Skip conveyor device of sheet-fed piece printing part

A technology for conveyors and workpieces, used in printing presses, general parts of printing machinery, printing, etc., can solve problems such as reduced operating efficiency, complicated changes in the peripheral speed of the second conveyor belt, and complicated changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

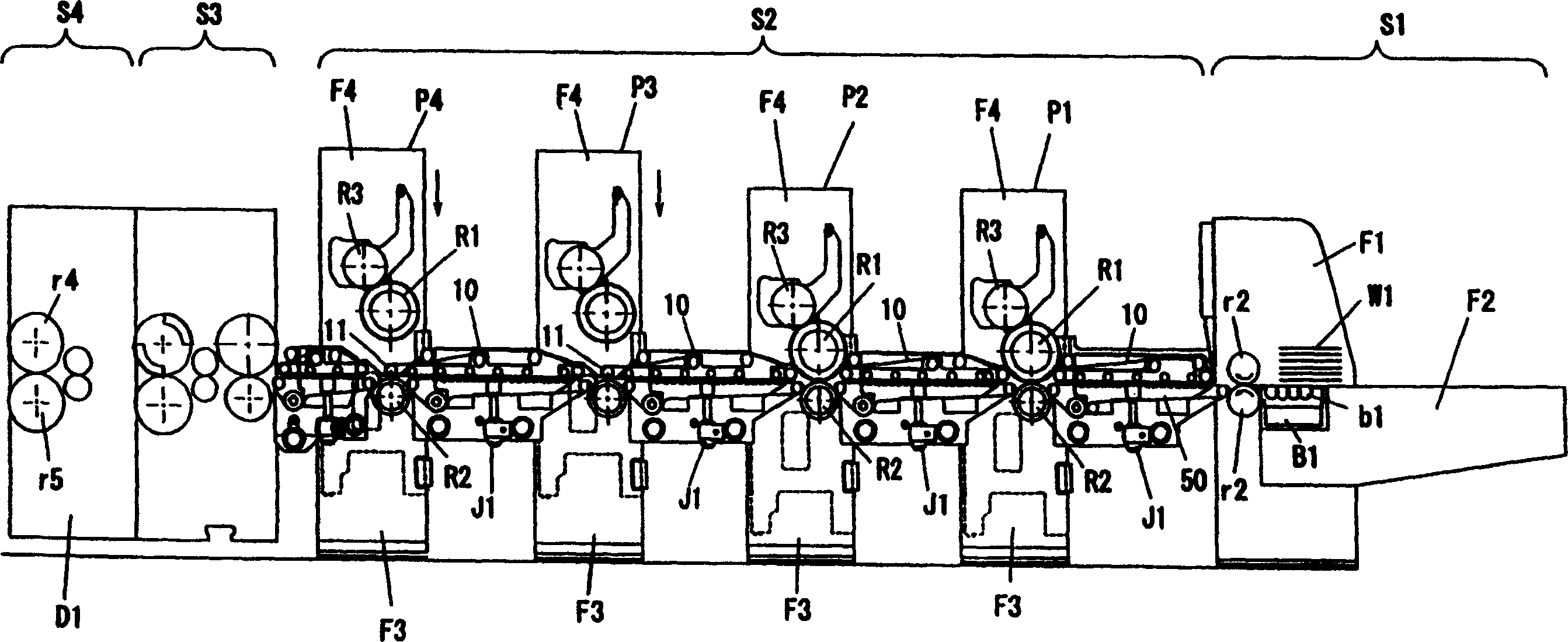

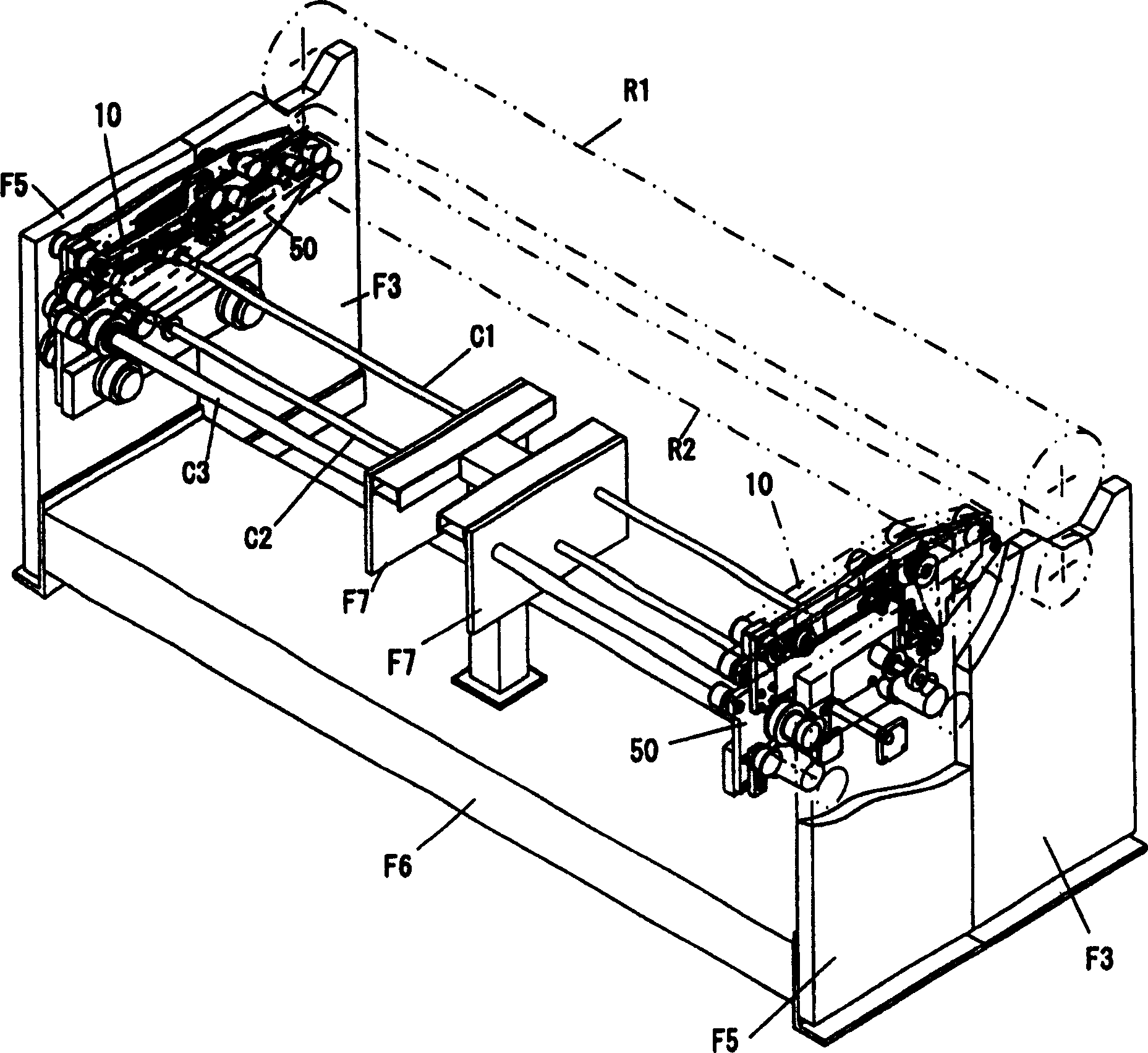

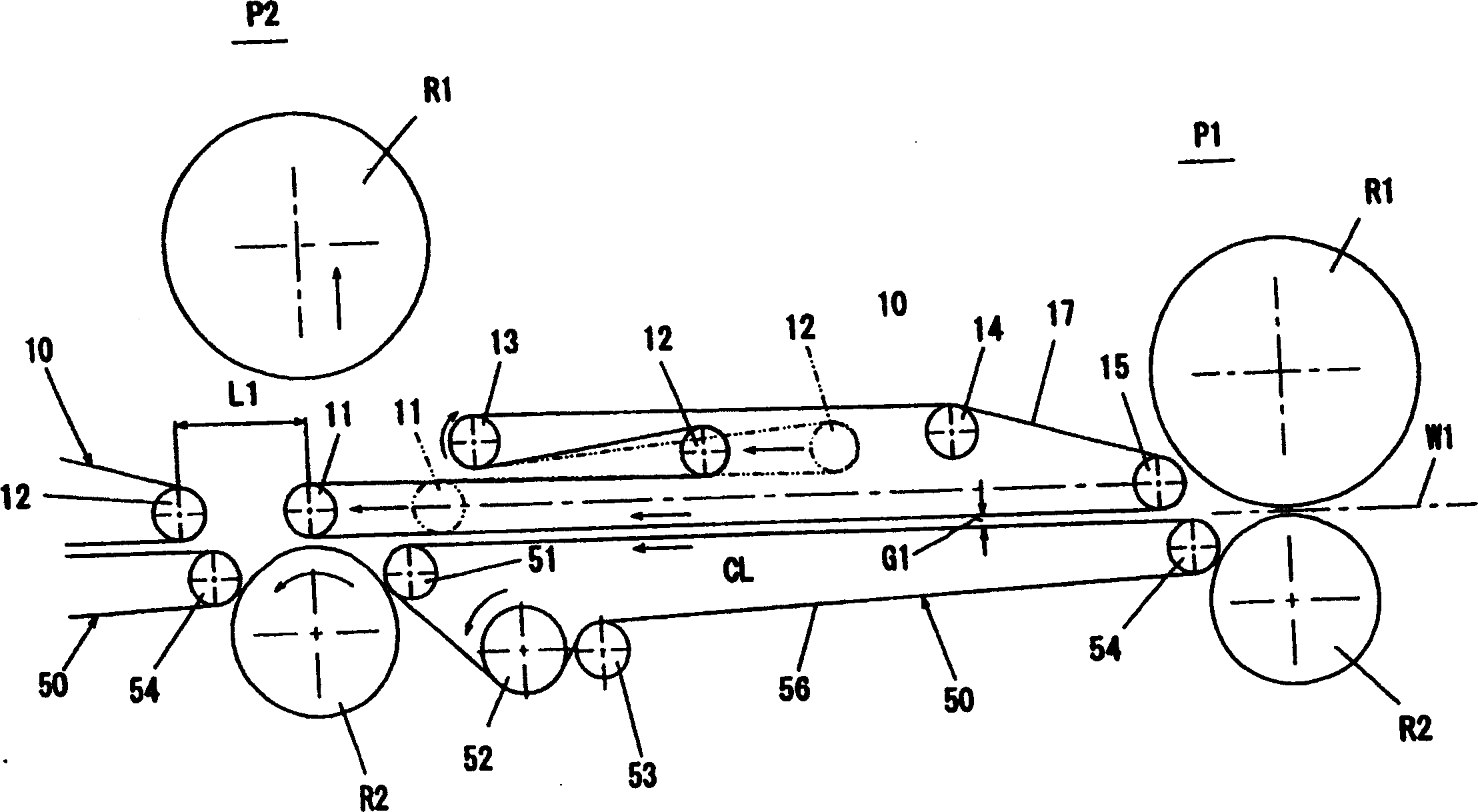

[0050] This embodiment is a corrugated box making machine ( figure 1 ). Below the upper feeding conveyor device 10, a lower feeding conveyor device 50 is arranged. The box making machine is connected in the order of paper feeding part 51, printing part 52, slotting part S3, punching part 54, folding part and delivery part from front to back. The