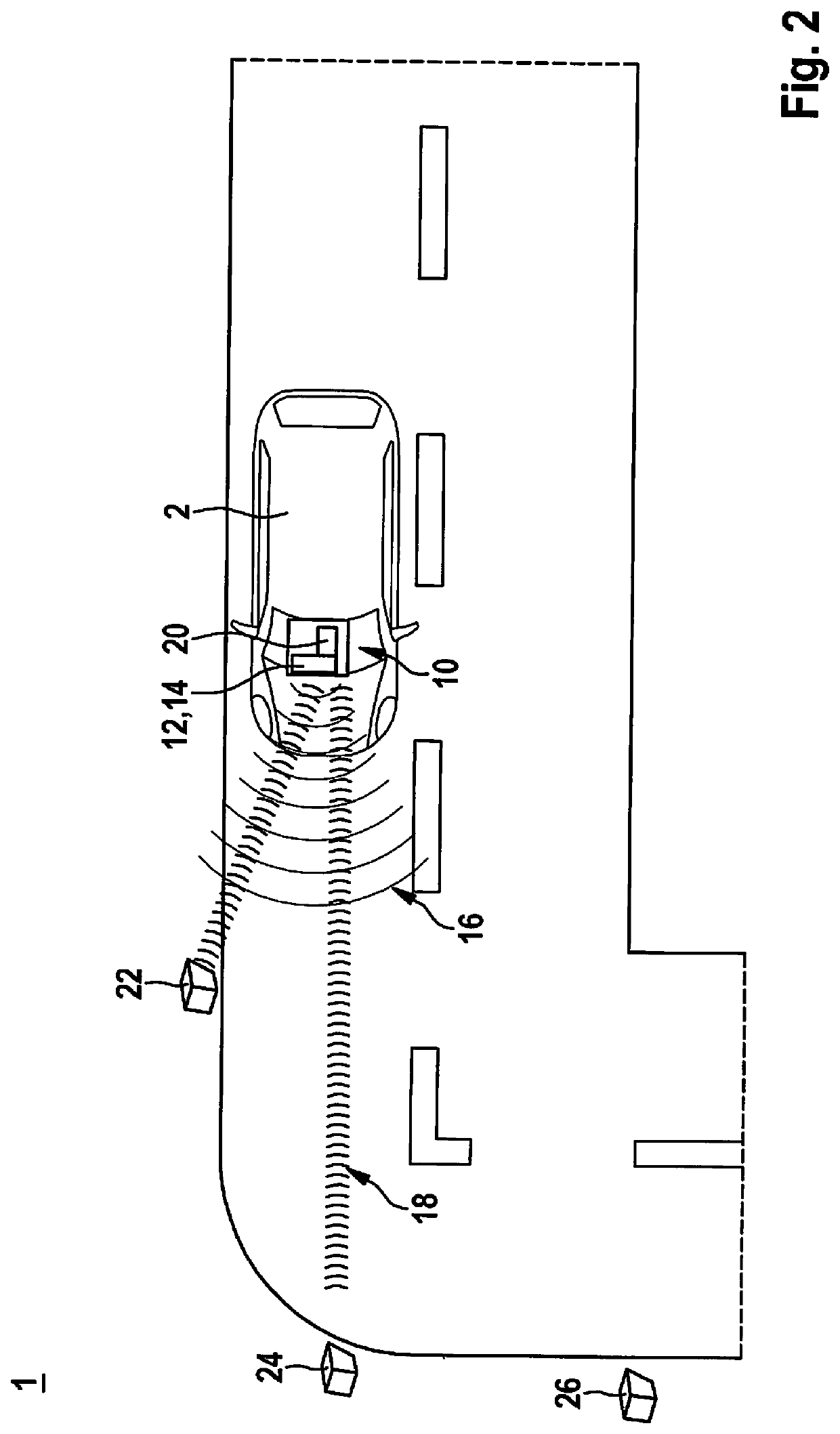

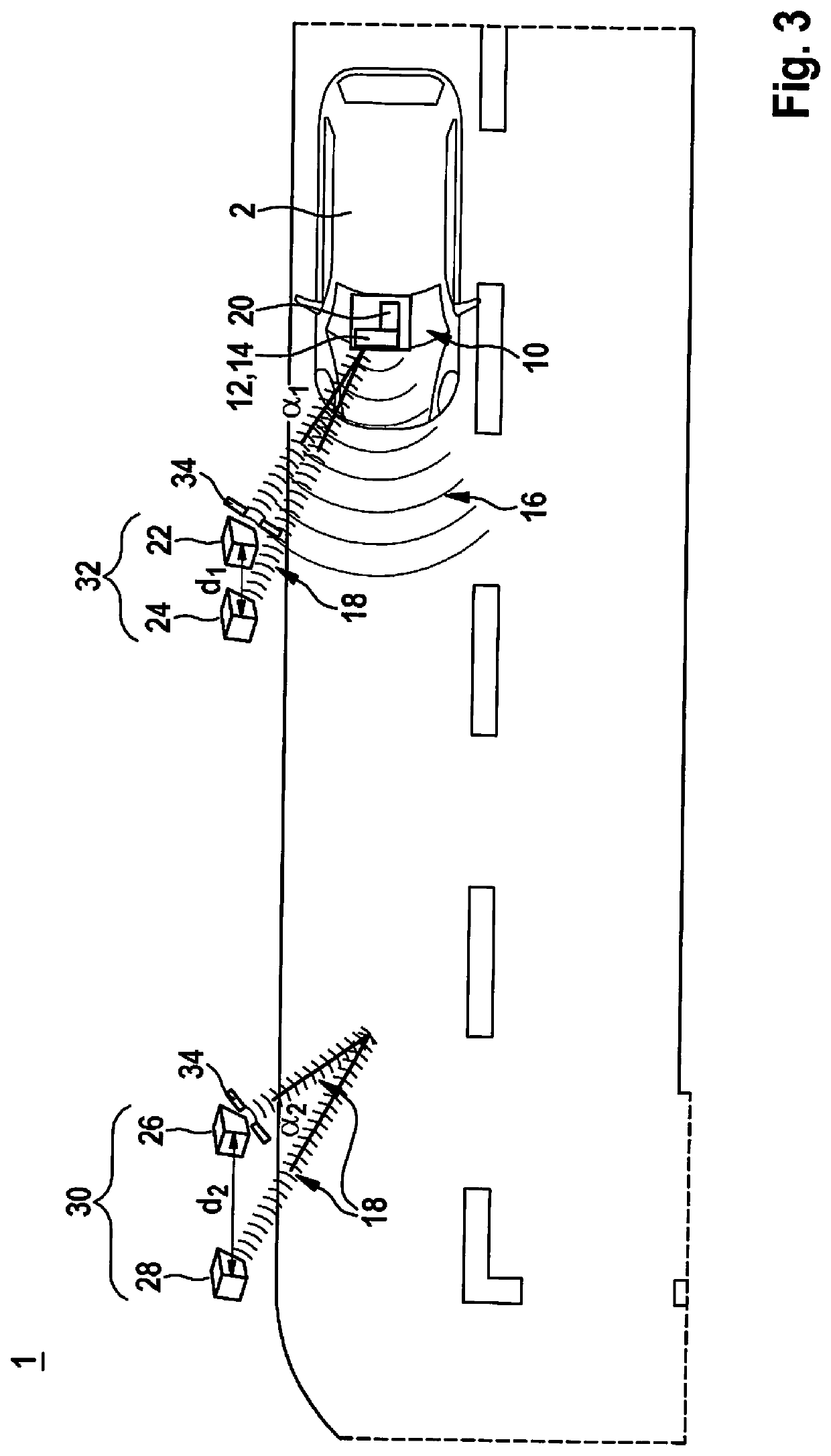

System and method for determining the position of a vehicle for automated driving on a site

A system is described for determining the position of a vehicle on a site and for calculating a trajectory, including at least one vehicle, at least one auxiliary device and at least one reflector element, the at least one reflector element being mounted in the surroundings of the vehicle along a designated route section and the auxiliary device being suitable for transmitting and receiving electromagnetic beams. A method is also described.

