Paper box for foods

A food and carton technology, applied to rigid containers, containers, packaging, etc., can solve the problems of time-consuming, labor-intensive, quality differences, and large manpower, and achieve the effects of stable quality, avoiding quality decline, and preventing quality unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

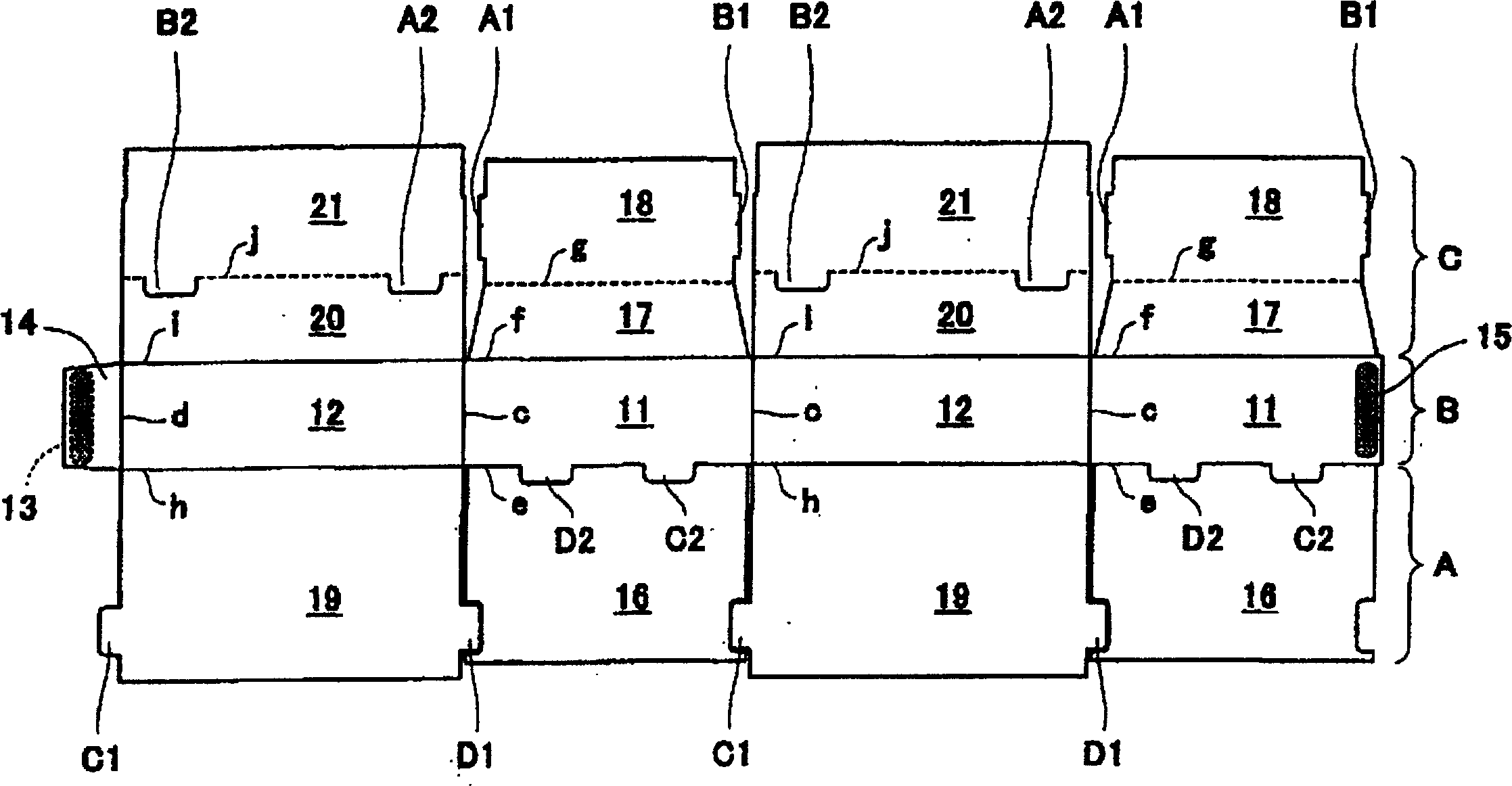

[0019] The structure of the food carton of the present invention will be described in detail below.