single workpiece W1 after printing processing is cut groove and scribed in the slotting part S3, punches hand holes and air holes in the punching part S4, bends in the folding part, and is stacked and sent out in the sending part.

[0051] The general structure of the paper feeding part S1 is a frame F1 vertically erected at a certain distance from the left and right sides of the machine, and a feeding table F2 is horizontally arranged between the frames F1, and a suction box B1 composed of a plurality of guide rollers b1 is embedded on the feeding table F2 . In addition, a pair of upper and lower feeding rollers r2 is arranged late...

no. 2 Embodiment approach

[0075] This embodiment is also a way to keep the relationship of the peripheral speed of the feed belt with respect to the single workpiece constant, and is about another feeding conveyor device 30 ( Figure 7 , Figure 8 ). In this embodiment, the lower loading conveyor device 50 disposed below the loading conveyor device 30 has the same structure as that of the first embodiment.

[0076] Feeding conveyor device 30 has the feed belt 18 of the front end side that is contained between the front end pulley 11 and the middle pulley 19 and the feed belt 17 of the rear end side that is contained between the middle pulley 19 and the rear end pulley 15. Intermediate pulley 19 is the belt pulley of the double hanging method that can hang 2 feeding belts 17,18, and front end side feeding belt 18 and rear end side feeding belt 17 hang on the position that is equivalent to belt width apart. Further, the front-side feed belt 18 and the rear-side feed belt 17 are synchronously driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com