Redwood plate surface treatment process

A surface treatment and board technology, applied in the direction of wood treatment, wood treatment details, wood processing appliances, etc., can solve the problems of difficult to realize assembly line automation, no layers of patterns, poor pattern definition, etc., to improve adaptability and economic benefits, Improved smoothness and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

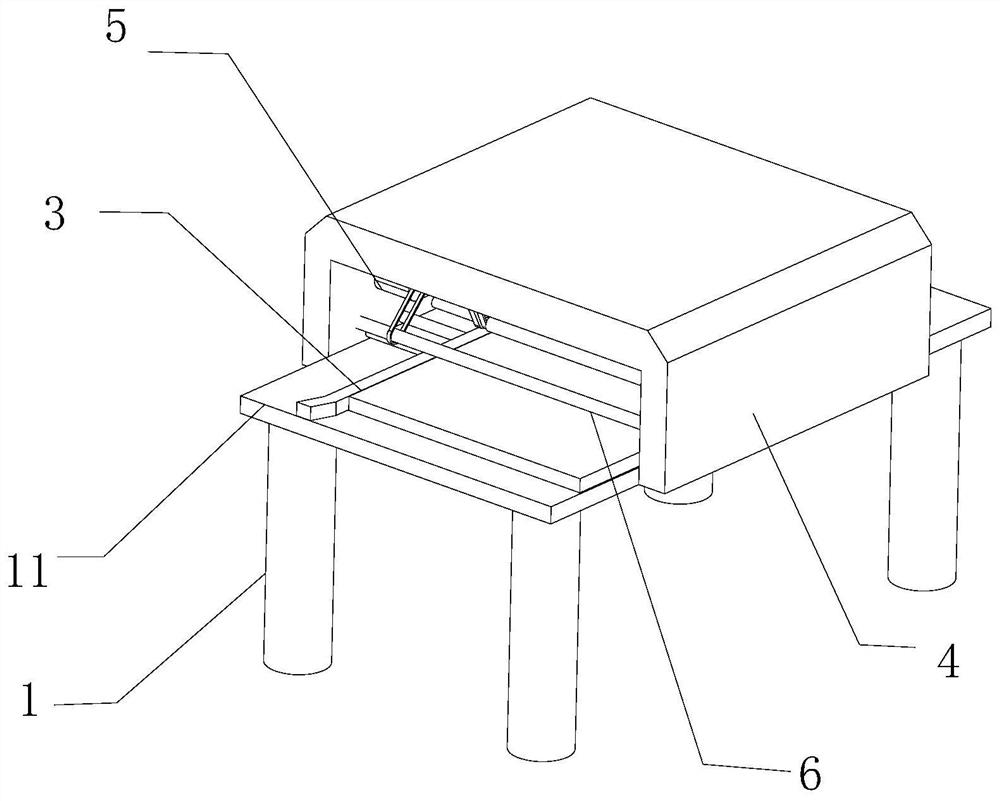

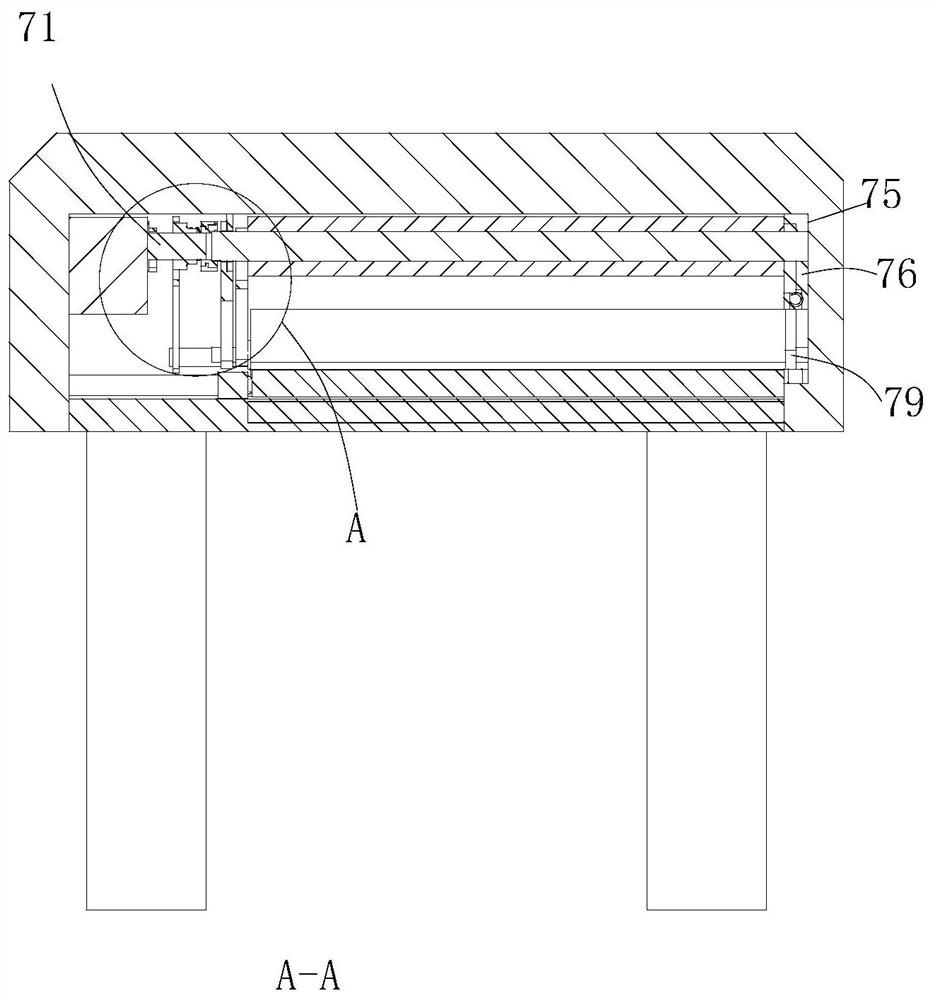

Image

Examples

Embodiment 1

[0044] A process for surface treatment of mahogany boards, comprising the following steps:

[0045] Step 1: a preparation step, uniformly mixing the anti-sticking agent with a weight ratio of 1% and the remaining photosensitive agent to form a photosensitive solution;

[0046] Step 2: Spraying step, evenly spraying the photosensitive solution on the surface of the paper medium;

[0047] Step 3: Drying step, dry the paper medium in a constant temperature and no light environment, the temperature is 25 degrees;

[0048] Step 4: The paper medium baking step is to bake the paper medium. The paper medium quickly passes through a constant temperature baking room, and the surface is instantly heated by scanning. The temperature of the constant temperature baking room is 80 degrees , the heating time for the paper medium is 13 seconds, and the molecules of the photosensitive agent break up and penetrate into the paper medium to form a photosensitive coating;

[0049] Step 5: Cooling...

Embodiment 2

[0072] A process for surface treatment of mahogany boards, comprising the following steps:

[0073] Step 1: a preparation step, uniformly mixing the anti-sticking agent with a weight ratio of 3% and the remaining photosensitive agent to form a photosensitive solution;