Owner:ROBERT BOSCH GMBH

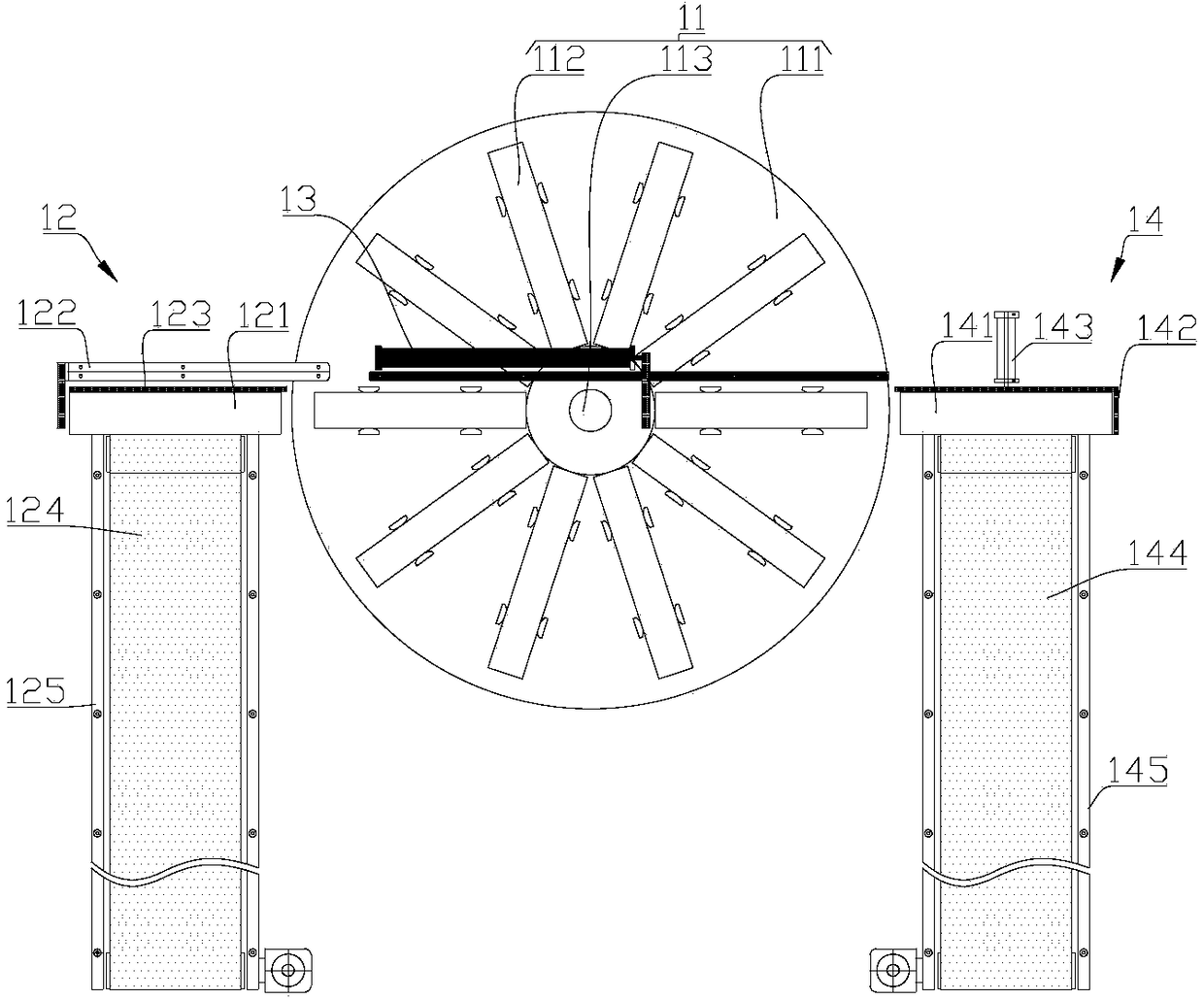

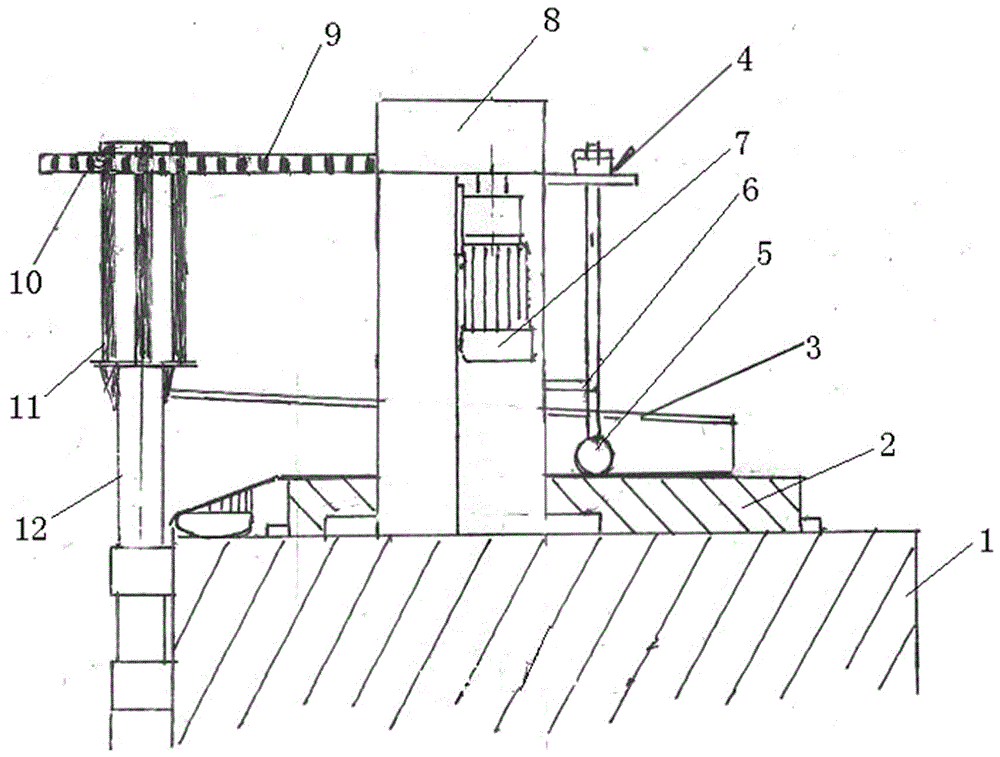

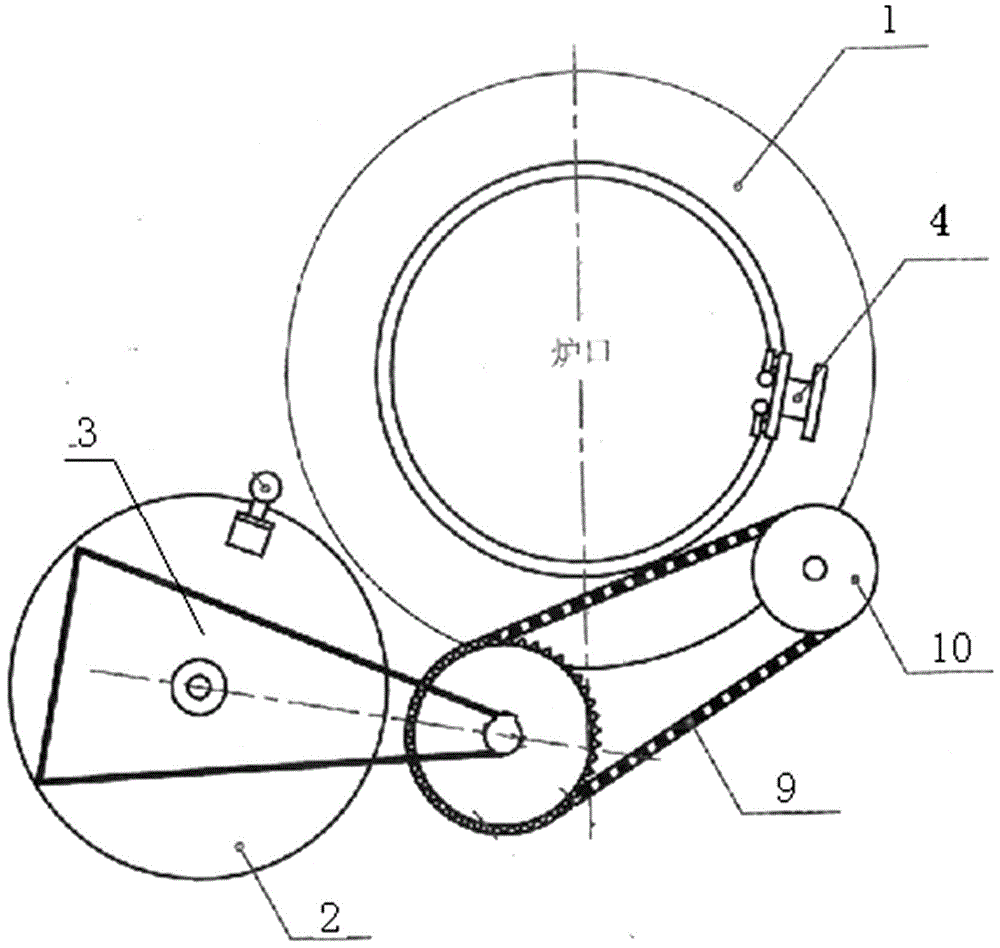

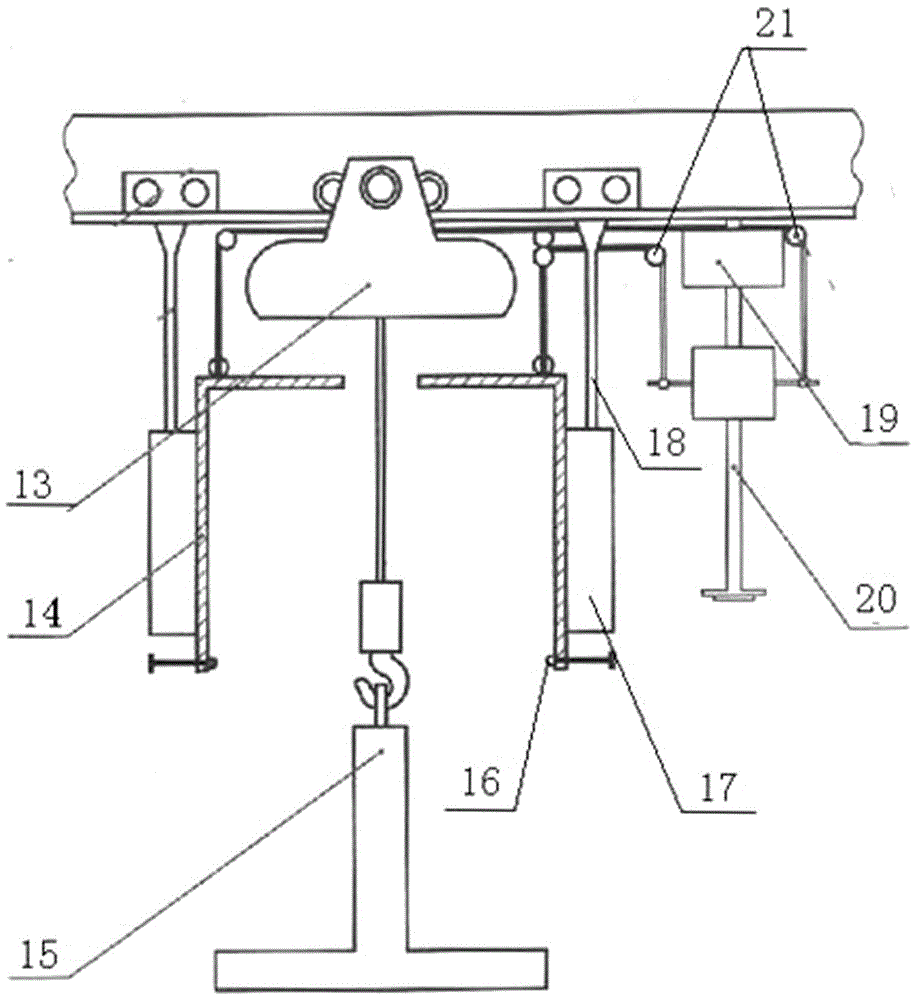

Automatic production type heat treatment pit furnace and accessory device

ActiveCN106370011AEliminates wobbleAccelerateRemovable covers for furnacesEngineeringMaterial resources

An automatic production type heat treatment pit furnace comprises a pit furnace lid automatic lifting and rotating device, a pit furnace lifting material disk movable shield locking device, a program control crane automatic hanging device and a crane advancing accurate braking device. The pit furnace lid automatic lifting and rotating device enables a furnace lid to automatically ascend and rotate and enables a lid lock to be automatically released, when the furnace lid returns to the original position, the lid lock is made to be automatically locked, and therefore the furnace lid is accurately covered. The pit furnace lifting material disk movable shield locking device effectively eliminates shake generated when a steel wire rope lifting disk walks, and a shield can prevent cooling and oxidation. According to the program control crane automatic hanging device, when a lifting hook is locked in one direction, the lifting hook is made to be automatically hung on a lifting ring, automatic unhooking can also be achieved, unsafe factors existing during manual hanging are eliminated, the hanging speed is improved, and workers are prevented from being roasted by high-temperature furnace fire. A chain accurately brakes in the advancing process of a crane, and errors caused by the inertia of the crane are avoided. The automatic production type heat treatment pit furnace saves labor, material resources and financial resources and improves the product quality and the production efficiency.

Owner:WAFANGDIAN GUANGDA BEARING MFG

Accurate thread detecting equipment based on mechanical induction