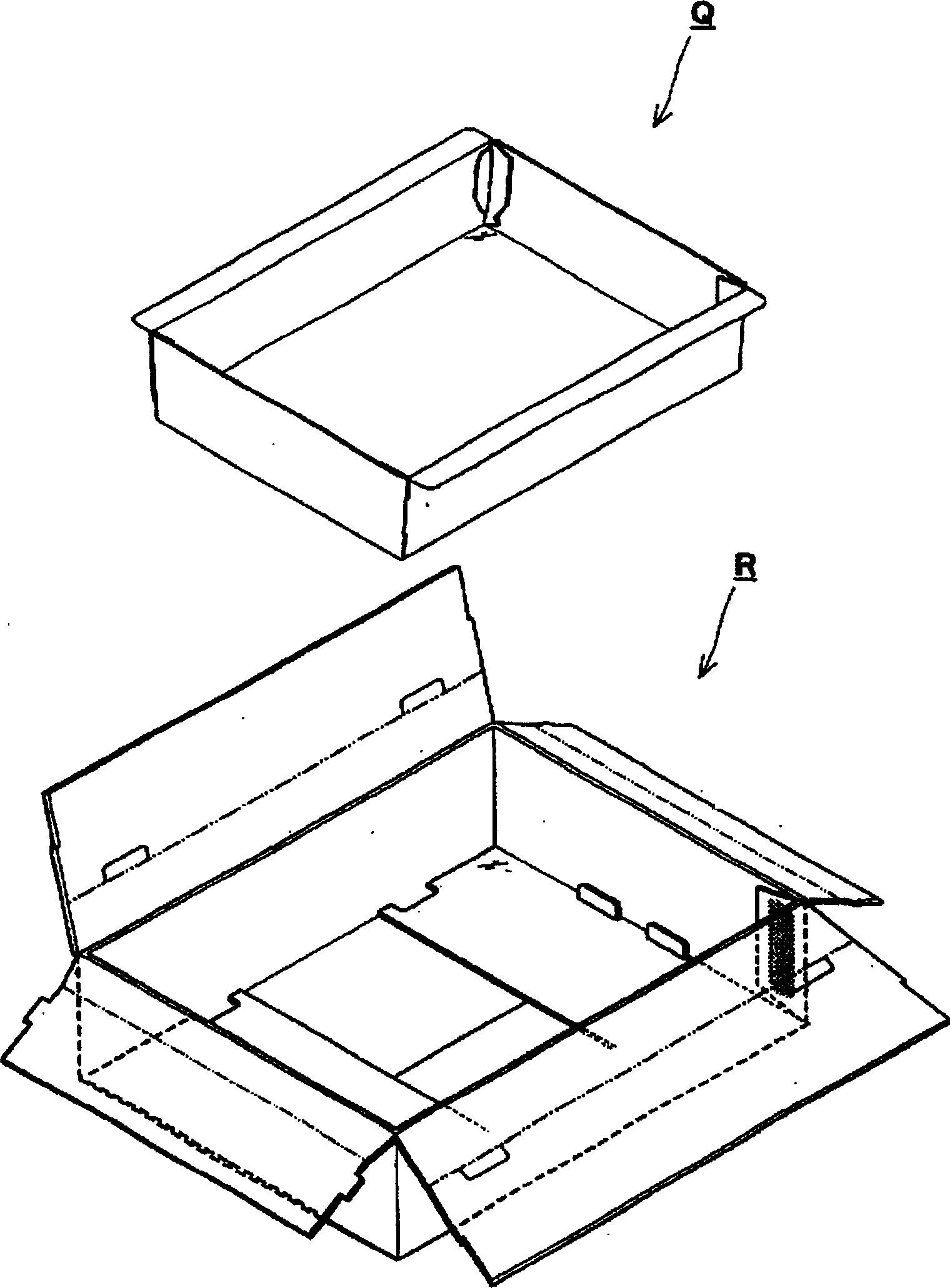

[0020] Such as figure 1 As shown, the food carton of the present invention is composed of a paper container Q for containing food and a paper storage box R for containing the paper container Q.

