Mesh Subdivision Method for Complicated Pores in Rock Core

A grid subdivision and grid technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as time-consuming, labor-intensive, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

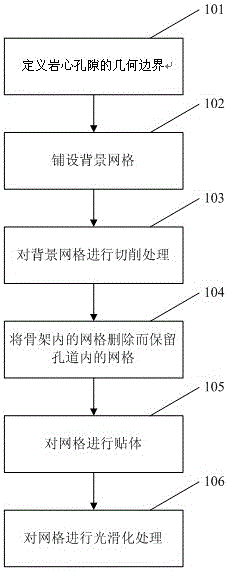

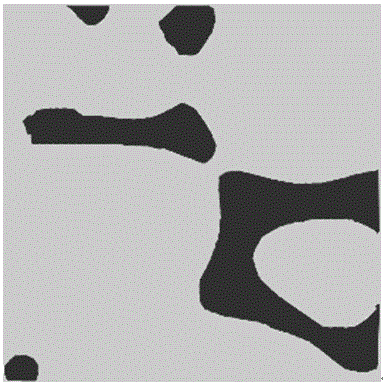

[0033] like figure 1 as shown, figure 1 It is a flow chart of the meshing method for the complex pores of the rock core of the present invention. In step 101, the geometric boundaries of core pores are defined. During the grid generation process, the boundary of the core pores needs to be specified by the user, and the specified format can be CAD format (such as: obj format or STL format, etc.). Due to the extremely complex geometry of the tunnel, non-defined surface points are automatically completed by spline interpolation. The process goes to step 102.

[0034] In step 102, a background grid is laid out for the target calculation area. A right-angle grid is laid on the CAD geometry of the core calculation area as the background grid. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com