ActiveCN109482513AAutomated precisionImprove reliabilitySortingEngineeringElectrical and Electronics engineering

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

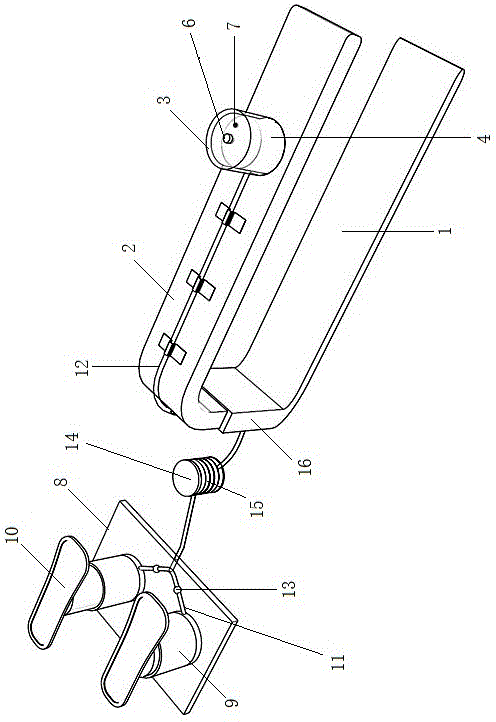

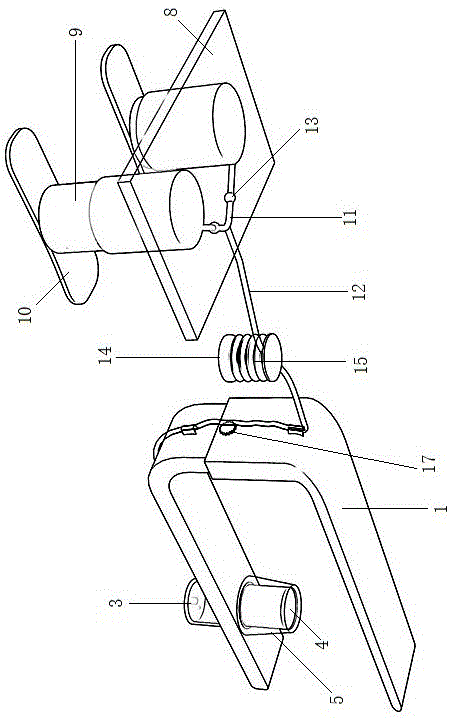

Foot step type cardio-pulmonary resuscitation pressing device

InactiveCN105596202AEasy to fixSmall footprintElectrotherapyHeart stimulationEngineeringGas pressure transducer

The invention discloses a foot step type cardio-pulmonary resuscitation pressing device, and relates to the technical field of cardio-pulmonary resuscitation devices. The foot step type cardio-pulmonary resuscitation pressing device comprises a C-shaped supporting plate, a pneumatic piston mechanism and a foot step type air inflation mechanism; a piston push rod in sliding and sealing fit with the inner wall of a piston cylinder is arranged in the piston cylinder; an electromagnetic switch valve as well as an air pressure sensor used for measuring air pressure of a piston cavity is mounted on the top surface of the piston cylinder; the air pressure sensor is connected with the input end of a microprocessor; the output end of the microprocessor is connected with the electromagnetic switch valve; a dual start-up air inflation device comprises a baseplate and two air inflation cylinders mounted on the baseplate in parallel; the output ends of the two air inflation cylinders are both connected with branch air guide pipes; the tail ends of the two branch air guide pipes are both connected with a main air guide pipe; the other end of the main air guide pipe is communicated with the piston cavity of the piston cylinder; one-way valves for guiding the two branch air guide pipes to the main air guide pipe are mounted on the two branch air guide pipes respectively. Through the adoption of the soft structure, the foot step type cardio-pulmonary resuscitation pressing device can sleeve lower limbs, the massage areas are large, and influence on normal walking and work can be avoided.

