Ink line puller

A technology of puller and ink line, applied in workshop equipment, manufacturing tools, etc., can solve problems such as shortened life, ink specific gravity imbalance, ink line breakage, etc., achieve long contact time, short contact time, and prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be described below with reference to the drawings.

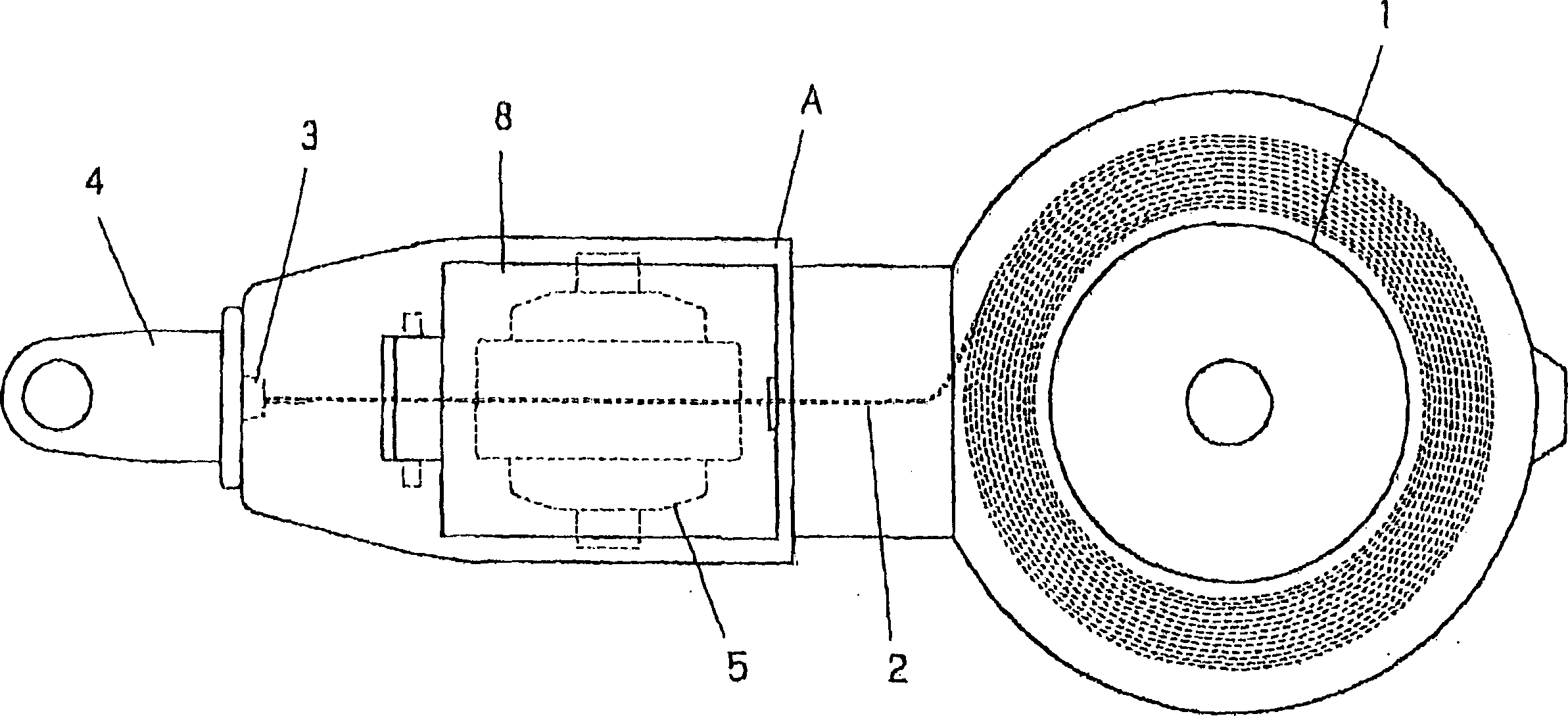

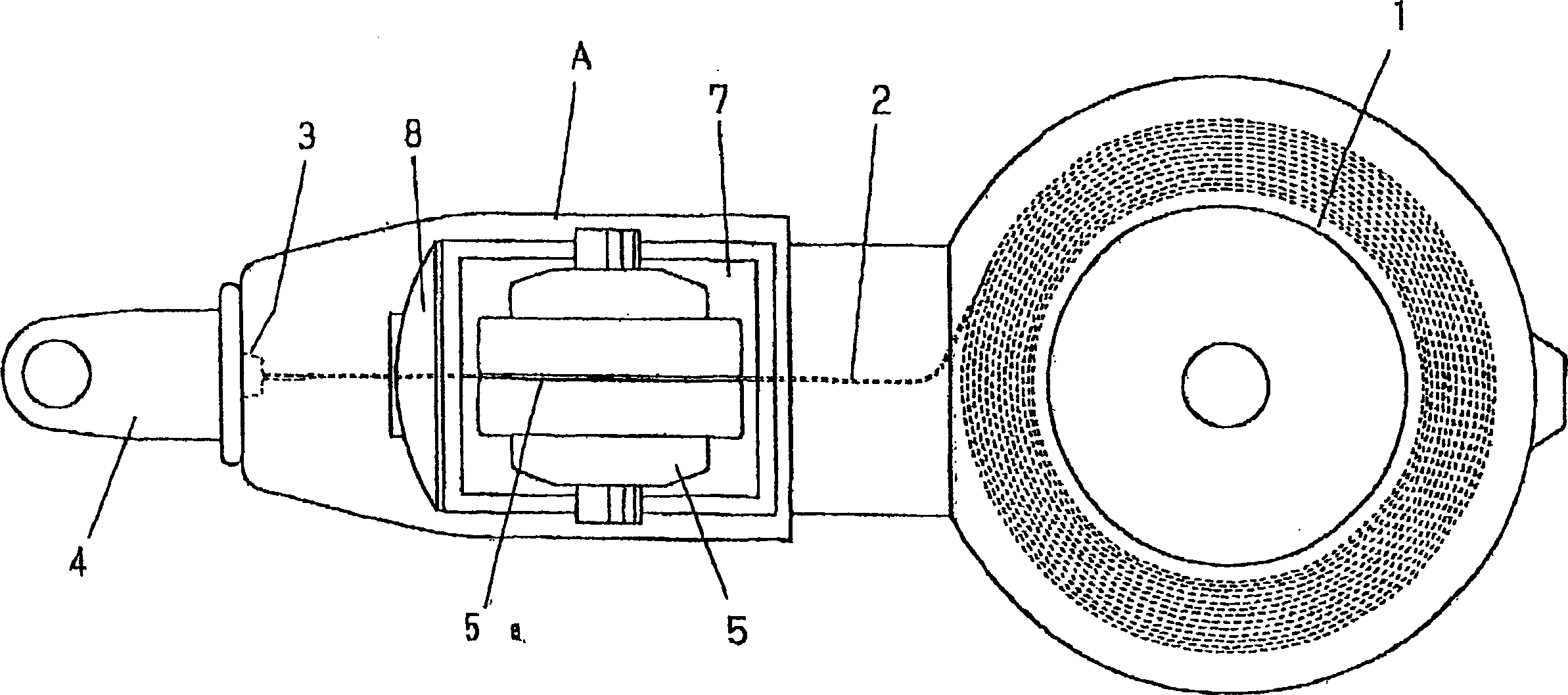

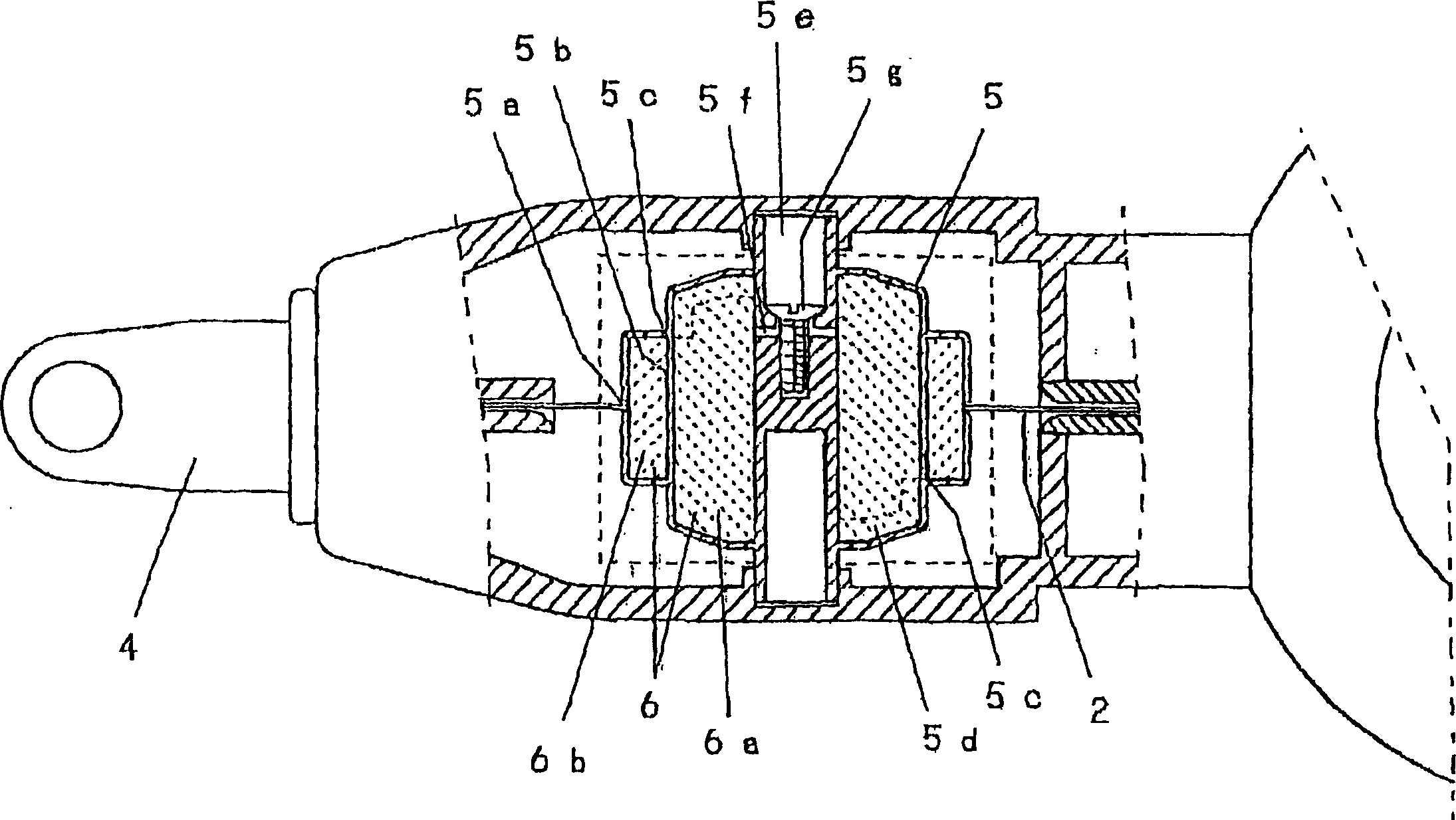

[0013] figure 1 is a plan view representing the overall shape, figure 2 is a plan view showing an open state, image 3 is a cross-sectional view of the rotary drum part, Figure 4 It is a longitudinal sectional view of the rotary drum part.

[0014] figure 1 , figure 2 The symbol A shown is a housing part, and the bobbin 1 is installed in the rear part. The spool 1 is a spring structure, which can automatically return to the normal winding state. In addition, the front end of the housing A is provided with a thread take-out port 3 for taking out the ink thread 2 wound on the spool, and a thread stopper 4 connected to the front end of the ink thread 2 is detachably installed at the thread take-out port 3 . The stop 4 has a needle 4a.

[0015] Between the bobbin 1 and the thread take-out port 3 is detachably disposed a rotary drum 5 for ink dipping that presses the ink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com