Loop forming device for ring stitch sewing machine

A technology for sewing machines and stitches, which is applied to sewing machine components, sewing machine housings, sewing machine ferrule mechanisms, etc. It can solve the problems of inability to form loops and send out loops, etc., and achieve the effect of reliable formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below, refer to the embodiment of the present invention Figure 1 to Figure 6 Be explained.

[0047] The ring-type (chain-type) stitch sewing machine of this embodiment is a ring-type stitch sewing machine capable of overlock stitching and flat stitching, and will be described below based on this sewing machine.

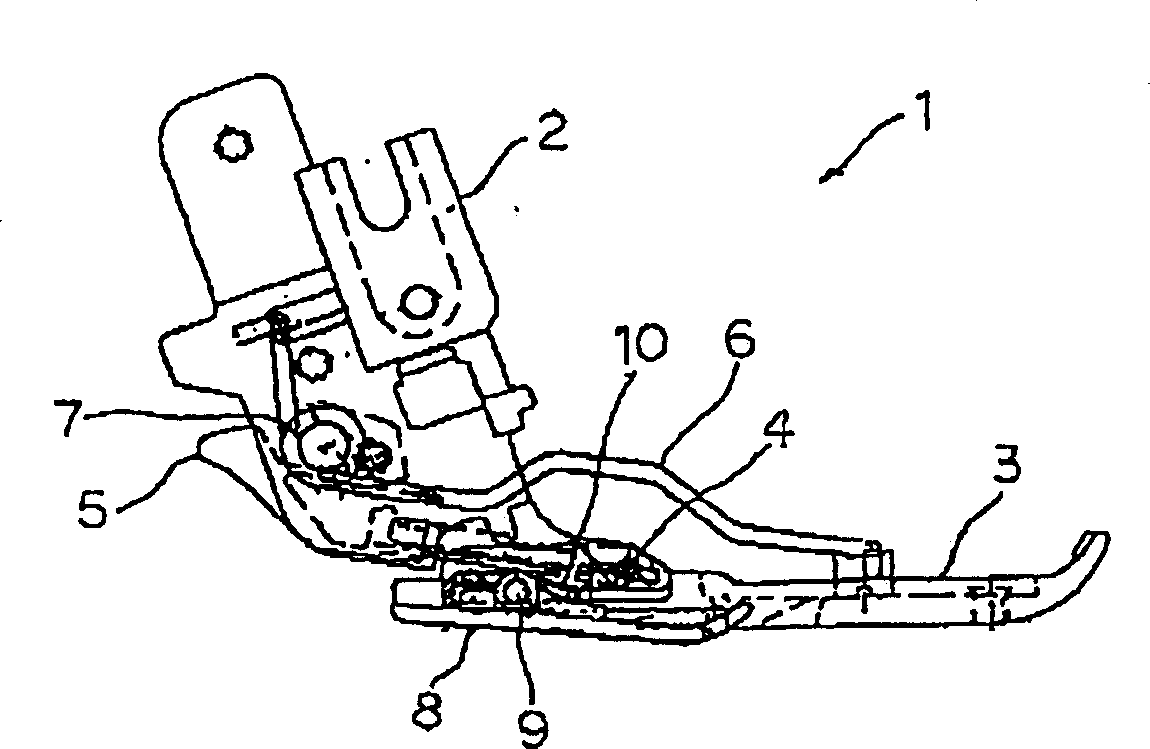

[0048] figure 1 It is a side view of the cloth pressing device 1, and 2 is a support body, which is freely attachable and detachable at the lower end of the pressing rod not shown. 3 is a presser foot, and the shaft 4 in its horizontal direction can be loaded and unloaded with respect to the lower end of the support body 2 through a rod 5 . 6 is a spring, the base is supported by the shaft 7 of the support body 2, and the front end is crimped on the front of the presser foot 3, giving the presser foot 3 a rotational force clockwise around the shaft 4. Reference numeral 8 denotes a loop presser foot, which is supported by a horizontal shaft 9 rotatably rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com