Owner:YICHANG NO 1 PEOPLES HOSPITAL PEOPLES HOSPITAL OF CHINA THREE GORGES UNIV

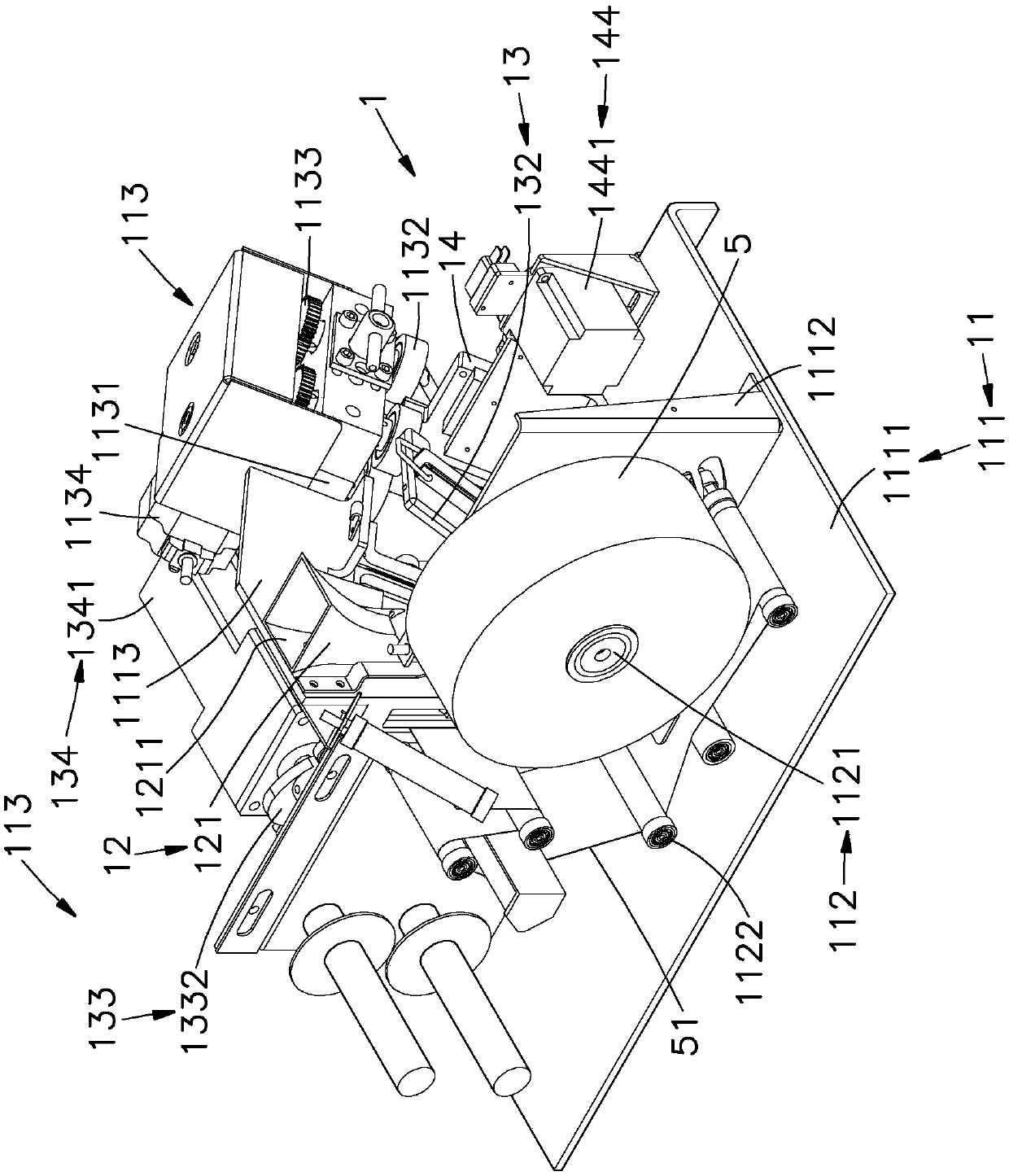

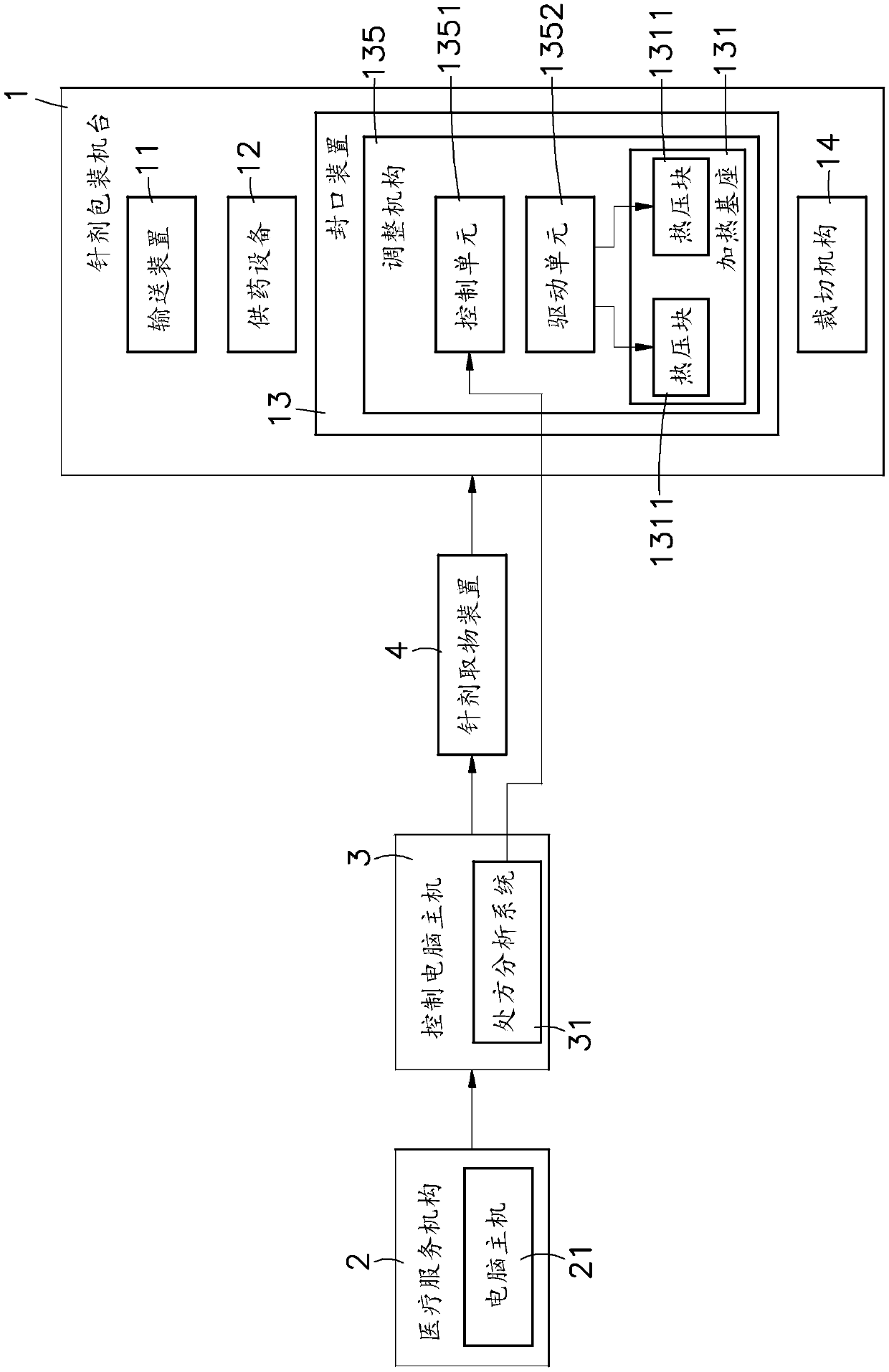

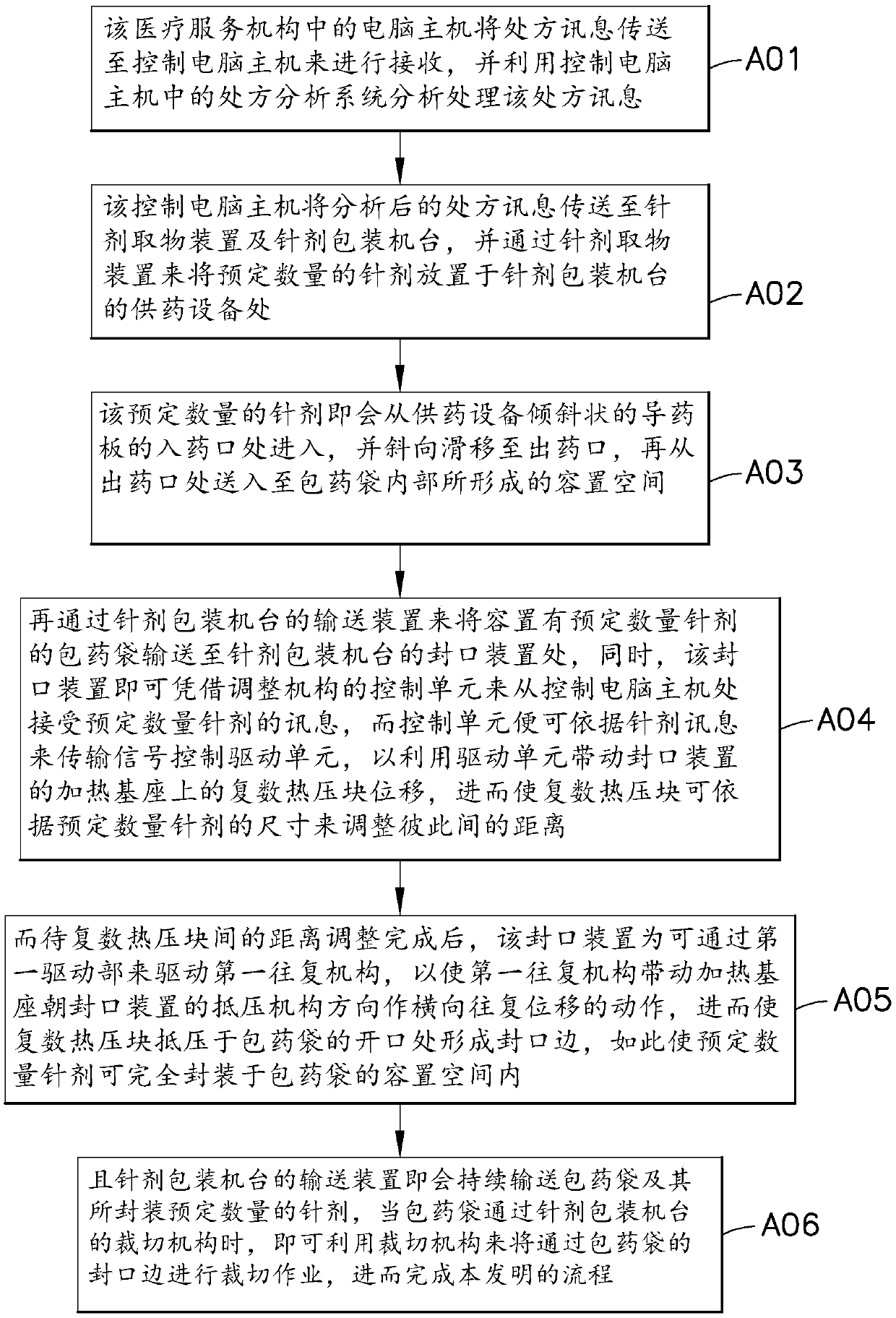

Injection packaging machine table and packaging method thereof

InactiveCN110576998AAutomate quicklyAutomated precisionWrapper twisting/gatheringEngineeringControl unit