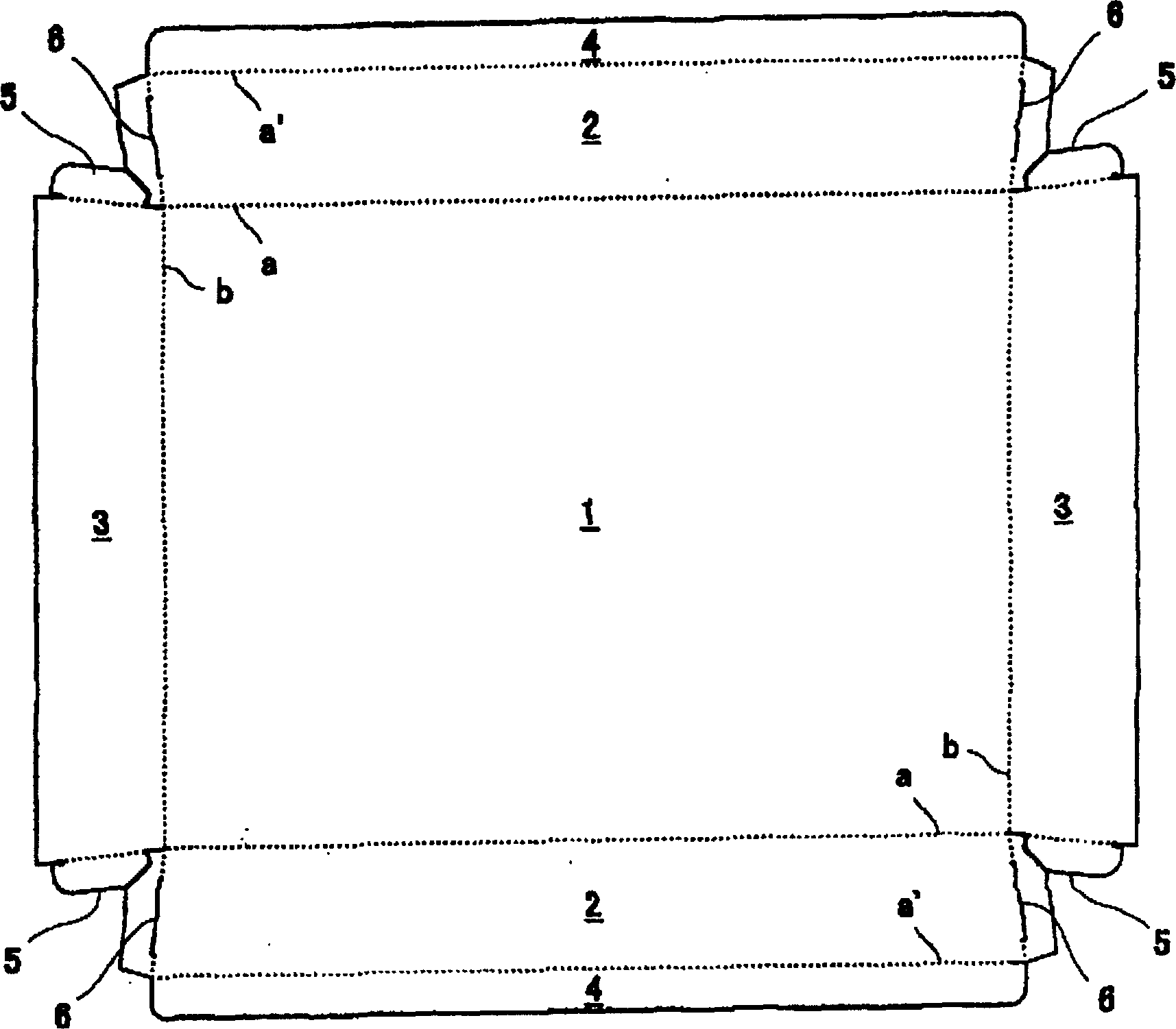

[0021] Paper container Q is a container made of a single cardboard, such as figure 2 As shown in the development view of the paper container Q, the bottom panel 1, the side panels 2, 2 connected to the bottom panel 1 through creases a, a, and the bottom panel 1 through creases b, b are basically used. The connected end panels 3, 3 are made of cardboard. At the outer ends of the side panels 2, 2, in order to reinforce the side panels 2, 2, folded pieces 4 are also provided via creases a', a'.

[0022] Slits 6, 6 are formed near both ends of the side panels 2, 2. As shown in FIG. At both ends of each end panel 3 , 3 there are engaging pieces 5 , 5 which will be inserted into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com