[0074] Step 2: Spraying step, evenly spraying the photosensitive solution on the surface of the paper medium;

[0075] Step 3: Drying step, dry the paper medium in a constant temperature and no light environment, the temperature is 26 degrees;

[0076] Step 4: The paper medium baking step is to bake the paper medium. The paper medium quickly passes through a constant temperature baking room, and the surface is instantly heated by scanning. The temperature of the constant temperature baking room is 115 degrees , the heating time for the paper medium is 2 seconds, the molecules of the photosensitive agent break up and penetrate into the paper medium to form a photosensitive coating;

[0077] Step 5: Cooling of ...

Embodiment 3

[0093] A process for surface treatment of mahogany boards, comprising the following steps:

[0094] Step 1: a preparation step, uniformly mixing the anti-sticking agent with a weight ratio of 5% and the remaining photosensitive agent to form a photosensitive solution;

[0095] Step 2: Spraying step, evenly spraying the photosensitive solution on the surface of the paper medium;

[0096] Step 3: Drying step, dry the paper medium in a constant temperature and no light environment, the temperature is 28 degrees;

[0097] Step 4: The paper medium baking step is to bake the paper medium. The paper medium quickly passes through a constant temperature baking room, and the surface is instantly heated by scanning. The temperature of the constant temperature baking room is 150 degrees , the heating time for the paper medium is 3 seconds, and the molecules of the photosensitive agent break up and penetrate into the paper medium to form a photosensitive coating;

[0098] Step 5: Cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com