The invention discloses an injection packaging machine table and a packaging method thereof. The packaging method comprises the following steps: the injection packaging machine table receives the prescription information; after the injection is placed in medicine supply equipment, the injection automatically slides into a packaging bag from an inclined medicine guiding plate of the medicine supplyequipment; a conveying device is adopted to convey the packaging bag filled with the injection to a sealing device; at the moment, a control unit of an adjusting mechanism of the sealing device controls a driving unit according to the injection information to drive a plurality of hot pressing blocks to adjust the space between every two adjacent hot pressing blocks according to the size of the injection; then, the hot pressing blocks are propped against the opening of the packaging bag at one time to form a sealing edge; the injection is packaged in the packaging bag; the packaging bag is conveyed to a cutting mechanism; the cutting mechanism is utilized to cut the sealing edge of the packaging bag; and the hot pressing blocks adjust the space according to the size of the injection, so that the situation that the hot pressing blocks damage or crush the injection is avoided to further realize the effect of packaging the injection in a fast, precise and automatic manner.

Owner:郝荣华

Automated climate control system

ActiveUS10696137B2Reduce riskReduce the burden onAir-treating devicesVehicle heating/cooling devicesControl systemControl engineering

A control unit for a climate control system for a vehicle, comprising; a monitoring module arranged to monitor at least one demand representative of an environmental parameter change within the vehicle and / or at least one active user input relating to an environmental parameter within the vehicle; a storage means storing a control policy for configuring at least one climate control element; a feedback module configured to receive the at least one demand from the monitoring module and to receive a simulated control policy from a simulation module; wherein the feedback module is configured to update the control policy, based on the simulated control policy, in response to receiving the at least one demand; and an implementation module for controlling said at least one climate control element in accordance with said control policy.

Owner:JAGUAR LAND ROVER LTD

Device for fetching/putting volume label of sticking mark inside module

A marker getting / putting apparatus for sticking a marker on a finished plastic product in its mould is composed of a manipulator controlled by computer, a fixing seat for holding the finishe dproduct unloading unit and the marker getting / putting unit, a finished product unloading unit with multiple sucking disks for taking finished products out of their moulds, and a marker getting / putting unit for sucking marker and pushing it into mould.

Owner:黄胜昌 +1

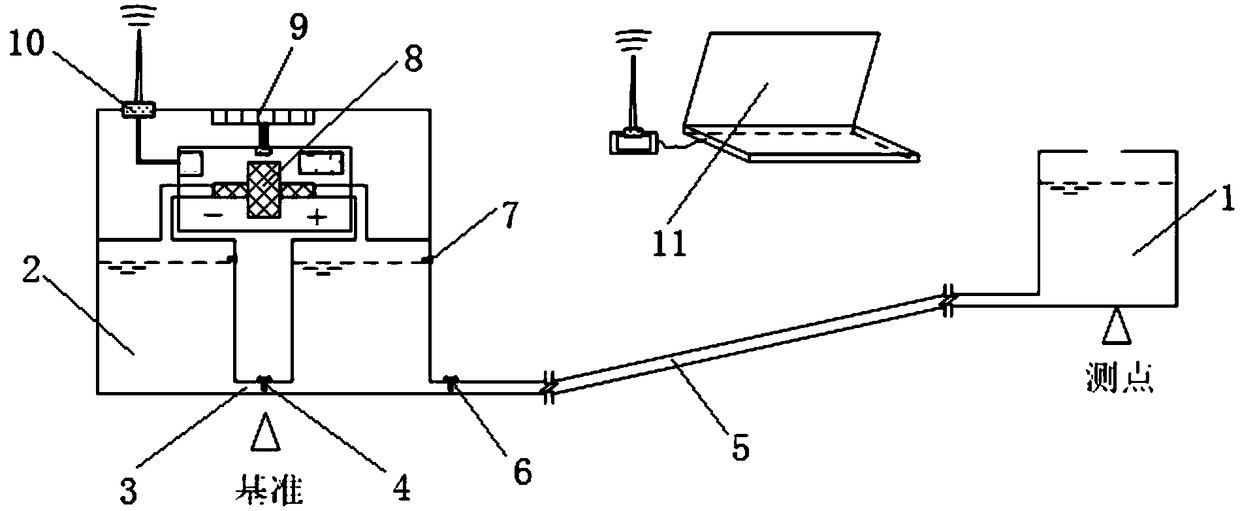

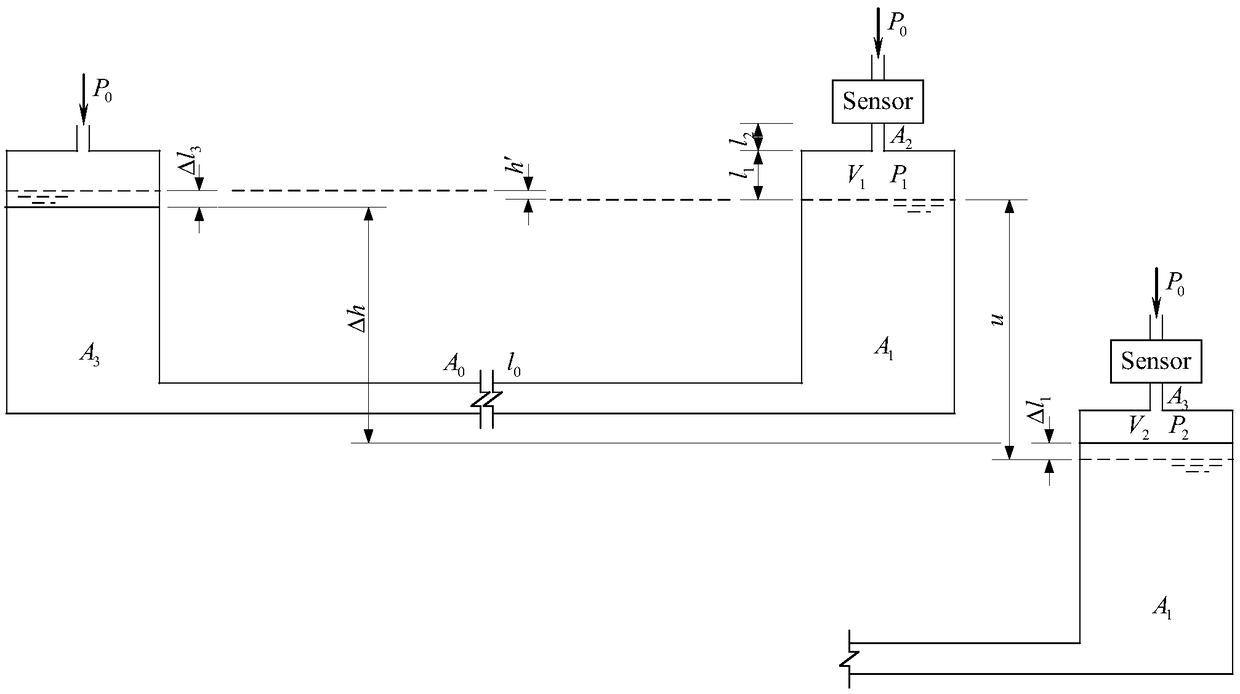

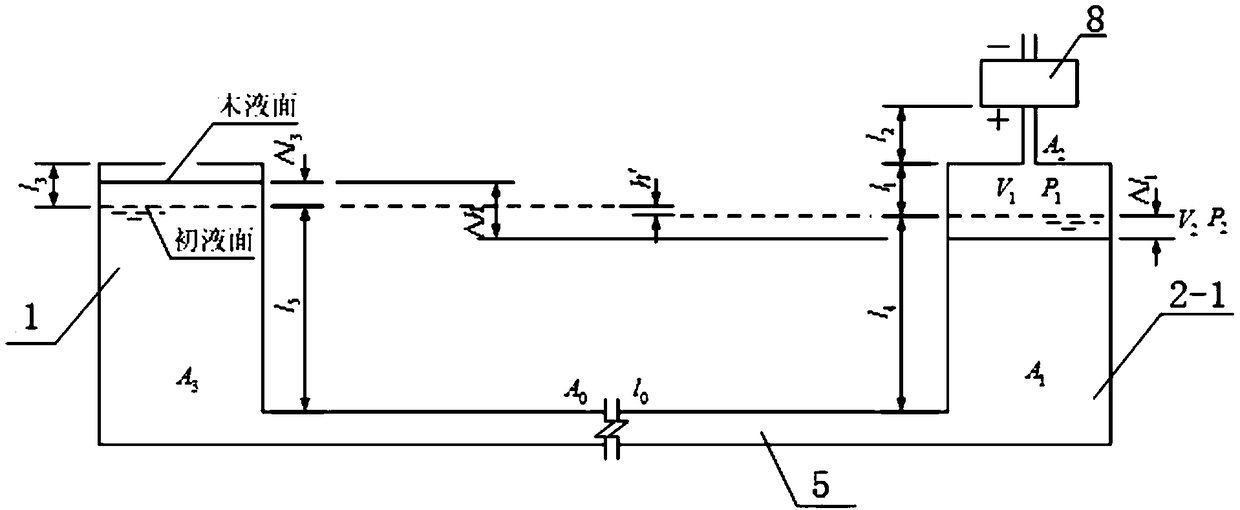

Vertical displacement monitoring device and method for initial large height difference structure

PendingCN108759781AImprove applicabilityAutomated precisionHydrostatic levellingNuclear energy generationDifferential pressureLiquid storage tank

The invention discloses a vertical displacement monitoring device and method for an initial large height difference structure. The device comprises a measuring point liquid storage tank filled with liquid; and a pair of measuring end liquid storage tanks, wherein through holes passing through the exterior are correspondingly arranged at the same height of the upper part, and the bottoms of the pair of measuring end liquid storage tanks are connected by a first connecting pipe as an integrated structure; the first connecting pipe is provided with a first valve; the bottom of one measuring end liquid storage tank is also communicated with the measuring point liquid storage tank through a second connecting pipe, and the upper surfaces of the pair of measuring end liquid storage tanks have same openings. The device also comprises a differential pressure sensor, wherein the negative electrode end and positive electrode end are communicated with the openings of the measuring end liquid storage tanks in a seal manner through pipelines, respectively. The device provided by the invention and the method for the measurement by the device successfully eliminate the influence of the initial height difference on the automatic monitoring of the sub-millimeter vertical displacement and effectively avoid the influence of temperature and atmospheric pressure on monitoring results.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Sample processing device including magnetic and mechanical actuation elements using linear or rotary motion and method of use thereof

ActiveCN108136392BSimple designReduce manufacturing costHeating or cooling apparatusShaking/oscillating/vibrating mixersAssayEngineering

The present invention provides methods and devices for simple, low power, automated processing of biological samples through multiple sample preparation and analysis steps. The described methods and devices facilitate point-of-care implementation of complex diagnostic assays in an equipment-free, non-laboratory setting.

Owner:NOVEL MICRODEVICES LLC

An automated motor assembly line

ActiveCN105871129BHigh degree of automationImprove assembly qualityManufacturing dynamo-electric machinesProduction lineElectricity

Owner:GUANGDONG LXD ROBOTICS CO LTD

Redwood plate surface treatment process

ActiveCN112621924AVivid colorsImprove textureDecorative surface effectsWood treatment detailsDust controlElectric machinery

The invention discloses a redwood plate surface treatment process. The redwood plate surface treatment process comprises the following steps: 1, blending; 2, spraying; 3, airing; 4, paper intermediate material baking, namely paper intermediate material baking executing; 5, paper intermediate material cooling, namely paper intermediate material cooling executing; 6, acrylic acid solution spraying; 7, plate baking; 8, high-definition photoprinting; 9, film coating; 10, primer spraying; 11, polishing; 12, spraying of a ceramic paint layer on the surface of a UV primer layer; and 13, ceramic paint layer curing to obtain a finished product. An automatic film laminating machine in the step 9 comprises supporting columns, a workbench, a driving roller, a limiting mechanism, an upper cover plate, a working motor, a dust removing mechanism, a film laminating mechanism, a stopping mechanism and a roll changing mechanism. Patterns can be clearly and permanently stored on the surface of a redwood plate through a series of surface treatment and the automatic film laminating machine, and the value of the plate is improved.

Owner:白诗佳

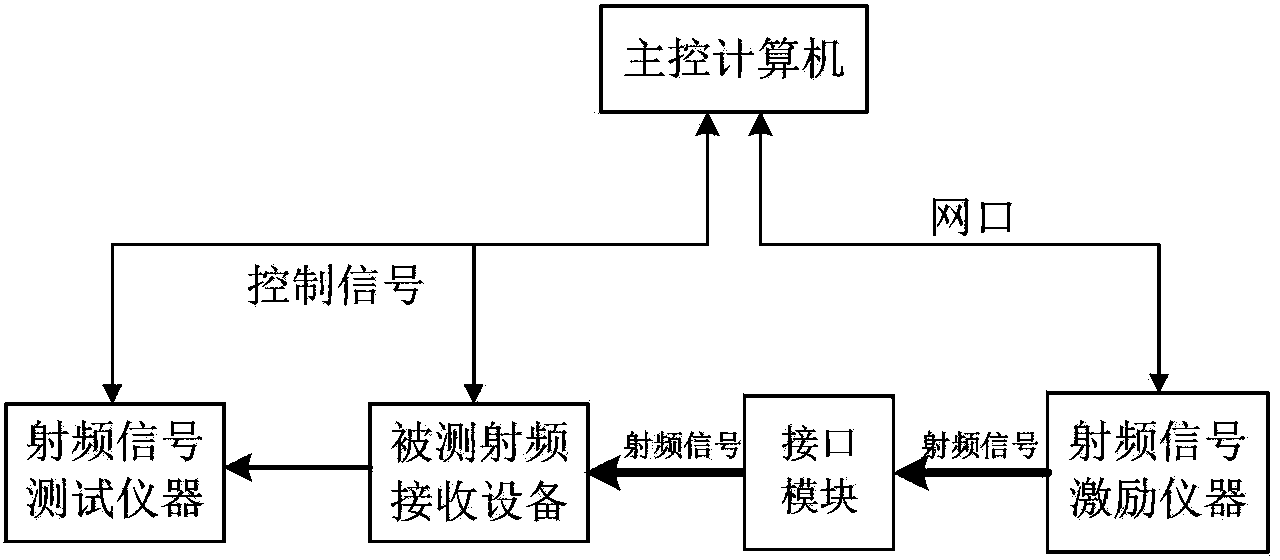

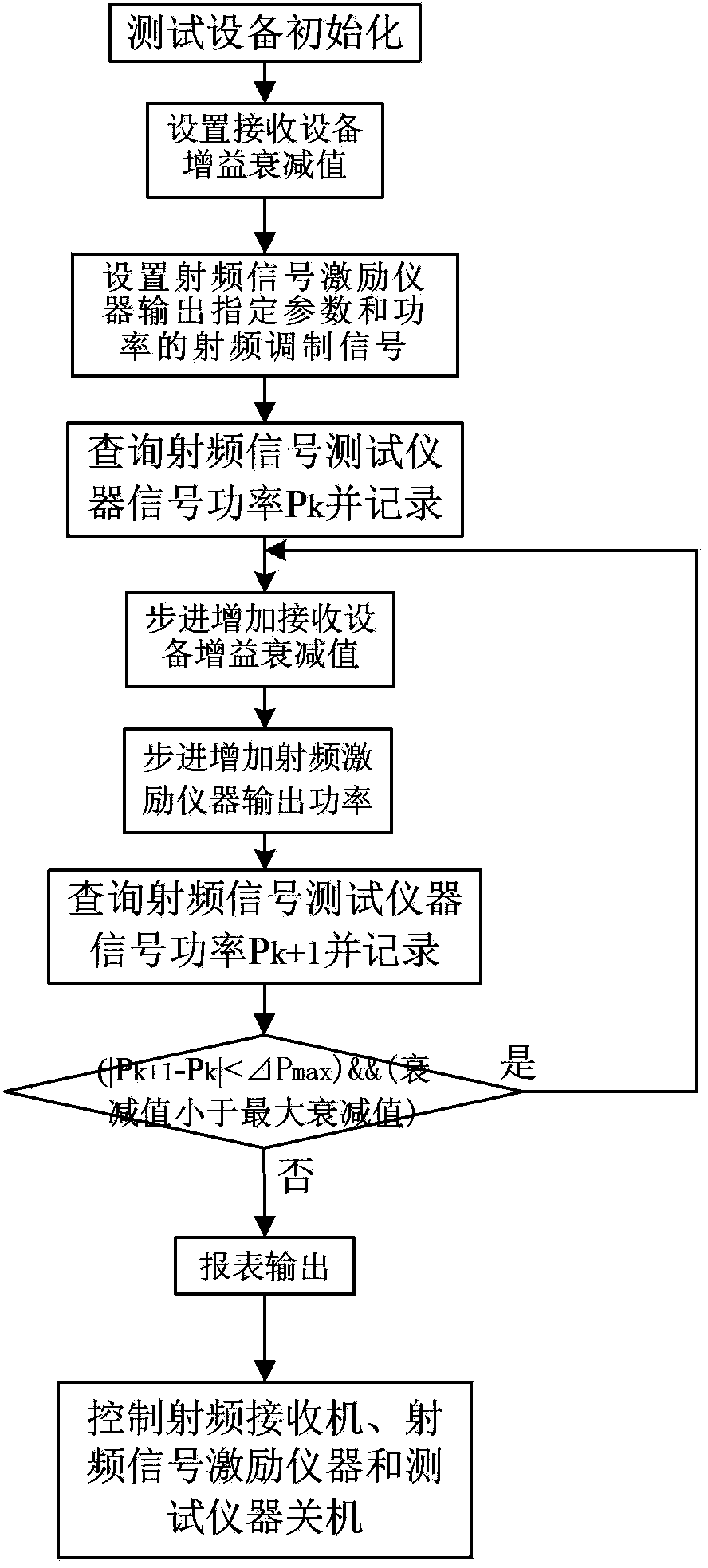

Gain control index testing method of radio frequency receiver

InactiveCN103220053BImprove utilization efficiencyAutomated precisionReceivers monitoringTuned radio frequency receiverUltrasound attenuation

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Copper pipe processing system

PendingCN108247359AAutomated precisionExact lengthMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringUltimate tensile strength

Owner:宋仕密

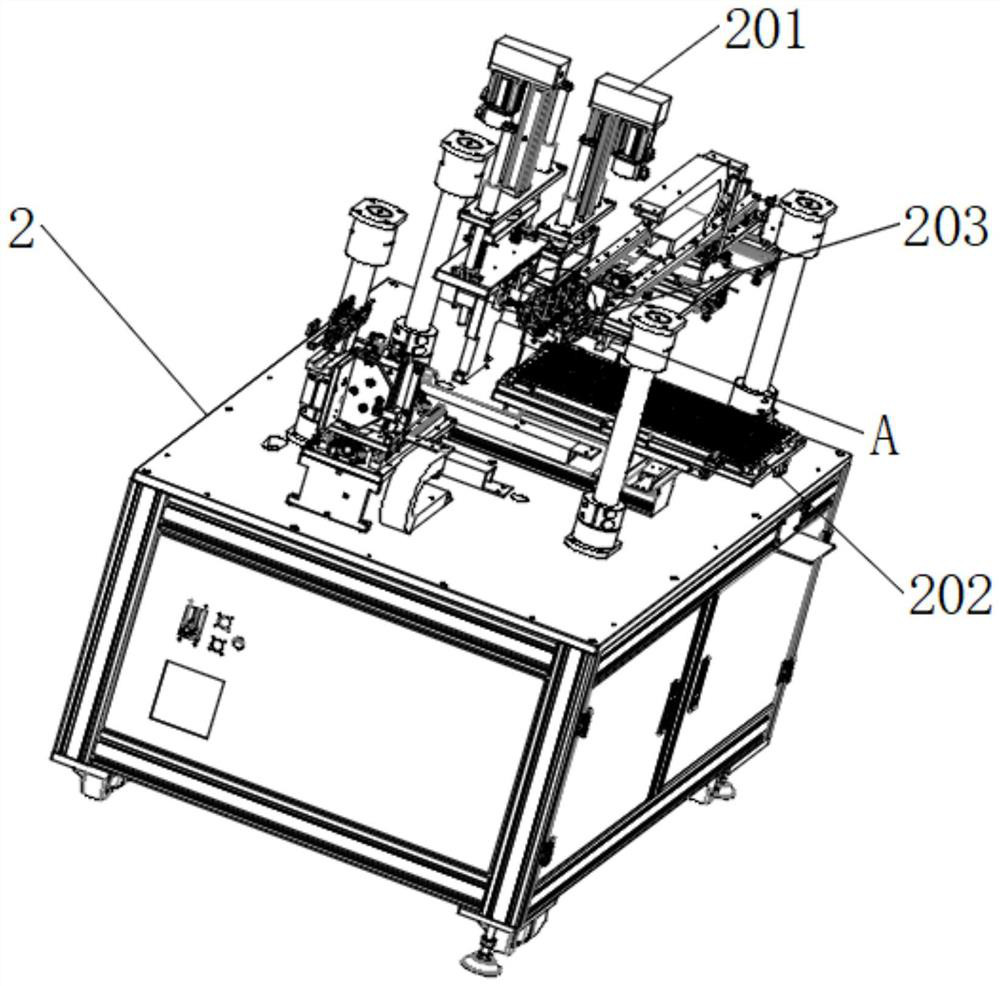

Injection tube assembling equipment

The invention provides injection tube assembling equipment which comprises a core rod feeding machine, an empty disc bin and a full disc bin are arranged at the top of the core rod feeding machine, a grabbing robot is arranged at the top of the core rod feeding machine, a first equidistant clamping jaw is arranged at one end of the grabbing robot, and a core rod rubber plug assembling machine is arranged on one side of the core rod feeding machine. An outer sleeve feeder is arranged on one side of the core rod and rubber plug assembling machine, a press-fitting device is arranged on one side of the core rod and rubber plug assembling machine, a discharging conveying belt is arranged on one side of the press-fitting device, and the device is further provided with equidistant clamping jaws and plastic uptake discs with the same spacing distance as the equidistant clamping jaws. Through the consistent distance, the distance error in the transferring process can be effectively reduced, meanwhile, due to the arrangement of the flexible clamping jaws, scratches caused by scratching can be avoided when a core rod and an outer sleeve are clamped, and friction caused by large errors can be avoided when the core rod and the outer sleeve are transferred and stored on a blister tray; therefore, scratches are generated on the surfaces of the core rod and the jacket.

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

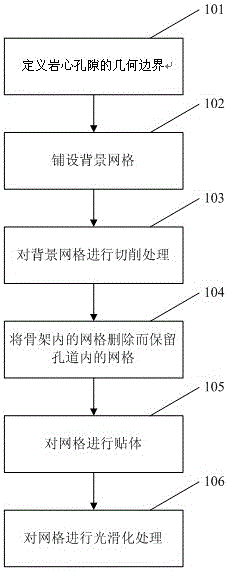

Mesh Subdivision Method for Complicated Pores in Rock Core

ActiveCN104850671BAutomated precisionBuild accuratelySpecial data processing applicationsComputer graphics (images)Mesh generation

The invention provides a mesh generation method for core complex pores. The mesh generation method for the core complex pores comprises a first step of computing a regional laying background mesh aiming at a core target; a second step of cutting the background mesh by use of a mesh cutting algorithm; a third step of deleting the mesh in a skeleton and retaining the mesh in the pores; a fourth step of performing body fitting on the mesh generated by the cutting algorithm; and a fifth step of smoothing the mesh generated by the cutting algorithm. According to the mesh generation method for core complex pores, an accurate and automatic technology capable of cutting any pore structure of mesh is created, so that the complex geometry in the interior of the core is descripted accurately, and a foundation is laid for core microcosmic flow numerical simulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automatic mounting and demounting device and system for motor testing platform

An automatic mounting and demounting device and system for a motor testing platform, adapted to enable a control host to control automatic mounting and demounting between an axle of a motor under test and an axle of a testing apparatus, includes a mobile platform and a positional information sensing member. The control host controls the mobile platform according to positional information generated by the positional information sensing member, such that a carrier for carrying the motor under test is automatically driven to a corresponding position to thereby effect alignment and connection or separation of the axle of the motor under test and the axle of the testing apparatus. Therefore, preparation for the motor dynamics testing is automatically carried out effectively and correctly, thereby reducing the time and manpower required for testing-related preparation.

Owner:CHROMA ATE

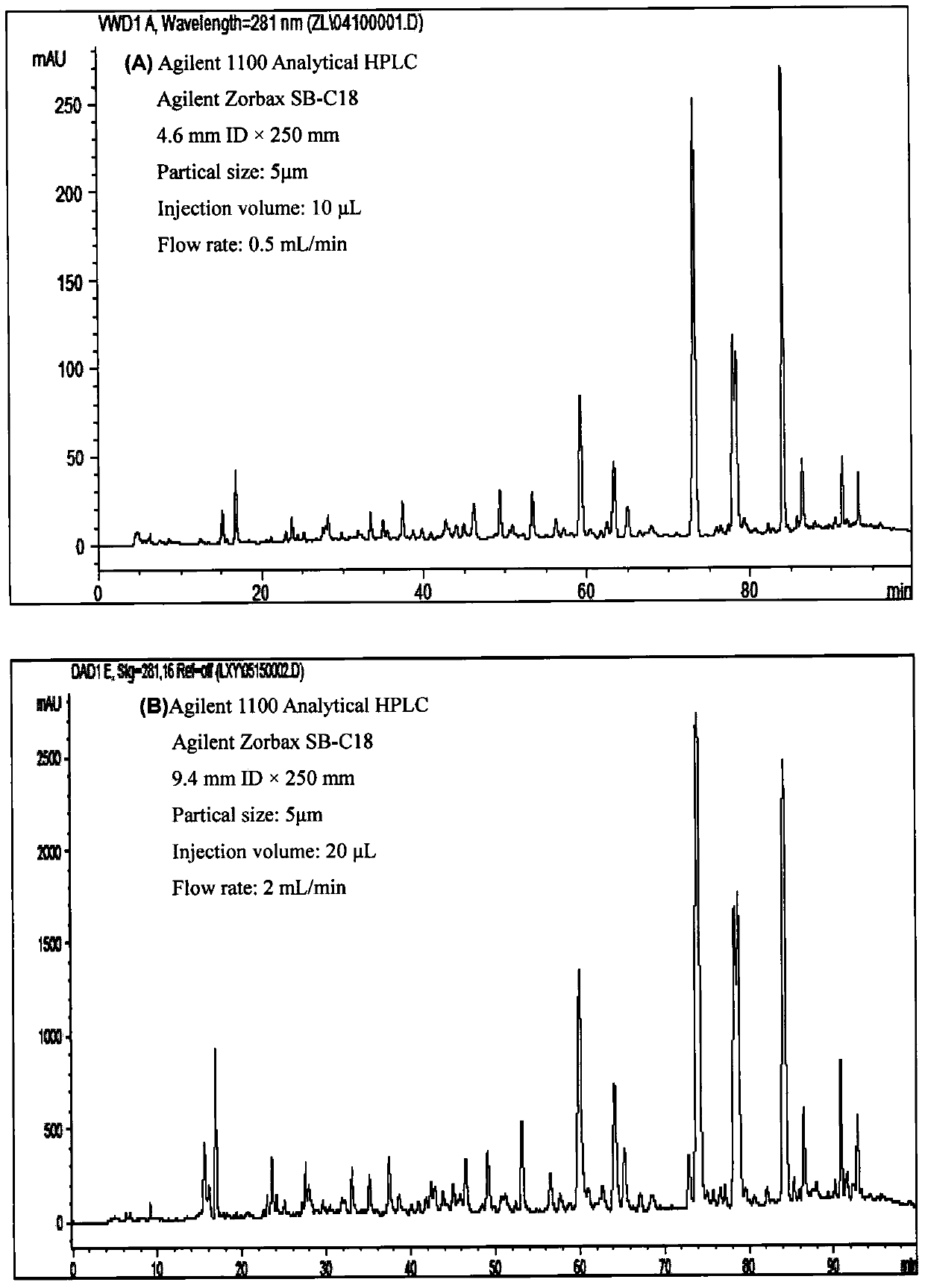

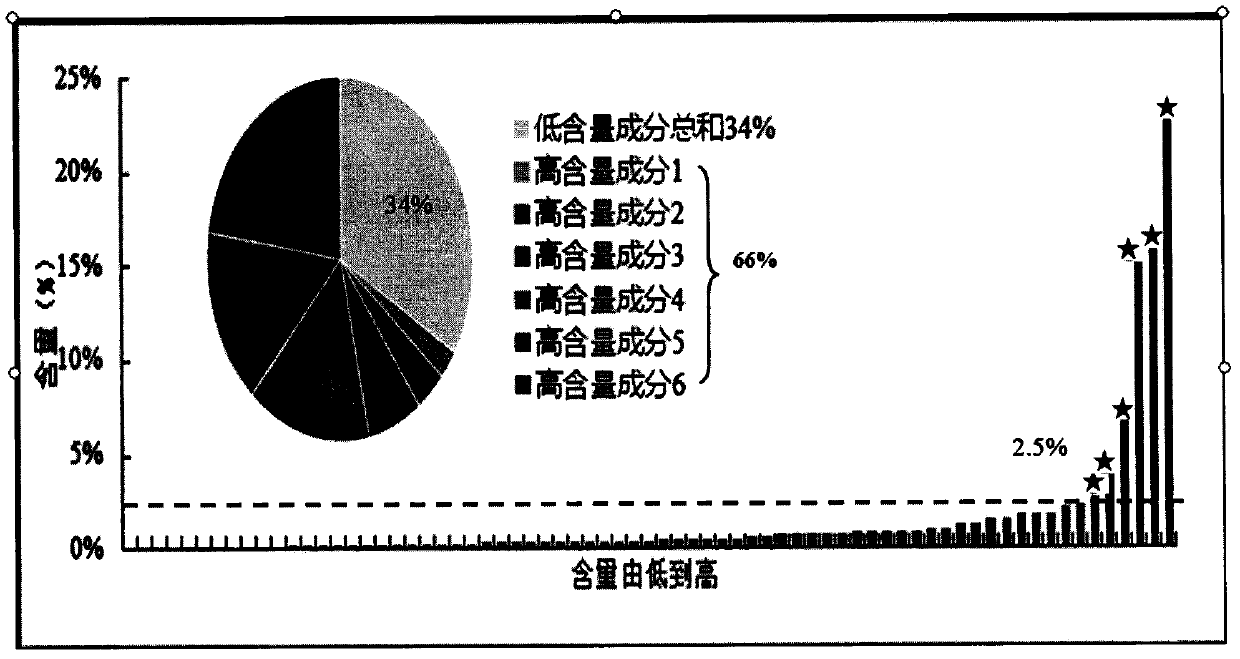

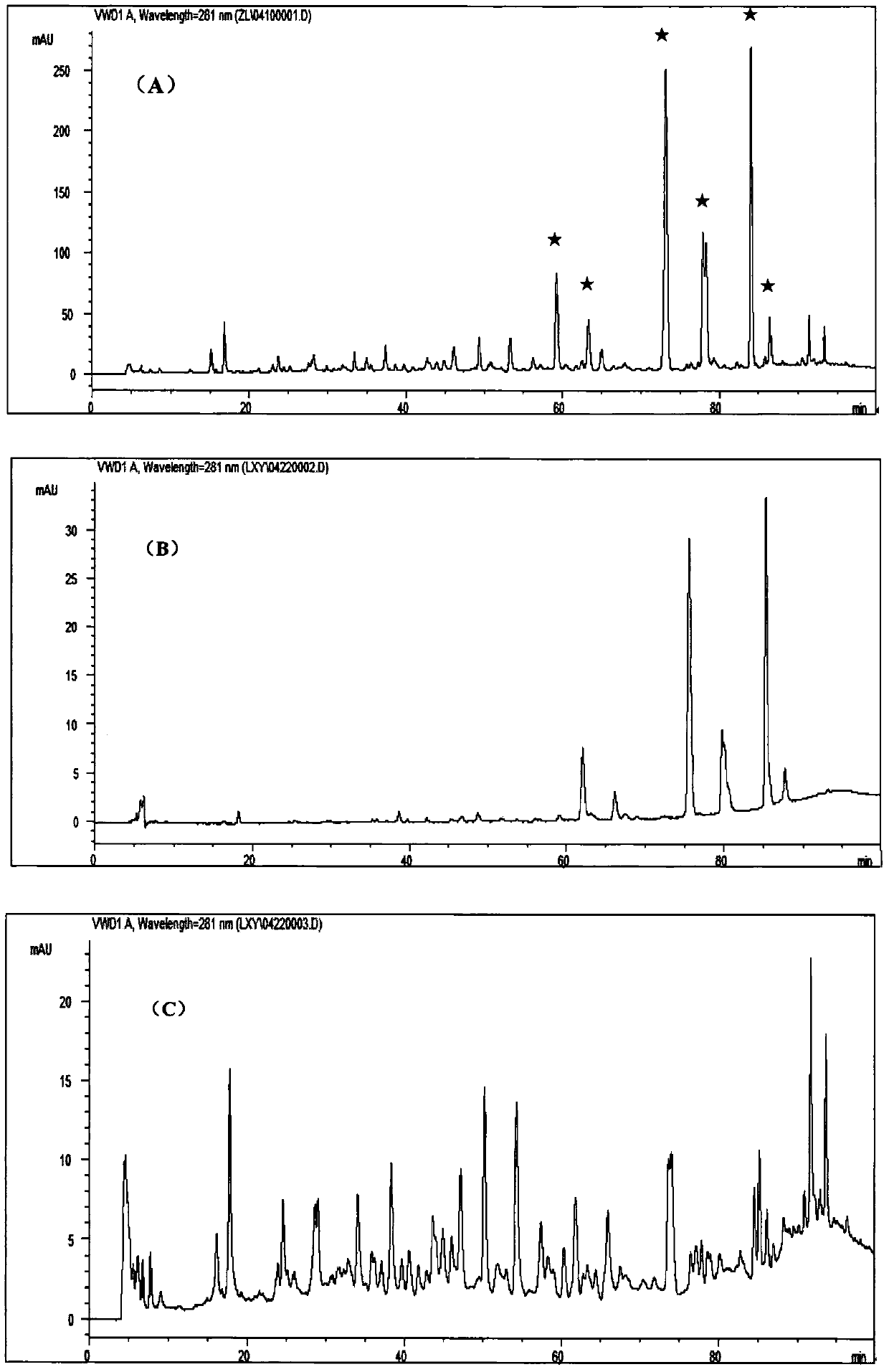

A new method for rapid discovery of low-level active ingredients in natural products

ActiveCN105259262BAvoid missingImprove the efficiency of discovering trace amounts of active ingredientsComponent separationNatural productAdditive ingredient

The invention relates to the field of natural medicines, in particular to a method for quickly discovering low-content active ingredients in natural products. The method divides the whole components of natural medicine into high-content components and low-content components through relative quantification, and uses the high-resolution chromatographic peak fraction preparation method to directly establish a high-content fraction library and obtain corresponding mass spectrum information. After knocking out these high-content components, the low-content components were enriched, and the low-content fraction library was obtained after solvent concentration and secondary separation, and the mass spectrum information of the low-content components was obtained at the same time. On this basis, activity screening was carried out on high and low content fractions respectively. This method has the advantages of rapidity, precision, high degree of automation, simple operation, low cost, and strong applicability, and is suitable for the discovery of low-level active ingredients in natural products.

Owner:CHINA PHARM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com